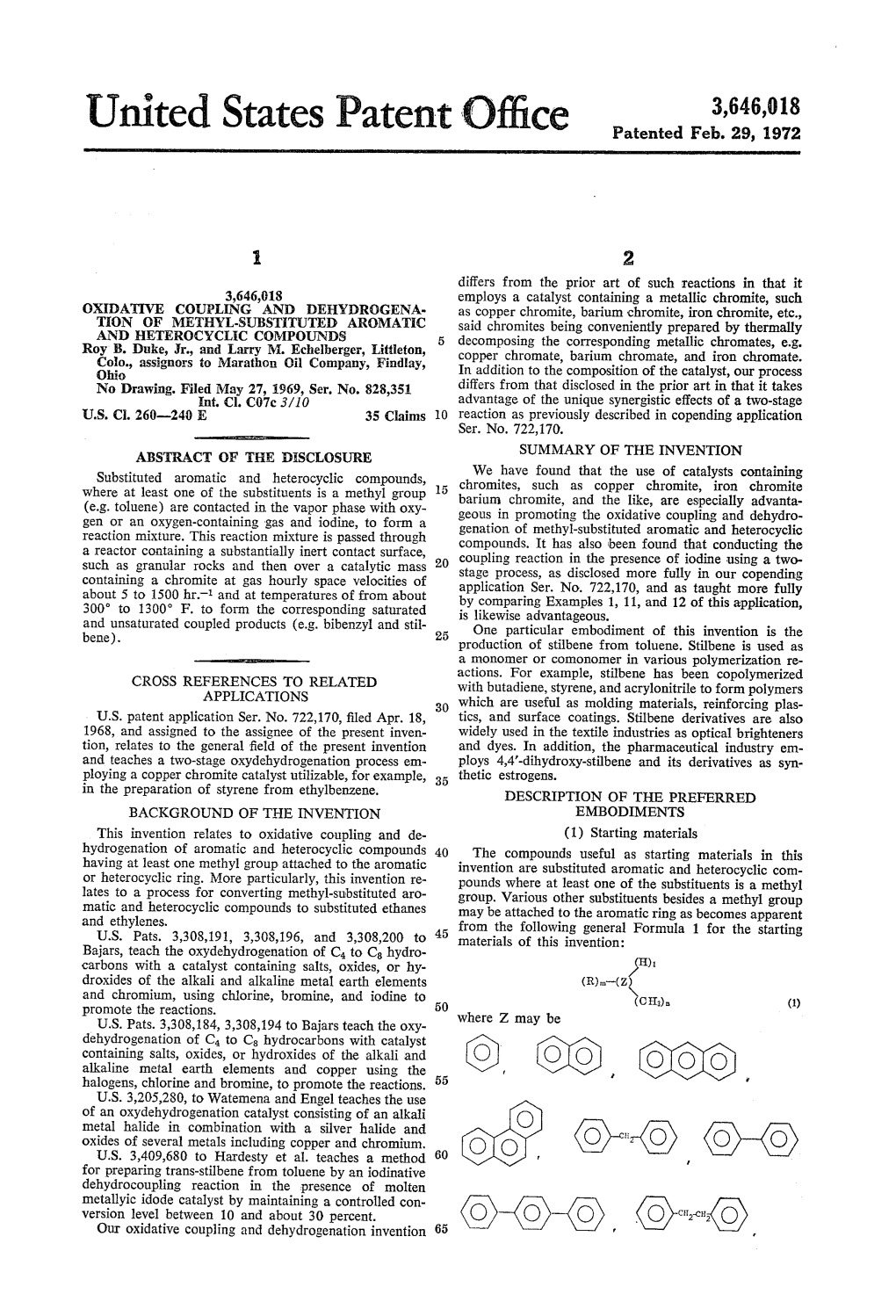

(O) (Oo) (Ooo) U.S

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Industrial Applications of Nano Cu-Chromite Catalyzer

International Journal of Chemical Studies 2018; 6(4): 86-90 P-ISSN: 2349–8528 E-ISSN: 2321–4902 IJCS 2018; 6(4): 86-90 Industrial applications of nano Cu-Chromite © 2018 IJCS Received: 26-05-2018 catalyzer Accepted: 29-06-2018 Pouresmaeily Seyed Mohammad Pouresmaeily Seyed Mohammad, H Shirkavand Behzad, Shahidzadeh Department of Chemistry & Mansour and Ebrahimi Sobhan Chemical Engineering Malek-e- Ashtar University of Technology, Shabanlou, Iran Abstract Nano Cu-Chromite catalyzer is a high usage catalyzer in chemical reactions. This catalyzer has many H Shirkavand Behzad applications in oxidation, hydrogenation, dehydrogenation, alkylation, alcohol decomposition, useful Department of Chemistry & reactions in petroleum include: reforming. Recyclable is one of advantages of this catalyzer. This Chemical Engineering Malek-e- catalyzer produces by sol-gel, co-precipitating, deposition in vacuum and ceramic methods. This paper Ashtar University of explores applications of this catalyzer in various industries. Technology, Shabanlou, Iran Shahidzadeh Mansour Keywords: Nano Cu-Chromite, hydrogen producing, nano catalyzer Institute for Color Science & Technology, Shams, Iran Introduction Cu-Chromite is an important catalyzer in chemical reactions that has wide application in Ebrahimi Sobhan synthesis of organic chemistry processes. Uses in many reactions such as: hydrogenation, Department of Material Science and Engineering, Sharif dehydrogenation, hydrogenolysis, oxidation, alkylation, cycloaddition, as catalyzer for University of Technology, -

Synthesis and Characterization of Amorphous Cycloaliphatic Copolyesters with Novel Structures and Architectures

Synthesis and Characterization of Amorphous Cycloaliphatic Copolyesters with Novel Structures and Architectures Yanchun Liu Dissertation submitted to the faculty of the Virginia Polytechnic Institute and State University in partial fulfillment of the requirements for the degree of Doctor of Philosophy In Chemistry S. Richard Turner, Committee Chair Timothy E. Long Paul A. Deck Herve Marand Judy S. Riffle March 22, 2012 Blacksburg, Virginia Keywords: amorphous copolyesters, cycloaliphatic monomers, melt-phase polymerization, glass transition temperature, structure-property relationship Copyright @ 2012 by Yanchun Liu Synthesis and Characterization of Amorphous Cycloaliphatic Copolyesters with Novel Structures and Architectures Yanchun Liu ABSTRACT A series of random and amorphous copolyesters containing different cycloaliphatic rings within the polymer chains were prepared by melt polycondensaton of difunctional monomers (diesters and diols) in the presence of a catalyst. These polyesters were characterized by nuclear magnetic resonance (NMR), size exclusion chromatography (SEC), thermogravimetric analysis (TGA), differential scanning calorimetry (DSC), tensile tests and/or dynamic mechanical analysis (DMA). The copolyester based on dimethyl bicyclo[2.2.2]octane-1,4-dicarboxylate (DMCD-2) was observed to have a higher Tg, about 115 ºC, than the other copolyesters with the same compositions in this study. For copolyesters containing different compositions of dimethyl-1,4-cyclohexane dicarboxylate (DMCD) and DMCD-2, the Tg increased linearly with the increase of DMCD-2 mole content. DMA showed that all of the cycloaliphatic copolyesters had secondary relaxations, resulting from conformational transitions of the cyclohexylene rings. The polyester based on DMCD-3 in the hydrolytic tests underwent the fastest hydrolytic degradation among these samples. A new triptycene diol (TD) was synthesized and incorporated into a series of cycloaliphatic copolyester backbones by melt condensation polymerization. -

Copper ( II ) Chloride

Copyright © Tarek Kakhia. All rights reserved. http://tarek.kakhia.org Copper Contents 1 Introduction 2 History o 2.1 Copper Age o 2.2 Bronze Age o 2.3 Antiquity and Middle Ages o 2.4 Modern period 3 Characteristics o 3.1 Color o 3.2 Group 11 of the periodic table o 3.3 Occurrence o 3.4 Mechanical properties o 3.5 Electrical properties o 3.6 Corrosion . 3.6.1 Pure water and air/oxygen . 3.6.2 In contact with other metals . 3.6.3 Sulfide media . 3.6.4 Ammonia media . 3.6.5 Chloride media o 3.7 Germicidal effect o 3.8 Isotopes 4 Production 5 Applications o 5.1 Piping o 5.2 Electrical applications o 5.3 Architecture / Industry o 5.4 Household products o 5.5 Coinage o 5.6 Biomedical applications o 5.7 Chemical applications o 5.8 Other 6 Alloys 7 Compounds 8 Biological role 9 Recycling 1 Copyright © Tarek Kakhia. All rights reserved. http://tarek.kakhia.org 1 Introduction : Copper is a chemical element with the symbol Cu ( Latin : cuprum ) and atomic number 29 . It is a ductile metal with very high thermal and electrical conductivity. Pure copper is rather soft and malleable and a freshly - exposed surface has a pinkish or peachy color. It is used as a thermal conductor, an electrical conductor, a building material, and a constituent of various metal alloys. Copper metal and alloys have been used for thousands of years. In the Roman era, copper was principally mined on Cyprus, hence the origin of the name of the metal as Cyprium, "metal of Cyprus", later shortened to Cuprum. -

![United States Patent [191 [11] Patent Number: 4,605,812 Nowack Et A1](https://docslib.b-cdn.net/cover/1920/united-states-patent-191-11-patent-number-4-605-812-nowack-et-a1-1621920.webp)

United States Patent [191 [11] Patent Number: 4,605,812 Nowack Et A1

United States Patent [191 [11] Patent Number: 4,605,812 Nowack et a1. [45] Date of Patent: Aug. 12, 1986 [54] PROCESS FOR REMOVAL OF ARSENIC 4,532,115 7/ 1985 Nishino et a1. .................... .. 423/210 FROM GASES FOREIGN PATENT DOCUMENTS [75] Inventors: G. P. Nowack; M. M. Johnson, both 18784 V1982 J8 _ pan 208/253 °f Bamesv?le, Okla- 77627 5/1982 Japan . 423/210 [73] Assignee: Phillips Petroleum Company’ 168034 4/ 1985 Japan . 423/210 Bartlesvme’ Okla 1119720 10/1984 U.S.S.R. ............................ .. 423/210 [21] Appl‘ No’: 617,430 OTHER PUBLICATIONS [22] Filed: Jun_ 5, 1984 “Reactions of Hydrogen with Organic Compounds - Over Copper-Chrommm Ox1de and Nickel Catalysts”, [51] Int. C1.4 ..................... .. C07C 7/148; C10G 29/04 H. Adkins’ 1937, pp. 11_25~ [52] U.S. C1. .................................. .. 585/845; 423/210; “Girdler Catalysts», Girdler Chemical’ Inc" Louisville, [58] Field of Search """" “Advanced Inorganic Chemistry”, F. A. Cotton and G. ’ ’ Wilkinson, Second Edition, 1966, p. 823. [56] References Cited Kirk-Othmer, “Encyclopedia of Chemical Technol P ogy”,“Comprehenslve V01. 3, InorganicEdltlOll, Chem1stry”, J. andC. Bailar et 2,511,2882,513,508 7/19506/1950 M01111]Mornll et6t 81.a1. ....................... ... 252/447252/431 a] " ’ pp ' ' 2,781,297 2/1957 Appell ...... .. 208/253 P - - _ H_ 2,920,050 1/1960 Blacet et a1. 252/447 Ag'flwgztlglféggrlggggMygsetz 3,112,998 12/1963 Grosskopf.. 23/254 Attome em or Firm~K K B and 3,542,669 11/1970 DeFeo .......... .. .. 208/91 y’ g ' - - r es 3,758,606 9/1973 Horowitz et al. 585/950 ’ 3,812,652 5/1974 Carret a1 .... -

United States Patent Office Patented Oct

2,768,978 United States Patent Office Patented Oct. 30, 1956 2 with the yield. Conversion to the glycol varies almost directly with the temperature up to about 290 C. 2,768,978 The catalyst employed in this process is essentially CONTINUOUS PROCESS FOR MAKING 1,5-PEN copper chromite in which the CuO:Cr2O3 ratio may be TANEDOL FROM TETRAHYDROFURFURYL 5 varied within the limits about 40:60 to 85:15. Optimum ALCOHOL results are obtained at above about 45% Cu.O. For effec JaEmes A. Robertson, Lewiston, N.Y., assignor to E. I. du tive results catalytic pellets must be employed, powder Pont de Nemours and Company, Wilmington, Del. clogging up the reaction system. In all cases, an inor ganic binder is required to compact the chromite into No Drawing. Application August 28, 1952, O pellets. Various binders are operative for this purpose Serial No. 306,967 including silica, alumina, chromates such as magnesium chromate and silicates such as magnesium and sodium 4 Claims. (CI. 260-635) silicate. Practically all of these materials are recognized binders for catalysts and are available commercially for This invention relates to the synthesis of 1,5-pentane 5 compacting copper chromite. The particular method diol and more particularly to a continuous process for chosen for forming the pellets is not critical to this inven this synthesis. tion. One process which may be used includes pre A useful intermediate in the production of organic cipitating copper chromite from quantities of copper compounds is 1,5-pentanediol nitrate and ammonium chromite chosen to give the de 20 sired CuO:Cr2O3 ratio, adding a calculated amount of an aqueous solution of a binder Such as sodium silicate, This compound can add a reactive group at each end of , collecting the impregnated catalyst on a filter, and pel its carbon chain and thus produce linear polymers similar letizing the dry solid. -

The Copper-Catalysed Dehydrogenation of Methanol

i . THE COPPER-CATALYSED DEHYDROGENATION OF METHANOL by STEPHEN PATRICK TONNER B.Sc.(Hons.) A Dissertation submitted to the School of Chemical Engineering and Industrial Chemistry in partial fulfilment of the requirements for the degree of Doctor of Philosophy. The University of New South Wales May 1984 ii. Doctor of Philosophy (1984) University of New South Wales (School of Chemical Engineering Sydney, Australia and Industrial Chemistry) TITLE: The Copper-Catalysed Dehydrogenation of Methanol AUTHOR: Stephen Patrick TONNER, B.Sc. (Hons.), U.N.S.W. SUPERVISORS: Professor D.L. Trinm Associate Professor M.S. Wainwright NO. OF PAGES: i-xvi; 1-295. RESEARCH PUBLICATIONS: 1. Tonner, S.P., Wainwright, M.S., Trimm, D.L., and Cant, N.W., J. Chem. Eng. Data, 28, 59 (1983). 2. Tonner, S.P., Trinun, D.L., Wainwright, M.S., and Cant, N.W., J. Mol. Catal., 18, 215 (1983). 3. Evans, J.W., Tonner, S.P., Wainwright, M.S., Trimn, D.L., and Cant, N.W., Proceedings of the 11th Australian Chemical Engineering Conference, Brisbane, 509, Sept. (1983). 4. Tonner, S.P., Wainwright, M.S., Trimm, D.L., and Cant, N.W., Appl. Catal., In Press. 5. Tonner, S.P., Trinm, D.L., Wainwright, M.S., and Cant, N.W., Ind. Eng. Chem. Prod. Res. Dev., In Press. 6. Cant, N.W., Tonner, S.P., Trinm, D.L., and Wainwright, M.S., Submitted to J. Catal., April (1984). iii. CANDIDATES CERTIFICATE This is to certify that the work presented in this thesis was carried out in The School of Chemical Engineering and Industrial Chemistry University of New South Wales, and has not been submitted previously to any other university or technical institution for a degree or award. -

Tetrahydrofuhfuraldeh

TETRAHYDROFUHFURALDEHYDE AND RELATED COKPOUNDS DISSERTATION Presented in Partial Fulfillment of the Requirements for the Degree Doctor of Philosophy in the Graduate School of The Ohio State University By / ALBERT ANTOINE, B.S. The Ohio State Uhiverslty 1953 I'»*■•••* /••*** ,* • i'll* 1 • *I i• n i : - Approved bys i i ii i ii • • ♦ « » J * Adviser i ACKNOWLBDGBKBHT The author wishes to express his thanks and deep appreciation to Dr. Christopher L. Wilson for his con stant encouragement and guidance throughout the course of this work. K 1 3 6 6 6 ii TABLE OF CONTENTS Page I. INTRODUCTION 1 II. HISTORICAL 4 III. EXPERIMENTAL 8 A. Tetrahydrofurfuraldehyde 8 1. McFadyen-Stevena reaction 8 2. Roaennrund reaction 10 3* Oppenauer oxidation 12 If. Sodium trlmethoxyborohydride reduction * of tetrahydrofuroyl chloride 13 B. Preparation of tetrahydrofurfuraldehyde 15 C. Attempted rearrangement of tetrahydrofur furaldehyde 16 1. In ethanol, with mercuric chloride 16 2. In n-pentanol, with mercuric chloride 16 3* In ether, with phoephorua pentachloride 17 Ij.. Over acid-aaturated pumice 17 D. Preparation of a&hydroxyraleraldehyde 18 B. Preparation of glutaraldehyde 19 F. Pyrolyaia apparatua 20 1. Catalyata 20 2, Furnace 20 3« Catalyat tube 20 H i TABLE OP CONTENTS (continued) Page i|.. Constant rate addition funnel 22 5>. Control of a carrier gas 22 6. Activation of the catalyst 22 G, Behaviour of proposed intermediates in lactone formation 23 1. Tetrahydrofurfuraldehyde over 90Cu, lOPe catalyst 23 2* Dihydropyran and water over 90Cu, lOPe catalyst 26 3. c^Hy dr oxyvaloraldehyde over 90Cu, lOPe oatalyst 27 Ij.. ^Hydroxyvaleraldehyde over copper chromite catalyst 31 5. -

Synthesis and Structural Characterization of Cu-Cr Catalysts for Cumene Alkylation

Synthesis and structural characterization of Cu-Cr catalysts for cumene alkylation. I.M. Sinev 1, O. Shutkina 2, W.Grünert 1, I. Ivanova 2 1 Lehrstuhl Technische Chemie, Ruhr-Universität Bochum, 44780 Bochum, Germany 2Department of Chemistry, Moscow State University Copper chromite (CuCr 2O4) has been recently described as an effective catalyst for a broad range of industrially important processes like alcohol dehydrogenation [1] and hydrogenolysis [2]. Partial (reversible) reduction considerably changes its catalytic properties: the reduced form is much more active in acetone hydrogenation [3]. It was observed by HRTEM that after reduction at 250-320 oC reduced copper forms a Cu(0) phase epitaxially related to the spinel structure, which is not destroyed by the reduction. Inelastic neutron scattering indicated that protons oc- cupy positions in the spinel structure vacated by the Cu ions, thus forming acidic sites. In-situ pyridine FTIR spectra show bands between 1400 and 1610 cm -1 from both Brønsted and Lewis acidic sites [3]. Thus, reduced copper-chromite potentially offers two types of active sites – metallic copper and proton substituted spinel. On this basis, the present study aims at creating an effective and stable catalyst for the one-pot synthesis of cumene from benzene and acetone (eq. (1)), in which the two steps required – acetone hydrogenation to isopropanol, which subse- quently alkylates the benzene, proceed over one – bifunctional - catalyst. This catalyst should offer sites for selective hydrogenation (of acetone, in presence of benzene) and acidic sites for alkylation. As described above copper chromite potentially fits these requirements. To enhance the alkylation activityit may be deposited on an acidic support (e.g. -

Durham E-Theses

Durham E-Theses Heterogeneous catalytic hydrogenation and purication applied to commercial processes Willett, Paul How to cite: Willett, Paul (2002) Heterogeneous catalytic hydrogenation and purication applied to commercial processes, Durham theses, Durham University. Available at Durham E-Theses Online: http://etheses.dur.ac.uk/4099/ Use policy The full-text may be used and/or reproduced, and given to third parties in any format or medium, without prior permission or charge, for personal research or study, educational, or not-for-prot purposes provided that: • a full bibliographic reference is made to the original source • a link is made to the metadata record in Durham E-Theses • the full-text is not changed in any way The full-text must not be sold in any format or medium without the formal permission of the copyright holders. Please consult the full Durham E-Theses policy for further details. Academic Support Oce, Durham University, University Oce, Old Elvet, Durham DH1 3HP e-mail: [email protected] Tel: +44 0191 334 6107 http://etheses.dur.ac.uk Heterogeneous Catalytic Hydrogenation and Purification Applied to Commercial! Processes Paul Willett The copyright of this thesis rests with the author. No quotation from it should be published in any form, including Electronic and the Internet, without the author's prior written consent. All information derived from this thesis must be acknowledged appropriately. Submitted for the Degree of Doctor of Philosophy University of Durham ' Department of Chemistry 2002 1 1 JUN 2002 Intellectual Property and Confidentiality This report is covered by the agreement between Davy Process Technology and The University of Durham dated 10th June 1996. -

Homer Burton Adkins

NATIONAL ACADEMY OF SCIENCES H O M E R B U R T O N A DKINS 1892—1949 A Biographical Memoir by F A R R I N G T O N DANIELS Any opinions expressed in this memoir are those of the author(s) and do not necessarily reflect the views of the National Academy of Sciences. Biographical Memoir COPYRIGHT 1952 NATIONAL ACADEMY OF SCIENCES WASHINGTON D.C. HOMER BURTON ADKINS 1892-1949 BY FARRINGTON DANIELS Organic chemistry in the United States underwent an extraordinary expansion in the three decades which included the two world wars. This period of development was character- ized by a rapid increase of laboratory knowledge which was quickly applied to industry; and also by a large expansion in the number of organic chemists who had graduate training in research. Among the pioneering and influential leaders of this period was Homer Adkins, whose death on August 10, 1949, at the age of fifty-seven came as a shock to his many friends. He was the world's authority on hydrogenation of organic compounds; he made important laboratory contributions to the mechanisms of catalyzed reactions of organic chemistry and he led the teaching of organic chemistry at the University of Wisconsin for thirty years, during which time he trained over one hundred Ph.D. students who are now in positions of responsibility and leadership in industry and education. He belonged to the close-knit group of leaders including Adams, Conant, Gilman, Marvel, Whitmore and others who did much to influence the course of organic chemistry throughout the second quarter of the twentieth century. -

Catalytic Hydrogenation of Furfural and Furfuryl Alcohol to Fuel Additives and Value-Added Chemicals

Turkish Journal of Chemistry Turk J Chem (2019) 43: 24 – 38 http://journals.tubitak.gov.tr/chem/ © TÜBİTAK Review Article doi:10.3906/kim-1808-47 Catalytic hydrogenation of furfural and furfuryl alcohol to fuel additives and value-added chemicals Obaid ALDOSARI1;2;∗,, Hamed ALSHAMMARI3,, Mosaed ALHUMAIMESS4,, Ibrahim WAWATA5, 1Department of Chemistry, College of Science and Human Studies at Hautat Sudair, Majmaah University, Majmaah, Saudi Arabia 2Department of Chemistry, College of Science and Humanities, Prince Sattam bin Abdulaziz University, Alkharj, Saudi Arabia 3Department of Chemistry, Faculty of Science, Ha’il University, Ha’il, Saudi Arabia 4Department of Chemistry, College of Science, Jouf University, Sakaka, Saudi Arabia 5Department of Pure and Applied Chemistry, Kebbi State University of Science and Technology, Aliero, Nigeria Received: 16.08.2018 • Accepted/Published Online: 23.10.2018 • Final Version: 05.02.2019 Abstract: The selective hydrogenation of furfural and furfuryl alcohol at different temperatures has been studied using several catalysts. The effect of various reaction conditions (pressure, catalyst amount, and solvent) was studied. We have shown that Pd/TiO 2 catalysts can be very effective for the synthesis of 2-methylfuran at room temperature. Using octane as a solvent, the solvent effectiveness was investigated and showed actively high selectivity towards 2-methylfuran and furfuryl alcohol, but there were many byproducts that were still noticed. Although adding Ru to the Pd/TiO 2 catalyst contributed to reducing the catalytic activity, this addition improved the selectivity to 2-methylfuran and furfuryl alcohol with decreased byproduct formation. The Ru/Pd variation demonstrated a considerable influence on the selectivity. While adding a small amount of Ru (1 wt.%) shifted the selectivity towards 2-methylfuran and furfuryl alcohol, increment of the Ru ratio reduced the catalytic activity and revealed very poor selectivity towards 2-methylfuran. -

United States Patent (19) 11 Patent Number: 4,935,556 Pohl Et Al

United States Patent (19) 11 Patent Number: 4,935,556 Pohl et al. 45 Date of Patent: Jun. 19, 1990 54 ACID-RESISTANT CATALYSTS FOR THE 58) Field of Search ......................................... 568/885 DRECT HYDROGENATION OF FATTY ACDS TO FATTY ALCOHOLS (56) References Cited 75) Inventors: Joachim Pohl, Duesseldorf; U.S. PATENT DOCUMENTS 2,109,844 3/1938 Lazier ................................. 568/885 Franz-Josef Carduck, Haan; Gerd Goebel, Erkrath, all of Fed. Rep. of 4,524,225 6/1985 Qualeatti et al. .................... 568/885 Germany 4,804,790 2/1989 Schuett ............................... 568/885 73 Assignee: Henkel Kommanditgesellschaft auf FOREIGN PATENT DOCUMENTS Aktien, Duesseldorf, Fed. Rep. of 1159925 12/1963 Fed. Rep. of Germany ...... 508/885 Germany 8203 1/1976 Japan ................................... 568/885 21 Appl. No.: 356,476 768199 2/1957 United Kingdom ................ 568/885 Primary Examiner-J. E. Evans 22 Filed: May 24, 1989 Attorney, Agent, or Firm-Ernest G. Szoke; Wayne C. Related U.S. Application Data Jaeschke; Real J. Grandmaison 62 Division of Ser. No. 162,537, Mar. 1, 1988, Pat. No. 57 ABSTRACT 4,855,273. Process for the production of a new copper (II) chro 30 Foreign Application Priority Data mite spinel catalyst using colloidal silica gel and to its use for the direct fixed-bed hydrogenation of fatty acids Mar. 2, 1987 DE Fed. Rep. of Germany ....... 37O6658 to fatty alcohols of corresponding chain length. 51) Int. Cl.................... CO7C29/136; C07C31/125 52 U.S. C. .................................................... 568/885 22 Claims, No Drawings 4,935,556 1. 2 and/or unsaturated fatty alcohols (cf. for example U.S.