Case Studies

One of the most important tasks to be undertaken when beginning a new design is the investigation of current case studies. Case studies which have been constructed can be used as real life prototypes. This allows some of the advantages and problems that have been discovered to be identified and this allows the design proposals to be designed in the most effective way possible. As the project is based on a low carbon housing scheme, several case studies which have been constructed and rated in line with this new legislation have been identified and can be seen below. Information displayed below has been taken from two approved low carbon sources: PassivHaus UK and The Zero Carbon Hub.

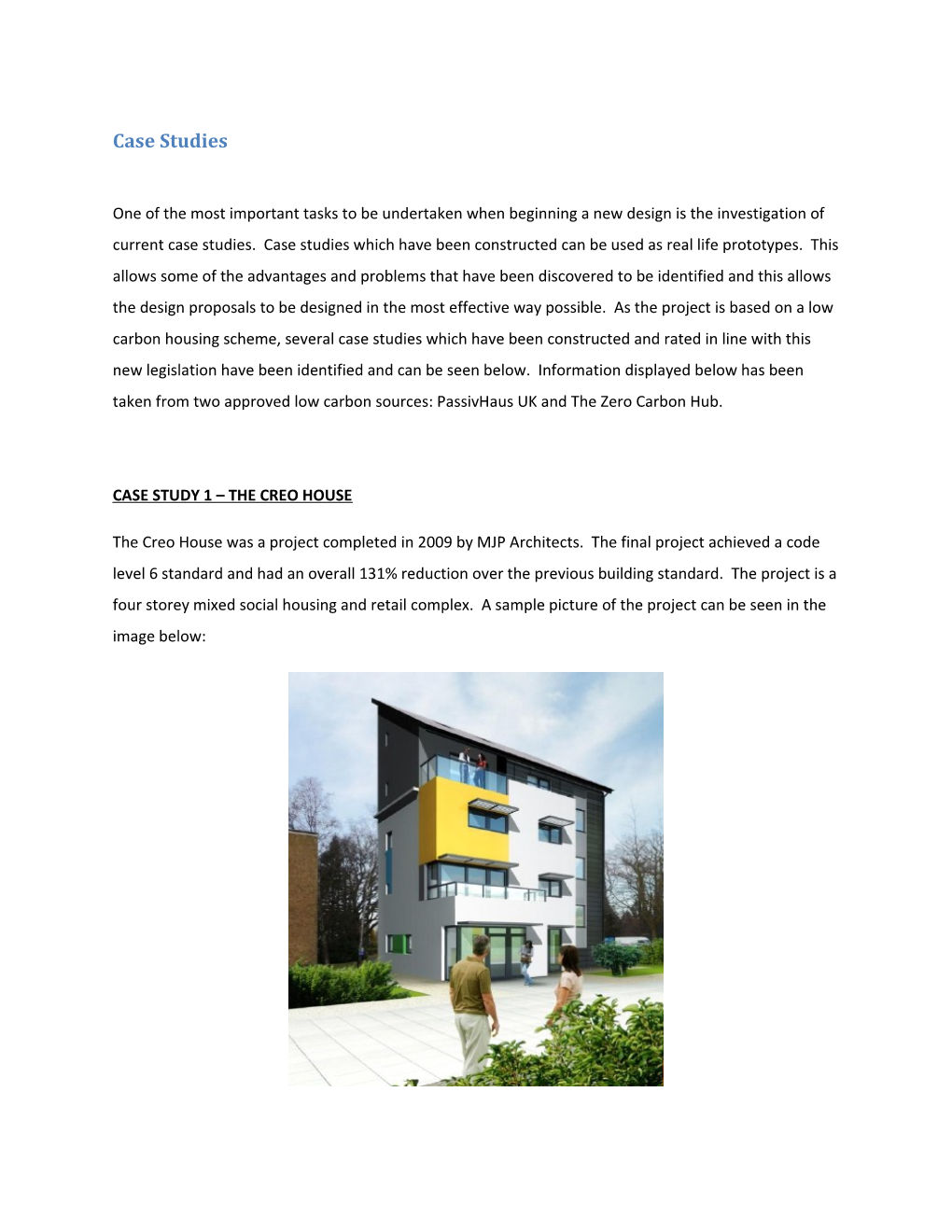

CASE STUDY 1 – THE CREO HOUSE

The Creo House was a project completed in 2009 by MJP Architects. The final project achieved a code level 6 standard and had an overall 131% reduction over the previous building standard. The project is a four storey mixed social housing and retail complex. A sample picture of the project can be seen in the image below: Summary of design:

Insulated concrete formwork (ICF) walls with 150mm Walls U = 0.15 W/m2K concrete core and grey expanded polystyrene blocks with a 150mm outer and 50mm internal wall

Roof U = 0.15 W/m2K 150mm grey expanded polystyrene interlocking blocks

Triple Glazed, Low E glass, krypton gas filled, warm edge Windows U = 1.16 W/m2K spacer, five chamber uPVC frame ICF walls used provide good airtight barrier and minimum Airtightness 2.5 m3/m2/hr at 50 Pa openings provide low leakage

Foundation - Driven Steel Screw Piles

Lightweight steel framework carrying EPS insulation Ground Floor - boards and in-situ concrete A Daikin high temperature ASHP is used to provide mechanical ventilation, underfloor heating and hot water. ASHP, MVHR - An electrical immersion heater in the hot water tank provides addition hot water if required Panels on the south facing mono-pitched roof provide PV Panels - electricity to the building

CASE STUDY 2 – BRAMALL’S WINDMILL VIEW HOUSE

This study was part of a social housing development in West Yorkshire completed in 2008. The building achieved a level 4 code for sustainable homes. The buildings have been constructed at low cost due to local demand needs and coupled with reduced running costs attained with the level 4 design, they have become a very good financial investment. A sample house can be seen in the image below followed by a summary of the projects construction and attained insulation values. 300mm cavity fully filled with water repellent glass wool Walls U = 0.12 W/m2K slab insulation 450mm glass wool roll insulation consisting of three Roof U = 0.10 W/m2K 150mm thick layers placed at alternating 90 degree angles as to cover all roof area. Double Glazed, Low E glass, krypton gas filled, warm edge Windows U = 1.2 W/m2K spacer, uPVC frame First floor plasterboard ceiling fixed prior to wall studding Airtightness 5.0 m3/m2/hr at 50 Pa to reduce the number of joists and reduce loss

Foundation - Concrete strip

Ground Floor - Insulated pre-cast concrete beam and block system

A NIBE ‘Fighter 360P’ system provides mechanical ASHP, MVHR - ventilation and space and water heating. Rooms heated using low heat radiators. Panels used are of black design providing pleasing PV Panels, - aesthetic views while providing electricity and hot water Solar Thermal for the dwelling

CASE STUDY 3 – MILLER ZERO HOUSING PROJECT

Case study three outlines the design of a level 6 code building as part of a renewable housing development in Hampshire. The dwelling is two storeys and has a total of four bedrooms. The development attained a 148% reduction in carbon emissions. Walls U = 0.09 W/m2K EWIS wall using 200mm of rigid phenolic insulation Mono pitched roof using 190mm polyurethane insulation Roof U = 0.12 W/m2K between the rafters underclad with thermalboard Triple Glazed, Low E glass, krypton gas filled, insulated Windows U = 0.68 W/m2K edge technology, uPVC frame Internal wall plaster and large aircrete concrete Airtightness 1.5 m3/m2/hr at 50 Pa planks/thin-joint mortar minimise air-leaks

Foundation - Concrete strip

Ground Floor - Pre-cast reinforced aircrete planks

Biomass A Baxi Multi-Heat wood pellet biomass boiler (located in 15 kW an exterior boiler house) provides underfloor space Boiler heating and hot water for two homes A Vent Axia MVHR system allows the supply of fresh air PV Panels, - while recovering the heat from the outgoing air and PV MVHR panels allow the generation of electricity on south face

CASE STUDY 4 – TARMAC HOMES PROJECT

This project was a design for the University of Nottingham and was completed in 2009. The home was constructed as part of the Universities built environment department as a showcase house of the future. The project aimed to provide the lowest cost solution possible while remaining to attain a level 6 standard.

215mm solid wall aircrete blocks with external expanded Walls U = 0.15 W/m2K polystyrene (EPS) insulation provides continuous layer of thermal insulation with minimal thermal bridging Timber trussed with an asymmetric pitch south facing at a Roof U = 0.10 W/m2K 22 degree angle to the horizon to maximise micro generation of electricity Windows U = 1.5 W/m2K Double glazed with argos gas fill Achieved by finishing the internal walls with a Airtightness 2.0 m3/m2/hr at 50 Pa traditional lightweight plaster

Foundation - Concrete strip

Ground Floor - Pre-cast concrete beams infilled with EPS panels Biomass Wood pellet boiler which provides space heating for two 10 - 15 kW Boiler homes Panels used are of black design providing pleasing PV Panels, - aesthetic views while providing electricity and hot water Solar Thermal for the dwelling

CASE STUDY 5 – SOUTHDALE HOMES HILL TOP POINT This case study is based on a development of several new homes which were built to attain a code for stainable homes level of 3. The development took place in Worsley in Manchester. Construction was completed in 2008 by architect Nicol Thomas.

Factory-fitted insulation between studs of timber closed panel Walls U = 0.20 W/m2K (150mm thick) 400mm of layered glass quilt insulation in the roof in layers, with Roof U = 0.10 W/m2K the first layer between the joists, the second at 90 degrees to the first, and the third layer at 90 degrees to the second Double Glazed, Low E glass, 20mm air gap, uPVC Windows U = 1.60 W/m2K Framework Airtightness 6.6 m3/m2/hr at 50 Pa -

Foundation - Strip footings with mass fill concrete

Ground Floor - Pre-cast beam and block system

Solar Thermal 4 m2 Flat plate Viridian system incorporating a condensing Array boiler in the kitchen and a cylinder in the roof space

CASE STUDY 6 – THE WOODMANS COTTAGE

Case study 6 is based on a project covered on the hit TV show Grand Designs. The cottage was a project undertaken by a woodsman named Ben Law. The project was to be undertaken using all renewable sources and in harmony with the surrounding forest. The design was undertaken using primarily wood with straw bale insulation for the walls. The project was completed using a budget of only £25,000 and included the installation of solar and wind electricity. An image of the completed project can be seen below.

The fundamental aim of the building was similar to the aim of the given brief. The project set out to use materials which were available locally in order to attain a building which was as environmentally friendly as possible. Ben Law has achieved this goal by using the wood and materials available from local sources. The main body of the building has been constructed with timber from the forest in which it is situated. The walls have been given depth using straw bales from a local farm and the windows have been sourced locally also. In undertaking this venture with the clear sustainability goal, Ben Law has produced a building through which many designers aiming to achieve an environmentally friendly build can learn from. Ben has showed how using the local, low carbon materials can produce a comfortable and structurally sound dwelling.

When designing the buildings which are going to be used for the local community outlined in the brief, the ideas displayed by Ben have been taken and implemented to provide a low carbon solution. The use of locally sourced material has been used for all elements of the design and the group is also using locally sourced timber and straw bales for the body of the building. The buildings shall then be finished using a smooth lime plaster in order to produce a clean, modern looking building whilst allowing the straw to breathe and significantly reducing the carbon content compared with conventional build materials and methods.

References:

BRE – PassivHaus UK, www.passivhaus.org.uk www.zerocarbonhub.org

Grand Designs Webpage, www.channel4.com/4homes