Coloree Las Unidades Sus Rojos Parecen Anaranjados? Quite Dos Capful De Revelador Rojo

Total Page:16

File Type:pdf, Size:1020Kb

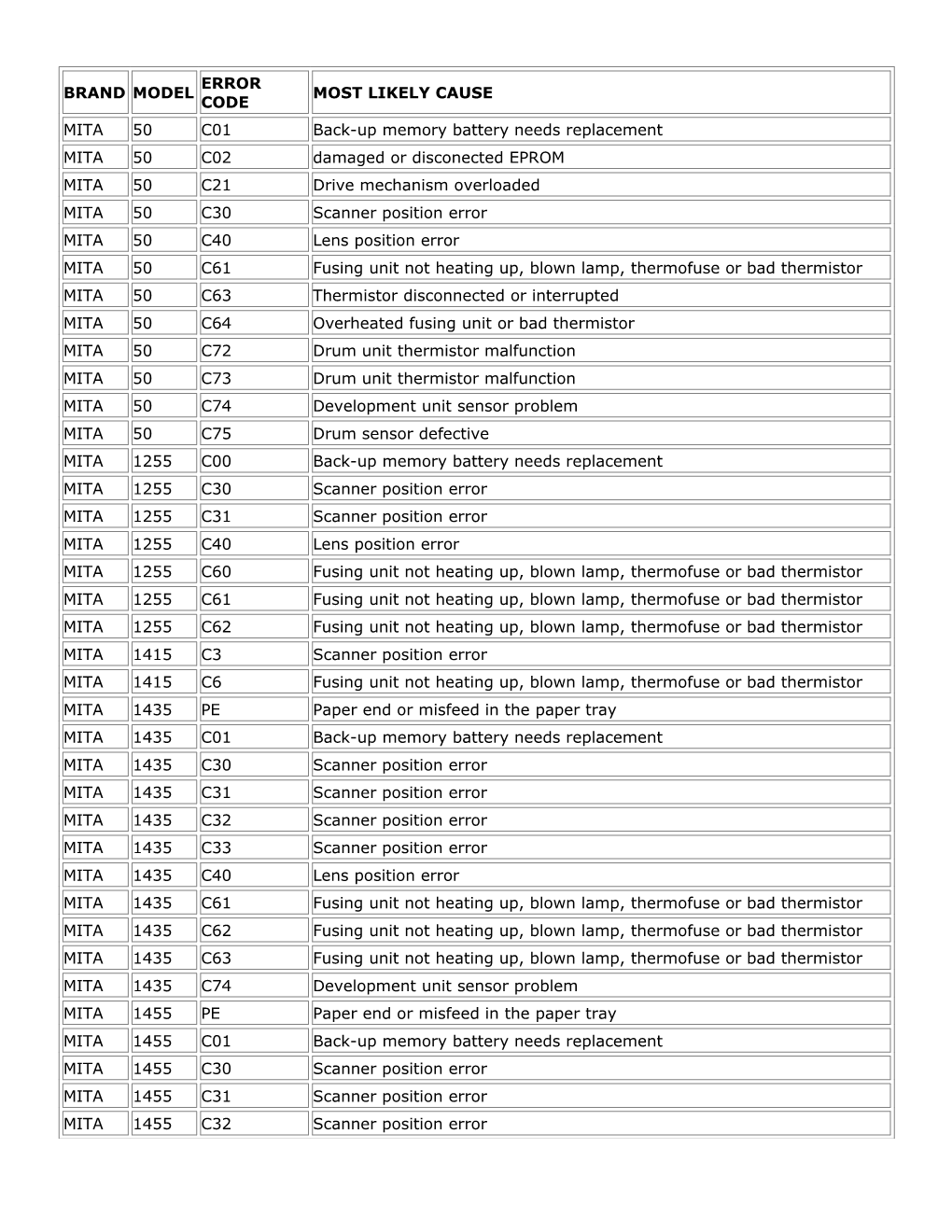

ERROR BRAND MODEL MOST LIKELY CAUSE CODE MITA 50 C01 Back-up memory battery needs replacement MITA 50 C02 damaged or disconected EPROM MITA 50 C21 Drive mechanism overloaded MITA 50 C30 Scanner position error MITA 50 C40 Lens position error MITA 50 C61 Fusing unit not heating up, blown lamp, thermofuse or bad thermistor MITA 50 C63 Thermistor disconnected or interrupted MITA 50 C64 Overheated fusing unit or bad thermistor MITA 50 C72 Drum unit thermistor malfunction MITA 50 C73 Drum unit thermistor malfunction MITA 50 C74 Development unit sensor problem MITA 50 C75 Drum sensor defective MITA 1255 C00 Back-up memory battery needs replacement MITA 1255 C30 Scanner position error MITA 1255 C31 Scanner position error MITA 1255 C40 Lens position error MITA 1255 C60 Fusing unit not heating up, blown lamp, thermofuse or bad thermistor MITA 1255 C61 Fusing unit not heating up, blown lamp, thermofuse or bad thermistor MITA 1255 C62 Fusing unit not heating up, blown lamp, thermofuse or bad thermistor MITA 1415 C3 Scanner position error MITA 1415 C6 Fusing unit not heating up, blown lamp, thermofuse or bad thermistor MITA 1435 PE Paper end or misfeed in the paper tray MITA 1435 C01 Back-up memory battery needs replacement MITA 1435 C30 Scanner position error MITA 1435 C31 Scanner position error MITA 1435 C32 Scanner position error MITA 1435 C33 Scanner position error MITA 1435 C40 Lens position error MITA 1435 C61 Fusing unit not heating up, blown lamp, thermofuse or bad thermistor MITA 1435 C62 Fusing unit not heating up, blown lamp, thermofuse or bad thermistor MITA 1435 C63 Fusing unit not heating up, blown lamp, thermofuse or bad thermistor MITA 1435 C74 Development unit sensor problem MITA 1455 PE Paper end or misfeed in the paper tray MITA 1455 C01 Back-up memory battery needs replacement MITA 1455 C30 Scanner position error MITA 1455 C31 Scanner position error MITA 1455 C32 Scanner position error MITA 1455 C33 Scanner position error MITA 1455 C40 Lens position error MITA 1455 C61 Fusing unit not heating up, blown lamp, thermofuse or bad thermistor MITA 1455 C62 Fusing unit not heating up, blown lamp, thermofuse or bad thermistor MITA 1455 C63 Fusing unit not heating up, blown lamp, thermofuse or bad thermistor MITA 1455 C64 Overheated fusing unit or bad thermistor MITA 1455 C74 Development unit sensor prblem Front cover not properly closed, clamshell not properly closed, bad safety MITA 1555 OP switches MITA 1555 U1 Key counter or coin-up device must be activated MITA 1555 UF Development unit sensor problem or not installed MITA 1555 C01 Back-up memory battery needs replacement MITA 1555 C20 Drive mechanism overloaded MITA 1555 C30 Scanner position error MITA 1555 C31 Scanner position error MITA 1555 C32 Scanner position error MITA 1555 C33 Scanner position error MITA 1555 C40 Lens or mirror position error MITA 1555 C50 Charge unit current leak or bad high voltage board MITA 1555 C51 Transfer corona leak MITA 1555 C60 Fusing unit not heating up, blown lamp, thermofuse or bad thermistor MITA 1555 C61 Fusing unit not heating up, blown lamp, thermofuse or bad thermistor MITA 1555 C62 Fusing unit not heating up, blown lamp, thermofuse or bad thermistor MITA 1555 C63 Fusing unit not heating up, blown lamp, thermofuse or bad thermistor MITA 1555 C70 Drum thermistor is shorted MITA 1555 C71 Drum thermistor is disconnected MITA 1560 PF Blocaj la alimentarea cu hirtie MITA 1560 J30 Registration paper jam MITA 1560 J40 Transport or fusing entrance paper jam MITA 1560 J50 Fusing exit or paper exit jam MITA 1560 C01 NVRAM defective or missing MITA 1560 C20 Drive mechanism overloaded MITA 1560 C30 Scanner position error MITA 1560 C40 Lens position error MITA 1560 C50 Charge unit current leak or bad high voltage board MITA 1560 C61 Fusing unit not heating up, blown lamp, thermofuse or bad thermistor MITA 1560 C63 Fusing unit not heating up, blown lamp, thermofuse or bad thermistor MITA 1560 C64 Overheated fusing unit or bad thermistor MITA 1560 C72 Drum thermistor disconnected MITA 1560 C73 Drum thermistor shorted MITA 1560 C74 external thermistor disconnected MITA 1560 C75 External thermistor shorted MITA 1560 C90 Communication with the feeder is lost Front cover not properly closed, right cover not properly closed, bad MITA 1656 OP safety switches MITA 1656 U1 Key counter or coin-up device must be activated MITA 1656 C01 Back-up memory battery needs replacement MITA 1656 C20 Drive mechanism overloaded MITA 1656 C30 Scanner position error MITA 1656 C31 Scanner position error MITA 1656 C32 Scanner position error MITA 1656 C33 Scanner position error MITA 1656 C40 Lens and mirrors position error MITA 1656 C50 Charge unit current leak or bad high voltage board MITA 1656 C51 Transfer corona leak MITA 1656 C60 Fusing unit not heating up, blown lamp, thermofuse or bad thermistor MITA 1656 C61 Fusing unit not heating up, blown lamp, thermofuse or bad thermistor MITA 1656 C63 Drum thermistor defective MITA 1656 C70 Drum thermistor shorted MITA 1656 C71 Drum thermistor disconnected Front cover not properly closed, right cover not properly closed, bad MITA 2556 OP safety switches MITA 2556 U1 Key counter or coin-up device must be activated MITA 2556 C01 Back-up memory battery needs replacement MITA 2556 C03 Main board to scanner interface board communication lost MITA 2556 C21 Drive mechanism overloaded MITA 2556 C22 Motor overload at registration roller drive MITA 2556 C23 Drive mechanism overloaded MITA 2556 C24 Vacuum fan paper transport overload MITA 2556 C31 Scanner position error MITA 2556 C41 Lens position error MITA 2556 C51 Charge unit current leak or bad high voltage board MITA 2556 C52 Transfer corona leak MITA 2556 C61 Fusing unit not heating up, blown lamp, thermofuse or bad thermistor MITA 2556 C63 Fusing unit not heating up, blown lamp, thermofuse or bad thermistor MITA 2556 C64 Overheated fusing unit or bad thermistor MITA 2556 C65 Development unit sensor problem MITA 2556 C71 Development unit sensor problem MITA 2556 C73 Drum thermistor shorted Front cover not properly closed, right cover not properly closed, bad MITA 3055 OP safety switches MITA 3055 U1 Key counter or coin-up device must be activated MITA 3055 C01 Back-up memory battery needs replacement MITA 3055 C03 Main board to scanner interface board communication lost MITA 3055 C21 Drive mechanism overloaded MITA 3055 C22 Motor overload at registration roller drive MITA 3055 C23 Drive mechanism overloaded MITA 3055 C24 Vacuum fan paper transport overload MITA 3055 C31 Scanner position error MITA 3055 C41 Lens position error MITA 3055 C51 Charge unit current leak or bad high voltage board MITA 3055 C52 Transfer corona leak MITA 3055 C61 Fusing unit not heating up, blown lamp, thermofuse or bad thermistor MITA 3055 C63 Fusing unit not heating up, blown lamp, thermofuse or bad thermistor MITA 3055 C64 Overheated fusing unit or bad thermistor MITA 3055 C65 Development unit sensor problem MITA 3055 C71 Development unit sensor problem MITA 3055 C73 Drum thermistor shorted MITA 2556 C01 Back-up memory battery needs replacement MITA 2556 C03 Main board to scanner interface board communication lost MITA 2556 C05 secondary processor error MITA 2556 C21 Drive mechanism overloaded MITA 2556 C22 Motor overload at registration roller drive MITA 2556 C23 Drive mechanism overloaded MITA 2556 C24 Vacuum fan paper transport overload MITA 2556 C31 Scanner position error MITA 2556 C41 Lens position error MITA 2556 C51 Charge unit current leak or bad high voltage board MITA 2556 C52 Transfer corona leak MITA 2556 C61 Fusing unit not heating up, blown lamp, thermofuse or bad thermistor MITA 2556 C63 Fusing unit not heating up, blown lamp, thermofuse or bad thermistor MITA 2556 C64 Overheated fusing unit or bad thermistor MITA 2556 C65 Photoconductor unit needs replacement MITA 2556 C72 Drum thermistor disconnected MITA 2556 C73 Drum thermistor shorted MITA 2556 C74 Development unit thermistor disconnected MITA 2556 C81 Sorter paper feed motor error MITA 2556 C82 Sorter bin up/down movement motor overload MITA 2556 C83 Counter movement motor lock in sorter MITA 2556 C84 Limit positions error in sorter MITA 2556 C85 Sort motor lock MITA 2556 C86 Shift motor lock in sorter MITA 2556 C87 Counter movement motor lock in sorter MITA 2556 C88 Jogging problem MITA 2556 C89 Punch stuck or blocked

Coloree Las Unidades ¿Sus rojos parecen anaranjados? Quite dos capful de revelador rojo y agregue dos capful de negro entonces calibran. El rojo viene fuera de más oscuro.

PATRONES DE PRUEBA Mire sus blancos de prueba del mita. Cuando se exponen a la luz consiguen más oscuras. Aparecerá que las copias están a la obscuridad. Compruebe la venda y el color grises del papel.

ATASCOS DE LA ALIMENTACIÓN DE RADF La mejor manera de eliminar los atascos y las alimentaciones múltiples de la alimentación, aparte del generalmente la limpieza de proceedures y los reemplazos de los rodillos de alimentación, debe ajustar el medio neumático de centro tres de la luna pisa adelante de los neumáticos externos de la luna. Esto cortes del procedimiento que atoran y doblez de los problemas 10 de la alimentación múltiple.

RADF II

Muchos distribuidores de Mita han aumentado los montajes primarios de la alimentación del anterior la versión RADF I con la alimentación nueva del estilo se cansa. Estos neumáticos de la alimentación son medio estilo individual de la luna que cupo en el eje con el tornillo de allen. Ajuste el medio rodillo de centro de la luna adelante los externos cerca de 2-3 pisa longitudes ayudará a guardar la presión en originales apiladas sin la fabricación de la alimentación de papel más difícilmente. Esto vertually elimina atorar y la multi-alimentacio'n incluso con gravemente rodillos gastados.

Azul De Misfeeding Se es un rato puesto que trabajé para Mita así que no soy seguro del RADF modelo # puede ser RADF II. Es el alimentador que cabe los 4086 y los 5685. De todas formas, Mita salió con esta MOD aseada, medios neumáticos de la alimentación de la luna y ellos ¡aspire! ¿Probado moviendo el neumático medio fuera de 5 grados? ¿Realmente no trabajó para de largo usted dijeron? Entonces salieron con ésos tontos el separador actualizado se cansa con los ejes break-away, usted sabe los que si usted utilizó dos rodillos de goma de sept el alimentador multifed, si usted utilizó la MOD, 4 neumáticos de goma, no alimentaría cualquier cosa. ¡Encontré una solución! Tome 2 ejes del separador de RADF I, quite los neumáticos a partir del uno de los ejes y pegúelos en el otro donde el nilón blanco o fijado en segundo lugar del caucho los neumáticos irán. Substituya el eje entero del separador y lance lejos eso eje seccional estúpido. Los neumáticos de RADF I sept son más anchos y tienen no pise, cuatro de ellos trabajo con error MUY PEQUEÑO. Hice esto a 40+ las máquinas en mi territorio y creen que él solucionó mi no de multifeed/or problemas de alimentación.

SRDF1 En el rodillo más bajo de la separación donde las fijaciones del resorte al metal, archivo cerca de la milipulgada 4 de 1 lado de cada resorte apagado para librar la presión. Esto es un recurso pasado si todas las mejoras no trabajan. El problema sigue siendo demasiada presión.

COMPAGINADORES As-s5120 EL ESTRELLARSE Un par de compaginadores en el campo se ha estrellado, en algunos casos que rompían los compartimientos ellos mismos del compaginador. ¡Rebiulding estos compaginadores en muy desperdiciador de tiempo y la frustración! La aplicación de la grasa a todas las guías y a los marcos que los compartimientos del compaginador resbalan encendido se parece fijar el problema. Hacer esto en el sistema para arriba y en cada P.M. hecho en la copiadora sí mismo asistirá a eliminar este problema.

El compartimiento que se estrella o las piezas rotas es a menudo el resultado del usuario que quita un apilado sujetado con grapa antes de que se haya lanzado la barra de la prensa. Cuando sucede esto la impulsión de la barra y/o del compartimiento de la prensa mech. sale de tiempo. Repase cuidadosamente el SM durante re- tiempo apropiado de la manera estas dos impulsiones e informe al keyop sobre quitar copias sujetadas con grapa.

Ai 2310 Y Ai 3010 Cuando usted está teniendo copias en blanco, las imágenes están consiguiendo impresión cambiada de puesto, doble, o medias copias. Quite la unidad del laser de la máquina. Abra la unidad que usted encontrará el espejo de polígono tiene cierto tipo de mirada manchada a ella. Limpie todos los lados del espejo y su problema será ido. Usted encuentra este problema para ser peor era humo de la gente o en áreas polvorientas.

BAJO - MODELOS MEDIADOS DE DEL VOLUMEN CALIDAD DE COPIA ¿Quite 3-5 capfuls de DV de las máquinas del volumen de mid/high? NO LO HAGA. Hacen absolutamente muchos de investigación en cuanto a la cantidad de revelador que entre en un modelo particular. Aunque muchos diversos modelos utilizan el exacto el mismo revelador (busque los códigos en las botellas, es decir N18-t), la cantidad es qué les hace el específico modelo.

LA MAYORÍA DE LAS MÁQUINAS DE MITA BOTÓN DE IMPRESIÓN ROTO Botón de impresión roto, si no hay ordenador actual intercambio el botón con un botón del ordenador.

MEDIO/VELOCIDAD

CAMBIE LOS PROBLEMAS En las máquinas de alta velocidad, doble el cheque el interruptor de la cama del transporte, cerca de la base del brazo del interruptor. El papel cortará realmente adentro a este interruptor, causando un surco y cogiendo o retrasando el papel. La cinta o una garra más baja de la salida del metal de Mita 2585 (viejo estilo), corte de Mylar para caber el brazo del interruptor, le pasará hasta que un nuevo interruptor puede ser pedido.

CALIDAD DE COPIA Quite 3-5 capfuls de revelador en su cambio siguiente de DV en cualquier Mita los 55cpm o suba. Usted notará el aumento de la calidad.

Cc-50

CÓDIGOS J01 nuevo en el frente del mita cc50: según un boletín informativo del utax (otra compañía que vende las máquinas del mita) un mal contacto de la caja de la corona de la carga y del acoplamiento de alambre de la unidad de tambor puede causar a J01 los atascos de papel.

Dc-111 CERRADO TRAGA El completar un ciclo de off/on causado en el Mita más viejo 111 es debido a los condensadores agujereados en el tablero del sorce de la energía.

FUENTE DE ALIMENTACIÓN Máquina que cierra abajo en varias ocasiones. Quite La Fuente De Energía PCB. Check suelde los empalmes en cada cinco pernos de conectador. el perno 0V tendrá grieta alrededor de él. Resuelde los cinco con la soldadura fresca.

FUENTE DE ALIMENTACIÓN Trabaje a máquina las energías para arriba y cierra abajo en varias ocasiones por ninguna razón con excepción de la fuente de alimentación va mala y debe ser substituida pero, compruebe los bloques de la corona primero pues la fuente de alimentación es muy difícil de substituir

CÓDIGO C1 Si esta máquina le da un código C1 después de que caliente y sale si usted le da vuelta apagado y la deja refrescarse abajo para un rato, intento que substituye el fusible termal. Oí hablar esto de otro tech y lo vi suceder cerca de 2 semanas más adelante.

Dc-111/112/113

EL SESGAR Sesgando cerca de 5m m, compruebe los tornillos llevados a hombros esos las bisagras de la cubierta encendido. Aflojan y caen del hombro. ROTURA ROTA DEL CARRO Rotura rota del carro, placas de embrague magnéticas del explorador del electro limpio.

Dc-111/1205

CALIDAD DE COPIA EL BORDE DE FUGA/POSTERIOR DE LA MIRADA DE LAS COPIAS ELIMINÓ COMO CHARGE/SEP. APUROS. INCLUSO HABÍA SUBSTITUIDO EL RODILLO DE REGISTRO DE ETC. REPLACED DE LAS CORONAS DE LAS UNIDADES DEL ALTO VOLTAJE DE LOS PERNOS DE BISAGRA Y LOS BUJES Y ÉL FIJARON PROBLEMA.

Dc-122

RODILLO DE LA GUÍA Cuando el rodillo de la guía se desintegra (rodillo entre el tambor y el fusor trayectoria), quito el viejo neumático o rueda y la substituyo generalmente por a la arandela de goma negra del grifo del coste de los almacenes del hardware del AS es centavos del 22

Dc-142re

J1/J2 INTERMITENTE J1/J2 intermitentes, estas máquinas son propensos a la flexión si los 4 pies no están en el gabinete. Abra la mirada de la cubierta a lo largo de la parte posteriora de la máquina de la parte posterior del fusor, como se doblan a lo largo de la parte fina en la parte posteriora de la corona de T/S. Curva justa él detrás.

Dc-152z

FUSIÓN DEL FUSOR El fusor puede recalentarse, derretir los dedos del recogedor y combar de vez en cuando rodillo de fusor superior. Esto se puede causar por los alambres de la lámpara del fusor el poner en cortocircuito a la unidad superior del fusor. Si los clips que sostienen los alambres del la lámpara se ha dado vuelta la manera incorrecta que hacía los alambres conseguir atrapados debajo las costillas bajo cubierta anaranjada entonces la lámpara no se apagarán hasta C6 ocurre. SESGAR J1/J2 intermitentes (de papel) Sesgando cerca de 5m m y/o J1/J2 intermitentes, compruebe los pernos que la cubierta abisagre encendido (éstos se presionan en una placa pequeña que pueda ser quitada) mientras que éstas usan. Coloque el perno en un buen vicio y martille las placas alrededor de 180 grados. IMAGEN DOBLE La compensación de imagen doble cerca de 3m m, comprueba el espejo sobre el fusor tiene el lado de plata hacia adentro pues éste es everytime quitado que se limpia la óptica.

Dc-191

CALIDAD DE COPIA Copias ligeras, eliminada densidad. Compruebe el sello de la espuma en el lado del bloque de la óptica de fibra. Esta luz quizá que permite a entrar. Substituya en caso de necesidad.

Dc-213

CÓDIGOS C3/C4 Problema: Los códigos intermitentes C3 y C4, la lámpara de exposición y el interruptor thermo comprueban fuera de multa. El cable eléctrico de la unidad del explorador es culpable. Substituya el montaje del alambre de la lámpara.

Dc-213/313

CÓDIGO C5 Podía ser el relais negro de la energía. Usted puede desmontar el relais y limpiar los contactos.

313

Fueron en viaje a América central considerada muchos techs allá que usaban 2 botellas del revelador DC152. Quién habría calculado, pero trabaja mientras usted utiliza el toner 152.

SERIE Dc-1200/1400

CALIDAD DE COPIA Línea negra pequeña que va de lado a lado 3/4 de la manera abajo de la página. Cerciórese de que los alambres de la corona de S/T no sean flojos.

CALIDAD DE COPIA Copias negras. Lámpara de exposición inoperable. Allí quizá una rotura en uno de los alambres en el cable de cinta que acciona la lámpara. Compruebe la continuidad en cada uno de los alambres en el cable de cinta. Repare si es posible o mejórelo con todo apenas substituya.

FUSOR El engranaje del rodillo de calor se rompe absolutamente a menudo, usted puede desear guardar algunos de éstos en la mano si usted tiene un número de máquinas. También, cuando substituir este engranaje del rodillo de calor, si después de que el reemplazo usted oiga un sonido que golpea pesadamente usted pudo haber instalado el engranaje al revés. Quite, rote y substituya.

Dc-1205

CÓDIGO C3 Usted puede substituir el engranaje 42 A y limpiar los embragues pero en algunas semanas cortas usted será detrás para otro CÓDIGO C-3 si substituya el embrague del explorador y usted no está detrás para ese problema durante mucho tiempo

CÓDIGO C-3 La limpieza apenas del mag, no curará su problema. La limpieza de la pintura negra de cada eje en el embrague reducirá sus códigos c-3. También compruebe el engranaje y eje debajo del pak del embrague, podría estar doblado.

Código C3 Después de substituir el engranaje de 42 dientes, separe ambo el clutchec del mag. Usted encontrará que el perno para el engranaje quebrado está doblado. Substituya por acero (la original es aluminio). Limpie la cara de el embrague del mag pero al volver a montar puesto de las arandelas finas de mylar entre las caras. Esto se cerciora de que el embrague desuna correctamente. La falta del engranaje es debido a ambos embragues que intentan conducir. Han hecho esto a cada problema C3 y nunca han estado de nuevo a cualesquiera de ellos.

RODILLO DEL REEMPLAZO Siga a través del rodillo que está entre el tambor y el fusor es no más largo hecho. El rodillo de goma deteriora en tiempo pero he encontrado que una arandela de goma del almacén del hardware (usado para los grifos) trabajará agradable.

Dc-1205/1255

Código C-3 Antes de que substituya el engranaje quebrado, cubro siempre el exterior del engranaje nuevo con la autógena de J-b. Las garantías agregadas de la ayuda casi usted no estará detrás.

PREVENGA LA QUEMADURA DEL TAMBOR Desconecte los conectadores de la tapa dos en el interruptor con./desc. principal. Esto inhabilita el calentador de la contra-condensacio'n y previene la quemadura del tambor en las máquinas del bajo volumen.

CALIDAD DE COPIA Si su copia tiene una luz, fuera de la venda el cerca de 1/2 del foco avance a poquitos levemente de par en par en el lado trasero, (y usted se han cerciorado de que no es su unidad que se convierte) intentan doblarse hacia arriba en el resorte de ayuda de la corona de T/S en la parte posterior de la máquina. ELÉCTRICO Apagón intermitente. El interruptor principal en esta máquina es propenso a la falta. Substituya como necesario.

Vele 2/3 manera abajo paginan. Podía ser causado fácilmente por el rodillo inútil del registro levemente de la vacilación de la caja. Lubrique el resbalador en sostenedor de la caja.

Luz de las copias en los bordes Se puede causar por el papel el tacto de la pieza del metal de la unidad de la corona de T&S porque el mylar ha usado abajo. Aísle el metal con la cinta eléctrica donde el papel pudo frotarlo. Esto evitará que la carga de la transferencia se escape a la tierra.

1255/1001

C3 SCANNER PROBLEMS Gear 42 broken, take top off machine, take plate off back (3 screws), remove scanner clutch assembly, replace gear, clean electromagnetic clutch plates (otherwise it will just happen again), reassemble.

1256 SMEARED COPIES If you run into smeared copies on the 1256 and the fixing section is theproblem see that the oval white plastic spacers on the ends of the press roller are removed. The manual doesn't mention them at all. The training video says to remove them. I've had them warp and jam into the end of the press roller causing it to drag.

1355

OUT OF TONER CODE If the machine won't add toner, check the toner drive gear, it is to faraway from the toner hopper. It can be adjusted from the optics area. Look by the black box you will see a cut-out and you can access the set screw there.

DC-14XX

Had a 1435 with paper jams every time at the same position. To make it short: the hairs of the registration roller cleaner were so long that the paper sensor got stuck at nearly every pass. If you open the machine the sensor fell back into place of course. Now I gave this bristles a haircut and the machine runs like new :-)

DC-1415

COPY QUALITY Toner spots on copies. You may have a buildup of toner on the shelf between the drum and DV unit. Vacuum this off. The developer may need to be replaced if machine is very overtoned. (As is the case with most copiers.)

1415-1435 Thermal fuses keeps blowing It's because of the double fuses inside the rubber cover, to solve the problem at installation replace thermal fuse with DC-152 or DC-111 thermal fuse and keep it far from heat roller, believe me it works.

Erratic registration First few copies will be OK, then image slowly moves down paper and getsprogressively worse. Check foam pad on registration clutch solenoid. The arm will stick to the pad and paper will keep feeding. Clean off glue and replace pad with packing tape, or something similar.

DC 1435 THERMAL FUSE On virtually every new Mita 1435 the thermal fuse blows between 3K to 6K. Before delivery of any 1435 move the thermal fuse as far away from the heat roller as possible.

DC-1560 Problem: Intermittent C 50 code. Solution: There is a junction box that joins the wires from the transfer/separation and the high-voltage transformer PCB that develops a hair line crack where the separation wires meet. Use a short screw and nut with a lock washer to join the wire ends together. Tape up with electrical tape and put back into junction box. Never have to worry about this arcing again.

NOISE IN DRIVE TRAIN Noise in the drive train is usually caused by the white fuser drive gear. Noise starts between 80 and 100K . Part Number 34920240 Gear 22, Fixing Input.

DC-1605/1656

JAMMING Pre-registration roller jams. Problem maybe caused by improper positioning of the plate just before the registration roller. Try and adjust this plate closer to the roller.

DC 1656

Get rid of Conveyance fan filter, set fan to full speed ALL the time, rewire all coronas with mita gold wire, keep to the recommended PM schedule(30K) absolutely watch out for varience in toner ref on set up and sim 65 (must be the same or very close)

DOCUMENT FEEDERS If you find that a mita 1656 document feeder will feed the paper onto the glass but gets stuck at the white flimsy mylar guide that leads the paper off of the glass. There is a quick, easy, cheap and permanent solution. No, it is not to remove the feeder. Take the black mylar strip that comes with all 20 bin stand-up sorters that attach to the Mita 55 and 56 cpm machines. Replace the white mylar with the black mylar and your non-feeding out problems are solved. The Monroe part number is BH56806330, I assume the mita part number is the same except for the BH.

DC-1685

DARK STREAKS / BACKGROUND Pull the blank lamp assy'. The small lamps fit into a cover which can be carefully removed. Clean the lamps and the inside of the cover. Change developer if problem returns because the machine is dusting toner. Check the seal on the developer unit that it is tight against the drum.

DC-1824, THE ZOOMER, MEGA POSTER MAKER, BRUNING 510

JAMMING Fuser area. This machine uses a Silocone gel in the oil roll in the fuser. This gel is sticky to the touch. This machine uses magnetic sensors. This lubricate will contaminate the actuator on the fuser exit sensor and cause it to stick to the sensor. Symptoms are cardstock will run but paper will jam especially the first few copies ran.

If anyone encounters one of these machines and runs into trouble you can E-mail me at [email protected] I worked on these machines for five years and have the manual for them.There are also many 18x24 copiers and laser printers that wear the Graphic Enterprises badge that I can help you with."Zoomer,Zoomer Q, Zoomer Q-205,Super Zoomer(found at most Kinkos),Zoomer 10+,ReproA2D, Pagescan 3&3+,Pro-Setter,and Neg-Setter.The last three are laser printers and are extremely sensitive and should not be adjusted unless you know what you are doing.

DC 1855/2155

COPY QUALITY These machines sometimes produce wrong blanking lamp patterns as well as poor/light C.Q. Clean the primary and t/s corona reflectors throughly at each and every service call!!!

NOISE Problem: Squeaking noise from center of machine. Probrably registration clutch. Solution: Disassemble, clean old grease and relube with suitable lube. This has happened on virtutally every 1855/2155 that we have sold.

BYPASS JAMS Form plate downwards slightly to add pressure to mylar fingers on plate. The mylar strip will push downwards on paper and feed it into the copier better. Has worked everytime for us when we have customers complaining about bypass jams.

2054 / 2055

COPY QUALITY Poor copy quality shadows and dusting problem, the mag brush moves with age. solution on toner cart. side loosen the set screw on the brass collar and move the nap up about 2mm make test copy repeat if needed this is a trial and error fix

DC-2055 COPY QUALITY Poor fill in solid black areas is often caused by the transfer sep corrona blasting toner. Turn it down just a tad.

2055 CONSTANTLY JAMMING PAPER The Mita copiers are built with magnetic clutches at their paper feed units. These clutches tend to get full of developer, dust particles to reduces their ability to close properly thereby causing constant paper jams. Get a contact cleaner and spray on the clutch until the clutch moves freely, otherwise you will have to take them apart and clean them with a chemical that dissolves grease. I prefer a contact cleaner used on switches for television tuners, the ones that dry off and do not leave residue.

DC-2055/2085/2254/2255

BLANK COPIES Blank copies, check blank lamps, try disconnecting them.

DC-2254

C6,C7 Codes. Check thermal fuse. Replace if necessary.

2285

Erroneous Jams Lower the shift bias 120V

2355

Jamming 1) Jamming problems due to transport fan pulling the paper too hard into the transport section: Double up the transport belts. 2) Scanner hums and selects wrong size of paper: Replace the rear scanner shaft plastic bushing with a brass one and clean the thick grease from rails and use thin silicone oil.

JAMMING AT REG ROLLER If the paper stops at the registration roller and the machine keeps running, and it won't continue, clear or show jam, unplug the sorter and plug it back in. This resets the sorter.

SCANNER PROBLEM If the scanner tries to and doesn't move out of home position when you put paper on the glass, and the machine says check paper size. check the large white drive gear next to the optics motor (behind inner front cover) the set screw is loose. Remove the motor to gain better access to the allen set screw.

LIGHT COPIES This model needs constant transfer corona wire replacement. If copies light, and weak half-tones, replace, don't clean wires (it will last until you get down the street). Not unusual to replace wires and clean shields a couple of times between drum replacements. If drum not making it to normal life, (copies usually get dark), try using electrical tape on very ends of charge corona grid that faces drum. Helps!

2556/3055 When changing developer on these copiers, please make certain that simulation codes 62 is set to 85, 63 is set to 98, and 69 falls below 1.95volt. Any tech will save his company a lot of money with this procedure.

On models with toner problems (units with constant add toner message) make sure that you have the latest toner sensor with red dot. When installing, first push down on the hole in the aluminum plate. This plate tends to warp with use and heat. Push it down to put it back closer to developer flow. UNEVEN COPY DENSITY Check erase lamps as this will cause poor copies and your machine will use more toner.

DOUBLE FEEDING Double feeding from the paper trays usually results in the separation roller getting replaced with little improvement. As these machines age, the paper pick up clutches start to grab too much. Replace the clutch and several paper-feed calls will be prevented.

2556/3055 Double Feeding. Double feeding from the paper trays usually results in the separation roller getting replaced with little improvement. As these machines age, the paper pick up clutches start to grab too much. Replace the clutch and several paper feed calls will be prevented.

DC-3055 WASTE TONER I have used the waste toner in this machine in a pinch with no ill affects so far

TONER YIELD PROBLEM The Mita 3055 is known for haveing Toner Yields of 300-1500 copies. Mita recently confirmed their need to revamp the 3055 toner. Even with their new batch of toner, there has still been yielding prolems. It has been proven that discarding one cap full of Developer increased the Toner Yield to an average of 8500 copies, and eliminated toner dusting in machine without compromising black fill.

FALSE TONER EMPTY Solution: Remove the DV unit. Remove silver toner shield. Be sure that the toner sensor has a red dot (sticker) on it. If it is green you need to order the revision of this sensor. If it has a red dot, replace Developer, Run SIM 60, Check SIM 62 data. (factory set at 83) If the data is not betwen 80 & 90, Remove DV section, Peel back the red sticker and adjust the VR until you get a reading of 80 - 90. This may take a few trys and the VR is VERY sensitive. Run a SIM 60, then check SIM 62 data to be sure it is correct.

3060

IF WHEN TURNING MACHINE ON YOU GET A BRIEF LIGHTING OF THE CONTROL PANEL THEN THE POWER RELAY KICKS OUT, BEFORE SWITCHING THE POWER SUPPLY 3 TIMES...CHECK THE SERVICE LOG TO SEE IF FEED TIRES WERE CHANGED RECENTLY IN THE CASSETTE AREA IF SO CHECK FOR PF CLUTCH WIRES SHORTED TO GROUND..I FOUND THIS AFTER 2 DAYS AND 9 HOURS WHEN UNITS WERE SLID IN THE PF CLUTCH WIRES GOT TORN OUT OF PLACE AND GOT PINCHED

3060/4090

FUSING UPDATE There is now an update for the lower separation pawls in the fixing unit. This is the second update which replaces the thin metal pawls with new separation claws, guide plate and films. The new separation claws are mounted with springs allowing the claw to move away from the press roller during fixing jams, preventing the claw from damaging the press roller. Installing the other two updates and EPROMS has helped to lengthen the days between service calls!

FUSER On the 3060 and 4090 models there have been several changes to the fuser unit. one problem that I have found is that the lower fuser pawls tend to get caught by the pressure roller and bend them down causing deep cuts in the roller. Best method is to remove them. These pawls are not necessary for proper operation.

DUSTING PROBLEMS While nothing ends dusting completely you can reduce it , first vaccum the exess toner in the toner auger tube going from the toner hopper to the developing unit, change the developer run simulation 60 to set the toner reference values, once sim 60 is done, enter sim 62 and change the time setting from 0 to 11 this will reduce the amount of toner normally added with new developer, as this machine will compensate toner regulation over time and other factors, have tried this on many machines and it greatly reduces the dusting problem. DC-3085 On all Mita machine that use these plastic corona pins, I have been putting a drop of grease on the pin before installing them. This makes them easy to remove without breaking off, even when yellowed.

DC-3585/ DC-4585 EXHAUST FAN To get exhaust fan by fuser assembly to run at high speed all the time elinimate the little resistor on back of machine next to main board. Cut wires to resistor join and insulate...

DC-3648

C51 Codes C51 codes are caused by excessive load on transfer or detack. Due to the length of these corona wires the wires tend to loop or swing causing them to arc to the frame causing a C51. Placing a piece of mylar, trimmed into a V at the top, under the middle of the transfer wire. This will help support it and will prevent it from swinging.

40 SERIES

LIGHT COPIES Light CQ on 40 series machines? Although they were the last of their generation of density based sensors, there were some improvements. One was a modification that placed a mylar wiper on the upper auger that would assist DV flow over the sensor. Along with this mod, you needed to clean the sensor surface (take it out, it's only two screws) to remove the solidified toner.

DC 4056 / 4086

LIGHT COPIES This was actually on a Gestetner 2440. From brand new, a copy with good density was only produced after severly overtoning (which of course caused dusting all over). No way to adjust doctor blade & adjusting mag pole position improved density but hopelessly messed up the toner sensor. DV unit was defective right out of the box causing light & uneven toner density. New unit cured problem instantly.

DC4085

BREAKING GEARS If you get the two gears breaking that are commonly know as the "clamshell gears". Your problem is not the gears themselves or the clutches binding up. It took me 3 visits to a machine that broke these 2 gears about every 3 weeks before I finally found what it was. You can find out very easily by removing belt pressure from the gear that drives the transport belt assembly. Try turning this gear by hand, if you find it is tight, there is your problem. Because this machine is known as a "duster", it drops toner everywhere including the transport unit. The toner gets into the white rollers that turn the transport belts. Not the rollers towards the fuser section but the ones closest to the transfer/separation assembly. Those rollers are on a gold shaft that has a cog in it. Just pull the roller assy out through the machine, take off the c-clip and remove the white cogs/rollers clean their insides as well as the gold rod that they ride on. Usually you will find a hard crust of toner built up on them causing drag on the transport drive gear which subsequently causes drag on the clamshell gears causing those gears to break. Clean them approx every 80,000 copies and you won't be replacing any more gears and you WILL get rid of those pesky C2 codes.

NOISE Chatter when using the duplexer.There may also be jamming. The duplex feeder clutches in the rear of the machine, (as well as the other clutches in the machine), wear and need to be replaced. You can try cleaning them first, but I would reccomend just replacing them if you can.

NOISE 4085 noise on duplex? There was a tech bulletin that recommended a shim between the magnet and friction plate, as well as cleaning the clutches. You will find this shim much less expensive and time consuming than replacing the clutches.

COPY QUALITY This machine is very sensitive to minor deviations in the DV Calibration. If you are getting light or grainy copies soon after replacing the developer, try re-calibrating the developer.

COPY QUALITY With a known good developer tank (ie. developer bearings not leaking). First level machine front to rear. Add developer until the toner light flickers at 50% than add 1 mounded CAPFUL of developer only. This is less then the recommended scoupe. Adding more only undertones the system and causes premature breakdown of the carrier coating reducing its ability to hold on to the toner.

COPY QUALITY DO NOT LEVEL THIS MACHINE, if you notice the toner sensor sits towards the front of the dev. unit. You must un-level this machine for proper dev. flow. (about a 1/2 inch higher in the rear) I had 18 MITA DC-4085's in one of my school dist, running 40,000-60,000 copies per month. I had to find the problem real fast. My CBC'S went from 5k to 6k copies to a high of 25,000 copies. This machine must also have all of its updates to run efficiently.

DC 4086

TONER DUSTING To help cut down on Toner Dusting on 4086, Elongate the screw holes on upper cleaning unit cover to allow you to adjust the cover as close to drum as possible, but leave a little room for air circulation around drum.

DC5055

BLANK DISPLAY / MACHINE INOPERATIVE Check the regulator board above the fuser for bad solder joints. The fuser heats up the board and may also blow the 7 volt regulator by overheating it. If this is the case, de-solder this component and replace it with a new one. You can get this at any electronics supply store.

55 SERIES

PRE-TRANSFER LAMP Failing pre-transfer lamps on 55 series? The lamps themselves rarely fail. Cleaning them is a good idea, as well as the driver board on the back of the cleaning section. A toner buildup on the back of the board (remember, toner is conductive) can cause all sorts of trouble. The boards themselves usually fail before the lamp.

DC5585

COPY QUALITY Poor transfer. Check that the pre transfer lamp is clean. It is located under the drum near DV unit.

Duplex Jams/Disappearing Copies Clean the duplex refeed clutch. The refeed clutch in the duplex will get dirty and cause the feed shaft to pull paper behind it, lodging it behind the duplex vertical transport and the LCT.

DC-3585/4585

JAMMING Check ozone filter on rear of copier. This maybe clogged and may prevent the flow of air through the transport belts by the suction fan.

DC-5585/7085 Light copies from premature developer failure The developer tank has two small square slots held on by a small screw, there are sponges in them, if they get clogged the developer unit suffocates and causes the dv unit to buildup moisture thus breaking down the triboelectric charge. This is especially true in high humidity areas, like Florida; home of the gigantic palmetto bugs.

COPY QUALITY Transfer. Maybe caused by inoperative or dirty pretransfer lamp. Lamp is found between the drum and the DV unit, you have to remove the drum to clean it, but if it is dirty and you clean it, it may help it quite a bit. These lamps are also known to go bad and may need to be replaced.

DC-5685/90 AND 7085/90

DASH MARKS ON DRUM When getting dash marks on the drum, check the single pin that the cleaning unit brush connects to on the pcb. They might have broken loose from the board and not making a connect. Another clue is the cleaning brush is packed with toner. Resolder or replace board.

6090

C570: Drum potential sensor is dirty or needs replacing.. Mita will warranty this item, so return it. Make sure all optics are clean. Also, replace the upper developer seal. For a $120.00 it will eliminate alot of headaches. Also, Mita has a tech bulletin on this.

6090/6590 Gray Background Grey background but black fill is normal (not over-toned). A quick check is to unplug the PTC corona and see if background clears. If so, replace PTC blocks and wire. Have seen this in both the 6090 and 6590.

6590/6595/8090/8095 BACKGROUND ON COPIES. CAUSED BY DEVELOPER FAILURE. REPLACEMENT HAS BEEN CHANGED TO 150,OOO FROM 300,000

9285 A PROBLEM OCCURED ON A 92 SERIES . THE SUCTION FAN ON THE DUPLEX WAS TURNING ON AND OFF DURING A COPY. THE FAULT WAS FIRST THOUGHT TO BE THE MOTHER BOARD SENDING THE SIGNAL TO THE MOTOR. A FIXED VOLTAGE WAS ALWAYS PRESENT, RELYING ON THE SIG FROM MPCB TO TURN IT ON. AFTER ESTABLISHING A SIGNAL WAS ALWAYS PRESENT, WE RULED OUT THE MPCB. NOW THE POWER SUPPLY WAS SUSPECT BUT AFTER A TEST, WE REALIZED A VOLTAGE WAS ALWAYS PRESENT WITHOUT DROPPING. THE MAIN POWER RELAY WAS TAKEN OUT AND EXAMINED, FINDING ARCED OUT CONTACTS. AFTER FILING THE CONTACTS THE PROBLEM WAS FIXED

ADF1

DOCUMENT FEED Plan on replacing the feed rollers as well as the feedback rollers at least every 200K. You can only use Fedron for so long.