UN/SCETDG/

COMMITTEE OF EXPERTS ON THE TRANSPORT OF DANGEROUS GOODS AND ON THE GLOBALLY HARMONIZED SYSTEM OF CLASSIFICATION AND LABELLING OF CHEMICALS

Working Group on the Transport of Lithium Batteries

4th Session 18-20 May 2010 Washington, DC

Internal Short Circuit Ad Hoc Group Update

Submitted by: The Internal Short Circuit Ad Hoc Team

Introduction

Discussion at the third informal working group session in Kyoto, Japan in November, 2009 resulted in the formation of an ad hoc group to address development of a true internal short circuit test for the UN model regulations. The ad hoc groups has met via conference call several times and proposed several options for an internal short circuit test. These options include:

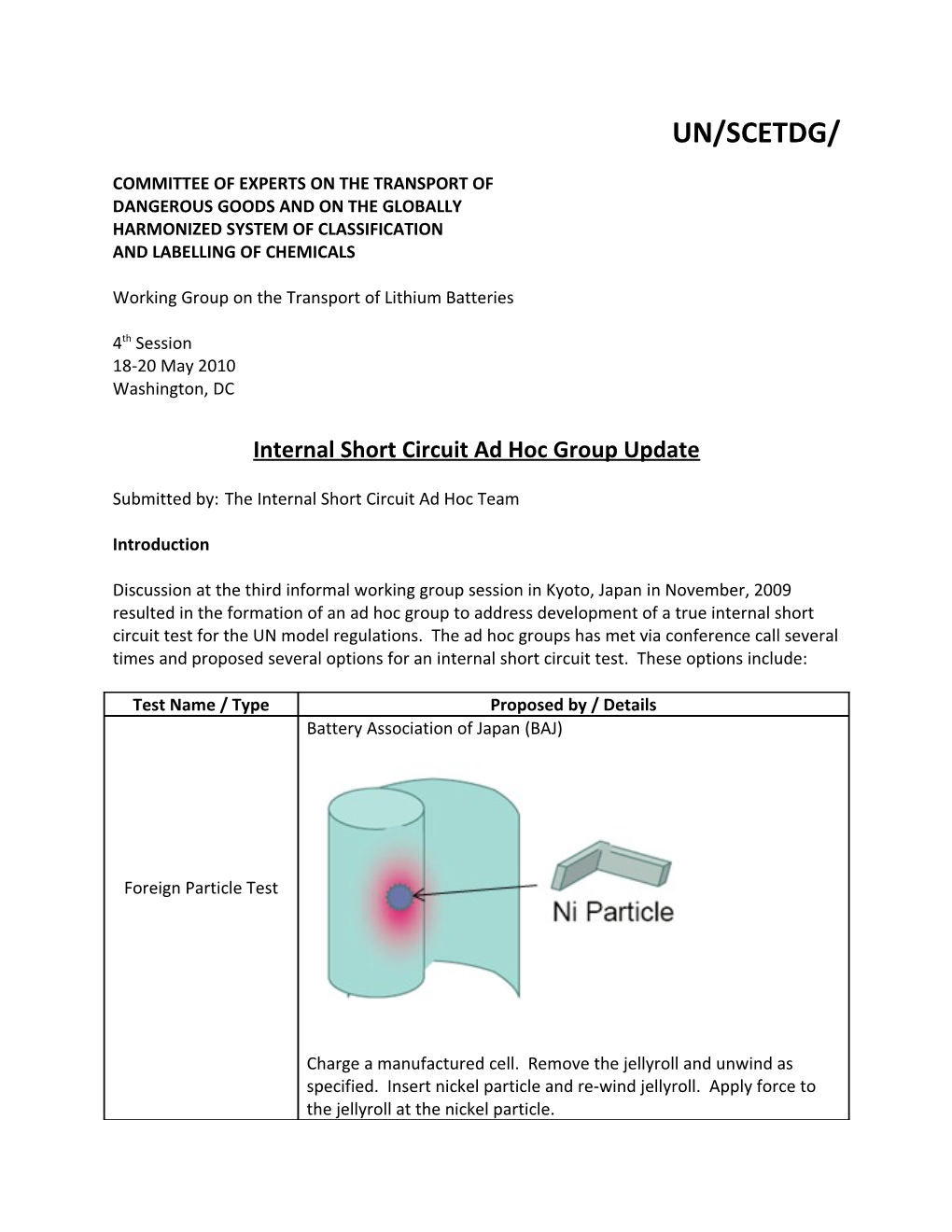

Test Name / Type Proposed by / Details Battery Association of Japan (BAJ)

Foreign Particle Test

Charge a manufactured cell. Remove the jellyroll and unwind as specified. Insert nickel particle and re-wind jellyroll. Apply force to the jellyroll at the nickel particle. Underwriters Laboratories

Blunt Nail

Use a rounded nail to dent, but not penetrate the cell until the point of short circuit.

Energizer

Blunted Crush

Crush a cell at 90° or 45° to the longitudinal axis until one of the following occurs. Voltage drops by at least 100 mV, or The cell is deformed by 50% of its original thickness.

Discussion

Foreign particle test There are reservations this test does not represent field conditions or an assembled battery. There are also safety concerns about running this test, especially on primary batteries, and some test labs and battery manufacturers expressed they could not run such a test due to internal safety procedures.

Blunt nail test While this test can generate an internal short circuit, concerns were expressed about the nail often penetrating the battery can and biasing the test. In tests run by a particular manufacturer, the battery can was pierced in 9 of 10 samples, although admittedly, the downward speed of the nail was nearly manual and greater than the proposed 0.1 mm/sec.

Ad hoc team members were asked to generate data with varying speeds and nail diameters. Some additional options may include:

The test fixture on the far left with the small diameter nails shows the nails from the initial test procedure.

Blunt crush test Initial blunt crush testing has shown an ability to short circuit the cell internally when the crush depth is near 50% of the thickness. Some concerns have been expressed about the amount of damage done to the cell during this test as the goal of a true internal short circuit test is to minimize external damage to the cell in generating the short circuit.

Joint IEC TC35 (primary batteries) and SC21A (rechargeable batteries) discussion The two portable battery committees as Joint Maintenance Team 18 (JMT18) met during the last week of April, 2010 and discussed options for an internal short circuit test. While no decisions were made, JMT18 did agree to continue this work.

Proposals

1. As the May, 2010 Informal Working Group meetings are the last scheduled meetings, move development of an internal short circuit test into IEC TC35 / JMT18. JMT18 is scheduled to meet later this year and will likely meet every 6-8 months afterward.

2. Encourage competent authority and interested party participation in IEC TC35/JMT18 either directly or through their respective nationals committees.