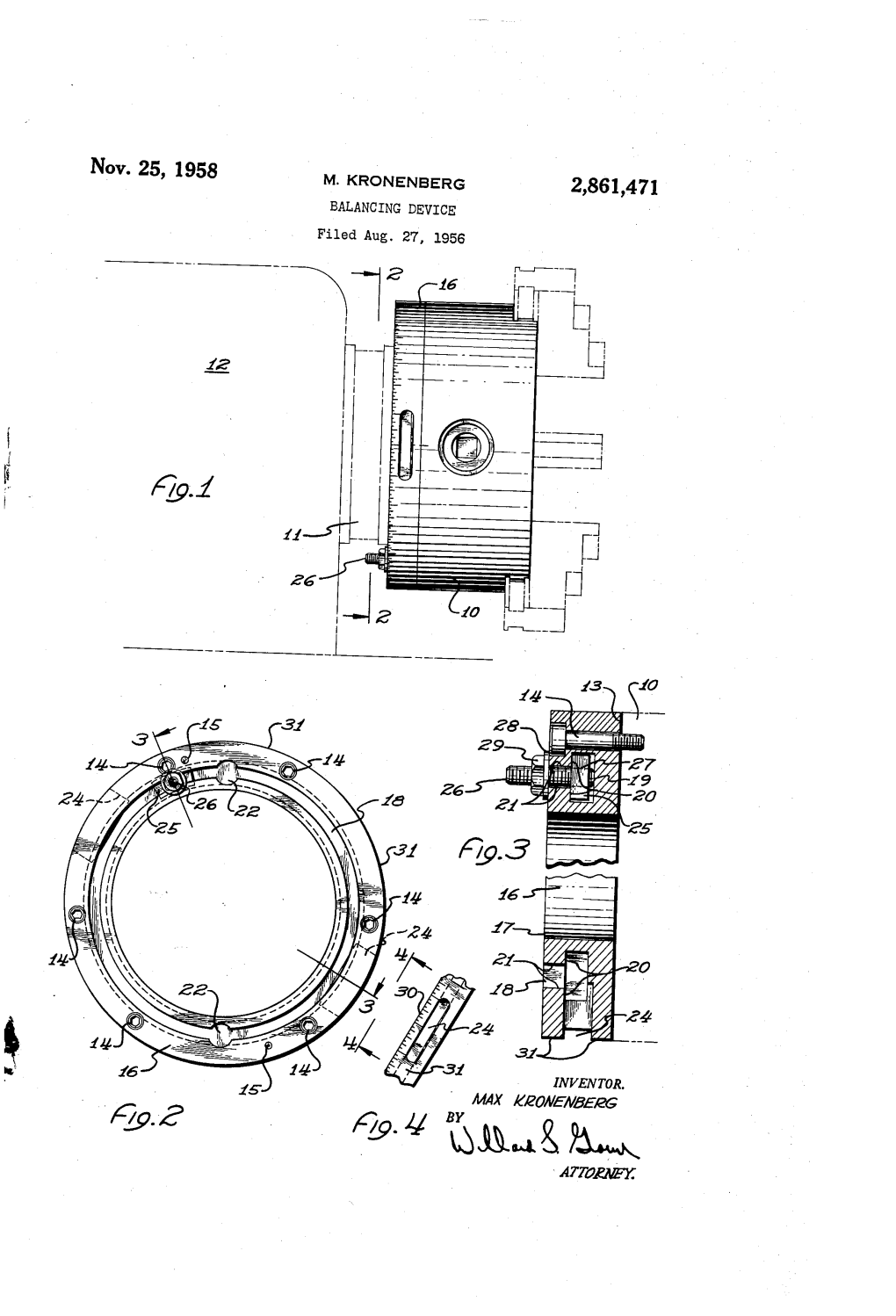

Nov. 25, 1958 M, KRONENBERG 2,861,471 BALANCING DEVICE Filed Aug

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

TRAININ' Dogs

TheThe AmericanAmerican BrittanyBrittany December 2016 • Volume LXVIII • Number 12 SSIC/C LA HA C M CK CLA G O SS P C IC O I D / D O O C N O H N S W A U H M & G I P P E C I S B O U A N O S H R I G P C B A GFC/FC/AFC Sniksoh Spank's Hank Iron Ivy SSIC/CHA A M SSIC/CH L P LA A C I C M L O I R P N I A A O S K U N H U Q S I P H H C C I B P C A B A GFC/FC/AFC Black Creek Deacon DC Mikey's Spice Girl SSIC/C SSIC LA HA LA /CH C M C A T M N P N E I P O A K I S O C N A I N S E S H H H H C I P P I C P C B B A A Marshfield, MO Marshfield, FC/AFC Hal-Js Smarteyes-Jokers EZ Ace PAID FC Kokomo Josey Joe POSTAGE Periodical B:8.75 in T:8.5 in S:7.5 in IF SOMEONE TOLD YOU THAT OF THE TOP 100 B:11.25 in T:11 in T:11 SPORTING S:10 in DOGS* EAT THE SAME BRAND OF FOOD Would you ask what it is? HELPS OPTIMIZE 30% PROTEIN / SUPPORTS HELPS KEEP OXYGEN METABOLISM 20% FAT IMMUNE SKIN & COAT FOR INCREASED HELPS MAINTAIN SYSTEM IN EXCELLENT ENDURANCE LEAN MUSCLE HEALTH CONDITION proplansport.com SOLD EXCLUSIVELY AT PET SPECIALTY RETAILERS *Based on the National, World and Invitational Champions and Purina Award Winners during the 12-month period ending December 31, 2015. -

GETTING HIS CUT Former Heavyweight Chuck Wepner Finally Got Actor Sylvester Stallone to Pay up for Using His Likeness in the Creation of the Rocky Character

GETTING HIS CUT Former heavyweight Chuck Wepner finally got actor Sylvester Stallone to pay up for using his likeness in the creation of the Rocky character. Now Hollywood is telling the story of ‘The Real Rocky’ WORDS: MARK KRAM JNR MAIN PHOTO: STEVEN HENRY huck Wepner looked better to celebrate the event and I had been than he should have, given invited to come along, given that Chuck the years of abuse that his face and I had a friendly relationship that and body had absorbed in the dated back some years. By occupation boxing ring. At 72, the 6ft 5in, a liquor salesman, Chuck eyed the clear C230-pound Wepner remained lean and liquid in the glass before me and asked, unscarred – or, shall we say, less scarred ‘Is that a martini?’ When I said that it was, than the pummelling he took during his he replied with a trace of longing in his 14-year career would have foretold. Years voice: ‘Yeah, I used to drink those until I ago, if you would have placed him side by walked into a joint one night and shot out side with some of his rivals, Sonny Liston the mirror behind the bar.’ That was back and Muhammad Ali, you would have during his wild, pre-prison days, which called it even odds that Wepner would were not without some amusing elements have been the one who was either dead if you remove the prison sentence, the or in some steep state of physical decline. cocaine addiction that led to it, his ‘Mike follows her into the back room,’ Instead, as Liston lies in his grave and Ali divorce and assorted other problems. -

Ring Turning Chuck Instructions Optional Uses for the Ring Chuck 1

v07.18 Artisan Ring Turning Chuck Instructions Optional Uses for the Ring Chuck 1. Becuase the ring chuck is threaded 3/8"x16tpi you can use this Supplies Needed chuck for any project kit that has the same thread such as; the • Revolving Center • Ring Chuck Bushings bottle opener, pizza cutter, bottle stoppers, coffee scoop, and • Prepped Ring Blank • Eye and Ear Protection much more. Using the Ring Chuck 2. Using the ring chuck for these other projects is easy, simply use the required project bushing and thread your project 1. Before using the ring chuck make sure you have followed our blank directly onto the ring chuck and follow your project kit instructions on ring turning and have a prepped ring blank. instructions. 2. Mount the prepped ring blank on the ring chuck using the bushings. Note: For 3mm wide cores, sizes 4-7 you may need flip one of the bushings for them to mount securely. • Small Bushings fit rings 4-7 • Medium Bushings fit rings 8-11 • Large Bushings fit rings 12-16 3. Once the ring is mounted between the bushings secure them using the knurled brass nut. Bring up a revolving center for support. See Fig. 1 4. Turn the blank to your desired shape. Sand the blank through 320 grit or higher. 5. Finish the blank with your choice of finish, we recommend doing a CA finish as it will be glossy and resistant to moisture. 6. Your ring is now ready to wear! Figure 1 Ring Blank Ring Bushings Knurled Nut Ring Chuck 1-800-551-8876 www.woodturnerscatalog.com © 2018 Craft Supplies USA. -

Phillymagarticle.Pdf

1. AUTHOR 2. PHOTOGRAPHER 3. NOTES What really happened in Chuck Peruto’s house that night? 78 philadelphia september 2013 september 2013 philadelphia 79 1. It’s 10 a.m., the Saturday of Memo- English is Jaime’s second language, but he knew rial Day weekend, when he gets enough, apparently, to say: There’s a girl in your bathtub. the call. He’s at the Shore. Chuck “She’s allowed to be there,” Chuck recalls replying. is always at the Shore, particularly “That’s my girlfriend.” the first weekend of “Chuck’s season,” as But Jaime presses, tries to tell Chuck that the girl isn’t his friends call summer. This isn’t moving. Chuck remembers thinking: Please don’t let him unusual. Nor is it unusual for this tell me she’s dead. particular 58-year-old man, Chuck “Get her out of there! Pull her out! Wake her up!” Peruto Jr., a hugely suc- Chuck orders through the phone. And then Jaime tells cessful criminal defense him he thinks she may be … muerta. Now Chuck is shak- attorney and son of one of ing, crying, he’s throwing on his sweats from the floor the most esteemed law- and running to his car, he’s not believing this can be yers in Philadelphia his- happening. “What color hair does she have?” he says he tory, to be waking up to the ring of his cell phone at 10, having spent much of asked Jaime. An odd question, to say the least, but as he the previous night at the legendary beach bar that is the Princeton in Avalon. -

RENNETT-DISSERTATION-2017.Pdf

Copyright by Michael David Rennett 2017 The Dissertation Committee for Michael David Rennett certifies that this is the approved version of the following dissertation: HOW GROWN-UPS ARE BORN: THE EMERGING-ADULT GENRE AND AMERICAN FILM AND TELEVISION Committee: Thomas Schatz, Co-Supervisor Janet Staiger, Co-Supervisor Mary Celeste Kearney Mary Beltran Julia Mickenberg HOW GROWN-UPS ARE BORN: THE EMERGING-ADULT GENRE AND AMERICAN FILM AND TELEVISION by Michael David Rennett Dissertation Presented to the Faculty of the Graduate School of The University of Texas at Austin in Partial Fulfillment of the Requirements for the Degree of Doctor of Philosophy The University of Texas at Austin August 2017 Acknowledgements The idea for my dissertation started to coalesce in 2006 and developed bit-by-bit over the last eleven years. I am truly thankful for all the personal and professional support I received throughout this time to pursue my project. First, I would like to thank the members of my dissertation committee – Janet Staiger, Tom Schatz, Mary Kearney, Mary Beltrán, and Julia Mickenberg – for their hard work and insightful feedback. Janet Staiger has been instrumental in developing this project since I arrived at the University of Texas in 2011. Like any great mentor, Janet would know when I needed to meet and talk through my idea, and would know when I needed my space to write and work through each part on my own. In our meetings, Janet would facilitate deep conversations about the core issues surrounding my project and keep me focused on the media’s representations of emerging-adults. -

New Broadcast TV Series: the Good, the Bad, and the Too Bad by Steve Sternberg

March 2021 #103 __________________________________________________________________________________________ _____ New Broadcast TV Series: The Good, the Bad, and the Too Bad By Steve Sternberg Because of the pandemic, this is the first time in 30 years I haven’t seen any fall pilots and have only seen a few mid-season shows prior to their premieres. So I’m reviewing these new series after watching at least the first few episodes during their regular broadcast runs. Also due to the pandemic, many returning scripted shows didn’t premiere until January or later. These include, ABC’s The Rookie, Black-ish, Mixed-ish, NBC’s Zoey’s Extraordinary Playlist, Chicago Fire, Chicago Med, Chicago P.D., Law & Order: SVU, New Amsterdam, Good Girls, FOX’s Prodigal Son, The Resident, 9-1-1, 9-1-1: Lone Star, CW’s Batwoman, All American, Riverdale, Nancy Drew, Legacies, Charmed, Black Lightning, The Flash. Still to come this spring include, NBC’s Manifest, FOX’s The Moodys, and CW’s Legends of Tomorrow, In the Dark, and Dynasty. Here’s a look at the new broadcast series premiering so far this season: A Sternberg Report Sponsored Message The Sternberg Report ©2021 __________________________________________________________________________________________ _____ Big Sky (ABC): David E. Kelley crime drama centering around a seemingly harmless long-haul trucker (the always good Brian Geraghty) and state trooper (John Carroll Lynch) in Montana, an unlikely pair who are involved in abducting women as part of a human trafficking ring (and killing anyone who gets in their way). When teenage sisters (Natalie Alyn Lynd, Jade Pettyjohn) and a trans sex worker (Jesse James Keitel) are taken, an ex-cop and private detective (Katheryn Winnick, Kylie Bunbury) race against the clock to find the girls – bumping heads with local police along the way. -

Notes for Making Wood Rings with Stainless Steel Insert Centers

Notes for Making Wood Rings With Stainless Steel Insert Centers Background These notes describe how to make a ring with a stainless steel (SS) insert and a wood exterior band. They also include information on how to make the necessary tools and jigs that are required to turn the wood exterior band. A wooden ring without the SS insert can be made using many of the same techniques, however, the ring will be weak, even if the wood is stabilized, and probably crack either during construction or while wearing it. Also, with the SS insert, the ring can be made much thinner and is more attractive and comfortable to wear. When choosing wood for the ring, spindle blanks are best because the grain will run across the ring and there will be no end grain showing on the ring. In the case of burls, it does not matter, since there generally is no pronounced grain direction. Also, choose a wood that has a grain pattern that is small relative to the ring size, otherwise there may only be a couple of grain lines showing on the ring. Good woods also have a lot of contrast in the grain lines. Good examples are burls, dyed burls, cocobolo, zebrawood, some highly figured maple and spalted wood if the spalt lines are close together. Stainless steel inserts can be purchased on-line by searching for “stainless steel rings”. The ring blank should have a flat surface on the outside diameter. Etched decorations and grooves are OK, but beveled or decorated edges will not give a smooth edge when finishing the wood. -

Tidland Winding Solutions

TIDLAND WINDING SOLUTIONS Tidland Raptor Series Air Powered Chuck Operation and Maintenance 3.00 inch 6.00 inch EN MI 660290 1 P TABLE OF CONTENTS Table of Contents .................................................................................................................. 2 Customer Service .................................................................................................................. 2 Caution .................................................................................................................................. 3 Recommended Tools ............................................................................................................. 4 Maintenance Schedule .......................................................................................................... 4 Daily .................................................................................................................................. 4 Periodic Cleaning ............................................................................................................... 4 Complete Maintenance ...................................................................................................... 4 3" Air Powered Lug Chuck ..................................................................................................... 5 Technical Overview............................................................................................................ 5 Assembly Diagram and Parts List ..................................................................................... -

Chuck Howley

THE COFFIN CORNER: Vol. 6, Nos. 9 &10 (1984) CHUCK HOWLEY By Bob Barnett & Bob Carroll It's less than a three-hour jet flight from the hills of Appalachia to Dallas, but a million miles from pumping gas in Wheeling, W.Va., to the Ring of Honor at Texas Stadium. Chuck Howley made that trip. In 1960, he was a gas jockey in Wheeling, his short-lived pro football career apparently over, his future none too bright. That was a long drop for a guy who was one of the best all-around athletes ever to come out of West Virginia. He was used to being on top. Chuck never tried football until his junior year at Warwood High School, but by the next season he was good enough to be named all-state tackle while playing for a team that could win only three games. He also excelled at basketball, baseball, track, and public relations with an easy manner and easy smile that maintained his popularity among his classmates despite the attention he got from college recruiters. He chose West Virginia University, where he lettered in five sports: football, track, gymnastics, swimming, and wrestling. In football, he the logical successor to the All-American mantle worn earlier by Sam Huff and Bruce Bosley. He was a regular for three years at guard, center, and linebacker. The shifting of positions and WVU's mediocre records cut into his All-American notices, but the Chicago Bears made him their number one draft pick in 1958. In 1958 the Bears already had two All-Pro linebackers in Bill George and Joe Fortunato, but Chuck looked like he'd become a third until he tore up his knee. -

No. 323,279, Patented July 28, L885, Zzz

(N 0 Model,) T. H. COSTELL, O, IATHE CHUCKJAW, No. 323,279, Patented July 28, l885, Zzz/ %22 Z5 Og N. PETERs. Photo-Lithographer, Washington, D.C. UNITED STATES PATENT OFFICE, THOMAS H. COSTELLO, OF CHICAGO, ILLINOIS, ASSIGNOR TO H. H. GOSS, OF SAMIE PLACE. LATH E a CHUCK JAW. SPECIFICATION forming part of Letters Patent No. 323,279, dated July 28, 1885. Application filed May 8, 1882. (No model.) To all whon, it may concern: placing the ring with its openings e over the Beit known that I, THOMAS H. COSTELLO, projections C on the bottom of the groove; of Chicago, county of Cook, and State of Illi but, on the other hand, when it is desired to nois, have invented certain Improvements in have the ring C held in position in a higher Lathe-Chucks, of which the following is a speci plane the said projections will hold it so upon 55 fication. the ring being moved around so far that the My invention relates to certain improve body of the same will rest upon said projec ments inlathe-chucks generally, and especially tions. These openings and projections are not to Such an one as is shown and described in designed to have any agency in moving the IO the Letters Patent of the United States issued ring C and annular gear C from a higher to a to me for an improvement in lathe-chucks, lower plane, or vice versa, for in my said Let dated the 13th day of June, 1882, No. 259,291; ters Patent I have described and claimed a and my said improvement claimed herein will special device for that very purpose, but mere be fully described hereinafter with reference ly to provide the said openings or recesses into to the accompanying drawings, in which which the projections are to be received and Figurel represents a cross-section of a lathe lkept out of the Way when not in use, to raise chuck embracing my improvement in its con the annular gear C into mesh with the pinions struction, taken as indicated by the broken a upon the screw-shafts a”. -

Labours of Love: Affect, Fan Labour, and the Monetization of Fandom

Western University Scholarship@Western Electronic Thesis and Dissertation Repository 8-22-2014 12:00 AM Labours Of Love: Affect, Fan Labour, And The Monetization Of Fandom Jennifer Spence The University of Western Ontario Supervisor Dr. Susan Knabe The University of Western Ontario Graduate Program in Media Studies A thesis submitted in partial fulfillment of the equirr ements for the degree in Master of Arts © Jennifer Spence 2014 Follow this and additional works at: https://ir.lib.uwo.ca/etd Part of the Film and Media Studies Commons Recommended Citation Spence, Jennifer, "Labours Of Love: Affect, Fan Labour, And The Monetization Of Fandom" (2014). Electronic Thesis and Dissertation Repository. 2203. https://ir.lib.uwo.ca/etd/2203 This Dissertation/Thesis is brought to you for free and open access by Scholarship@Western. It has been accepted for inclusion in Electronic Thesis and Dissertation Repository by an authorized administrator of Scholarship@Western. For more information, please contact [email protected]. Labours Of Love: Affect, Fan Labour, And The Monetization Of Fandom (Thesis format: Monograph) by Jennifer Spence Graduate Program in Media Studies A thesis submitted in partial fulfillment of the requirements for the degree of Master of Arts The School of Graduate and Postdoctoral Studies The University of Western Ontario London, Ontario, Canada © Jennifer Spence 2014 Abstract Fans who launch campaigns to “save our show” or protest storytelling decisions typically see their efforts as standard fannish practices, but these “labours of love” must also be considered, as the name suggests, as labour. Using affect theory, I argue that fan activities and activism are motivated by affect, which in turn drives the affective, immaterial, and digital labour that makes up fandom. -

Chuck Episode Guide Episodes 001–091

Chuck Episode Guide Episodes 001–091 Last episode aired Friday January 27, 2012 www.nbc.com c c 2012 www.tv.com c 2012 www.nbc.com The summaries and recaps of all the Chuck episodes were downloaded from http://www.tv.com and http://www.nbc. com and processed through a perl program to transform them in a LATEX file, for pretty printing. So, do not blame me for errors in the text ^¨ This booklet was LATEXed on June 28, 2017 by footstep11 with create_eps_guide v0.59 Contents Season 1 1 1 Pilot ...............................................3 2 Chuck Versus the Helicopter . .5 3 Chuck Versus the Tango . .7 4 Chuck Versus the Wookiee . .9 5 Chuck Versus the Sizzling Shrimp . 11 6 Chuck Versus the Sandworm . 13 7 Chuck Versus the Alma Mater . 15 8 Chuck Versus the Truth . 17 9 Chuck Versus the Imported Hard Salami . 19 10 Chuck Versus the Nemesis . 21 11 Chuck Versus the Crown Vic . 23 12 Chuck Versus the Undercover Lover . 25 13 Chuck Versus the Marlin . 27 Season 2 29 1 Chuck Versus the First Date . 31 2 Chuck Versus the Seduction . 35 3 Chuck Versus the Break-Up . 39 4 Chuck Versus the Cougars . 43 5 Chuck Versus Tom Sawyer . 47 6 Chuck Versus the Ex . 51 7 Chuck Versus the Fat Lady . 55 8 Chuck Versus the Gravitron . 59 9 Chuck Versus the Sensei . 61 10 Chuck Versus the Delorean . 65 11 Chuck Versus Santa Claus . 69 12 Chuck Versus the Third Dimension . 71 13 Chuck Versus the Suburbs . 75 14 Chuck Versus the Best Friend .