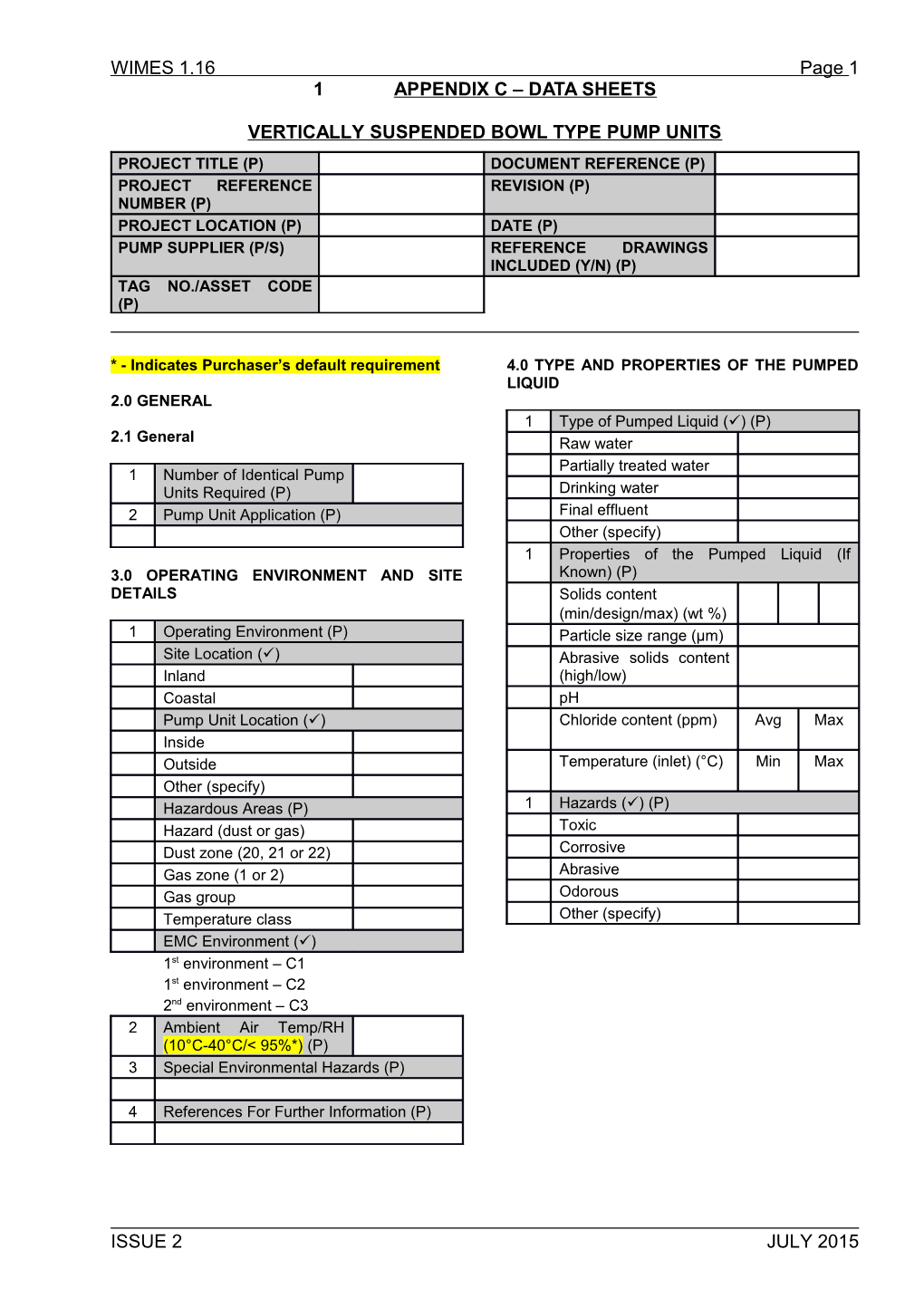

WIMES 1.16 Page 1 1 APPENDIX C – DATA SHEETS

VERTICALLY SUSPENDED BOWL TYPE PUMP UNITS PROJECT TITLE (P) DOCUMENT REFERENCE (P) PROJECT REFERENCE REVISION (P) NUMBER (P) PROJECT LOCATION (P) DATE (P) PUMP SUPPLIER (P/S) REFERENCE DRAWINGS INCLUDED (Y/N) (P) TAG NO./ASSET CODE (P)

* - Indicates Purchaser’s default requirement 4.0 TYPE AND PROPERTIES OF THE PUMPED LIQUID 2.0 GENERAL 1 Type of Pumped Liquid () (P) 2.1 General Raw water Partially treated water 1 Number of Identical Pump Units Required (P) Drinking water 2 Pump Unit Application (P) Final effluent Other (specify) 1 Properties of the Pumped Liquid (If 3.0 OPERATING ENVIRONMENT AND SITE Known) (P) DETAILS Solids content (min/design/max) (wt %) 1 Operating Environment (P) Particle size range (µm) Site Location () Abrasive solids content Inland (high/low) Coastal pH Pump Unit Location () Chloride content (ppm) Avg Max Inside Outside Temperature (inlet) (°C) Min Max Other (specify) Hazardous Areas (P) 1 Hazards () (P) Hazard (dust or gas) Toxic Dust zone (20, 21 or 22) Corrosive Gas zone (1 or 2) Abrasive Gas group Odorous Temperature class Other (specify) EMC Environment () 1st environment – C1 1st environment – C2 2nd environment – C3 2 Ambient Air Temp/RH (10°C-40°C/< 95%*) (P) 3 Special Environmental Hazards (P)

4 References For Further Information (P)

ISSUE 2 JULY 2015 WIMES 1.16 Page 2 5.0 PERFORMANCE SPECIFICATION 9 Minimum Flow Rate at N2 (l/s) (S) 5.1 General 10 Pump Unit to be Capable of Discharging 1 Mode of Operation () (P) into an Empty Main Solo (Y/N) (P) Parallel 11 Performance at Closed Valve at N2 (S) Series Head (m) 1 Type of Drive () (P) Max. operating time (s) Fixed 12 NPSHA at N2 (m) (P) Variable At the GP 2 Service Life (yrs) (P) At the maximum flow 3 Utilisation (%) (P) 12 NPSH3 at N2 (m) (S) 4 Anti-Reverse Rotation At the GP Device Required (Y/N) At the maximum flow (P) 12 NPSHA Safety Margin (1.3 x NPSH3 or 2 m*) 5.2 Operating Speed(s), Hydraulic Performance, (P) Efficiency and Power Input (All Heads are Relative to the Pump Inlet) 12 NPSH safety margin at the maximum flow (S) 1 Operating Speed (rpm) (P/S) 13 Minimum Submergence Depth at N2 (m) (P) Max. (1500*) (P) At the GP Actual (S) N1 N2 At the maximum flow

2 Hydraulic Performance at the Guarantee 5.3 Noise and Vibration Point (GP) at N2 (P) Flow rate (l/s) 5.3.1 Noise Static head (m) Dynamic head (station) 1 Noise Levels at the GP (dB (A) at 1 m) (S) (m) Expected (S) Dynamic head (main) 2 Source of Data (S) (m) 2 Variable Speed Pumping Duties (P) Minimum flow rate (l/s) 5.4 Life Cycle Costs (LCC) Maximum flow rate (l/s) 5.4.1 General 3 System Data (P) Reference for data/curve 1 LCC Assessment Min/max static head (m) Required (Y/N) (P) 4 Pump Curve No. (S) 6 Q (GP)/Q (BEP) at N2 – Upper and Lower 5.4.2 Motor Power Input Limits (%) (P) Limits (80 and 105*) 1 Motor Power Input at the GP (kW) (S) 7 Pump Efficiency at N2 (Uncoated/Coated) (%) (S) At the GP At the maximum flow 7 Pump Power Input at N2 (Uncoated/Coated) (kW) (S) At the GP At the maximum flow Maximum 8 Maximum Flow Rate at N2 (l/s) (S)

ISSUE 2 JULY 2015 WIMES 1.16 Page 3 5.4.3 Service Lives and Costs of Components 6.1.4 External Corrosion Protection

1 Expected Service Lives of Components 1 Coating Requirements (P) (P/S) a Pump (Suppliers Component (Specify) Life (x103 hrs) (S) standard paint finish*) b Support structure (WIMES 4.01*)

6.1.8 O & M Manuals

1 Type Required () (P/S) Supplier’s standard Purchaser’s standard (specify reference) 3 Costs of Components (£)/Time Required to Replace Components (hrs) (S) 6.2 Soleplate Component £ Hrs 2 Material (S)

6.3 Bellmouth, Pump Casing(s), Column Pipe(s) and Outlet Bend

6.3.1 General

2 Efficiency Enhancing/Sustaining Coating Details (P/S) 6.0 DESIGN SPECIFICATION Composition Thickness (µm) 6.1 General Expected efficiency increase (%) 6.1.1 General Expected service life (yrs) 1 Pump Unit Designation/Model No. (S) 3 Boss Thread Types/Sizes (P/S)

2 Number of Stages (P/S) 3 Outlet Bend to Discharge () (P/S): 6.3.2 Bellmouth Above ground level Below ground level 1 Material (P/S)

6.1.2 Weights and Lifting Arrangements 6.3.3 Pump Casing(s)/Bowl(s) 1 Weights (S) Component (specify) Weight (kg) 1 Material (P/S)

4 Renewable Wear Parts (P/S) Required/provided (Y/N) Fixing Method 1 Heaviest Maintenance Material(s) Lift (S) 1 Heaviest Erection Lift 6.3.4 Column Pipe(s) (S) 1 Material (P/S)

ISSUE 2 JULY 2015 WIMES 1.16 Page 4 6.3.5 Outlet Bend Pin Shrink fit 1 Material (P/S) Other (specify)

2 Outlet Bend Connection (P/S) 6.6 Pump Top Shaft Seal Nominal bore (mm) Flange type (PN16*) 6.6.1 General 3 Boss Thread Types/Sizes (P/S) 1 Seal Type () (P/S) Mechanical* 6.4 Impeller(s) Packed gland 2 Seal Details (P/S) 1 Impeller Type () (P/S) Manufacturer Closed Designation Semi-open 3 Seal Flushing/Cooling Open Required (Y/N) (S) Other (specify) 3 Method of flushing/cooling (S) 2 Material (P/S) 3 Flushing/Cooling Liquid Requirements (S) 3 Direction of Rotation of Impeller(s) Type (viewed from the non-drive end) (S) Supply Pressure (bar) Flow rate (l/s) 4 Impeller Dimensions (mm) (P/S) 6.6.2 Mechanical Seal (Preferred Option) (Where Actual diameter fitted Required) Maximum diameter 5 Method of Securing Impeller(s) to Pump 2 Type (Cartridge*) (P) Shaft () (P/S) 3 Radially Split Seal Key Required (Y/N) (P) Bolt 5 Seal Component Materials (P/S) Conical taper Seal cover plate Shrink fit Throttle bush Other (specify) Rotating ring 8 Wear Rings (P/S) Stationary ring Required/provided (Y/N) Secondary seals Fixing Method Spring Material(s) Other (specify) 9 Machining Allowance Required (Y/N) (P/S) 6.6.3 Packed Gland Seal (Non-Preferred Option) (Where Required) 6.5 Pump Shaft System 1 Seal Component Materials (P/S) 6.5.1 Pump Shaft System Gland follower Packing 2 Material (P/S) Lantern ring

6.5.2 Shaft Sleeve(s) (Where Fitted)

1 Material (P/S)

2 Method of Securing Sleeves to Pump Shaft () (P/S) Key

ISSUE 2 JULY 2015 WIMES 1.16 Page 5 6.7 Bearings and Bearing Lubrication 6.8 Couplings

6.7.1 Thrust and Radial Bearing(s) 6.8.2 Pump Top Shaft Coupling

6.7.1.1 Bearings and Bearing Lubrication 1 Coupling Details (S) Type 2 Minimum L Life at the 10h Manufacturer GP (50,000 hrs*) (P) 1 Spacer Coupling 2 Actual L Life (S) 10h Required (Y/N) (P) 3 Bearing Details (P/S) 2 Component Materials (S) Manufacturer Hub Designation Spacer 3 Lubrication Method () (S) Flexible component Sealed for life Guard Re-greasing facilities required 6.10 Information Plate 3 Bearing Lubricant (P/S) Type (oil/grease) 1 Additional Information Required (P) Grade 5 Type of Grease Lubrication System () 2 Duplicate Information (P/S) Plate Required (Y/N) (P) Automatic* Manual 6.11 Condition Monitoring & Protection Sensors 5 Grease Dispenser Type () (P/S) Replaceable 1 Condition Monitoring & Protection Rechargeable Sensors Required () (P) Bearing temperature 6.7.2 Intermediate Shaft Bearing(s) Bearing vibration 6.7.2.1 Bearings and Bearing Lubrication Bearing acoustic emission 2 Minimum Bearing Life at Other (specify) the GP (P/S) 2 Sensor Fixing Arrangements (P) 3 Bearing Details (P/S) Manufacturer Material 6.12 Auxiliary Pipework and Equipment 4 Lubrication Method () (P/S) 6.12.2 Outlet Bend Venting Pipework Pumped liquid lubricated (open non-pressurised) 1 Venting Location (P) Pumped liquid lubricated (enclosed pressurised) 4 Type and Size of Air Valve Potable water lubricated Required/Provided (P/S) (enclosed pressurised) Grease/oil lubricated (enclosed pressurised) 6.12.3 Mechanical Seal Venting Pipework 4 Bearing Lubricant (P/S) Type (oil/grease) 1 Venting Location (P) Grade

ISSUE 2 JULY 2015 7.0 TESTS

7.1 Test Regime (Clause 1)

Acceptance Test Location Witnessing Test Standard Levels & (P) Requirements (P) (P/S) Type of Test (P) Tolerances (P) Works Site (Y/N) Notice (Days) Hydrostatic 1.5 x Pmax1 Acceptance BS EN ISO 9906 (Q, H, Power, Effy) (specify grade) BS EN ISO 9906 NPSH (specify grade) String test (variable BS EN 12483 speed pumps only) Noise Vibration BS ISO 10816-7 4.2 or 5.2 mm/s2 Thermodynamic Other (specify)

Notes:

1 - P max is the sum of the closed valve and maximum suction heads. 2 – Depending on pump unit rating. NOTES: WIMES 1.16 Page 8 2 APPENDIX D – SUPPLIER’S SUPPLEMENTARY DATA SHEET INFORMATION

Clause Supplementary Information

ISSUE 2 JULY 2015