ENTWINEMENTS Karren K. Brito

PREDICTABLE COLOR FROM DYEING USING CIBACRON F DYES (for cellulose fibers) This is a long class, like a college quarter, for the serious and committed student. It will take 3 months of dedicated time and effort; no time off for extended vacations.

The class begins Friday, 9 June and runs to Friday, 26 August , that is 12 weeks, all of your summer. You need to plan at least one dyeing session per week plus your study and prep work. This is a BIG commitment. You will also need some supplies before the class begins: the Munsell Student Kit, a digital balance and calibrating weight, 7 manufactured colors of Cibarcron F dye and at least a hundred 5g sample skeins (all the same exact fiber) and some measuring equipment; this could be a major investment if you do not have this equipment.

Participants need to be enough tech savvy to be able to use the following: a tele-conferencing session for 1-2 hours each week, Google Documents to share your pictures, documents and enter your results in spreadsheets there and a forum on Weavaloution for discussion. You will get the most of this class if you feel comfortable downloading documents, uploading pictures of your work and participating in on-line discussions. You should finish with a working dye studio where you can reliably dye with Cibacron F dyes, trouble shoot dyeing problems, a better understanding of color and some words to talk about it, better understanding of how to achieve a specific color in your dyeing. This class is available for 5 serious, committed students. The fee for the 12 weeks is $350. Equipment required before the class begins: • The New Munsell Student Color Set (2nd Edition) • Digital Balance • Dye Pot for Sample Dyeing • 100ml volumetric flask • • Wash Bottle •Cibacron F dyes and auxiliaries • 2 lbs, or more of the yarn you plan to dye Details follow and this is not an through list but covers the things you can not improvise. The New Munsell Student Color Set (2nd Edition) Available from : . amazon.com . Fairchild books Most of the benefit comes from working with the chips. I suggest using a repositionable adhesive, this will allow you to change your mind (color chip position) for a little while. Optional: Munsell poster from Babel Color. Digital Balance capacity: 200g or greater readability: 0.1g (no greater) tare function calibration weight Digital Balance or scale is to weigh fiber and dye powder. This may be the biggest investment in equipment for dyeing so it spend some time to get one that will work for you. We need a robust, easy to use scale that gives us enough information to do accurate dyeings. Balances have two important limitations : capacity (how much they can weigh; a bit of weed or a cow), and readability (does it take a kilogram or a mg to make the balance change its reading). Both effect the price. I have found Acculab top loading balances to be good value for dyers, the price range of the useful ones is $100 -$205. Here is a link to a table of Acculab balances. So you should have a good idea of the maximum amount you will dye at one time. This will probably be limited by the largest pot you have. The largest pot I have is 60L and with the thin silk cloth that I usually dye max. is about 600 g, with silk or wool yarn I can go to 1000g. So for these circumstances I would pick model VIC-1502 with a capacity of 1500g and a readability of 0.1g. The balance should have a tare function and a way to calibrate the balance. These balances are not available at your corner store but they are readily available on the Internet. You do not want a balance that has readability to 0.01g or less, they are so sensitive that an air current will change the weight. They also cost more. Since this is the most important piece of equipment, buy the best you can afford. When your balance arrives check that you know how to adjust the zero and calibrate your balance. Do you have a calibration weight, it is often 200g? I you are using a balance you already have please check the zero and make sure it calibrates. In the study group people lost a month of work when their balances wouldn’t calibrate and had to be replaced. Dye Pot for Sample Dyeing Life is easier in the dye studio if you can dye more than one sample at a time. A canner with pint glass canning jars, a thermometer and burner are readily available and well used solution but will require constant baby sitting for this dye. We will be working at a constant temperature, 60°C, and it is much easier with a thermo-regulated set up. A turkey roaster (some thing like a Nesco Roaster) or a steam table (make sure they will heat and produce steam at 100°C/212°F) will make your life a lot easier. Measuring Equipment 100ml volumetric flasks, one or more. Used to make accurate stock solutions. A Wash Bottle This is my favorite tool and it costs just $3. I get it from my local plastics company. Cibacron F dyes 2 oz. each; Sun Yellow Gold Scarlet Fuchsia National Blue Royal Blue Navy Soda Ash, several pounds Salt, NaCl without iodine, 5 lbs or more

citric acid or vinegar for neutralizing the soda ash strong detergent for scouring(Synthrapol or a less toxic version

Just general things you will need: • Something to measure accurate larger volumes, 500-1000mL ,of water graduated cylinders or metric measuring cups things to measure smaller volumes, small graduated cylinders (not accurate under 10mL) and pipets (graduated or Mohr's), down to 1mL graduated. I don’t like syringes, but if you already have them and you can use them accurately... Or you can also use your balance . Jars to store stock solutions. Pouring spouts are nice and waste less.

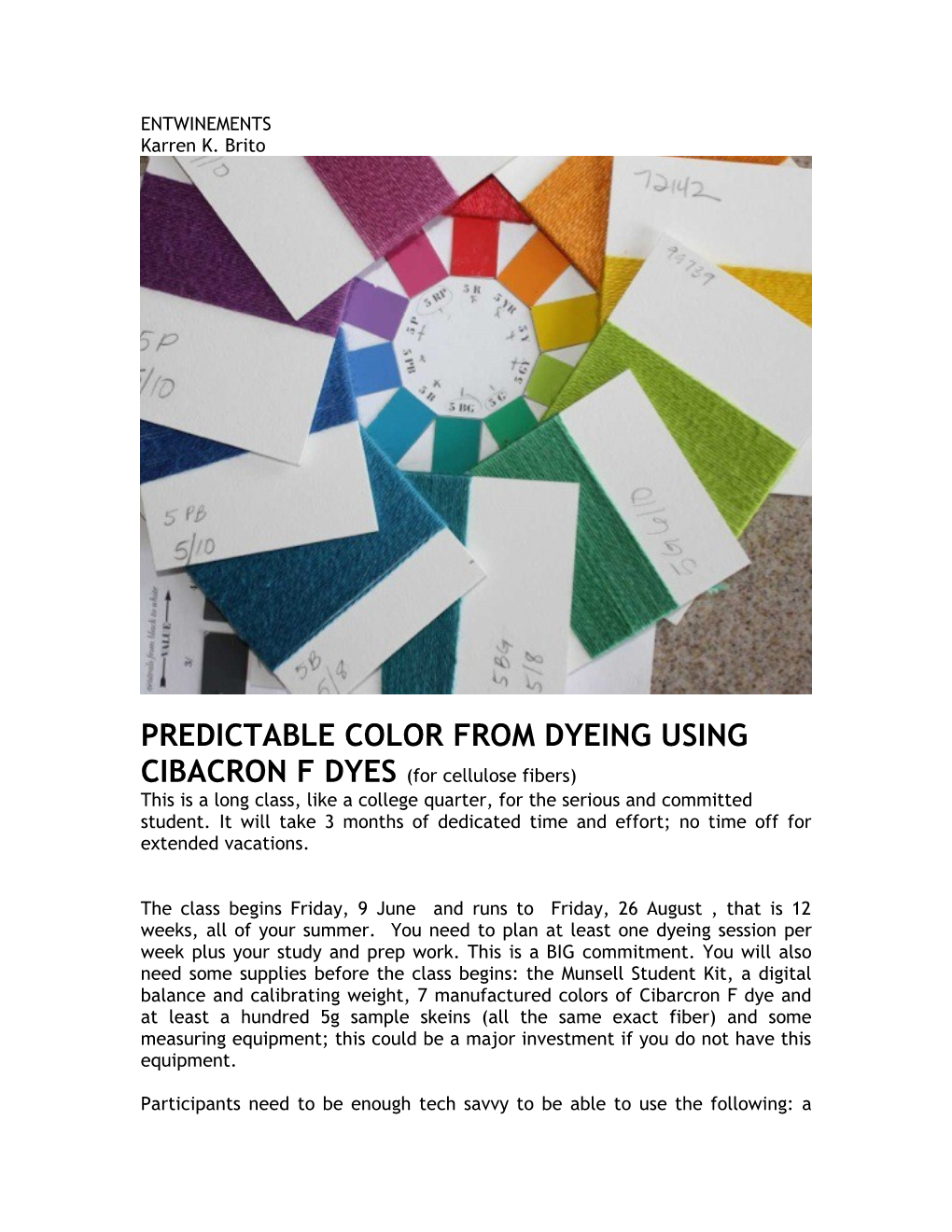

Activities include: assembling the Munsell Student Kit studying the Munsell booklet making stock solutions commissioning and testing the dye process dyeing the pure colors at 3 DOS on your substrate assigning Munsell notation to all colors dyed mixing the dye to achieve the 10 colors of the color wheel dyeing some low chroma colors dyeing black dyeing a color to match your choice