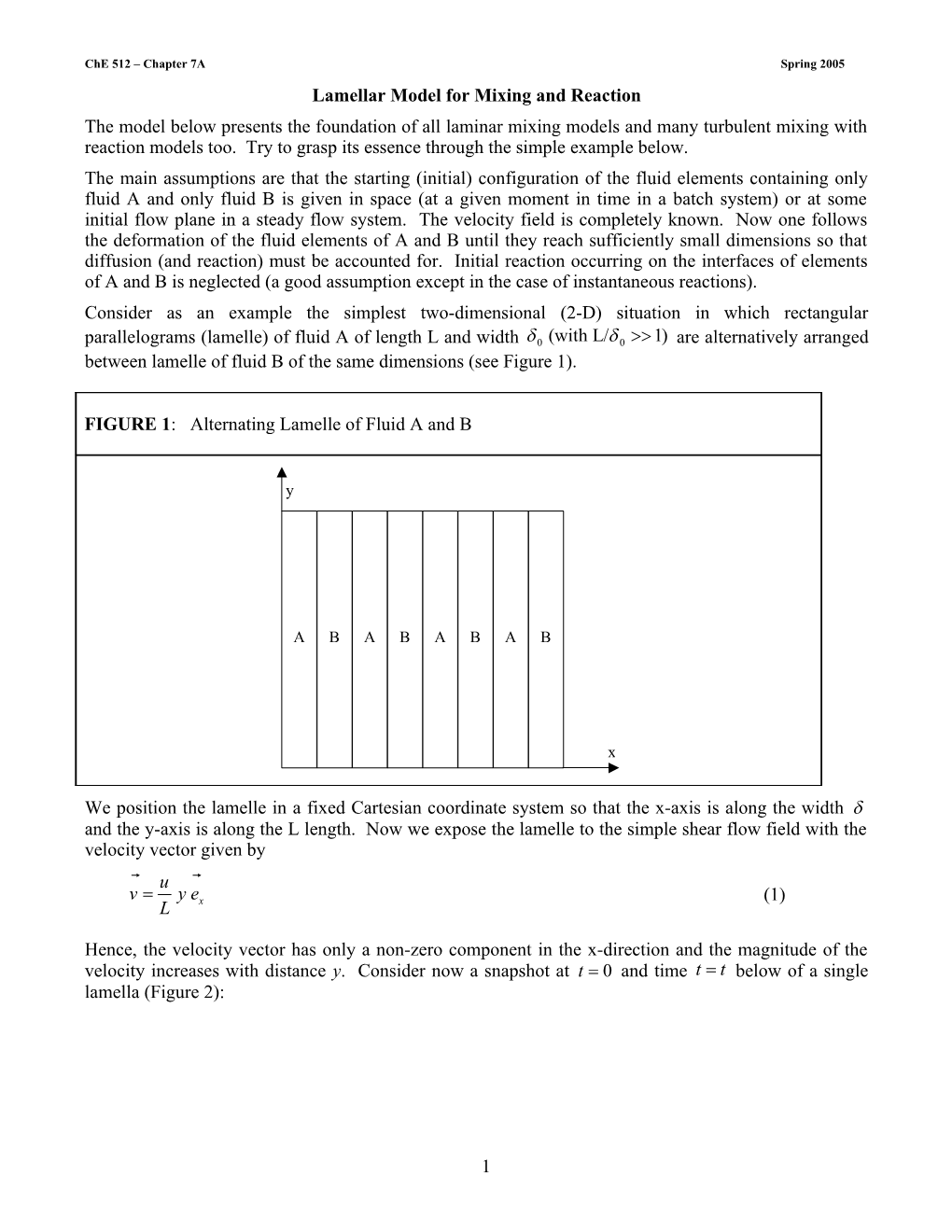

ChE 512 – Chapter 7A Spring 2005 Lamellar Model for Mixing and Reaction The model below presents the foundation of all laminar mixing models and many turbulent mixing with reaction models too. Try to grasp its essence through the simple example below. The main assumptions are that the starting (initial) configuration of the fluid elements containing only fluid A and only fluid B is given in space (at a given moment in time in a batch system) or at some initial flow plane in a steady flow system. The velocity field is completely known. Now one follows the deformation of the fluid elements of A and B until they reach sufficiently small dimensions so that diffusion (and reaction) must be accounted for. Initial reaction occurring on the interfaces of elements of A and B is neglected (a good assumption except in the case of instantaneous reactions). Consider as an example the simplest two-dimensional (2-D) situation in which rectangular

parallelograms (lamelle) of fluid A of length L and width d0(with L/ d 0 >> 1) are alternatively arranged between lamelle of fluid B of the same dimensions (see Figure 1).

FIGURE 1: Alternating Lamelle of Fluid A and B

y

A B A B A B A B

x

We position the lamelle in a fixed Cartesian coordinate system so that the x-axis is along the width d and the y-axis is along the L length. Now we expose the lamelle to the simple shear flow field with the velocity vector given by u v= y e (1) L x

Hence, the velocity vector has only a non-zero component in the x-direction and the magnitude of the velocity increases with distance y. Consider now a snapshot at t = 0 and time t= t below of a single lamella (Figure 2):

1 ChE 512 – Chapter 7A Spring 2005

FIGURE 2: Snapshot of a single lamella of fluid A exposed to the shear induced by velocity field of eq(1) over time period of t.

y t t t 0 L

L Le

o x ut

Clearly the point that was the top right corner (d0 , L) at time t = 0 has moved in the axial direction x by

distance ut and is at time t at position (d0 + ut, L) . At the same time, due to the nature of this simple

shear flow, the lower right corner (d0 , 0) stays at the same position. Simple geometry dictates that the angle is given by

L 1 tan w = = (2) ut Gt

u with G = being the shear rate in (1/s). L

Due to assumed constant density (incompressible fluid) the area of the lamella must remain the same (i.e is conserved). Hence

A= Led = A0 = d 0 L (3)

where d is the height normal to the new length of the lamella Le .

By geometric arguments (refer to the previous diagram)

L = sinw (4) Le

and from equation (3) of continuity it follows that

2 ChE 512 – Chapter 7A Spring 2005 dL tan w = =sin w = 2 (5) d 0 Le 1+ tan w

The last equality above comes from the well known trigonometric identity. After replacing tan w by equation (2), and upon rearranging, we get

d 1 = 2 2 (6) d 0 1+ G t

and by differentiation

1 dd dℓ n d G2 t - = - = = W (7) d dt dt1+ G2 t 2

Note 1: In any flow field then, the first order of business is to describe the original geometry of the pure fluid element and its deformation due to the forces acting on it generated by the known flow field.

Now we want to look at events from the point of view of the fluid element, i.e we want to transfer our observations to the orthogonal Cartesian coordinate system that has the x direction always in the

direction of lamellar thickness d and its y direction along the lamellar length Le . The two coordinate systems at time t (i.e., our original stagnant coordinate system (x,y) and the new system (x’,y’)) are sketched below (Figure 3). One should keep in mind that in general the origins of the two systems need not coincide.

FIGURE 3: Two Cartesian Coordinate Systems

y y

x

x

3 ChE 512 – Chapter 7A Spring 2005

Basically the transformation from the ( x, y) to the ( xⅱ, y ) coordinate system obeys the well known rule for linear transformations

x= C11 x' + C 12 y ' + b 1 (8a)

y= C21 x' + C 22 y ' + b 2 (8b) with C11= ex� e x ' C 12 e x e y ' (9) C21= ey� e x ' C 22 e y e y ' where ei are orthogonal unit vectors in the ( x, y) system and ei are orthogonal unit vectors in the ( xⅱ, y ) system.

Transformation of derivatives follows the chain rule:

抖 抖x y = + (10a) 抖x' x 抖 x ' y x ' 抖 抖x y = + (10b) 抖y' x 抖 y ' y y '

抖x y But =C, = C etc. (see eqs. 8a, 8b) 抖xⅱ 11 x 21

Now armed with this review of elementary vector calculus, we can represent our velocity vector in the new coordinate system as: v= Gyex = v x' e x ' + v y ' e y ' (11) Clearly: ex'� e y ' �0 ; e x ' e x ' 1 (12)

骣p p ex� e x'-cos琪 =w - - sin sin( = w) = sin w C 11 (13) 桫2 2

So the velocity component in the direction of striation thickness d at all times is Gy vx' = Gy sinw = (14) 1+ G2 t 2 v You should be able to get by the analogous approach the velocity component y' ! v Now consider the derivative x' using eq (10a) and (8a, 8b) x ' 抖v v v x'= x 'C + x ' C (15) 抖x' x11 y 21 4 ChE 512 – Chapter 7A Spring 2005

We have found C11= ex� e x ' sinw by eq (13)

Similarly from eq (9) C21= ey� e x ' +cos(p = w) - cos w (16)

Thus, using eq (14) (15) (13) and (16) we get

抖v v G x'=0 - x ' cosw = -G sin w cos w = - sin 2 w 抖x' y 2 (17) Gtanw G2 t = - = - = -W 1+ tan2w 1 + G 2 t Hence:

vx' = -W x ' (18)

Now we should recall that continuity equation must hold, which in the x , y coordinate system requires v v x' +y ' = 0 (19) 抖x' y '

v Since we know that x' = -W , we get x '

vy ' = W;vy ' = W y ' (20) y '

Equation (18) for vx' and equation (20) for vy' clearly indicate that the lamella is continuously being squeezed (compressed) in the x ' direction so that thickness d is constantly reduced in time (this is also evident from equation (7), while it is being pulled (elongated) in the y ' direction.

Let us now consider that the lamella are small enough so that we must also consider diffusion and reaction. Consider the lamella that originally contained only reactant A.

We write then the fundamental species continuity equation for species A in the coordinate system ( x , y ). Where 1 indicates that the operator is applied in ( x ' , y ' ) coordinates. C A + �(vC ) � D2 C R (21) t 1A A 1 A A-

5 ChE 512 – Chapter 7A Spring 2005 Now 抖 �1vCA+ ( v x ' C A) ( v y ' C A ) 抖x' y ' (22) 抖Cv C v =vA + Cx + v A + C y ' x'抖x' A y ' y ' 抖 y ' A y '

Due to the continuity equation (19) the second and fourth term above in equation (22) cancel out.

Moreover since the lamella is considered very long compared to its striation thickness d (same effect as if the ends in the y ' direction were sealed) there can be no concentration gradients in the y ' direction so that the third term in equation (22) is zero. Now consider the Laplacian terms

抖2C 2 C �2C + A A (23) 1 A 抖x'2 y ' 2

Due to the lack of gradients in the y ' direction the last term in eq. (23) is zero.

Upon substituting all the nonzero terms of equations (22) and (23) into eq. (21) we get

2 抖CA C A C A +v = D - R - (24) 抖tx' x' A x '2 A or 2 抖CA C A C A - Wx = D - R - (24a) 抖t x'A x '2 A

R where A- is the rate of disappearance of A .

NOTE 2:

Only the above described mathematical operations are needed to follow lamellal mixing and reaction in much more complex geometry. No new concepts are involved only more laborious application of the same simple mathematical rules.

If you are open minded, and consider this in a broader context, then clearly, following individual lamelle is needed (Lagrangian perspective) to capture the phenomena of diffusion and reaction accurately. At the same time this information must be constantly communicated to the flow field especially in a large vessel (Eulerian perspective). Two interlocked computations can be set up.

Have fun thinking about all the wonderful problems that you can solve using this general approach.

6 ChE 512 – Chapter 7A Spring 2005 Let us consider now the solution of eq (24a). Since the lamella is constantly shrinking in the x ' direction, i.e., its thickness d is being reduced in time, it is useful to immobilize this moving boundary by introducing new dimensionless coordinate x ' z = (25) d

Since the characteristic diffusion time is d 2 D , we define dimensionless time, measured in units of characteristic diffusion time by t dt q = D 2 (26) o d

Thus, we need to transform equation (24a) from the ( t, x ' ) coordinate system to (q , z ) coordinate system. Hence, the time derivative becomes

抖 抖q 抖z D x' d d = + = - 抖tq 抖 t z 抖 t d2 q d 2 dt z

d ln d But since x' d = z and - = W we get dt 抖 D = + W z (27a) 抖td2 q z

Similarly, the spatial derivative is:

抖 抖q 抖t 1 = + =0 + 抖x'q 抖 x ' z 抖 x ' d z Therefore 抖 1 = (27b) 抖x' d z and 抖21 2 = (27c) 抖x'2d 2 z 2 Upon substitution of eqs (27a, 27b, 27c) into eq (24a) we get

2 D抖 CA C A 抖 C A D C A + Wz - W z = - R - (28) d2抖 qz 抖 z d 2 z 2 A Upon rearrangement we get

2 2 抖CA C A d = - R - (29) 抖q z2 D A

We can now normalize the concentration 7 ChE 512 – Chapter 7A Spring 2005

CA C1 = (30a) CAo

The rate of reaction

R R A- A - r1 = = (30b) R C, C R0 A-( Ao Bo ) A - and the striation thickness

d d = (30c) d o to obtain:

2 d 2 Ro 抖C1 C 1 o A- =2 - d r1 (31) 抖q z D CAo

We recognize the Thiele modulus-like term:

骣charasteristic diffusion 2 0 琪 d R 2 o A- 桫time in original lamella f1 = = D CAo (characteristic reaction time)

However, if the modulus is large, the reaction originally occurs only close to the interface but gradually extends into the interior as the effective modulus f1eff = f 1 d always is reduced in time as d decreases in time.

Thus, we can now write the final governing equations for reaction of A and B

a CBo (C2 = CB C Bo ) ; b = . b CAo

抖C2 C 1= 1 - f2 d 2 r (32) 抖q z2 1 1

抖C2 C f 2 2= 2 - 1 d 2 r (33) 抖qz2 b 1

8 ChE 512 – Chapter 7A Spring 2005 I.C.

q =0C1 = 1, C 2 = 0, 0# z 1 (34)

C1=0, C 2 = 1, - 1# z 0

B.C.

1 抖C C z =� 1 = 2 0 (35) 2 抖z z

Conversion of A, xA , as a function of time is given by:

1 2 x=1 - 2 Cq , z dz A 1 ( ) (36) 1 - 2

To solve eqs (32-36) one must be able to specify the variation of the dimensionless striation thickness d as a function of dimensionless time q .

Let us at the end return to the equation for the reduction of the striation thickness, eq (7)

dln d G2 t - = = W (7) dt1 + G2 t 2

In a superior batch shear mixer we would like to maximize W , i.e., maximize the rate of relative decrease of striation thickness d . (One should note that eq (7) holds also for the dimensionless striation thickness d ). Now Wmax occurs (take derivative of eq (7) with respect to time and set it to zero) when 1 t= = L u and hence, when tanw = 1 and w = p 4 or 45. The rate of energy dissipation (power) G per unit volume, e˙v , is

2 2 P骣d Vx 骣 u 2 e˙v = = m琪 = m琪 = m G (37) V桫 dy桫 L where P is the power, V, volume of the system and , the viscosity.

Hence,

u e˙ G = = v (38) L m

1 e˙v and Wmax = (39) (shear flow) 2 p

For an impeller mixed vessel in laminar flow the power number is inversely proportional to the Reynolds number. Therefore, 9 ChE 512 – Chapter 7A Spring 2005

P C C m =1 = 1 (40) rN3 d 5Re d 2 N r

r where is density, N-rotational speed, d-impeller diameter, and C1 is a constant. Assuming by geometric similarity that the volume of the tank is always proportional to the impeller diameter cubed, d 3 , we get:

P ' 2 e˙ = = C1 m N (41) v V e˙ W a v N (42) m

The representative strain velocity e˙v / m is directly proportional to agitator speed and the rate of reduction of striation thickness is directly proportional to agitator speed (rpm).

It can be shown that the maximum possible rate of change in striation thickness d can be achieved in stagnation point flow where

e˙v Wmax = (43) (st. flow) 2m

Mixing efficiency can then be defined as:

W -dln d dt hmix = = (44) Wmax(st . flow) e˙v / 2 m

The maximum possible efficiency then of a simple shear mixer considered here would be:

1 2 1 (hmix ) = = = 0.707 (45) mix. shear mix . 1 2 2

Let us relate now the variation in d with time to the performance of the mixer as a reactor, i.e., relate it to the solution of eqs (32-26).

In our simple shear mixer from eq (6) we see that

d 1 d = = 2 2 (6) d o 1 + G t

We can substitute eq (6) into eq (26) to get:

t 2 D2 2 D骣 G 3 q =2(1 +G t) dt = 2 琪 t + t (45) doo d o 桫 3 10 ChE 512 – Chapter 7A Spring 2005 and we know from eq (7)

dlnd 1 d d G2 t = = - (46) dtd dt1 + G2 t 2 t =0d = 1 (46a)

By solving eqs (46-46a) and relating time t to q via eq (47) we have the information needed to numerically solve eqs (32-36).

Now we may be interested in what the best possible stagnation point mixer could achieve. In such case (ideally and optimally)

d ln d e˙ - = v (47) dt 2 m t =0d = 1 (47a)

So we get:

- e˙ 2 m d =ev t = e-WM t (48)

where WM = e˙ 2 m

Substitution of eq (48) into eq (26) yields

D 2WM t q =2 (e - 1) (49) d o2 W M

Equation (40) can be solved explicitly for time t 1 骣 2 d2 W q t =ln琪 1 + o M (50) 2 WM 桫 D

We also see that

1 d 2 =e-2 WM t = 2 d 2 W (51) 1 + o M q D

Hence, we can substitute eq (51) into eqs (32) and (33), solve equations (32-37) for conversion of A, xA , as a function of q and relate each value of q to the value of time t by eq (50).

You should proceed to solve the problem for a second order rate and other nonlinear rate forms.

11