ECE 477 Digital Systems Senior Design Project Rev 8/09

Homework 13: User Manual

Team Code Name: ___A.F.C.I______Group No. _12___

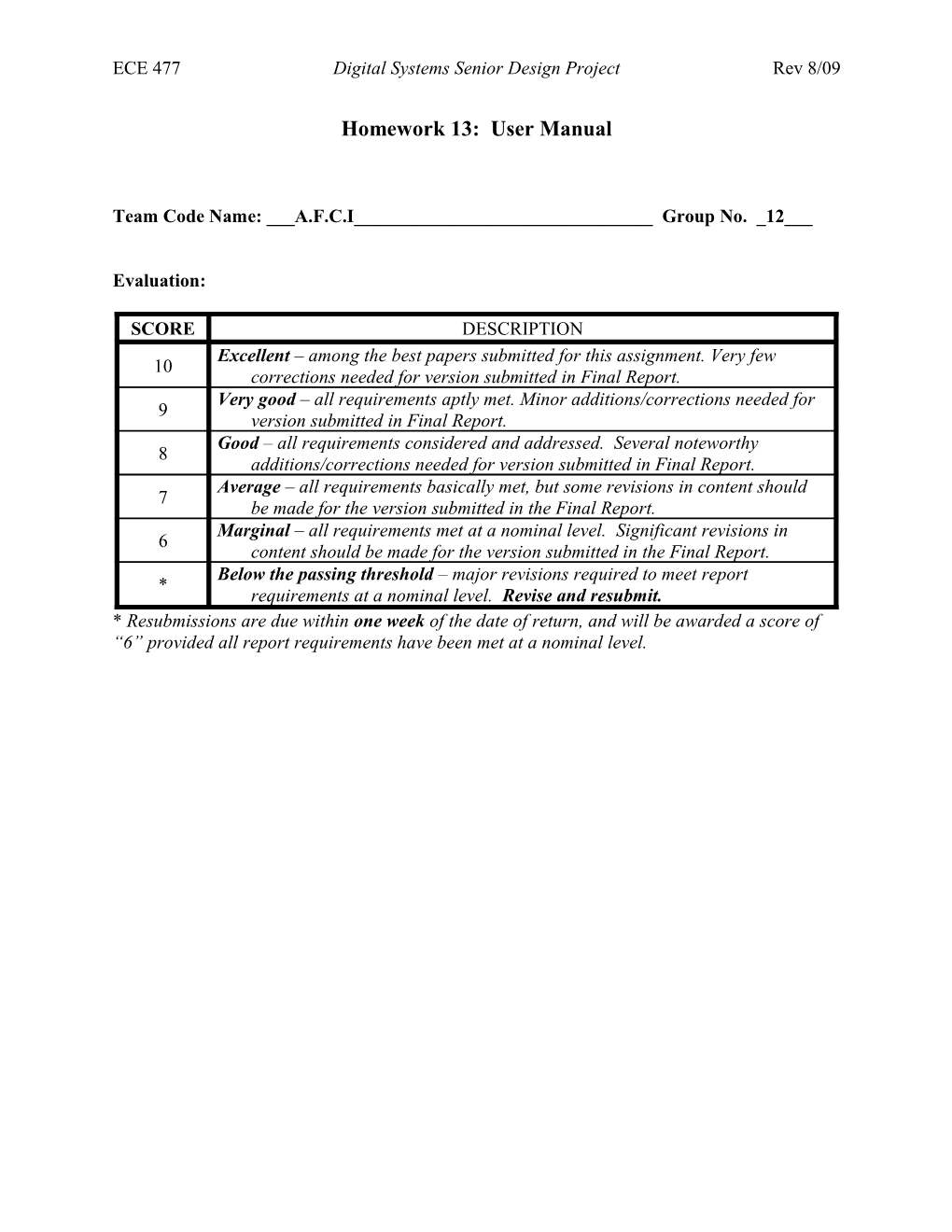

Evaluation:

SCORE DESCRIPTION Excellent – among the best papers submitted for this assignment. Very few 10 corrections needed for version submitted in Final Report. Very good – all requirements aptly met. Minor additions/corrections needed for 9 version submitted in Final Report. Good – all requirements considered and addressed. Several noteworthy 8 additions/corrections needed for version submitted in Final Report. Average – all requirements basically met, but some revisions in content should 7 be made for the version submitted in the Final Report. Marginal – all requirements met at a nominal level. Significant revisions in 6 content should be made for the version submitted in the Final Report. Below the passing threshold – major revisions required to meet report * requirements at a nominal level. Revise and resubmit. * Resubmissions are due within one week of the date of return, and will be awarded a score of “6” provided all report requirements have been met at a nominal level.

ECE 477 Digital Systems Senior Design Project Rev 8/09 Product Description

With all the hype about upcoming electric and hydrogen-powered automobile technology, a recent research project from Purdue University really stands out from the crowd. Professor Jerry Woodall, National Medal of Technology Laureate and the inventor of the Light-Emitting Diode (LED), has discovered a safe and efficient solution that might just create a revolution in the impact our vehicles have on the environment.

This technology solves the problem of dangerous hydrogen transportation by creating hydrogen gas on demand from water. By inserting a block of aluminum-gallium into a tank of water, hydrogen gas is instantly created that can be used to power a vehicle. In its current incarnation the system consists of a water tank connected to a hydrogen reactor, which in turn is connected to the car battery to recharge it. There are temperature and pressure sensors in both the reactor and tank, and a hydrogen leak sensor on top of the reactor to detect hydrogen leaks. This system has been successfully tested on a golf cart at Purdue University.

Because this technology is so new, there has yet to be any tools that can analyze the functionality and performance of such a system. This is where our product, Alumoline Fuel Cell Instrumentation (AFCI) comes in. AFCI is a turnkey solution that monitors several important facets of an aluminum-gallium hydrogen system and has the ability to log monitored data on a Secure Digital card for reference later.

Our package contains a computer desktop-like box that contains our digital analysis circuitry, a touchscreen 800x600 resolution LCD monitor that displays system data in real time and that the user can use to interact with the system, and a 36V lead acid battery to power the system. Because this technology is so new, this product is geared more towards research purposes. As such, we have decided to monitor data that will be more useful for research purposes rather than data a typical motorist would be more interested in. That being said, it would not be difficult to extend the system to determine information such as current miles per gallon and amount of fuel left. Currently the following data can be monitored: temperature in both the water tank and the reactor, pressure in both the water tank and reactor, and hydrogen gas content on top of the reactor.

Internally, AFCI uses a lightweight PC to generate its attractive interactive display. There is also a microcontroller that does most of the other work such as logging data to the Secure Digital card and interpreting sensor readings. The 800x600 LCD display can be customized to show all 5 readings, 2 readings, or just 1 reading at once. The user can directly control which data to log to the SD card through the touchscreen. The display can also show a graph for a given reading for comparison over a time period. Finally, the user can select how often data is logged to the SD card: every second, every 5 seconds, every 10 seconds, every 30 seconds or once a minute.

AFCI is projected to be available for $500 and is a cost-effective solution to monitor an up-and- coming technology that is poised to revolutionize the future.

Product Illustration

ECE 477 Digital Systems Senior Design Project Rev 8/09

Power/reset button

Figure 1: Product Enclosure

Menu and settings select buttons

Power button

Figure 2: LCD Touchscreen

ECE 477 Digital Systems Senior Design Project Rev 8/09

Logging toggle Change logging for each meter interval buttons

Shutdown button

Go to 1 meter mode button

Figure 3: Screenshot of AFCI Application

Product Setup Instructions

Although AFCI is easy to use, due to the nature of the application, it requires a few steps to setup. AFCI is designed to be used on golf carts that use aluminum-gallium hydrogen technology and would fit into such vehicles nicely. The best place to start is by mounting the LCD touchscreen. We provide a mount and bolts that can be fastened on to the dashboard of a standard golf cart. We recommend that it be placed so that it is a comfortable viewing distance and position from the driver.

Next, proceed to connect the USB and VGA cables from the LCD touchscreen to the ports at the rear of the AFCI enclosure. The power cord of the LCD should also be connected to the enclosure accordingly. The AFCI enclosure can then be mounted on the empty area in the dashboard on the passenger side that is present in most golf carts. We provide a holder and bolts which will fasten the enclosure firmly in place.

The next step is to connect the sensors to the AFCI enclosure. We provide long cables that will easily reach the water tank and reactor, wherever you decide to place them on the golf cart. However, depending on your setup you might have to solder the ends of the wires coming out of your sensors onto the ends of the provided cables. In our packaging we have also labeled which cable is to be used with which sensor.

Once your sensors are connected, the final step is to connect the battery. The lead acid battery we provided can supply a lot of current and can easily last around ten hours, however it is a little bulky. We have a standard power connector on the end of the battery which plugs easily into our enclosure. Furthermore, if your golf cart uses a battery within the 33-75V range you can opt to connect that battery to our system instead rather than use the included battery. Once the battery is plugged in, the system and LCD touchscreen can be turned on. Once the AFCI application has loaded, you will see the interface on the screen and begin analyzing your aluminum-gallium hydrogen setup.

ECE 477 Digital Systems Senior Design Project Rev 8/09 User Instructions Initial Start up In order to turn on the system there will be a red reset switch on the front of the package. By pressing this switch it will turn on the atom board which controls the LCD touch screen. The LCD screen should then show the startup for Ubuntu. Once Ubuntu loads the java application should immediately start up. The user will be presented with a screen with 5 meter bars along with a top panel with the current time and date. There should also be log buttons next to each meter bar. Also on the top panel will have a plus and minus button along with the current logging rate in seconds. The top left and top middle meter bars will correspond to the hydrogen tank temperature and pressure respectively. The top right and bottom left meters will correspond to the water tank temperature and pressure respectively. The bottom right meter will be the hydrogen leak detection. The current log rate should be set at 1 seconds and all log buttons should in the off state, be colored white.

Logging Data to SD Card The main mechanisms to be used to log data to the SD will be the plus and minus buttons on the top panel and the logging buttons next to each meter. The plus and minus buttons will either increment or decrement respectively the current logging rate. Instead of a linear method changing the log rate a predetermined set of values have been placed. This way the user doesn’t have to press either buttons many times to reach a range of logging rates. The logging rates that will be used: 1 second, 5 seconds, 10 seconds, 30 seconds, and 1 minute. In order to log a particular meter to the SD card simply click on the log button that corresponds to the meter. This button will turn red indicating that this particular meter is being logged to the SD card. In order to disable the logging of this meter simply click on the red logging button, the red button will turn white, and the system will stop writing data to the SD card. The title of the text file created on the SD card will be the current date and time. The entries in the file will all be marked with the current date and time. A new text file will be created every time the atom board boots, or every time the java application starts.

Graph Display

ECE 477 Digital Systems Senior Design Project Rev 8/09 The user will also have the option to see a graph display on the meter readings. In order to see the graph display click on one of the meter panels and the graph will show up corresponding to whichever meter was clicked. The graph will start to plot points based on the moment the graph has displayed. This graph will be a time series scatter plot. To go back to the original screen simply click on the graph and the display will be restored to the original panel with all the meters.

Figure 4: Graph Display

One Meter Mode It is also possible for the user to view only one meter one the screen. In order to do this there will be a “One Screen mode” button on the bottom middle of the interface. By pressing this the user will be brought to a screen where only one meter will take up the entire panel. At the top of this panel will be “Prev”, “LOG”, “Back”, “Next” buttons. The “Prev” will go to the previous meter, “LOG” will have the same functionality as in the main panel. “Back” will bring the user back to the main screen. “Next” will go on to display the next meter.

Figure 5: One Meter Mode

ECE 477 Digital Systems Senior Design Project Rev 8/09

Troubleshooting Instructions

Communication

Communication of data from the internal micro controller and the Intel Atom board are being done via RS-232. Any type of communication is prone to bit errors in transfer and receiving. Monitoring the condition of a hydrogen vehicle needs to communicate reliable information to the user. Because of this, the AFCI system implements reliability measures when it comes to transferring data. Every time an SD logging command is sent to the micro controller an acknowledgement is sent back to let the interface know that the command was received. However if a packet is received from the micro controller that it doesn’t recognize most likely there was bit corruption during the transmission process. The micro controller will then respond with an error code of 99. This means that all meter values will display as 99. Usually this would mean that the data communication buffer will be totally shifted and data from that point won’t be received correctly. In order to correct this, the only option of restoring the system is to restart the application to re-sync the communication process. There will be a shutdown button at the top right corner of the interface. The user should press this button when confronted with this error code.

SD Card One of the major features in the AFCI system is to allow users to log data to an SD card. However at some points these writes to the SD card may fail. The micro controller will inform the interface whenever an SD card write has failed. It will do this by sending the error code 98 to the Intel Atom board. This means that if there is an SD card write fail 98 will displayed for each meter value. If this error occurs, restart the application by hitting the shutdown button. If the code 98 continues to persist after a clean restart check the format of the SD card. The SD card should be formatted in FAT16. If there is no data on the SD card worth keeping, insert the card into a computer and re format the card in FAT16. Place the SD card back into the slot and restart the Intel Atom Board. If the problem still continues after taking these steps the SD card is most likely not functioning properly.

System Crashes Since the user interface will be running off the Intel Atom Board it will be susceptible to system crashes. If the user were to ever run into this situation there exists a hard reset button for the Atom Board. This button is red and in front on the packaging. This button will reboot the operating system, Ubuntu in this case, and automatically open the AFCI application.