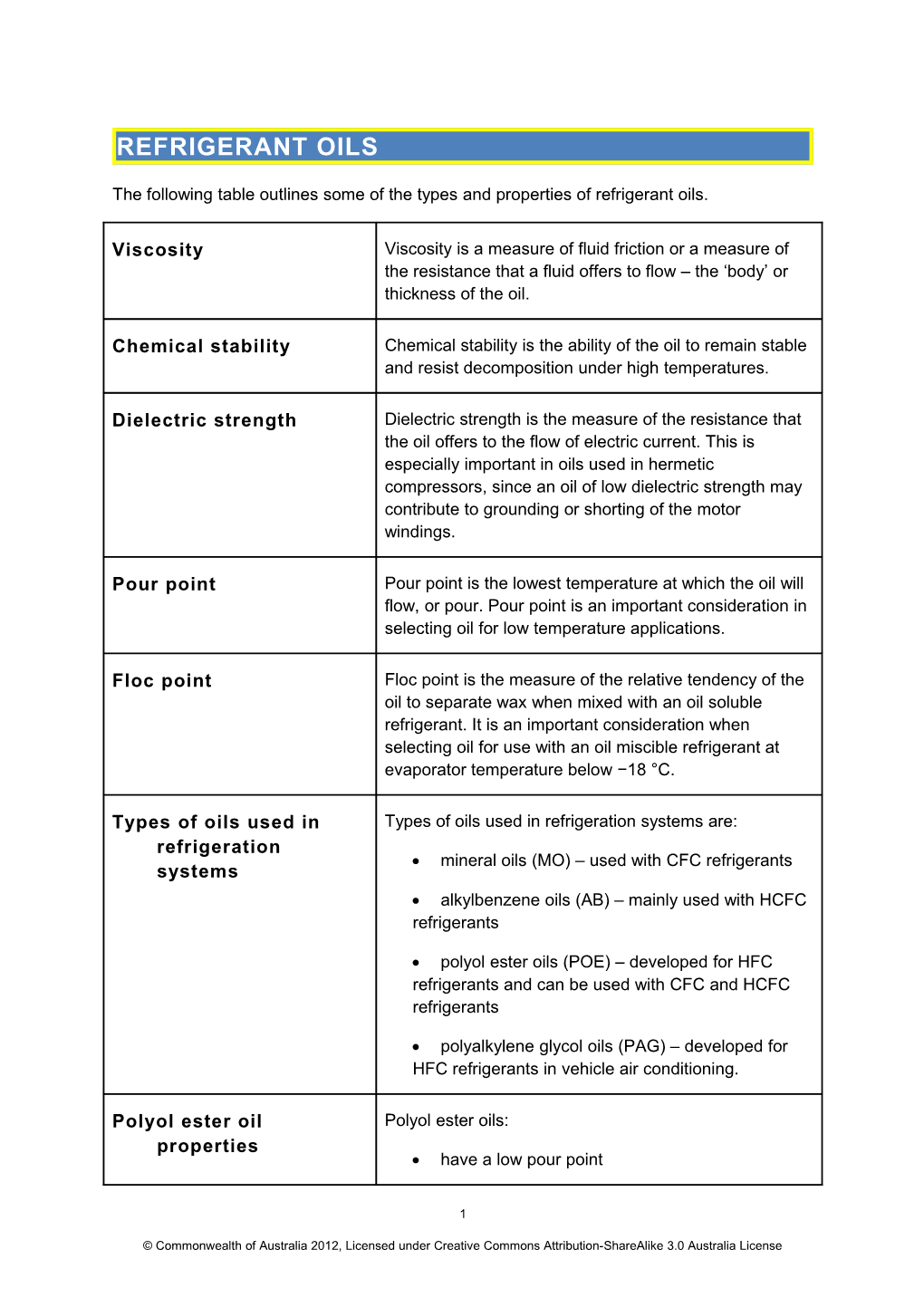

REFRIGERANT OILS

The following table outlines some of the types and properties of refrigerant oils.

Viscosity Viscosity is a measure of fluid friction or a measure of the resistance that a fluid offers to flow – the ‘body’ or thickness of the oil.

Chemical stability Chemical stability is the ability of the oil to remain stable and resist decomposition under high temperatures.

Dielectric strength Dielectric strength is the measure of the resistance that the oil offers to the flow of electric current. This is especially important in oils used in hermetic compressors, since an oil of low dielectric strength may contribute to grounding or shorting of the motor windings.

Pour point Pour point is the lowest temperature at which the oil will flow, or pour. Pour point is an important consideration in selecting oil for low temperature applications.

Floc point Floc point is the measure of the relative tendency of the oil to separate wax when mixed with an oil soluble refrigerant. It is an important consideration when selecting oil for use with an oil miscible refrigerant at evaporator temperature below −18 °C.

Types of oils used in Types of oils used in refrigeration systems are: refrigeration mineral oils (MO) – used with CFC refrigerants systems alkylbenzene oils (AB) – mainly used with HCFC refrigerants

polyol ester oils (POE) – developed for HFC refrigerants and can be used with CFC and HCFC refrigerants

polyalkylene glycol oils (PAG) – developed for HFC refrigerants in vehicle air conditioning.

Polyol ester oil Polyol ester oils: properties have a low pour point

1

© Commonwealth of Australia 2012, Licensed under Creative Commons Attribution-ShareAlike 3.0 Australia License are 10 times more hygroscopic than mineral oils

do not mix with MO or AB oil

have a greater solvent action, and are more solvent than mineral oils

are wax free.

Polyol ester oil The advantages of Polyol ester oils are that they: advantages have better oil return than mineral oils, less oil clogging of coils

have better heat transfer characteristics than mineral oils

are miscible with all refrigerants, CFC, HCFC, HFC and HC

are solvent in nature and can remove contaminants and return them to the sump and eventually to the filter drier

are wax free which means a lower operating pour point.

Polyol ester oil The disadvantages of Polyol ester oils are that they: disadvantages are extremely hygroscopic

retain moisture

attack roofing and certain sealing materials and wiping up does not stop the reaction – it must be neutralised.

2

© Commonwealth of Australia 2012, Licensed under Creative Commons Attribution-ShareAlike 3.0 Australia License