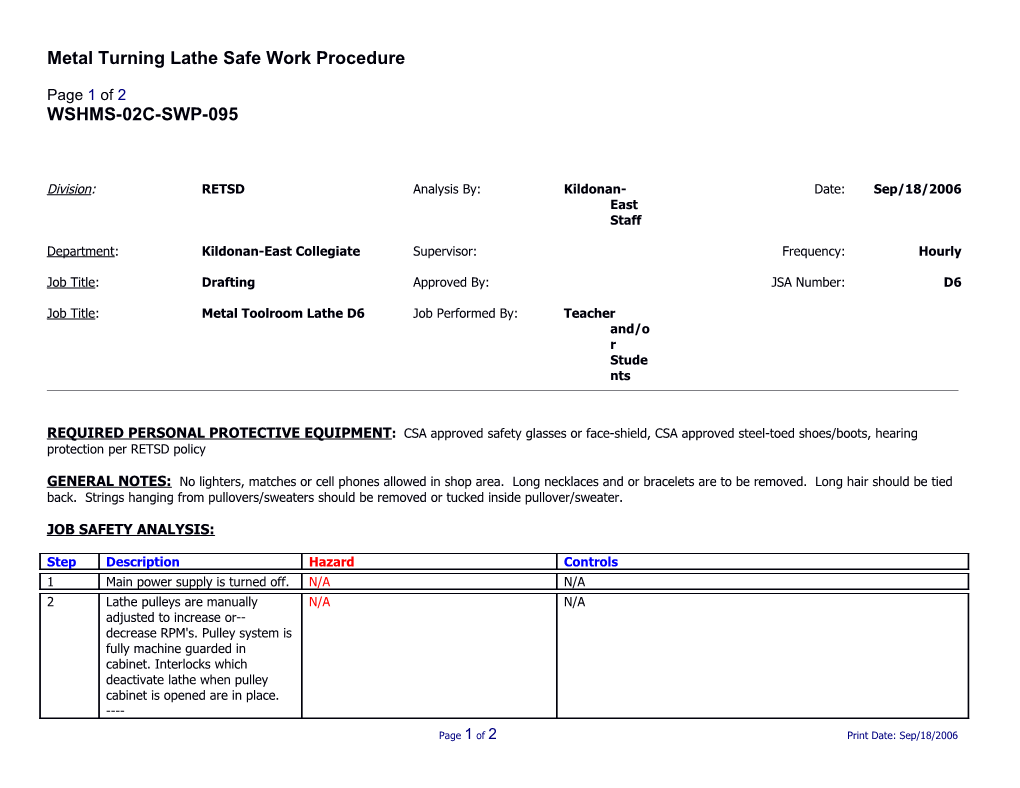

Metal Turning Lathe Safe Work Procedure

Page 1 of 2 WSHMS-02C-SWP-095

Division: RETSD Analysis By: Kildonan- Date: Sep/18/2006 East Staff

Department: Kildonan-East Collegiate Supervisor: Frequency: Hourly

Job Title: Drafting Approved By: JSA Number: D6

Job Title: Metal Toolroom Lathe D6 Job Performed By: Teacher and/o r Stude nts

REQUIRED PERSONAL PROTECTIVE EQUIPMENT: CSA approved safety glasses or face-shield, CSA approved steel-toed shoes/boots, hearing protection per RETSD policy

GENERAL NOTES: No lighters, matches or cell phones allowed in shop area. Long necklaces and or bracelets are to be removed. Long hair should be tied back. Strings hanging from pullovers/sweaters should be removed or tucked inside pullover/sweater.

JOB SAFETY ANALYSIS:

Step Description Hazard Controls 1 Main power supply is turned off. N/A N/A 2 Lathe pulleys are manually N/A N/A adjusted to increase or-- decrease RPM's. Pulley system is fully machine guarded in cabinet. Interlocks which deactivate lathe when pulley cabinet is opened are in place. ----

Page 1 of 2 Print Date: Sep/18/2006 3 Metal Toolroom Lathe is used N/A N/A only for small jobs. 4 Chip guard is in place which N/A N/A prevents metal that is being removed from stringing and whipping. 5 Stock to be tooled is mounted in N/A N/A chuck and chuck is tightened. 6 Material that is in excess of 2" Cut--Struck By Proper operating procedure should be followed-- away from chuck must be secured by live center. 7 Install proper sized chip breaker Cut--Eye Use chip breaker so that tooled metal does not string and whip. so that tooled--metal does not string. 8 Install correct cutting tool in tool N/A N/A carriage. 9 Set correct cutting speed. N/A N/A 10 Turn main power and lathe on Cut--Eye--Mechanical energy Training in the operation and maintenance of the Toolroom Lathe and begin tooling metal should be mandatory for all Machine Shop employees. --Training workers in proper lifting techniques

AUTHORIZED EMPLOYEE INFORMATION:

ID NUMBER: LAST NAME: FIRST NAME: REMARKS: JOB HISTORY INFORMATION:

DATE: REMARKS:

Approval Signature: Date: