Rapid Application Development Tool Tesla for Fast Prototyping of Electrical Machines Peter van Duijsen 1, Davor Gospodarić 2

1 Simulation Research P.O.Box 397, NL-2400 AJ, Alphen aan den Rijn, The Netherlands Tel: +31 172 492353, Fax: +31 172 492477 www.caspoc.com, e-mail: [email protected]

2 Trimerics TRIMERICS GmbH Karl-Benz-Str. 19 D-70794 FILDERSTADT Tel +49 711 700 1400 email [email protected]

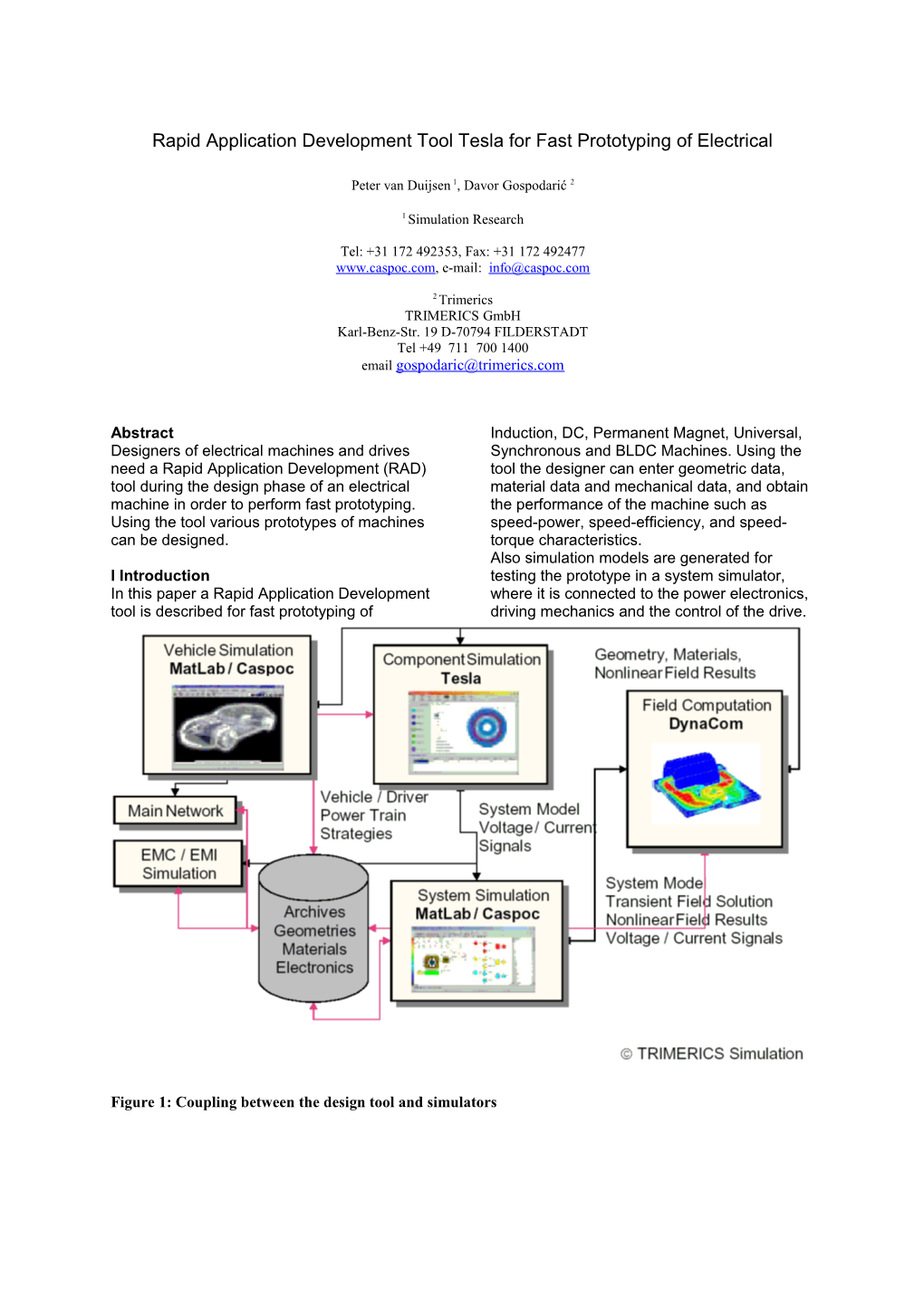

Abstract Induction, DC, Permanent Magnet, Universal, Designers of electrical machines and drives Synchronous and BLDC Machines. Using the need a Rapid Application Development (RAD) tool the designer can enter geometric data, tool during the design phase of an electrical material data and mechanical data, and obtain machine in order to perform fast prototyping. the performance of the machine such as Using the tool various prototypes of machines speed-power, speed-efficiency, and speed- can be designed. torque characteristics. Also simulation models are generated for I Introduction testing the prototype in a system simulator, In this paper a Rapid Application Development where it is connected to the power electronics, tool is described for fast prototyping of driving mechanics and the control of the drive.

Figure 1: Coupling between the design tool and simulators Coupling to FEM/BEM tools is provided for a D.C motor with compound more detailed design of the machine where a excitation magnetic, thermal and mechanical strength TESLA-P analysis can be performed. Optimization can Calculates permanent magnet D.C be performed on the design of the machine or motors. TESLA-P considers the on the overall design of the drive system, numerical possibilities of the iterative where the machine is one of the components. treatment of non-linearity and the The tool is based on the idea of a construction effect of magnetic field calculation. The kit where basic designs of typical parts, such program takes into account the effects as rotor, fan, windings, magnetic material, of demagnetization and temperature bearings, rotor bars, etc, can be constructed distribution. that are manufacturer specific. Using such TESLA-S libraries of components, the user can prototype Calculates the operational various variants of his design based on characteristics of synchronous motors. standard parts already designed. TESLA-U The calculation of the characteristics is done Calculates universal series motors. using analytical methods and dedicated TESLA-E numerical routines inside the Rapid Application Calculates brushless D.C. motors. Development tool and therefore the response TESLA-E solves both 2 phase and 3 to the user to a change in parameter is phase brushless D.C. motors with both interactive. In the tool the complete magnetic slotless and slotted stator windings. circuit is analyzed, resulting in the characteristics of the machine. Here the non- III. Requirements of the design tool linear material characteristics are used for the applied magnetic materials. Wire parameters A design tool for electrical machine would need are based on standards such as DIN, SEV, the following features: JASO, etc. For the geometric data the designer Direct interface to external field calculation can mix SI and US metrics such as "inch" and software, such as Ansys[6], DynaCom[1], "mm" in one design and couplings exists to Amperes[8] and Magneto[8] and simulation popular CAD packages. tools like Spice, Simulink and CASPOC[9] Compared to lengthy Finite Element Library of pre-calculated flux curves simulations the user is able to prototype a new Motor component library for easily type of electrical machine in a very fast way. designing stators, rotors and commutators Non-linear analysis capabilities II Basic Modules Calculation of mechanical and electrical losses due to air friction, bearing loss, The basic modules in the Tesla suite of design blower/fan loss, copper loss, hysteresis tools are broken down into six specific modules loss and eddy current loss for various types of motors. Outputs such as power, currents, efficiency, lamination data and TESLA-A dimensioning, speed/torque curve, etc Calculates the operational Graphical outputs such as lamination characteristics of 3-phase induction geometry, magnetization curves, current, motors. The software utilizes classical efficiency, speed, torque, power and power numerical theory for solving induction losses machines. TESLA-G Archiving capabilities of all motors and Offers the possibility of practice- motor components allowing for search oriented calculations of D.C capabilities on past motor designs. commutator motors. TESLA-G is used to model: IV Coupling Shunt connected commutator The design tool should have the possibility to motors (self-excited) couple directly with CAD and Simulation Shunt connected commutator packages. motors (separately excited) In the first place the prototype is build from a Series motors basic geometry. From these data a 2D or 3D Figure 2: Generator simulation with stator design template CAD model can be exported for further Figure 2 shows the simulation of a mechanical and electromagnetic design. synchronous generator with rectifier and buck In many cases a rotational 2D model would be converter. The design of the generator is satisfactory. Also material data for the carried out in the RAD tool Tesla. The properties of the non-linear material has to be parameters of the behavioral model of the supplied to the CAD package. For 3D modeling generator are used for the model in Caspoc. in CAD packages the export of the lengths and The templates for the machine are selected an eventual rotor skewing has to be done. from the project manager in the design tool. In the second place the prototype has to be For each component a template exists that tested in a complete drive simulation. guides the designer to enter specific values for Therefore the electromagnetic model has to be the design of that particular component. exported into a behavioral model required for More components can be defined and stored in simulation. Not only should the model and the a project. For example, 3 different types of parameters contain the electrical parameters, stators can be defined and each of them can but also the mechanical parameters are be used in the total design. required for the simulation, such as the rotor The parameters for the prototype are inertia and friction of the bearings. automatically transferred to the simulation Since the prototyping takes place in the design tools, so changes in the design are tool and because of its connections to the immediately effective in the simulation. This system simulation, optimization can be allows fast prototyping of not only the machine performed based on the prototype of the but also performance of the machine in the machine inside the complete drive, including total drive system. the power converter, mechanical load and control circuitry or embedded control. Figure 3: Design Process V Machine EM design Manufacturers provide libraries with data for their materials, such as, for example, iron and The electrical machine is mainly designed for magnetic materials. From this data losses such the electromagnetic properties. In figure 3 the as hysteresis and eddy current losses are process from geometric data to design info is calculated. shown. The data for the windings allows copper losses The input for the design is not only geometrical to be calculated. data, but also material data has to be supplied In the design tool the behavior of the machine Important are the non-linear materials, see is calculated directly using analytical figure 4. expressions. This allows the fast determination of specific design considerations, such as power and speed curves. Also, for example, the efficiency as function of the speed of the rotor can be displayed graphically. From these data the machine can be optimized. Figure 5 shows the analytical results from Tesla. Shown are the efficiency (*10%), power (*1000 w), current (*100 A) and speed (*1000 rpm) as function of the torque (Nm)

The parameters for the behavioral model in Caspoc are exported in a model file. For example, parameters for a Switched Reluctance Machine are exported as:

Figure 4: Non-linear material properties .model srm68_1 user br=0.436 bs=0.349 lmax=110m lmin=10m nr=6 ns=8 r=50 jr=10m Figure 5: Graphical results from Tesla For a more detailed analysis of the electrical provided in addition to a rotational symmetrical machine the prototyped design can be 2D model. Figure 7 shows the model of a exported into a FEM/BEM package. Since all Switched Reluctance Machine in Ansys. geometric data is entered in the design tool, Also mechanical components are prototyped in the model is exported automatically to the the design tool. In figure 6 the template for a FEM/BEM package Only data such as the fan is shown. length of the rotor and rotor skewing has to be

Figure 6: Prototyping of mechanical components Summary A new Rapid Application Development tool is presented for fast prototyping of electrical machines. Models from the prototype can be used in CAD-, Finite Element and Simulation software. The electromechanical characteristics are obtained using the RAD tool and enable the designer to optimize the design in a short time and very cost efficient.

Literature

[1] Gospodaric D., Schmenkel A., Simulation of Power Trains for Hybrids and Electrical Cars, Proceedings PEMC Cavtat 2002 [2] Duijsen. P.J. van, Simulation and animation of power electronics and electrical drives, PCIM Europe, December 2001, p 26-28. www.caspoc.com [3] Otto J., Killat U. van Duijsen P.J., Energy Based Model Synthesis for Electrical Actuators and Sensors, PCIM, Conference proceedings IM, 2002, Nürnberg, Germany 2002 [4] Killat U., Otto J., van Duijsen P.J., Parameter extraction in FEM models for dynamic system simulations. PCIM, Conference proceedingsFigure 7: Model IM, 2002, of a Switched Reluctance Machine in a FEM package Nürnberg, Germany 2002 [5] Matveev A., van Duijsen P.J., Novel Caspoc-based software for multilevel simulation of switched reluctance drives. Proceedings PCIM 2003 [6] ANSYS Theory Manual, Release 5.7, Swanson Analysis Systems, Inc., 2001 [7] Simulation Research / Trimerics, Tesla users manual 2003, [8] IES Amperes / Magneto, Users manual 2003 [9] Simulation Research, Caspoc Users manual, 2003, www.caspoc.com