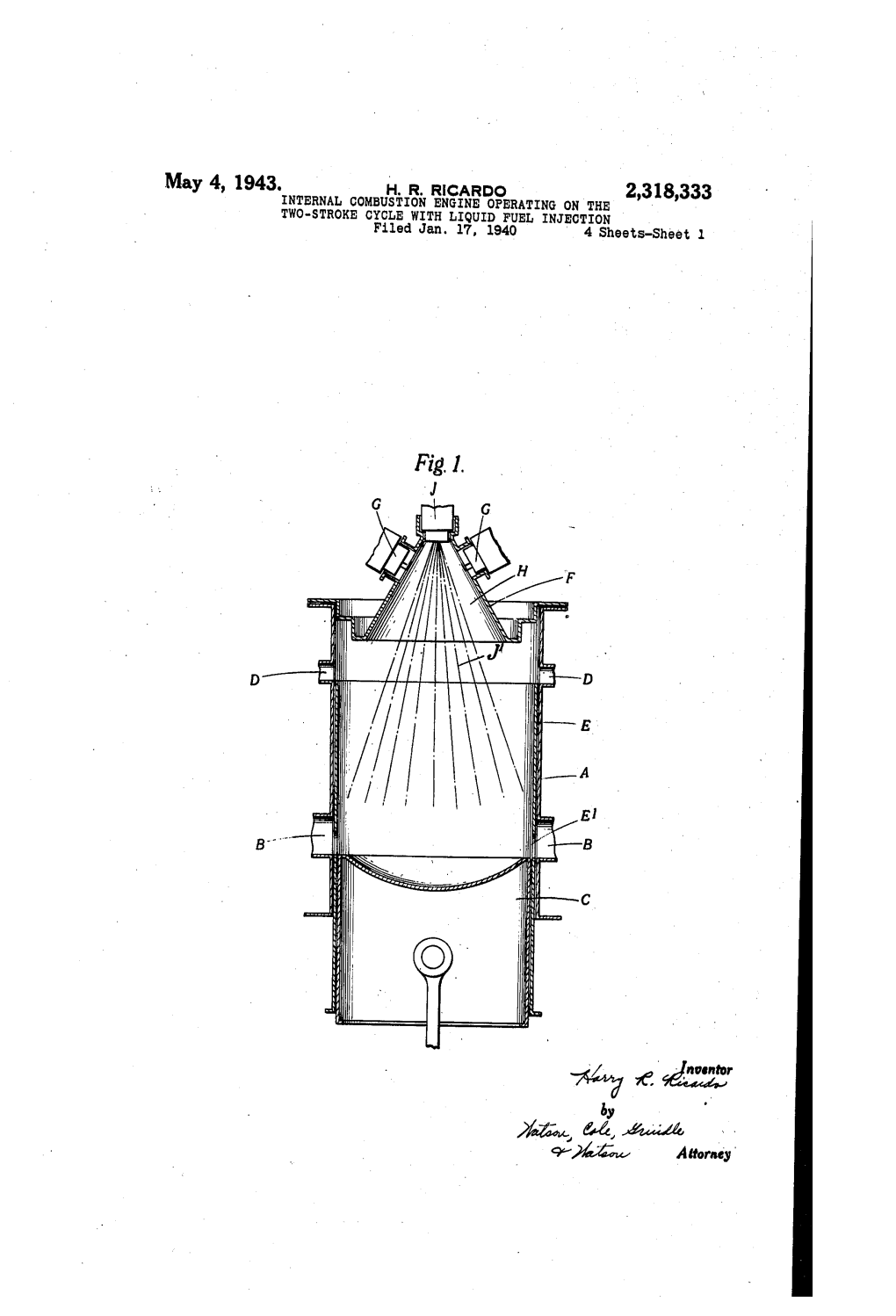

May 4, 1943. H. R. RICARDO 2,318,333 INTERNAL COMBUSTION ENGINE OPERATING on the - TWO-STROKE CYCLE with LIQUID FUEL Injection Filed Jan

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Terms and Definitions of Fuel Injection Management Systems

THROTTLE BODY TERMS AND DEFINITIONS OF INJECTION (TBI) — In TBI FUEL INJECTION systems the throttle body assembly has two major MANAGEMENT SYSTEMS functions: regulate the air- flow, and house the fuel Throttle Body Assembly (TBA) — The throttle body injectors and the fuel pres- assembly (also called air valve), controls the airflow to the sure regulator. The choices engine through one, two or four butterfly valves and of throttle bodies range provides valve position feedback via the throttle position from single barrel/single sensor. Rotating the throttle lever to open or close the injector unit generally sized for less than 150 HP to four bar- passage into the intake manifold controls the airflow to the rel/four injector unit capable of supporting fuel and air flow for engine. The accelerator pedal controls the throttle lever posi- 600 HP. The injectors are located in an injector pod above the tion. Other functions of the throttle body are idle bypass air throttle valves. The quantity of fuel the injector spray into the control via the idle air control valve, coolant heat for avoiding intake manifold is continuously controlled by the ECU. Most of icing conditions, vacuum signals for the the TBI systems use bottom fed fuel injectors. ancillaries and the sensors. MULTI-POINT FUEL INJECTION (MPFI) — In the multi point fuel FUEL INJECTOR — There are basically three approaches in injection system an injector is located in the intake manifold delivering the fuel to the engine: passage. The fuel is supplied to the injectors via a fuel rail in • Above the throttle plate as in throttle body injection the case of top fed fuel injectors and via a fuel galley in the • In the intake port toward the intake valves as in multi-port injec- intake manifold in the case of bottom fed fuel injectors. -

Nos Roots-Type Nitrous Systems Supercharger Series

NOS ROOTS-TYPE NITROUS SYSTEMS SUPERCHARGER SERIES P/N 13350NOS & 02520NOS INSTRUCTION P/N A5118-SNOS APPLICATIONS: These kits are designed to work on highly modified domestic V-8 engines using 671 and 871 roots-type superchargers, with mechanical fuel injection or carburetion. PERFORMANCE POTENTIAL: These kits come with jetting that allows power gain to be easily adjusted to 225-250 HP. Typical power gains for the roots-type supercharger systems are as follows: Nitrous/Fuel Power Gain (BHP) Jetting 16/20* 80 20/24* 120 26/29 175 32/36* 200 36/38* 200+ *Not supplied with kits. At the 200+ horsepower level, the Cheater nitrous solenoid is flowing at maximum capability. Increasing jetting sizes beyond this point will probably not result in any performance increase. If performance greater than 200+ horsepower is desired, it is recommended that the roots-type supercharger plate system be upgraded with a Pro Shot nitrous solenoid. This will increase maximum power capability to 325+. TUNING SUGGESTIONS: The tuning combinations listed on the next page are for engines using a moderate amount of supercharger boost (5-10 psi). If attempting to use one of these systems with elevated boost, extreme care should be taken in arriving at proper ignition timing setting. Ignition timing will vary with engine combination, but you can expect at least 4°-8° less than the value recommended in these tables. When using kit P/N 02520NOS at higher power levels, gasoline of at least 116 octane is required. Suggested Tuning Combinations for NOS Roots-Type Super -

FUEL INJECTION SYSTEM for CI ENGINES the Function of a Fuel

FUEL INJECTION SYSTEM FOR CI ENGINES The function of a fuel injection system is to meter the appropriate quantity of fuel for the given engine speed and load to each cylinder, each cycle, and inject that fuel at the appropriate time in the cycle at the desired rate with the spray configuration required for the particular combustion chamber employed. It is important that injection begin and end cleanly, and avoid any secondary injections. To accomplish this function, fuel is usually drawn from the fuel tank by a supply pump, and forced through a filter to the injection pump. The injection pump sends fuel under pressure to the nozzle pipes which carry fuel to the injector nozzles located in each cylinder head. Excess fuel goes back to the fuel tank. CI engines are operated unthrottled, with engine speed and power controlled by the amount of fuel injected during each cycle. This allows for high volumetric efficiency at all speeds, with the intake system designed for very little flow restriction of the incoming air. FUNCTIONAL REQUIREMENTS OF AN INJECTION SYSTEM For a proper running and good performance of the engine, the following requirements must be met by the injection system: • Accurate metering of the fuel injected per cycle. Metering errors may cause drastic variation from the desired output. The quantity of the fuel metered should vary to meet changing speed and load requirements of the engine. • Correct timing of the injection of the fuel in the cycle so that maximum power is obtained. • Proper control of rate of injection so that the desired heat-release pattern is achieved during combustion. -

AP-42, Vol. I, 3.3: Gasoline and Diesel Industrial Engines

3.3 Gasoline And Diesel Industrial Engines 3.3.1 General The engine category addressed by this section covers a wide variety of industrial applications of both gasoline and diesel internal combustion (IC) engines such as aerial lifts, fork lifts, mobile refrigeration units, generators, pumps, industrial sweepers/scrubbers, material handling equipment (such as conveyors), and portable well-drilling equipment. The three primary fuels for reciprocating IC engines are gasoline, diesel fuel oil (No.2), and natural gas. Gasoline is used primarily for mobile and portable engines. Diesel fuel oil is the most versatile fuel and is used in IC engines of all sizes. The rated power of these engines covers a rather substantial range, up to 250 horsepower (hp) for gasoline engines and up to 600 hp for diesel engines. (Diesel engines greater than 600 hp are covered in Section 3.4, "Large Stationary Diesel And All Stationary Dual-fuel Engines".) Understandably, substantial differences in engine duty cycles exist. It was necessary, therefore, to make reasonable assumptions concerning usage in order to formulate some of the emission factors. 3.3.2 Process Description All reciprocating IC engines operate by the same basic process. A combustible mixture is first compressed in a small volume between the head of a piston and its surrounding cylinder. The mixture is then ignited, and the resulting high-pressure products of combustion push the piston through the cylinder. This movement is converted from linear to rotary motion by a crankshaft. The piston returns, pushing out exhaust gases, and the cycle is repeated. There are 2 methods used for stationary reciprocating IC engines: compression ignition (CI) and spark ignition (SI). -

Gasoline Direct Injection: an Efficient Technology

Available online at www.sciencedirect.com ScienceDirect Energy Procedia 90 ( 2016 ) 666 – 672 5th International Conference on Advances in Energy Research, ICAER 2015, 15-17 December 2015, Mumbai, India Gasoline Direct Injection: An Efficient Technology S.P. Chincholkara,*, Dr. J. G. Suryawanshib aDept of Mech Engg, KITS, Ramtek, 441106, India bDept. of Mech Engg, VNIT, Nagpur, 440010 India Abstract Most of the researchers wanted to work with diesel engine because of complexity in the gasoline engine. Author tried to review gasoline direct injection (GDI) a new technology in the gasoline engine with the objective to motivate the researchers to work with this field. This paper reviews the benefits of direct injection in the gasoline engine in terms of fuel consumption and emission. The effect of stratified and homogeneous mode on the performance parameter along with combustion system (wall guided/ spray guided and air guided), its extend feasibility and complexity in the individual and combine mode of operation is reviewed in detail. The review comes up with the need of optimization in mixture formation to reduce in-cylinder wall wetting, increase combustion stability, and extend up to which charge cooling occurs and feasibility of stratified mode operation in GDI engine. Optical diagnostic and CFD are the tools which can help in optimizing this complex system © 2016 The Authors. Published by Elsevier Ltd. This is an open access article under the CC BY-NC-ND license © 2016 The Authors.Published by Elsevier Ltd. (http://creativecommons.org/licenses/by-nc-nd/4.0/). Peer-review under responsibility ofthe organizing committee of ICAER 2015. -

Effects and Advantages of Gasoline Direct Injection System Vishwanath M*, S

Journal of Chemical and Pharmaceutical SciencesISSN: 0974-2115 Effects and Advantages of Gasoline Direct Injection System Vishwanath M*, S. Madhu Department of Automobile Engineering, Saveetha School of Engineering, Chennai-602 105 *Corresponding author: E-Mail: [email protected] ABSTRACT Gasoline direct injection process is a form of gas give procedure used in current developments of vehicle. The gasoline financial system and the stringent exhaust emission norms has led to the transmission in the gasoline process from carburetor direct injection method. Probably the most predominant international initiative of the automobile industry is to improve an immediate-injection fuel engine. Four technical aspects that make up the groundwork applied sciences in direct injection methods. a) Air waft into the cylinder is improved. b) The form of the piston with curved high controls the combustion by way of mixing the air-gasoline combination. c) The stress of gas injection is accelerated by the excessive strain gas Pump. d) The vaporization and dispersion of the gas spray is managed by means of the excessive stress swirl injector Gasoline financial system will also be acquired by using adjusting air fuel ratio situated on the performing load. It presents a right estimation of the nice of gasoline required at right time and supplies manipulate over combustion. Gasoline in this paper advantages and effects of fuel direct injection procedure is reviewed. KEY WORDS: Gasoline direct injection (GDI), High Pressure Fuel Pump, Carburetor. 1. INTRODUCTION The fundamental goals of the automotive enterprise is to acquire a excessive energy, low precise fuel consumption, low emissions, low noise and higher drive relief cars. -

Efi Throttle

EFI THROTTLE BODIES BY JIM GIBSON The last carbureted passenger vehicles were manufactured almost 25 years ago, yet many performance engine builders still rely on carburetors. That’s changing, in part due to the availability of many fuel injection options. uilders of custom street rods and “resto mod” In simple terms, we have either throttle body injection vehicles are generally divided into two camps (TBI), where the injectors are mounted in the throttle body with regard to the engine’s fuel system. They assembly, providing a central point air/fuel delivery atop the either want to retain an old school carburetor intake manifold, or multipoint fuel injection (MPFI), where approach or upgrade to electronic fuel injec- one fuel injector is dedicated per cylinder, with each injector tion (EFI). Since an OE-type fuel injection providing fuel closer to each combustion chamber, at the system may be somewhat limited in terms of performance output end of each intake runner. Band definitely won’t cut it in terms of appearance, builders Aftermarket performance throttle bodies are current- are always looking for aftermarket options. ly available in a variety of configurations, to replace an Today’s offerings allow a choice between a system that fea- existing throttle body on an OE injection system tures a central plenum with a single “dry” throttle body (OE (mounted to a stock or aftermarket manifold plenum) or design approach but with added performance and custom ap- a throttle body that mounts to a 4-barrel-style intake pearance) or one that utilizes a carburetor-style intake mani- manifold. -

Electronic Fuel Injection Techniques for Hydrogen Fueled Internal

Electronic Fuel Injection Techniques for Hydrogen Fueled I. C. Engines C. A. r~acCarley M. S. Thesis @ Copyright by Carl Arthur MacCarley 1978 UNIVERSITY OF CALIFORNIA Los Angeles Electronic Fuel Injection Techniques for Hydrogen Fueled Internal Combustion Engines A thesis submitted in partial satisfaction of the requirements for the degree of Master of Science in Engineering by Carl Arthur MacCarley 1978 The thesis of Carl A. MacCarley is approved. 2!1~;Sti.~ William D. VanVorst JjlkWilliS University of California, Los Angeles 1978 ii TABLE OF CONTENTS Page ACKNOWLEDGMENTS . v ABSTRACT vi 1. INTRODUCTION 1 2. HYDROGEN COMBUSTION CHARACTERISTICS • 2 3. FUEL INJECTION TECHNIQUES FOR HYDROGEN 8 3.1 Manifold Injection ..••••• 8 3.2 Direct Cylinder Injection .••. 9 3.3 Mechanical Injection Development • 11 3.4 ElectroniQ~lly Controlled Fuel Injection • 13 4. SYSTEM REQUIREMENTS . 16 4.1 Control System . 16 4.2 Injection Valve 19 5. SYSTEM DEVELOPMENT 21 5.1 Control System •• 22 5.1.1 General Description • 22 5.1.2 Injection Triggering • • •• 23 5.1.3 Control Inputs • • • • 23 5.1.4 Pulse Generation 25 5.1.5 Dynamic Injection Timing 25 5.1. 6 Water Injection • 27 5.1. 7 Ignition Timing • 28 5.1.8 Fuel Supply Control • 29 5.1. 9 Instrumentation • 29 5.2 Injection Valve •.••• 30 5.3 Electronic Technique for High Speed Electro magnetic Valve Actuation . • •• 35 5.4 Hydrogen Flow Circuit 39 6. SYSTEM TESTING .. 41 6.1 Baseline Data Setup 41 6.2 Manifold Injection Setup . 42 6.3 Direct Injection Setup •.•••• 43 6.4 Test Apparatus • • • 44 :6.5 Experimental Results and Discussion 45 iii Page 7. -

CPCX Cardone Reman Diesel Fuel Injection Pump Mkt(BRO)

Remanufactured DIESEL FUEL INJECTION PUMP CARDONE Remanufactured Diesel Fuel Injection Pumps are re-engineered, Product Description built and tested to match O.E. performance. Our unique re-engineering process allows us to identify application-specific failure modes to address and Features and Benefits correct during re-assembly. Each unit features 100% new O-rings and gaskets to ensure leak-free, long-lasting performance. Every injector is tested at Good Maintenance Practices operating pressure ranges to measure fuel delivery and response time. • All gaskets and O-rings are replaced 100% to ensure Signs of Wear and optimal performance. Troubleshooting • All products are completely disassembled, thoroughly cleaned FAQs and inspected. All components are renewed or replaced as necessary to ensure high-quality and durability. • Each assembled unit is individually tested to ensure it meets or exceeds O.E. form, fit and function. • Improvements based on typical failure modes of the original fuel injection pumps are incorporated into the remanufacturing of the replacement unit, where applicable. This translates into longer service life, lower cost and reduced down time for the driver. Good Maintenance Practices • Use of fuels with higher sulfur content will impair the function of the emission components. • Replace fuel filter(s) at intervals specified by the O.E. manufacturer. • Do not allow fuel tank level to drop below one-quarter of the tank. • Do not use diesel fuel or additives not recommended for your vehicle. Subscribe to receive email notification whenever cardone.com we introduce new products or technical videos. Tech Service: 888-280-8324 Click Fuel/Air Systems Tech Help for technical tips, articles and installation videos. -

(Carburetor) System and Electronic Fuel Injection (Efi) Engine System of Toyota Kijang Series 7K-E

FINAL PROJECT COMPARISON ANALYSIS OF ENGINE PERFOMANCE BETWEEN CONVENTIONAL ENGINE (CARBURETOR) SYSTEM AND ELECTRONIC FUEL INJECTION (EFI) ENGINE SYSTEM OF TOYOTA KIJANG SERIES 7K-E RESEARCH PAPER Submitted as a Partial Fulfillment of the Requirements for Getting the Bachelor Degree of Engineering in Automotive Department Arranged by: SAFRI GUNAWAN D700 070 005 MECHANICAL ENGINEERING DEPARTMENT INTERNATIONAL PROGRAM IN AUTOMOTIVE/MOTORCYCLE ENGINEERING MUHAMMADIYAH UNIVERSITY OF SURAKARTA January 2011 i DECLARATION OF RESEARCH AUTHENTICITY I assert verily that the research entitles: COMPARISON ANALYSIS OF ENGINE PERFOMANCE BETWEEN CONVENTIONAL ENGINE (CARBURETOR) AND ELECTRONIC FUEL INJECTION (EFI) ENGINE OF TOYOTA KIJANG SERIES 7K-E That made to fulfill some of requirements to get bachelor degree of Engineering in Automotive Department of Muhammadiyah University of Surakarta, as far as I know is not a plagiarism of a research that has been published, except the information source that used to solve the problem. Surakarta, December 2010 Researcher, Safri Gunawan ii iii iv SUMMARY Safri Gunawan. D700 070 005. Comparison Analysis of Engine Perfomance between Conventional Engine (Carburetor) System and Electronic Fuel Injection (Efi) Engine System of Toyota Kijang Series 7k-E. Research Paper. Muhammadiyah University of Surakarta. 2010. The research is presented to get the number of comparison for torque, power, and specific fuel consumption between conventional engine (carburetor) system and electronic fuel injection (EFI) engine system. The method that used to get the data is by using the experiment method. The research is begun by preparing tools and materials those will be used for making test bed. After that is assembling the system on the engine alternately after getting the data including voltage, current, engine rotation (rpm), and fuel consumption (ml). -

1-MS-Module 1-Diesel Engine Fundamentals

DOE Fundamentals MECHANICAL SCIENCE Module 1 Diesel Engine Fundamentals Mechanical Science Diesel Engine Fundamentals TABLE OF CONTENTS TABLE OF CONTENTS .............................................................................................................. ii LIST OF FIGURES .................................................................................................................... iv LIST OF TABLES ....................................................................................................................... vi REFERENCES ......................................................................................................................... vii OBJECTIVES .......................................................................................................................... viii DIESEL ENGINES ..................................................................................................................... 1 Introduction ............................................................................................................................ 1 History .................................................................................................................................... 2 Diesel Engines ....................................................................................................................... 2 Major Components of a Diesel Engine.................................................................................... 3 The Cylinder Block ................................................................................................................ -

Air Fuel Control the Stoichiometric Mixture of 14.7:1 Is Critical to Emission Control

Air Fuel Control The Stoichiometric mixture of 14.7:1 is critical to emission control. 14.7 grams of Air mixed with 1 gram of Gasoline creates the most efficient air/fuel ratio (for the catalyst) The Stoichiometric mixture is critical for the catalytic converter to operate efficiently to reduce Hydrocarbons (HC) and Carbon Monoxide (CO) Air Fuel Control The PCM will sense how much air enters the engine and match it with the proper amount of fuel. The oxygen sensor will report to the computer if the air/fuel mixture is too Rich or too Lean. The PCM will “Trim” how much fuel is added by turning on the fuel injectors for a longer or shorter amount of time. Air Fuel Control Using a scan tool you can monitor “Fuel Trim” . Fuel trim is displayed in % (percentage) Numbers close to 0% mean the computer is sensing the proper amount of air entering the engine and adding the proper amount of fuel. Air Fuel Control Positive fuel trim means the oxygen sensor is reporting too much oxygen in the exhaust. To correct this the PCM will add extra fuel. A fuel trim of 10% means the PCM has to add 10% MORE fuel to keep the stoichiometric mixture of 14.7 grams of air to 1 gram of fuel. Air Fuel Control A fuel trim of -10% means the PCM has to add 10% LESS fuel to keep the stoichiometric mixture of 14.7 grams of air to 1 gram of fuel. Fuel trim numbers over 10% or under -10% should be investigated to ensure all sensors are accurate, fuel pressure is correct, and injectors are not leaking or plugged.