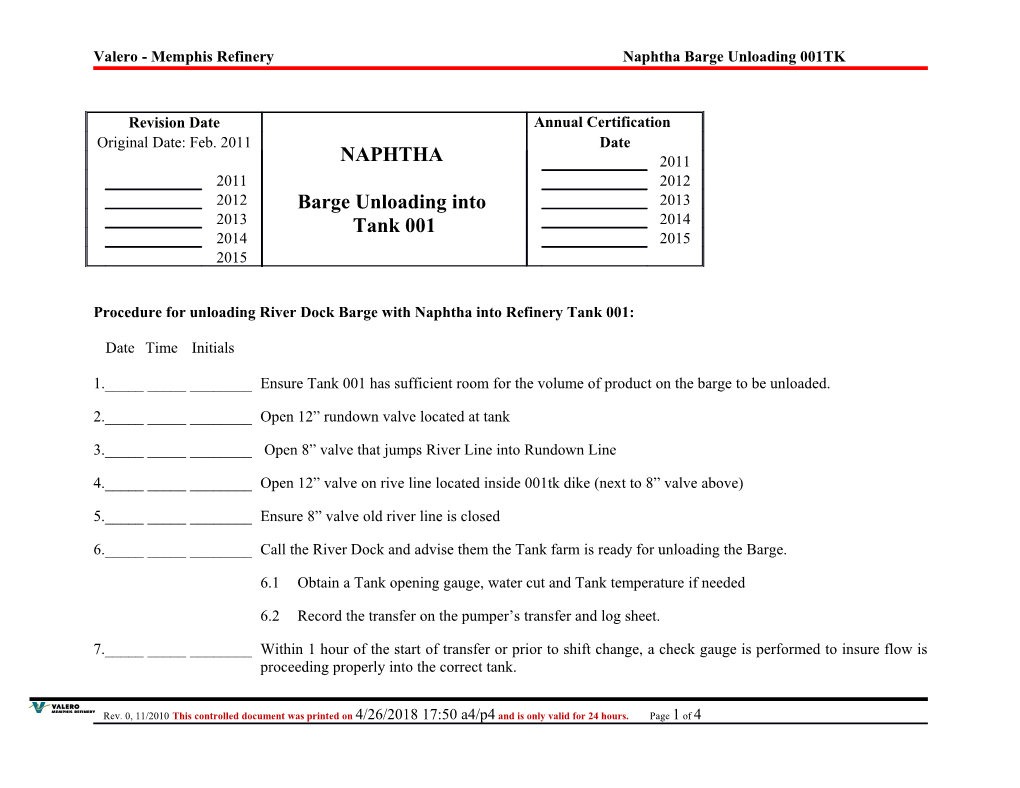

Valero - Memphis Refinery Naphtha Barge Unloading 001TK

Revision Date Annual Certification Original Date: Feb. 2011 Date NAPHTHA 2011 2011 2012 2012 Barge Unloading into 2013 2013 Tank 001 2014 2014 2015 2015

Procedure for unloading River Dock Barge with Naphtha into Refinery Tank 001:

Date Time Initials

1.______Ensure Tank 001 has sufficient room for the volume of product on the barge to be unloaded.

2.______Open 12” rundown valve located at tank

3.______Open 8” valve that jumps River Line into Rundown Line

4.______Open 12” valve on rive line located inside 001tk dike (next to 8” valve above)

5.______Ensure 8” valve old river line is closed

6.______Call the River Dock and advise them the Tank farm is ready for unloading the Barge.

6.1 Obtain a Tank opening gauge, water cut and Tank temperature if needed

6.2 Record the transfer on the pumper’s transfer and log sheet.

7.______Within 1 hour of the start of transfer or prior to shift change, a check gauge is performed to insure flow is proceeding properly into the correct tank.

Rev. 0, 11/2010 This controlled document was printed on 4/26/2018 17:50 a4/p4 and is only valid for 24 hours. Page 1 of 4 Valero - Memphis Refinery Naphtha Barge Unloading 001TK

Note: When any tank is receiving or transferring product beyond a shift change – a check gauge must be performed within 1 hour of the shift-change by the off-going Pumper and communicated to on-coming Pumper to alert the next shift of active tanks. The On- Coming Pumper must verify all active tanks, line ups and transfers. Active tanks must be walked out to verify line ups and varec check gauges.

Note: The Pumpers will also monitor the gauges on all associated product tanks for line ups, product transfers, product rundowns, barges, pipeline, and truck loading, utilizing PI or DCS technology to ensure proper line-up.

Tank Farm Actions after Transfer is Complete:

Date Time Initials

1.______Close out the transfer after the Barge unloading is complete

a. Obtain a Tank closing gauge, water cut and Tank temperature if needed.

b. Record the transfer on the pumper’s transfer log sheet. Include gauges, temperatures, water cuts and times.

12” tank 8” Jump over 12” River 8” Old River

PROCEDURE INFORMATION

PURPOSE

2 Valero - Memphis Refinery Naphtha Barge Unloading 001TK

This procedure provides Steps to follow to safely and efficiently unload a River Dock Barge with Naphtha into Refinery Tank 001.

PREREQUISITES The information on the shipment must have been communicated to the Refinery Tank Farm and Refinery River Dock. The appropriate orders must have been written in the Refinery Tank Farm Log concerning the shipment.

RESPONSIBILITY It is the responsibility of the Pumper Number 1 and the River Dock personnel to carry out this procedure in a safe and timely manner.

MATERIALS AND EQUIPMENT No special materials and / or equipment are required to carry out this procedure.

SAFETY Special or Unique Hazards:

Engineering Controls: N / A

Administrative Controls: This procedure is a control to ensure that the Barge is unloaded safely and efficiently.

Personal Protective Equipment (PPE): Normal Tank Farm personal protective equipment must be worn at all times. This includes hard hats, steel-toed safety footwear fire retardant clothing and safety glasses. Additional protective equipment may be required per permit requirements.

SAFETY SYSTEMS Shutdowns:

Other Safety:

QUALITY AND INVENTORY Inventory: Tank 001 should have sufficient level in the Tank to unload the Barge without over filling the tank. If there is not sufficient level in the Tank to accomplish this, other arrangements should be made.

Quality: Product being unloaded should meet the quality specifications of the product requested.

Rev. 0, 11/2010 This controlled document was printed on 4/26/2018 17:50 a4/p4 and is only valid for 24 hours. Page 3 of 4 Valero - Memphis Refinery Naphtha Barge Unloading 001TK

4