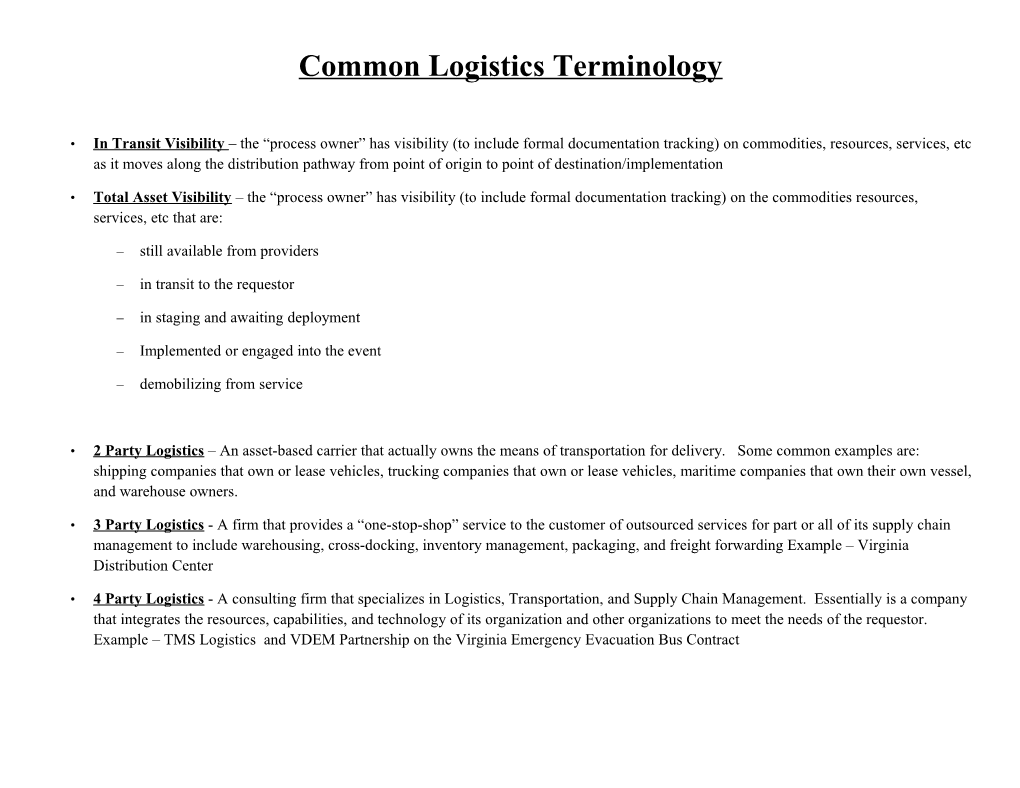

Common Logistics Terminology

• In Transit Visibility – the “process owner” has visibility (to include formal documentation tracking) on commodities, resources, services, etc as it moves along the distribution pathway from point of origin to point of destination/implementation

• Total Asset Visibility – the “process owner” has visibility (to include formal documentation tracking) on the commodities resources, services, etc that are:

– still available from providers

– in transit to the requestor

– in staging and awaiting deployment

– Implemented or engaged into the event

– demobilizing from service

• 2 Party Logistics – An asset-based carrier that actually owns the means of transportation for delivery. Some common examples are: shipping companies that own or lease vehicles, trucking companies that own or lease vehicles, maritime companies that own their own vessel, and warehouse owners.

• 3 Party Logistics - A firm that provides a “one-stop-shop” service to the customer of outsourced services for part or all of its supply chain management to include warehousing, cross-docking, inventory management, packaging, and freight forwarding Example – Virginia Distribution Center

• 4 Party Logistics - A consulting firm that specializes in Logistics, Transportation, and Supply Chain Management. Essentially is a company that integrates the resources, capabilities, and technology of its organization and other organizations to meet the needs of the requestor. Example – TMS Logistics and VDEM Partnership on the Virginia Emergency Evacuation Bus Contract • “ e – Logistics” - The use of a “web-based” comprehensive supply chain management system(s) to provide services such as logistical planning, ordering, dispatching, GPS –enabled routing, and electronic database inventory. High level of cost but high level of efficiency due to technology. Examples are Virginia’s eVA Procurement System, Private Sector Businesses with Online Services (Amazon, UPS, United Airlines, WalMart, Pizza Hut, etc)

• “ Just in Time Logistics” - An inventory strategy that incorporates the reduction of “on-site” warehousing of supplies and utilizes an extensive delivery system based on the resources being provided as close to the “time of need” as possible. It is having the right supplies at the right time at the right place in the exact amount needed. Higher risk to the company as it depends on “open delivery” routes being readily accessible. More of a “pull logistics” concept Examples – Automotive Production Companies and their Partner Companies.

• Vendor Managed Inventory - Where the buyer of a product gives consumption information to the supplier of that product for a given facility and puts the responsibility for maintaining a “suitable inventory” of the product on the provider. Used heavily by “Big Box Stores.” This concept is a “shared risk” agreement which means that both parties have cost incurred risks associated to the product. Examples – ABC of Virginia, Hallmark/WalMart Agreement, Coca Cola, Pepsi, etc

• Full / Total Requested Shipment – the full/total requested resource amount is delivered at 1 time

• Phased Shipment – the full/total requested resource amount is delivered over an “agreed upon” schedule – must be noted at time of purchase

• Cross-docked Shipment – the full/total requested resource amount is delivered to a staging area in “whole” and then is broken into “pre- determined packages or bundles”

• Direct Delivery – the resource requested is taken from the point of origin (source) to the exact distribution destination

• Indirect Delivery – the resource requested is taken from the point of origin (source) and then to a form of a staging area then on to the exact distribution destination.