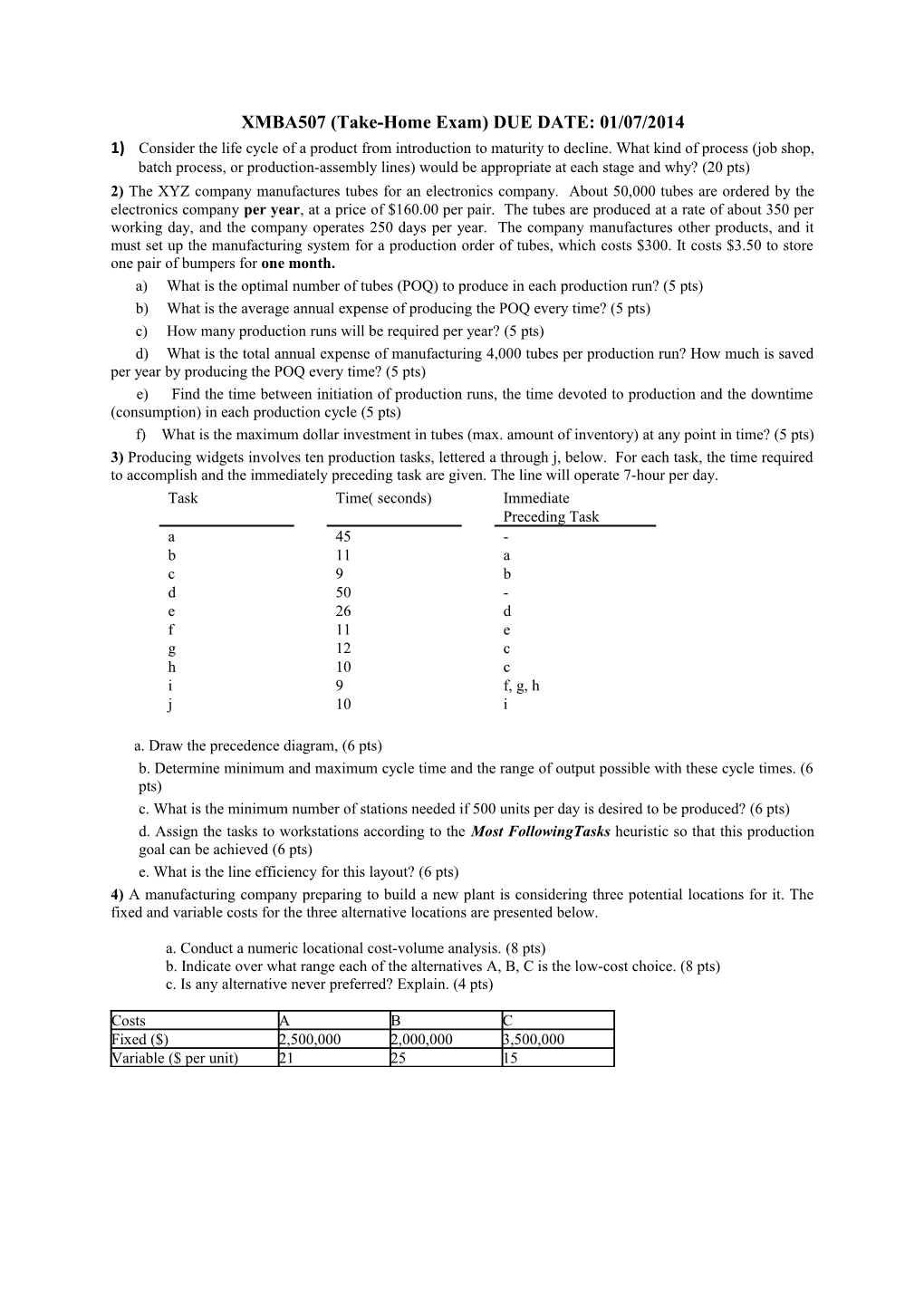

XMBA507 (Take-Home Exam) DUE DATE: 01/07/2014 1) Consider the life cycle of a product from introduction to maturity to decline. What kind of process (job shop, batch process, or production-assembly lines) would be appropriate at each stage and why? (20 pts) 2) The XYZ company manufactures tubes for an electronics company. About 50,000 tubes are ordered by the electronics company per year, at a price of $160.00 per pair. The tubes are produced at a rate of about 350 per working day, and the company operates 250 days per year. The company manufactures other products, and it must set up the manufacturing system for a production order of tubes, which costs $300. It costs $3.50 to store one pair of bumpers for one month. a) What is the optimal number of tubes (POQ) to produce in each production run? (5 pts) b) What is the average annual expense of producing the POQ every time? (5 pts) c) How many production runs will be required per year? (5 pts) d) What is the total annual expense of manufacturing 4,000 tubes per production run? How much is saved per year by producing the POQ every time? (5 pts) e) Find the time between initiation of production runs, the time devoted to production and the downtime (consumption) in each production cycle (5 pts) f) What is the maximum dollar investment in tubes (max. amount of inventory) at any point in time? (5 pts) 3) Producing widgets involves ten production tasks, lettered a through j, below. For each task, the time required to accomplish and the immediately preceding task are given. The line will operate 7-hour per day. Task Time( seconds) Immediate Preceding Task a 45 - b 11 a c 9 b d 50 - e 26 d f 11 e g 12 c h 10 c i 9 f, g, h j 10 i

a. Draw the precedence diagram, (6 pts) b. Determine minimum and maximum cycle time and the range of output possible with these cycle times. (6 pts) c. What is the minimum number of stations needed if 500 units per day is desired to be produced? (6 pts) d. Assign the tasks to workstations according to the Most FollowingTasks heuristic so that this production goal can be achieved (6 pts) e. What is the line efficiency for this layout? (6 pts) 4) A manufacturing company preparing to build a new plant is considering three potential locations for it. The fixed and variable costs for the three alternative locations are presented below.

a. Conduct a numeric locational cost-volume analysis. (8 pts) b. Indicate over what range each of the alternatives A, B, C is the low-cost choice. (8 pts) c. Is any alternative never preferred? Explain. (4 pts)

Costs A B C Fixed ($) 2,500,000 2,000,000 3,500,000 Variable ($ per unit) 21 25 15