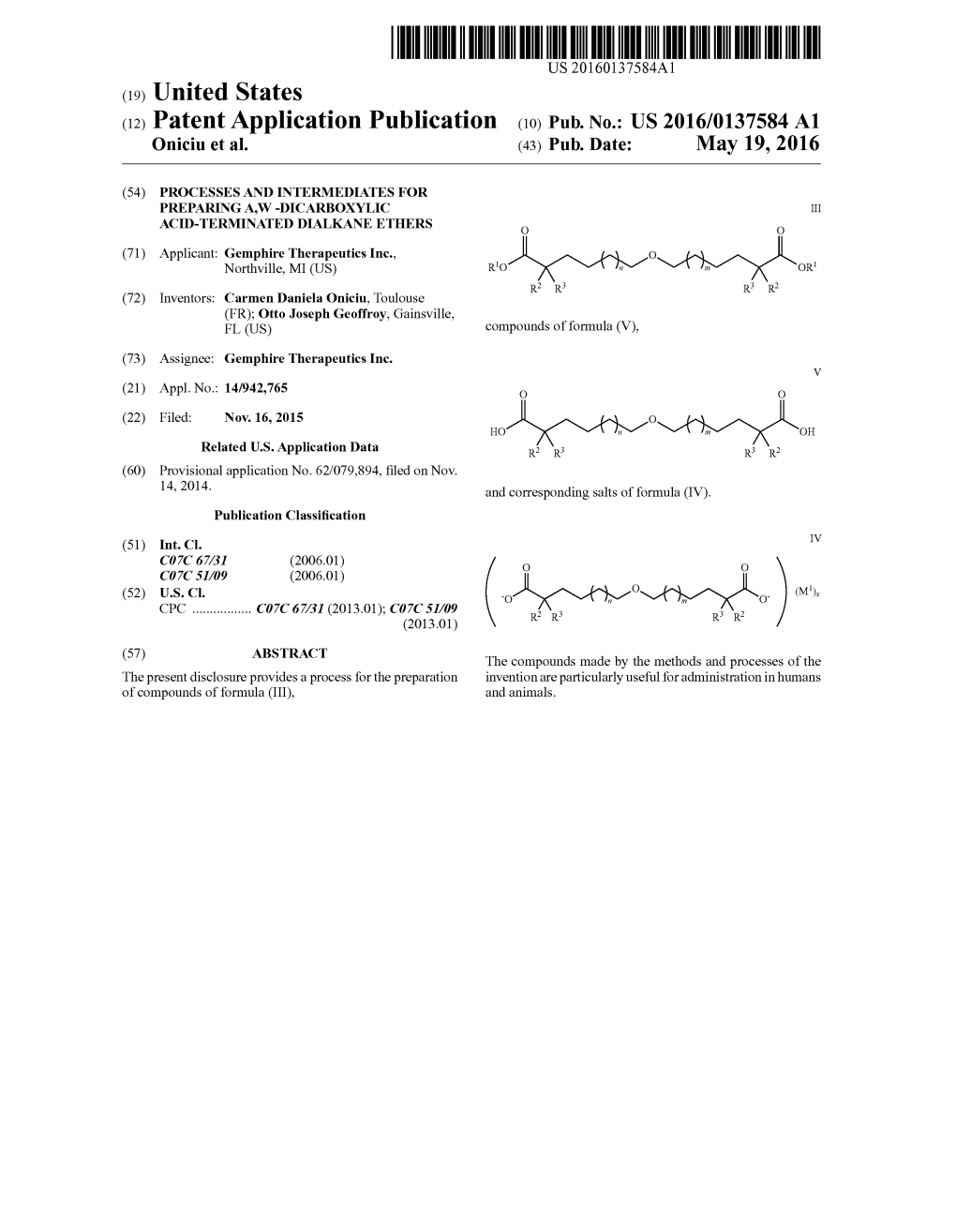

Nited States (12) Patent Application Publication (10) Pub

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Direct Preparation of Some Organolithium Compounds from Lithium and RX Compounds Katashi Oita Iowa State College

Iowa State University Capstones, Theses and Retrospective Theses and Dissertations Dissertations 1955 Direct preparation of some organolithium compounds from lithium and RX compounds Katashi Oita Iowa State College Follow this and additional works at: https://lib.dr.iastate.edu/rtd Part of the Organic Chemistry Commons Recommended Citation Oita, Katashi, "Direct preparation of some organolithium compounds from lithium and RX compounds " (1955). Retrospective Theses and Dissertations. 14262. https://lib.dr.iastate.edu/rtd/14262 This Dissertation is brought to you for free and open access by the Iowa State University Capstones, Theses and Dissertations at Iowa State University Digital Repository. It has been accepted for inclusion in Retrospective Theses and Dissertations by an authorized administrator of Iowa State University Digital Repository. For more information, please contact [email protected]. INFORMATION TO USERS This manuscript has been reproduced from the microfilm master. UMI films the text directly from the original or copy submitted. Thus, some thesis and dissertation copies are in typewriter face, while others may be from any type of computer printer. The quality of this reproduction is dependent upon the quality of the copy submitted. Broken or indistinct print, colored or poor quality illustrations and photographs, print bleedthrough, substandard margins, and improper alignment can adversely affect reproduction. In the unlikely event that the author did not send UMI a complete manuscript and there are missing pages, these will be noted. Also, if unauthorized copyright material had to be removed, a note will indicate the deletion. Oversize materials (e.g., maps, drawings, charts) are reproduced by sectioning the original, beginning at the upper left-hand comer and continuing from left to right in equal sections with small overiaps. -

Role of Organolithium Aggregates and Mixed Aggregates in Organolithium Mechanisms Hans J

Review pubs.acs.org/CR Role of Organolithium Aggregates and Mixed Aggregates in Organolithium Mechanisms Hans J. Reich* Department of Chemistry, University of Wisconsin, Madison, Wisconsin 53706, United States 3.3. Metalation Reactions 7148 3.3.1. Fluorene and Triphenylmethane 7148 3.3.2. Allylic and Benzylic Metalations 7149 3.3.3. Dipole-Stabilized Metalations 7150 3.3.4. Silane Metalation 7150 3.3.5. Acetylene Metalations 7150 3.3.6. Aromatic Ortho-Metalations 7151 3.3.7. Solvent Metalations 7153 3.3.8. Miscellaneous Metalations 7153 3.4. Alkene Addition (Carbolithiation) 7154 3.4.1. (Cyclopropylmethyl)lithium 7155 3.4.2. Addition to Aromatic Rings 7155 3.4.3. Addition to 1,1-Diphenylethylene 7155 CONTENTS 3.4.4. Addition to Ethylene 7156 1. Introduction 7130 3.4.5. Polyene Addition 7156 2. Structures of Organolithium Reagents 7131 3.5. Additions to Carbonyl Compounds 7156 2.1. Types of Solid-State Structures 7132 3.5.1. Ketones 7156 2.1.1. Hexamers and Higher Aggregates 7132 3.5.2. Enones 7158 2.1.2. Tetramers 7132 3.5.3. Aldehydes 7159 2.1.3. Trimers 7133 3.5.4. Aldol Condensation 7160 2.1.4. Dimers 7134 3.5.5. Carboxylic Esters 7161 2.1.5. Monomers 7135 3.5.6. Carboxylic Amides 7162 2.1.6. Substrate Complexes 7135 3.5.7. Imines 7163 2.2. Solution Structures of Organolithium Re- 3.5.8. Nitriles 7163 agents 7136 3.6. Elimination Reactions 7164 2.2.1. Colligative Properties 7136 3.7. Li/Br, Li/I, and Li/Sn Exchange 7164 2.2.2. -

Acroseal Packaging Your Solution for Air- and Moisture- Sensitive Reagents

AcroSeal Packaging Your solution for air- and moisture- sensitive reagents Extra dry solvents Deuterated solvents Organometallic compounds Reagents in solution Organics Introduction Since the launch of AcroSealTM packaging we have introduced a new septum, which helps preserve product quality for longer. In addition, our AcroSeal portfolio has been expanded to include a broad range of solvents, organometallics, reagents in solution and organic compounds. In this brochure we have categorized our products under chemical families to make it easier to locate the product you need. Introduction Page no. AcroSeal packaging highlights 3 AcroSeal packaging performance 4 New 25mL AcroSeal packaging 4 Solvents Extra dry solvents 5-7 Solvents for biochemistry 7 Deuterated solvents 7 Organometallics Grignard reagents 8-10 Organoaluminiums 11 Organolithiums 11 Organosodiums 12 Organotins 12 Organozincs 12 Reagents in solution Amines 13 Boranes 13 Halides 14-15 Hydrides 15 Oxides 16 Silanes 16 Other reagents in solution 17 Organics Aldehydes 18 Amines 18 Epoxides 18 Halides 19 Phosphines 19 Silanes 19 Other organics 20 How to use AcroSeal packaging 21 Alphabetical index 22-23 2 Introduction AcroSeal packaging: drier reagents for longer When using air- and moisture-sensitive solvents and reagents, it is essential that these products are not only as dry as possible when you first use them, but they should remain dry in storage as well. Through the innovative quadrant-style screw cap and specially designed septum, AcroSeal packaging ensures that you have access to high-quality and low-moisture products every use, guaranteeing improved yield and consistency of your research experiments while reducing chemical waste. AcroSeal packaging highlights New septum developed from a polymeric elastomer with an inert fluoropolymer-coated surface, preserves product quality for longer with better re-seal around needle punctures. -

Pyrophoric Organolithium Reagents

LABORATORY SAFETY FACT SHEET #34 Pyrophoric Organolithium Reagents Procedures1 for Safe Use of Pyrophoric Organolithium Reagents Scope Storage, transfer and use of organolithium reagents including (but not necessarily limited to): Alkyls – • Methyl-d3-lithium, as complex with lithium iodide solution 0.5 M in diethyl ether • Methyllithium lithium bromide complex solution • Methyllithium solution purum, ~5% in diethyl ether (~1.6M) • Methyllithium solution purum, ~1 M in cumene/THF • Methyllithium solution 3.0 M in diethoxymethane • Methyllithium solution 1.6 M in diethyl ether • Ethyllithium solution 0.5 M in benzene/cyclohexane (9:1) • Isopropyllithium solution 0.7 M in pentane • Butyllithium solution 2.0 M in cyclohexane • Butyllithium solution purum, ~2.7 M in heptane • Butyllithium solution 10.0 M in hexanes • Butyllithium solution 2.5 M in hexanes • Butyllithium solution 1.6 M in hexanes • Butyllithium solution 2.0 M in pentane • Butyllithium solution ~1.6 M in hexanes • Butyllithium solution technical, ~2.5 M in toluene • Isobutyllithium solution technical, ~16% in heptane (~1.7 M) • sec-Butyllithium solution 1.4 M in cyclohexane • tert-Butyllithium solution purum, 1.6-3.2 M in heptane • tert-Butyllithium solution 1.7 M in pentane • (Trimethylsilyl)methyllithium solution 1.0 M in pentane • (Trimethylsilyl)methyllithium solution technical, ~1 M in pentane • Hexyllithium solution 2.3 M in hexane • 2-(Ethylhexyl)lithium solution 30-35 wt. % in heptane Alkynyls – • Lithium acetylide, ethylenediamine complex 90% • Lithium acetylide, ethylenediamine complex 25 wt. % slurry in toluene • Lithium (trimethylsilyl)acetylide solution 0.5 M in tetrahydrofuran • Lithium phenylacetylide solution 1.0 M in tetrahydrofuran Aryls – • Phenyllithium solution 1.8 M in di-n-butyl ether Others – • 2-Thienyllithium solution 1.0 M in tetrahydrofuran • Lithium tetramethylcyclopentadienide • Lithium pentamethylcyclopentadienide Hazards In general these materials are pyrophoric; they ignite spontaneously when exposed to air. -

Organolithium Compounds Brochure

Contents I. Introduction . .4 II. Organolithium compounds, properties & structures . .5 III. Reactions of organolithium compounds . .6 a. Metallation . .6 b. Ortho-metallation . .7 c. Nucleophilic addition and substitution . .7 d. Halogen-Metal exchange . .8 e. Transmetallation . .9 f. Anionic Polymerisation . .9 IV. Named organic reactions with organolithium compounds . .10 a. [1,2] and [2,3]-Wittig rearrangement . .10 b. Shapiro Olefination . .10 c. Peterson Olefination . .10 d. Ramberg-Bäcklund-Reaction . .10 e. Parham Cyclization . .11 V. Indicators for the titration of organolithium compounds . .12 VI. Organolithium compounds available at Acros Organics . .14 Dry-solvents . .15 3 I. Introduction Organometallic compounds are amongst the most often used reagents in organic synthesis. The earliest organometallic compound was already discovered in the early 19th cen- tury (“Zeise’s salt”; a zinc-olefin complex was first reported in 1827!) and first exam- ples of synthetic organometallic chemistry are the organozinc-compounds, discovered by Edward Frankland in 1849, the organo-magnesium compounds discovered by Victor Grignard and his teacher Philippe Barbier in 1901 and the organolithium com- pounds, discovered by Wilhelm Schlenk in 1917(1) But only since the 1950th, based on the pioneering work of Georg Wittig and Henry Gilman, organometallic reagents became a routinely used tool in the syn- thetic organic laboratory. A very early but still invaluable application of organometallic reagents is the olefin- polymerisation with the so-called -

Acroseal Packaging an Application Guide

AcroSeal Packaging An Application Guide Solvents and Reagents Drier For Longer Introduction Organic reagents have a wide series of applications in drug discovery, agrochemical research, flavours and fragrances, diagnostics and NMR analysis. Reactions often involve the use of air and moisture sensitive solvents, pyrophoric and hazardous reagents. Our AcroSeal™ packaging is an industry leading packaging solution for safe handling of these types of materials. This brochure provides an overview of the key advantages of AcroSeal packaging for your research and outlines some important reactions that could benefit. AcroSeal Packaging Provides... PERFORMANCE The specially designed multi-layer septum ensures a better re-seal thus minimizing atmospheric exposure and protecting the quality of your air and moisture sensitive solvents and reagents. CONVENIENCE A wide range of pre-prepared reagents in solution are available, reducing the risks and saving the time and effort of making your own. SAFETY Our AcroSeal cap system ensures you can transfer the contents of the bottle safely into your reaction vessel minimizing your exposure to potentially hazardous chemicals. Contents Page no. Introduction ........................................................................................................................................................................................................................2 Performance .......................................................................................................................................................................................................................3 -

Pyrophorics Organolithium Reagents

Standard Operating Procedure Settlement Class: Pyrophorics Organolithium Reagents This SOP is not complete until it has been signed and dated by the PI and relevant lab personnel. Print a copy and insert into your Laboratory Safety Manual and Chemical Hygiene Plan . Refer to instructions for assistance. Department: Chemistry & Biochemistry – Chemical Engineering Date SOP was written: December 14, 2012 Date SOP was approved by PI/lab supervisor: January 18, 2013 SOP reviewed by: Alessandro Moretto, Chem. Lab. Safety Officer Principal Investigator: Prof. Susannah Scott Internal Lab Safety Coordinator/Lab Manager: Stephanie Goubert-Renaudin Lab Phone: 805- 893-8941 Office Phone: 805-893-7403 Emergency Contact: EH&S 24 hour line: 805-893-3194 Location(s) covered by this SOP: ESB 3324 and 3328 Type of SOP: ☐ Process ☐Hazardous Chemical ☒ Hazardous Class Purpose Organolithium reagents are pyrophoric organometallic compounds with the general formula RLi where R can be alkyls, aryls, and vinyls. Most organolithium reagents are highly pyrophoric substances and may spontaneously ignite in contact with air. These compounds have applications in organic synthesis since they are sufficiently strong bases to deprotonate many carbon acids, including benzene. In regard to molecular aggregation state, some of these compounds exist in clusters. These compounds can be used for the deprotonation of amines and activated C—H compounds. Examples of Lithium reagents Hexyllithium, (Trimethylsilyl)methyllithium, Butyllithium, Methyllithium Organolithium Reagents 1 Date: 11/1/2012 SOP Template developed by The UC Center for Laboratory Safety Physical & Chemical Properties/Definition of Chemical Group CAS#: Various Class: Pyrophoric, can ignite in air Molecular Formula: RLi (R = Alkyl, Aryl, Vinyl) Form (physical state): Solid, liquid Color: Various Boiling point: Various Potential Hazards/Toxicity Lithium reagents are pyrophoric. -

The Reaction Between Diphenylmethane and Butadiene with Organolithium Compounds "-X .. • "'- R / ··· ...X

Polymer Journal Vol. 3, No. 5, pp 573-580 (1972) The Reaction between Diphenylmethane and Butadiene with Organolithium Compounds Teruo YAMAGUCHI, Tadashi NARITA, and Teiji TSURUTA Department of Synthetic Chemistry, Faculty of Engineering, University of Tokyo, Japan. (Received December 20, 1971) ABSTRACT: The reaction between diphenylmethane and butadiene with organo lithium compounds was investigated in order to obtain telomers containing one butadiene unit in high selectivity. The lithium salt of methoxyethanol (CH3OCH2CH2OLi), N,N,N',N'-tetramethylethylenediamine(TMEDA), hexamethylphosphoric triamide(HMPT) and their related compounds were used as complexing agents for lithium alkyl. 5,5- Diphenyl-2-pentene and 5,5-diphenyl-1-pentene (DPPE) were obtained in high yields using these catalyst systems. The influence of molar ratio, [complexing agent]/[lithium alkyl], on the yield of DPPE was studied and the reaction was found to depend strongly on the nature of complexing agent. In order to discuss the specificity of the various catalyst systems, the metalation reaction of diphenylmethane was investigated. KEY WORDS Anionic telomerization / Butadiene / Diphenyl- methane / n-Butyllithium / Methoxyethanol / N,N,N',N'-Tetra methylethylenediamine / Hexamethylphosphoric triamide / 5,5- pheny1Di2-pentene / 1 2 It was reported in previous papers ' that the / CH2, ,, Li,, /CH2"- '-0,, • ',o " reactivity of styrene at an early stage of the CH2 ! i i CH2 styrene-butadiene copolymerization was in ". LL : ,Li / "-x .. • "'- R / ··· ..... X creased by n-butyllithium(n-BuLi)-CH3OCH2· [I] CH20Li catalyst system in toluene and that copolymers containing more styrene units than R, alkyl- or aryl-; the feed monomer ratio were formed. The X, -OCH3 or -N(CH3)2. -

Pyrophoric Organolithium Reagents Standard Operating Procedure

PYROPHORIC ORGANOLITHIUM REAGENTS STANDARD OPERATING PROCEDURE Type of SOP: ☐ Process ☐ Hazardous Chemical ☐ Hazard Class Department: ____________________________ Building: ___________________ Room #:___________ Principal Investigator: _______________________________________ Phone #:____________________ Prepared By: ________________________________ Email: ____________________ Date: __________ 1. HAZARD OVERVIEW This procedure will cover the storage, transfer and use of organolithium reagents including, but not necessarily limited to, the materials listed the Appendix. In general, the primary hazard of the materials are that they ignite spontaneously when exposed to air. These pyrophoric properties requires them to be handled carefully to exclude them from air/moisture. Additionally, they all tend to be toxic and come dissolved in a flammable solvent. Other common hazards include corrosivity, teratogenicity, water reactivity, peroxide formation, along with damage to the liver, kidneys, and central nervous system. 2. PERSONAL PROTECTIVE EQUIPMENT (PPE) At minimum, safety glasses, lab coats, and gloves are required. Additional or more protective PPE may be required. Gloves must be worn when handling pyrophoric chemicals. Nitrile gloves should be adequate for handling most of these in general laboratory settings, but they are combustible. Be sure to use adequate protection to prevent skin exposures. Sigma-Aldrich recommends the use of nitrile gloves underneath neoprene gloves. Flame-resistant gloves are also available for purchase, but are generally not used due to their poor dexterity when doing delicate chemical transfer work. A lab coat or apron, not made from easily ignited material like nylon or polyester, must be worn. Special fire-resistant lab coats are more expensive, but recommended for labs using these reagents routinely. Please refer to the NJIT Chemical Hygiene Guide and Hazard Assessment Form to determine the proper PPE for handling corrosive materials. -

Chemical Hygiene Plan

CHEMICAL HYGIENE PLAN Soka University of America Environmental Health and Safety 1 University Drive, Aliso Viejo, California 92656 Office: 949-480-4000 • Fax: 949-480-4151 Table of Contents CHAPTER 1: INTRODUCTION ............................................................................................... 1-1 CHAPTER 2: CHEMICAL HAZARD IDENTIFICATION ........................................................... 2-1 CHAPTER 3: CLASSIFICATION OF HAZARDOUS CHEMICALS .......................................... 3-1 CHAPTER 4: EXPOSURE CONTROL METHODS ................................................................. 4-1 CHAPTER 5: CHEMICAL EXPOSURE ASSESSMENT .......................................................... 5-1 CHAPTER 6: CHEMICAL MANAGEMENT ............................................................................. 6-1 CHAPTER 7: TRAINING AND RECORDKEEPING................................................................. 7-1 CHAPTER 8: LABORATORY SAFETY ASSESSMENTS AND COMPLIANCE ....................... 8-1 CHAPTER 9: HAZARDOUS (CHEMICAL) WASTE MANAGEMENT ...................................... 9-1 CHAPTER 10: EMERGENCY PROCEDURES ..................................................................... 10-1 Appendices Appendix A: General Rules for Laboratory Work ................................................................... A-1 Appendix B: List of Peroxide Forming Chemicals,.................................................................. B-1 Appendix C: Chemical Storage Guide .................................................................................. -

Organolithium Reagent 1

Organolithium reagent 1 Organolithium reagent An organolithium reagent is an organometallic compound with a direct bond between a carbon and a lithium atom. As the electropositive nature of lithium puts most of the charge density of the bond on the carbon atom, effectively creating a carbanion, organolithium compounds are extremely powerful bases and nucleophiles. Production Organolithium reagents are industrially prepared by the reaction of an halocarbon with lithium metal, i.e. RÄX + 2 Li Å RÄLi + LiX.[1] A side reaction of this synthesis, especially with alkyl iodides, is the Wurtz reaction, in which an RÄLi species reacts with an RÄX species forming an R-R coupled product. This side reaction can be almost completely avoided by using alkyl chlorides or bromides. A second method is the reaction of an alkyl halide or aryl alkyl sulfide with a radical anion lithium salt, such as lithium naphthalide. These radical anions can be prepared by the reduction of an aromatic system such as naphthalene with metallic lithium. As the organic reduction of alkyl halides is much faster with radical anions than it is with direct reaction with lithium metal, this reaction enables a number of more exotic organolithium compounds to be prepared. A third method involves the metal-halogen exchange between an organic halide compound (usually an iodide or bromide) and an organolithium species (usually n-BuLi, s-BuLi or t-BuLi). As this is an equilibrium reaction, the reaction is successful only if the formed lithium reagent has a more stable carbanion than the starting lithium reagent. This method is often used to prepare vinyl- aryl- and primary alkyllithium reagents, and is especially valuable for the preparation of functionalized lithium reagents where the harsher conditions required for reaction with lithium metal may be precluded. -

Organo Lithium Reagents

UCR EH&S Procedures1 for Safe Use of Pyrophoric Organolithium Reagents Scope........................................................................................................................................................1 Hazards ....................................................................................................................................................2 Controlling the Hazards ............................................................................................................................2 Personal Protective Equipment (PPE) ..................................................................................................2 Eye Protection ...................................................................................................................................2 Skin Protection ..................................................................................................................................2 Equipments and Notification..............................................................................................................3 Designated Area .......................................................................................................................................3 Eyewash................................................................................................................................................3 Safety Shower.......................................................................................................................................3