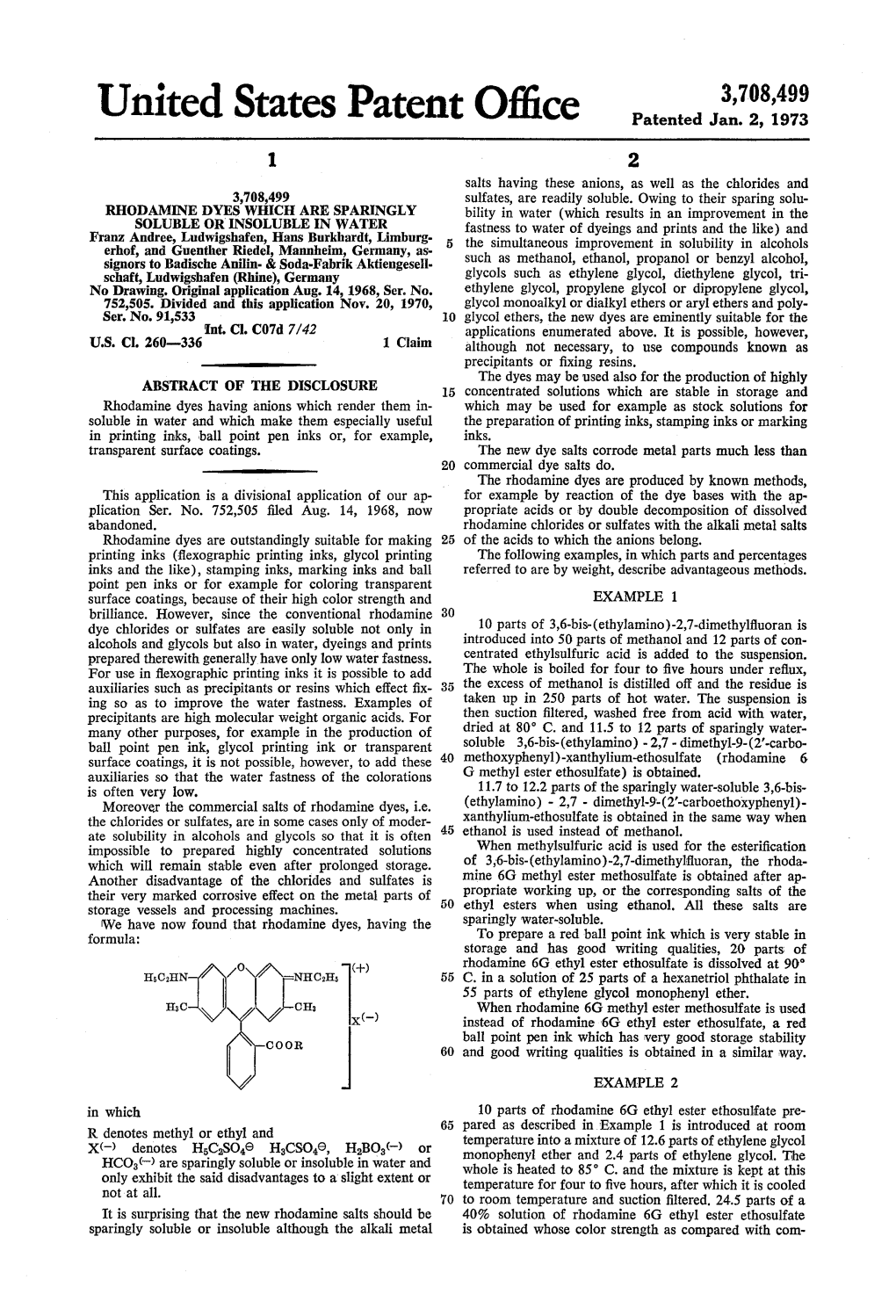

United States Patent Office Patented Jan

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

36Th ITC Report

Thursday August 17, 1995 Part V Environmental Protection Agency Thirty-Sixth Report of the TSCA Interagency Testing Committee to the Administrator; Receipt of Report, Request for Comments, Solicitation of Use and Exposure Data; Notice federal register 42981 42982 Federal Register / Vol. 60, No. 159 / Thursday, August 17, 1995 / Notices ENVIRONMENTAL PROTECTION comments and data in electronic form ``OPPTS±41043'' (including comments AGENCY must be identified by the docket number and data submitted electronically as OPPT±41043. No CBI should be described below). A public version of [OPPTS±41043; FRL±4965±6] submitted through e-mail. Electronic this record, including printed, paper Thirty-Sixth Report of the TSCA comments on this notice may be filed versions of electronic comments, which Interagency Testing Committee to the online at many Federal Depository does not include any information Administrator; Receipt of Report, Libraries. Additional information on claimed as confidential business Request for Comments, Solicitation of electronic submissions can be found in information (CBI), is available for Use and Exposure Data Unit III of this document. inspection from 12 noon to 4 p.m., FOR FURTHER INFORMATION CONTACT: Monday through Friday, excluding legal AGENCY: Environmental Protection Susan B. Hazen, Director, holidays. The public record is located in Agency (EPA). Environmental Assistance Division the TSCA Nonconfidential Information ACTION: Notice. (7408), Office of Pollution Prevention Center, Rm. NE-B607, 401 M St., SW., and Toxics, Environmental Protection Washington, DC 20460. SUMMARY: The TSCA Interagency Agency, 401 M Street, SW., Rm. E± Electronic comments can be sent Testing Committee (ITC), established 543B, Washington, DC 20460, (202) directly to EPA at: under section 4(e) of the Toxic 554±1404, TDD (202) 554±0551, [email protected] Substances Control Act (TSCA), Internet: TSCA- transmitted its Thirty-Sixth Report to [email protected]. -

![Dipropylene Glycol Ethyl Ether (DPGEE) [Ethyl DIPROXITOL] Product Stewardship Summary December 2017](https://docslib.b-cdn.net/cover/6544/dipropylene-glycol-ethyl-ether-dpgee-ethyl-diproxitol-product-stewardship-summary-december-2017-66544.webp)

Dipropylene Glycol Ethyl Ether (DPGEE) [Ethyl DIPROXITOL] Product Stewardship Summary December 2017

DiPropylene Glycol Ethyl Ether (DPGEE) [Ethyl DIPROXITOL] Product Stewardship Summary December 2017 DiPropylene Glycol Ethyl Ether (DPGEE) [Ethyl DIPROXITOL] Product Stewardship Summary (CAS number 30025-38-8) Chemical Formula for DPGEE C8H18 O3 What is DPGEE? DPGEE is a glycol ether based on Propylene oxide and ethanol. It is a speciality solvent having a bi- functional nature (ether-alcohol). It is a clear liquid with an ethereal odour. The Shell Chemicals range of Propylene oxide-based glycol ethers are sold under the trade name PROXITOL. How is DPGEE Used? It is used as an intermediate and in formulations in industrial, professional or consumer applications, mainly in surface coatings and printing inks and paints, cleaners, agrochemical or de-icing/anti-icing formulations. Health, Safety and Environmental Considerations DPGEE is flammable liquids with a flashpoint of 180 0F/82 0C. DPGEE is an isomer mix, of which the main component is 1-Ethoxypropanol-2 (typically 98% or more). Shell PROXITOLs are not classified as carcinogens or mutagens, are not expected to cause cancer in humans, nor do they impair fertility or damage the developing foetus. DPGEE is of low toxicity towards aquatic organisms. They are completely miscible with water, biodegradable and not expected to bio-accumulate. Storing and Transporting DPGEE DPGEE is transported by tank truck, rail car and vessel, primarily in bulk quantities, but also as packed product. Due to its flammability, they are classified as hazardous for transport under transport regulations. Glycol Ethers should be stored at ambient temperatures away from sources of ignition and substances with oxidising or corrosive properties. -

R Graphics Output

Dexamethasone sodium phosphate ( 0.339 ) Melengestrol acetate ( 0.282 ) 17beta−Trenbolone ( 0.252 ) 17alpha−Estradiol ( 0.24 ) 17alpha−Hydroxyprogesterone ( 0.238 ) Triamcinolone ( 0.233 ) Zearalenone ( 0.216 ) CP−634384 ( 0.21 ) 17alpha−Ethinylestradiol ( 0.203 ) Raloxifene hydrochloride ( 0.203 ) Volinanserin ( 0.2 ) Tiratricol ( 0.197 ) trans−Retinoic acid ( 0.192 ) Chlorpromazine hydrochloride ( 0.191 ) PharmaGSID_47315 ( 0.185 ) Apigenin ( 0.183 ) Diethylstilbestrol ( 0.178 ) 4−Dodecylphenol ( 0.161 ) 2,2',6,6'−Tetrachlorobisphenol A ( 0.156 ) o,p'−DDD ( 0.155 ) Progesterone ( 0.152 ) 4−Hydroxytamoxifen ( 0.151 ) SSR150106 ( 0.149 ) Equilin ( 0.3 ) 3,5,3'−Triiodothyronine ( 0.256 ) 17−Methyltestosterone ( 0.242 ) 17beta−Estradiol ( 0.24 ) 5alpha−Dihydrotestosterone ( 0.235 ) Mifepristone ( 0.218 ) Norethindrone ( 0.214 ) Spironolactone ( 0.204 ) Farglitazar ( 0.203 ) Testosterone propionate ( 0.202 ) meso−Hexestrol ( 0.199 ) Mestranol ( 0.196 ) Estriol ( 0.191 ) 2,2',4,4'−Tetrahydroxybenzophenone ( 0.185 ) 3,3,5,5−Tetraiodothyroacetic acid ( 0.183 ) Norgestrel ( 0.181 ) Cyproterone acetate ( 0.164 ) GSK232420A ( 0.161 ) N−Dodecanoyl−N−methylglycine ( 0.155 ) Pentachloroanisole ( 0.154 ) HPTE ( 0.151 ) Biochanin A ( 0.15 ) Dehydroepiandrosterone ( 0.149 ) PharmaCode_333941 ( 0.148 ) Prednisone ( 0.146 ) Nordihydroguaiaretic acid ( 0.145 ) p,p'−DDD ( 0.144 ) Diphenhydramine hydrochloride ( 0.142 ) Forskolin ( 0.141 ) Perfluorooctanoic acid ( 0.14 ) Oleyl sarcosine ( 0.139 ) Cyclohexylphenylketone ( 0.138 ) Pirinixic acid ( 0.137 ) -

Pesticides and Toxic Substances

UNITED STATES ENVIRONMENTAL PROTECTION AGENCY WASHINGTON, D.C. 20460 OFFICE OF PREVENTION, PESTICIDES AND TOXIC SUBSTANCES CERTIFIED MAIL Dear Registrant: This is to inform you that the Environmental Protection Agency (hereafter referred to as EPA or the Agency) has completed its review of the available data for the antimicrobials propylene glycol and dipropylene glycol. The Reregistration Eligibility Decision (RED) was approved in the form of a decision memorandum which summarized the regulatory decision for propylene glycol and dipropylene glycol on September 30, 2004. Based on its review, EPA is now publishing its Reregistration Eligibility Decision (RED) for propylene glycol and dipropylene glycol and its associated human health and environmental risks. A Notice of Availability will be published in the Federal Register announcing the publication of the RED. The RED and supporting documents for propylene glycol and dipropylene glycol will be available to the public in EPA’s Pesticide Docket EPA-HQ-OPP-2006-0831 at: www.regulations.gov. Please note that the attached RED document pertains only to propylene glycol and dipropylene glycol. This RED presents the Agency’s conclusions on the dietary, drinking water, occupational and ecological risks posed by exposure to propylene glycol or dipropylene glycol alone. This document also contains product-specific data that the Agency intends to require in Data Call-Ins (DCIs). Note that DCIs, with all pertinent instructions, will be sent to registrants at a later date. Currently, there are no generic data requirements. Additionally, for product- specific DCIs, the first set of required responses will be due 90 days from the receipt of the DCI letter. -

The Toxicology of Glycol Ethers and Its Relevance to Man (Fourth Edition) Volume I

The Toxicology of Glycol Ethers and its Relevance to Man (Fourth Edition) Volume I Technical Report No. 95 ISSN-0773-8072-95 Brussels, February 2005 The Toxicology of Glycol Ethers and its Relevance to Man ECETOC TECHNICAL REPORT No. 95 © Copyright – ECETOC AISBL European Centre for Ecotoxicology and Toxicology of Chemicals 4 Avenue E. Van Nieuwenhuyse (Bte 6), B-1160 Brussels, Belgium. All rights reserved. No part of this publication may be reproduced, copied, stored in a retrieval system or transmitted in any form or by any means, electronic, mechanical, photocopying, recording or otherwise without the prior written permission of the copyright holder. Applications to reproduce, store, copy or translate should be made to the Secretary General. ECETOC welcomes such applications. Reference to the document, its title and summary may be copied or abstracted in data retrieval systems without subsequent reference. The content of this document has been prepared and reviewed by experts on behalf of ECETOC with all possible care and from the available scientific information. It is provided for information only. ECETOC cannot accept any responsibility or liability and does not provide a warranty for any use or interpretation of the material contained in the publication. ECETOC TR No. 95 The Toxicology of Glycol Ethers and its Relevance to Man The Toxicology of Glycol Ethers and its Relevance to Man CONTENTS - VOLUMES I AND II EXECUTIVE SUMMARY 1 SUMMARY AND CONCLUSIONS 3 Recommendations for further work 13 1. INTRODUCTION 14 1.1 Conversion factors and physico-chemical properties 14 1.2 Production and use 14 1.2.1 Manufacture of ethylene-series glycol ethers 14 1.2.2 Manufacture of propylene-series glycol ethers 15 1.2.3 Uses 15 2. -

Formulating Water-Based Systems Y,Ith Propylene-Oxide Based Glycol Ethers

Formulating Water-Based Systems y,ith Propylene-Oxide Based Glycol Ethers Carmen l. Rodriguez and Julia Weathers-lyondell Chemical Company· Bernadette Corujo-Engineered Polymer Solutions Patricia Peterson-Avecia To camply with environmental regulations, formulators have reformulated to water-based systems using non-hazardous air pollutants (non-HAP) cosolvents and developed new resin technology. In fully formulated water-based systems, however, changing the solvent system to meet environmental regulations has wide ranging effects on viscosity, surface defects, film shrinkage, adhesion, and durability. Formulators often adjust paint viscosity by balancing the levels of cosolvents, surfactants, and rheology modifiers. Reformulating with non-HAPs solvents such as propylene oxide-based glycol ethers (PG-glycol ethers) helps reduce volah1e organic content WOC) to meet environmental compliance and eliminates HAPs reporting requirements. When replacing ethylene oxide-based glycol ethers (EG-glycol ethers) with their PG-glycol ethers, reformulation seems simple enough, particularly if evaporation rates and solubility parameters are matched. A drop-in replacement, however, requires optimization. This study compares the use ofPG-glycol ethers in four architectural latex paints and assesses their effects on rheology, drying, and some key performance attributes. INTRODUCTION ing a suitable coalescent solvent for a solvent in the filmis stronglydependent waterborne coating.1 However, chang on the end use. The principal positive The primary reason for reformulating a ing the solvent package in a coating for effect of solvent entrapment is the in solventsystemis to meet environmental mulation may also necessitate optimiza creased fleXIbility of the cured coating compliance in volatile organic content tion of the other paint components. and possibly superior cure. -

Page 1 of 43 RSC Advances

RSC Advances This is an Accepted Manuscript, which has been through the Royal Society of Chemistry peer review process and has been accepted for publication. Accepted Manuscripts are published online shortly after acceptance, before technical editing, formatting and proof reading. Using this free service, authors can make their results available to the community, in citable form, before we publish the edited article. This Accepted Manuscript will be replaced by the edited, formatted and paginated article as soon as this is available. You can find more information about Accepted Manuscripts in the Information for Authors. Please note that technical editing may introduce minor changes to the text and/or graphics, which may alter content. The journal’s standard Terms & Conditions and the Ethical guidelines still apply. In no event shall the Royal Society of Chemistry be held responsible for any errors or omissions in this Accepted Manuscript or any consequences arising from the use of any information it contains. www.rsc.org/advances Page 1 of 43 RSC Advances Sol-gel based simonkolleite nanopetals with SnO2 nanoparticles in graphite-like amorphous carbon as efficient and reusable photocatalyst Moumita Pal, Susanta Bera and Sunirmal Jana* Sol-Gel Division CSIRCentral Glass and Ceramic Research Institute (CSIRCGCRI) 196 Raja S.C. Mullick Road, P.O. Jadavpur University, Kolkata 700032, India Abstract We report a new sol-gel nanocomposite (STC) having simonkolleite nanopetals (SC) and quasi-spherical tin oxide (SO) nanoparticles embedded in graphite-like amorphous carbon (C) as an efficient and reusable photocatalyst towards degradation of Rhodamine 6G (Rh 6G) dye under UV (, 254 nm) illumination. -

Synthesis and Characterization of Ph-Sensitive Rhodamine 6G Spirolactam Structures

W&M ScholarWorks Undergraduate Honors Theses Theses, Dissertations, & Master Projects 5-2015 Synthesis and Characterization of pH-Sensitive Rhodamine 6G Spirolactam Structures Grace H. Taumoefolau Follow this and additional works at: https://scholarworks.wm.edu/honorstheses Part of the Organic Chemistry Commons, and the Other Chemistry Commons Recommended Citation Taumoefolau, Grace H., "Synthesis and Characterization of pH-Sensitive Rhodamine 6G Spirolactam Structures" (2015). Undergraduate Honors Theses. Paper 220. https://scholarworks.wm.edu/honorstheses/220 This Honors Thesis is brought to you for free and open access by the Theses, Dissertations, & Master Projects at W&M ScholarWorks. It has been accepted for inclusion in Undergraduate Honors Theses by an authorized administrator of W&M ScholarWorks. For more information, please contact [email protected]. Table of Contents Page Table of Contents ii List of Figures and Tables iii Abstract 5 Acknowledgements 6 Introduction 8 Results and Discussion Chapter I: Optimization of R6G derivatives Reaction Conditions 14 Chapter II: Characterization of di-ortho R6G Derivatives 30 Chapter III: Attempt at achieving RB and R6G FRET 44 Experimental 57 References 66 Appendix 68 List of Figures and Tables Page Figure 1 Jablonski Diagram of Fluorescence 9 Figure 2 Fluorescence Excitation (Absorption) and Emission Spectra 9 Figure 3 Rhodamine B and Rhodamine 6G 10 Figure 4 Yuan’s RSL compounds ethanol and adamantyl substituted R6G 11 Figure 5 Rhodamine 6G with the functional group at the upper ring system altered from an ethyl acetate to a carboxylic acid (shorthand, R6G-acid) 15 Figure 6 R6G-Acid salt, with the quaternary ammonium cation at the xanthene core 17 Figure 7 Aromatic region in the NMR of R6G-dMA before the alumina column 26 Figure 8 Aromatic region in the NMR of R6G-dMA byproduct 26 Figure 9 An example of an oxidized amine due to alumina 27 Figure 10 NMR spectra of R6G-aniline. -

Polarized Stimulated Emission Depletion Studies of Two-Photon Excited States

Polarised Stimulated Emission Depletion Studies of Two-Photon Excited States D. A. Armoogum, R. J. Marsh and A. J. Bain+ Department of Physics & Astronomy, University College London, Gower Street, London WC1E 6BT, UK ABSTRACT Stimulated emission depletion (STED) population and polarisation dynamics following two-photon excitation are investigated for rhodamine 6G in ethylene glycol. Time resolved fluorescence intensity and polarisation measurements were made using picosecond time-correlated single photon counting (TCSPC). Cross-sections for the stimulated transition were measured between 614nm (2.32×10-16 cm2) and 663.5nm (6.05×10 –17 cm2), ground state vibrational lifetimes were found to vary between 314fs and 467fs. A collinear (180°) excitation-detection geometry was employed to investigate re-polarisation of the excited state array yielding fluorescence anisotropies above the two-photon limit. The circumvention of single-photon selection rules is demonstrated allowing the measurement of higher order parameters and correlation functions that are wholly inaccessible to ‘conventional’ (spontaneous) time resolved fluorescence techniques. Key words: Stimulated emission depletion, vibrational relaxation, two-photon, polarisation, selection rules. 1. INTRODUCTION Stimulated emission depletion (STED) of excited states has proved to be both a valuable tool in high resolution molecular spectroscopy1, in time resolved spectroscopy as a means of orientational photoselection2 and in the study of ultrafast vibrational relaxation within electronic ground states3. There has been considerable interest in the use of single- photon STED in fluorescence microscopy4 where sub-wavelength image resolution has been recently demonstrated5. Recent work in our laboratory6,7 has demonstrated the feasibility of performing STED in two-photon excited states. In this work femtosecond two-photon 800nm excitation (PUMP) of the widely used fluorescent probe fluorescein was followed by picosecond stimulated emission depletion (DUMP) of the excited state at 580nm. -

Rhodamine 6G*

2150 Bixby Road Lockbourne, OH 43137 Tel: 614.492.5610 E-mail: [email protected] www.exciton.luxottica.com Rhodamine 6G* Synonym: 2-[6-(ethylamino)-3-(ethylimino)-2,7-dimethyl-3H-xanthen-9-yl]-benzoic acid, ethyl ester, chloride or or perchlorate; Basic Red 1 (Rhodamine 6G = ethyl ester; Rhodamine 590 = methyl ester; to the best of our knowledge, the two esters have equivalent performance) Catalog No.: 05906 (chloride); 05905 (perchlorate) CAS No.: 989-38-8 (05906); 13161-28-9 (05905) MW: 479.02 (05906); 543.01 (05905) Chemical Formula: C28H31ClN2O3 (05906); C28H31N2O3.ClO4 (05905) Appearance: Red solid (05906); red to violet (05905) Molar Absorptivity (in ethanol): 9.70 x 104 L mole-1 cm-1 (chloride form) Structure: + C2H5NH O NHC2H5 X- CO2Et X = Cl- or ClO - 4 Lasing Wavelength Laser Dye Max. Range Pump Source Concentration Abs Fl Catalog No. (nm) (nm) (nm) Solvent (molar) -max -max ___________________________________________________________________________________________________________ Rhodamine 6G 578 565-612 FL3 Methanol 5 x 10-5 530e 556e (Available as 584 570-618 FL3 Ethanol 5 x 10-5 the Chloride, 585 562-622 FL69 Methanol 4 x 10-5 Cl, 05906; the 586 563-625 FL11 Methanol 5 x 10-5 Perchlorate, 590 FL63 Methanol 8 x 10-5 69 ClO4, 05905) 596 577-614 FL MeOH/H2O,1/3 12 -4 598 577-625 FL MeOH/H2O,1/1 1.3 x 10 188 -4 590-610 FL -cyclodextrin/H2O 2.3 x 10 63 -4 600 FL 4% LO/H2O 1.2 x 10 12 -4 610 585-633 FL 4% LO/H2O 1.3 x 10 606 FL (Triaxial) 227 Acrylic Copolymer 1 x 10-4 580 KrF(248)44 Ethanol 1 x 10-3 590 KrF(248)46 -

Glycol Ether DPM CAS No

Dipropylene Glycol (Mono) Methyl Ether Glycol Ether DPM CAS No. 34590-94-8 Molecular Weight = 148.2 Description Glycol Ether DPM is a colorless, liquid with low toxicity having a mild, pleasant odor. It is completely water soluble, miscible with a number of organic solvents and has good solvency for a number of substances. Product Chemical Name Methoxy Propoxy Propanol Identification Chemical Family Propylene Glycol Ether Other Names DPG Methyl Ether Dipropylene Glycol Methyl Ether Dipropylene Glycol Mono Methyl Ether Chemical Formula…………………………C7H16O3 Property Acidity, wt. % as 0.01 Acetic acid, max. Water, Wt. %, max. 0.15 Color, APHA, max. 10 GC Purity, Wt. %, min. 99.0 Appearance Clear For the most current product specification, please call 1-888-777-0232 or your local sales contact. Typical Density (pounds per gallon at 25°C) 7.9 Properties Distillation @ 760mm Hg IBP, min 180°C DP, max 195°C Evaporation Rate (BuAc = 100) 2 Flash Point (Tag Closed Cup) C(°F) 75(176) Solubility by weight in water at 20°C Complete Solubility Parameter (Total Hansen) 10.0 Specific Gravity @25/25°C 0.949-0.960 Surface Tension (Dynes/cm) @ 25°C (77°F) 28 Refractive Index @ 25° (77°F) 1.422 Viscosity (centistokes) @ 25° (77°) 3.6 Vapor Pressure @ 25°C (mm Hg) 0.2 Applications Coatings: Glycol Ether DPM provides good solvency for a wide variety of resins including acrylic, epoxies, alkyds, polyesters, nitrocellulose and polyurethanes. Glycol Ether DPM has a relatively low vapor pressure (volatility) and evaporates at a slow rate. Key properties for coating applications include complete water miscibility and good coupling ability. -

Time-Resolved Spectra of Coumarin 30-Rhodamine 6G Dye Mixture

Pram~n.a - J. Phys., Vol. 34, No. 1, January 1990, pp. 77-83. © Printed in India. Time-resolved spectra of coumarin 30-rhodamine 6G dye mixture R D SINGH, D MOHAN, A K SHARMA and N V UNNIKRISHNAN* Department of Physics, Maharshi Dayanand University, Rohtak 124001, India *Department of Material Science, Mahatma Gandhi University, Kottayam 686 562, India MS received 9 March 1989; revised 30 September 1989 Abstract. The effect of acceptor concentration on the energy transfer from Coumarin 30 (donor) to Rhodamine 6G (acceptor) has been studied. The nature of energy transfer reaction has been studied through lifetime measurements by recording the time-resolved fluorescence decay curves. The energy transfer parameters calculated were used to confirm the occurrence of energy transfer on the basis of the emission-reabsorption effect. Keywords. Time-resolved spectra; energy transfer; fluorescence; Coumarin-Rhodamine mixture. PACS No. 42"55 1. Introduction Excitation transfer in laser dye mixtures has earlier been used to achieve better dye laser performance at the desired wavelengths (Morey 1972; Drake et al 1972; Cox and Matise 1980; Berlman et al 1973). The mechanism responsible for the intermolecular singlet-singlet electronic energy transfer in dye mixture can be directly determined by lifetime measurements. The studies so far reported in this field have been based on the indirect method of optical gain studies. We have studied the energy transfer mechanism in coumarin 30-rhodamine 6G (C 30-Rh 6G) dye mixture in ethanol by using a laser fluorimeter developed in the laboratory. The dependence of lifetime on dye concentration of the two dye molecules C 30 and Rh 6G in alcoholic solutions of methanol and ethanol, and ethylene glycol has also been studied.