Winged Screw (A) Adjusting Number of Stitches

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

INSTRUCTIONS for USING the GREIST ZIGZAG / AUTOMATIC BUTTONHOLE ATTACHMENT Model #;S 6, 7, 8, 9 &10

INSTRUCTIONS FOR USING THE GREIST ZIGZAG / AUTOMATIC BUTTONHOLE ATTACHMENT Model #;s 6, 7, 8, 9 &10 The possession of a Buttonhole Attachment is one luxury which is also an economy and sewing becomes a fascination anticipating the simplicity with which buttonholes can now be worked. You merely stitch and yet produce the very nicest buttonholes on a great variety of fabrics. There is no skill required. Your attachment furnishes the magic fingers which produce buttonholes in a fraction of the time it takes to work them by hand. They are more durable and stitches are more evenly spaced than those made by hand. SET OF TEMPLATES The Templates, which guide the stitches evenly around the entire buttonhole are furnished with the Buttonhole Attachment in the following 13 sizes: Plain buttonholes: 8mm, 10mm, 13mm, 16mm, 21mm, 22mm, 24mm, 25mm, 27mm Eylet 8mm Keyhole/ eylet buttonholes: 16mm, 22mm, 27mm To avoid any chance of confusion, in positioning the Templates, they have been designed with a larger rounded end which fits over the Pinion Gear on the underside of the attachment . To determine the Template required to make the correct size buttonhole for a flat button, place the button over the measurement line on the back of Templates. Make a sample of each size buttonhole and use it as a guide for working buttonholes to be used with irregular buttons. RELEASING RETAINER PLATE First turn Plastic Adjusting Knob on the top of the buttonholer clockwise until the Cloth Clamp is all the way forward toward you, and the Pinion Gear is at the back of the Feed Blade. -

Bm-3600 Bm-2600

BM-3600 BM -2600 BM-2600 BM-3600 Brother Brother BM-3600 35 Stitches BM-2600 25 Stitches 35 STITCHES (BM-3600) QUICK-SET BOBBIN 25 STITCHES (BM-2600) Ideal For BM-3600 I AUTOMATIC BUTTONHOLER STITCH WIDTH & NEEDLE Alterations & Repairs (1 STEP BM-3600) POSITION ADJUSTMENT BM-2600 (4 STEP BM-2600) I Garment Construction Sewing machines NEEDLE THREADER FREE ARM SEWING I Home Furnishings BM-3600 BM-2600 QUALITY FEATURES Stitch Name BM-2600 BM-3600 I 35 stitches (BM-3600) Automatic Buttonholer 4-step 1-step 25 stitches (BM-2600) Straight Stitch (Centre) ● ● I Automatic buttonholer Straight Stitch (Left) ● ● I Needle threader Straight Stitch (Right) ● ● I Quick-set top loading bobbin Zigzag Stitch ● ● I Stitch width & needle position adjustment Blind Hem Stitch ● ● I Stitch length control Shell Tuck Stitch ● ● I Free arm/flat bed convertible sewing surface Elastic Stitch ● ● I Twin needle for two-colour stitching Stretch Blind Hem Stitch ● ● I Automatic bobbin winder for fast and easy bobbin Elastic Shell Tuck Stitch ● ● winding Double Action Stitch ● ● I Accessories for zipper insertion, darning, buttonholes Bridging Stitch ● ● and button sewing included Rampart Stitch ● ● I Buttonhole fine adjustment Triangle Stitch ● ● I Thread tension control dial Triple Stretch Stitch (Centre) ● ● I Snap-on presser foot Triple Stretch Stitch (Left) ● ● I Light weight and compact size Triple Zigzag Stretch Stitch ● ● I Unit dimensions: 39.4cm 16.5cm 29.1cm Stretch Overlock Stitch ● ● I Unit weight: 5.0 kg Elastic Overlock Stitch ● ● I Shipping dimensions: -

Islander Sewing Systems: Tuesdays at Two with Janet Pray and Jessica

Islander Sewing Systems: Tuesdays at Two With Janet Pray and Jessica Johnson Index Through June 2019 Subject Type Topics Video Date Alterations Charge at least $10 to hem a pair of pants October 2, 2018 Alterations Tip If asked to hem pants or sew on a button, show the person who asked how October 2, 2018 Alterations Learn how to do alterations for any figure "flaws" and make it a priority for April 9, 2019 one's sewing education Alterations One can just say no to requests for alterations. Give the person who asks for October 2, 2018 alterations a high price; the individual will accept or say no. If one accepts alterations, do it under your conditions Batting Tip Use two layers of Insulbrite or similar batting with a silver backing, not one December 18, 2018 layer. Temporarily adher fabric to back, quilt top, and then put on the binding Bias Tape Maker Demo Make bias tape strip twice as wide as needed using iron and Simplicity Bias July 10, 2018 Tape Maker Books & DVDs Connie Crawford's Patternmaking Made Easy is a textbook, but filled with 3/27/18 & 11/13/2018 good information Books & DVDs Easy Zipper class is available online or on DVD and includes five different 4/24/18 & 8/28/2018 zipper techniques. The class is also on SewBetter.com Books & DVDs Fitting and Pattern Alteration by Elizabeth Leichty and Judith Rasband is an 5/15/2018 & 5/30/18 excellent resource, or take a class from Lorraine Henry Books & DVDs Gail Yellen's It's All About Embelishments is a good resource for decorative April 24, 2018 serger techniques. -

May 25 Online Auction

09/28/21 11:47:12 May 25 Online Auction Auction Opens: Thu, May 20 9:00pm ET Auction Closes: Tue, May 25 7:00pm ET Lot Title Lot Title 1 Smoky Mountain Propane Smoker, Works 101 Viagra Pfizer Plastic Wall Clock, Great Gag Great, Racks, Fire Box, Everything Here, Very Gift or Fun Conversation Starter in Your Man Little Wear, Good Condition, 16"W x 15"D x Cave, Very Good Working Condition, 11 1/2" x 45 1/2"H 10 1/4" 10 Combat WWII Box Set Don Congdon 1010 1795 Great Britain 1/2 Penny Paperback With Maps And Commentary WWII Four Books in Set, Very Good Condition 1011 Very Pretty Matching Silvertone Necklace and 100 Heavy Black Metal Bulldog Door Knocker, Pierced Earring Set, All New, Pretty Multi Good Condition, 5"W x 8"H Colored Hearts, 19"L Necklace, 1" Drop 1000 1967 Royal Canadian Mint Silver Proof Set Earrings With 1.1 Oz. of Silver 1012 1883 P Morgan Silver Dollar, AU 55 Cleaned 1001 Goldtone Butterfly Ring Size 9, Painted Enamel 1013 18" Silvertone Necklace With 2" Angel Pendant With CZ Accents, Stamped 925, Very Good Pin, Very Good Condition Condition 1014 1890 CC Morgan Dollar, Rare Key Date, 1002 1904-O Morgan Silver Dollar, MS63 Carson City Mint 1003 2 Piece Silvertone Fire Opal Ring Set, Size 8, 1015 30"L Silvertone Plastic Bead Necklace, Good Blue with Clear Stone, Matched Band, Stamped Condition 925, Very Good Condition 1016 Very Nice 1903 S Key Date Morgan Silver 1004 1881-S Morgan Dollar MS-63 Condition, San Dollar, Only 1,241,000 Minted, Attractive Coin Francisco Mint With Great Patina 1005 Vintage Arion Music Award Ribbon -

April 2019 S a N D I E G O Volume 39, Number 8

SUNSHINE QUILTERS OF April 2019 S A N D I E G O Volume 39, Number 8 Needle & Thimble News President’s Message I am sure that we all went home filled with quilting inspiration after the March meeting. We saw so many quilts that were quilted by our dear Judi Sample; blocks that were made at the Lyn Mann workshop; coiled rope baskets that were made after our last sew in; show and tell quilts made by members; and beautiful quilts made by our speaker, Wendy Knight. We had several visitors at our last meeting. And a great time was had by all who attended. We are in the home stretch of our guild year now. Many thanks to Susan Cox and Connie Smith who vol- unteered to serve as the nominating committee this year. We will need to fill the full slate of officers this year. The nominating committee will be looking for volunteers to fill the positions that keep our guild run- ning smoothly. Filling a position is one of the easiest ways to meet other people in the guild and develop friendships. Most of the jobs require only a minimal time commitment. And it is always wonderful to get input from new people. Please consider how you can serve. Our own Sandi Delman and Kerry Marksbury will be presenting a trunk show for our April meeting. These women make such wonderful quilts. I am sure that the meeting will be a feast for your eyes. I look forward to seeing you all at the April meeting. -

Our Annual Spring Fashions Section Facing Death, They Meet to Lift Their

Today: Our annual spring fashions section The Daily Register VOL. 99 NO.223 SHREWSBURY, N. J. TUESDAY, MARCH 29, 1977 15 CENTS Facing death, they meet to lift their spirits By LINDA ELMS At a CAP meeting last night, a psychiatric nurse, a so- seem to have passed the anger and the depression stages derstand his fears for his family's financial future. They are facing death. cial worker and American Cancer Society volunteers met and are coming into the acceptance phase. A woman who had a brain tumor removed related that Everyone Is, of course, but few of us know when, where with the four. There is a professional at all meetings. Any anger that surfaced was directed at unsympathetic she had shaken her feelings of anger at herself and fixed a or how. CAP is a project of the Monmouth County unit of the physicians and/or relatives, friends who will not grasp the fancy meal recently, something she has not done for years. Terminal cancer patients have the edge there. They American Cancer Society* The county is the second in the reality of the death that the patient wants desperately to She said it is Important to be valuable to her family while know the parameters of their lives. The details of death for state to form such groups and hopes to include Ocean Coun- talk about. she lives. them are not totally predictable, but there Is a pattern of ty residents in Us plans. "Cancer that has spread precipitates a crisis that can de- " Why mer I asked myself at first," Mr. -

Comox Valley Schoolhouse Quilters' Guild

Comox Valley Schoolhouse Quilters September 2009 Comox Valley Inside this issue: Presidents Address 1 http://www.schoolhousequilters.com President’s Address Executive 3 Refreshments 2009-10 3 Membership, Recipe, Fall 5 donation this year. I like the Retreat group projects and I think it Book Report & Library 6 brings people together which CVEX BEST OF SHOW 7 has always been a big part of Workshop Checklist 9 quilting ever since it began. NEW Block of the Month 10 Fabric Strip / Horoscope 11 Last Will and Testament 12 I know everyone in the Sunshine + Membership 13 guild will help the new execu- Billeting NEEDED for HAW 13 tive and it will be a very suc- Workshop info 14 cessful year. Barb Shapel Student works 15 Marie Trimmer Quilter Profile 16 Thanks for all your sup- Calendars - Sept 20 Hello Ladies, port over the last two years Words to Live by 20 Marie Trimmer Ad Rates for Newsletter 21 An exciting new quilting Haw Blocks & Fat Quarters 22 year is about to get underway. Thanks to all who volunteered for Puzzle 23 the Comox Valley Fall Exhibition! CVEX Pictures 24 Lots of new people on the So many great comments on the dis- executive with some of the posi- play and the quality of our work. We managed to reach a portion of REFRESHMENTS tions shared this year. Although the public who will attend Fall the elections have not happened Fairs, but would never think of at- 2009 - 2010 yet I don't see anyone rushing tending a Quilt Show. A few of our September - A B C more adventuresome members re- October - D E F G forward to surprise us. -

Full Page Photo

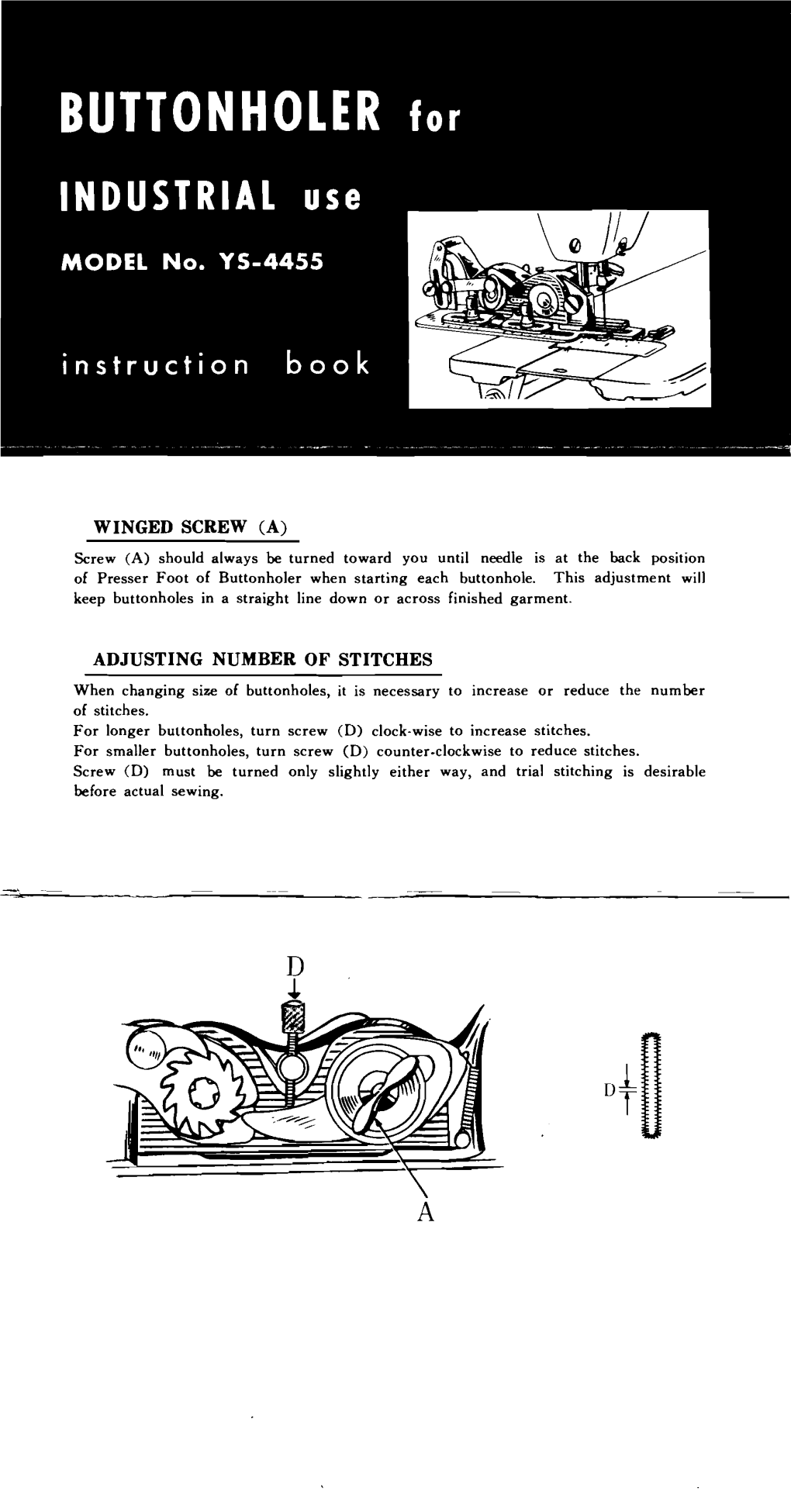

BUTTONHOLER FOR INDUSTRIAL USE Mode.l No. YS·4455 Luttlrl A4,ultlll Scr, .. Sut• ler ur•hl t •~: f')tpl\ • f Slt l f ll TO FASTEN FEED COVER WINGED SCREW (A) Remove Presser Foot at'ld Scre w (rom Presatr S.r of your sc:wi.og muh•ne 1nd pla.ce Screw (A) .-hould always be turned toward you until M!tdk i1 at the back position them in Buuonhokr Cue to avoid mialayinc. of Presser Foot of Buuonhokr when a-tartinc each buttonhole. This adjustme-nt will Place F«d Cover ( P) in position a.a shown, n\lking unaln needle passu throurh lceep buttonholes in a str•is ht line down or across finished garment. center of dot before firmly fastening with amaH screw suppllc<t. Use fine needle with pedect point, ti.ghten nce.dle •~• S(rew securt:ly. Thread mac hi n~ with fine thread, draw bobbin ADJUSTING NUMBER 01<' STITCHES ohreod up ohrough needle hole of pllle (Pl. r~ia.c Prust:r Bar and you are ready to 1ttach When changing size o£ buuonholu , il is necessary to increase or reduce the number your Buttonholer. of stitches. Not lee: When you intend to att•ch Button~ For longer bu.non.holu, turn acrcw (0) clock·wise to i.ncru•e stitcMs. ~ 9SK Sewing Mac:hine, pluM let u.s For smaller buttonholes.. turn tcrcw (0) countn-dockwise to rC"ducc a.titcM-1. know. a s we wiH. supply spec-&. I Needle: Stuing Screw (0) must be lutned only sliahcly either way, and trial stitching i.s. -

Rhyming Dictionary

Merriam-Webster's Rhyming Dictionary Merriam-Webster, Incorporated Springfield, Massachusetts A GENUINE MERRIAM-WEBSTER The name Webster alone is no guarantee of excellence. It is used by a number of publishers and may serve mainly to mislead an unwary buyer. Merriam-Webster™ is the name you should look for when you consider the purchase of dictionaries or other fine reference books. It carries the reputation of a company that has been publishing since 1831 and is your assurance of quality and authority. Copyright © 2002 by Merriam-Webster, Incorporated Library of Congress Cataloging-in-Publication Data Merriam-Webster's rhyming dictionary, p. cm. ISBN 0-87779-632-7 1. English language-Rhyme-Dictionaries. I. Title: Rhyming dictionary. II. Merriam-Webster, Inc. PE1519 .M47 2002 423'.l-dc21 2001052192 All rights reserved. No part of this book covered by the copyrights hereon may be reproduced or copied in any form or by any means—graphic, electronic, or mechanical, including photocopying, taping, or information storage and retrieval systems—without written permission of the publisher. Printed and bound in the United States of America 234RRD/H05040302 Explanatory Notes MERRIAM-WEBSTER's RHYMING DICTIONARY is a listing of words grouped according to the way they rhyme. The words are drawn from Merriam- Webster's Collegiate Dictionary. Though many uncommon words can be found here, many highly technical or obscure words have been omitted, as have words whose only meanings are vulgar or offensive. Rhyming sound Words in this book are gathered into entries on the basis of their rhyming sound. The rhyming sound is the last part of the word, from the vowel sound in the last stressed syllable to the end of the word. -

5, 6, 8, 10 Stitch Sewing Machine

5, 6, 8, 10 Stitch Sewing Machine Instruction Manual 5, 6, 8, 10 Stitch Sewing Machine Table of Contents 1. Getting To Know Your Machine Zig-Zag Zag Stitch Principal Parts Blindstitch Accessories Ladder Seams Important Safety Instructions Multi Stitch Zig-Zag "M" Stitch 2. Getting Ready To Sew Operating the Machine 5. Four Step Buttonhole Choosing and Changing Needles Changing Presser Feet 6. Free-Arm Sewing Changing the Needle Plate Attaching the Feed Cover 7. Twin Needle Sewing Removing and Replacing the Extension Table Fabric Thread and Needle Table Winding a Bobbin 8. Caring For Your Machine Inserting a Bobbin Removing and Replacing the Bobbin Case Threading the Machine Changing the Light Bulb Raising the Bobbin Thread Cleaning the Machine 3. Straight Stitching Lubricating the Machine Stitch Width Selector Needle Position Selector Additional Accessories Stitch Length Selector Reverse Stitch Button Attaching a Button Adjusting Thread Tension Performance Checklist Sewing a Seam Starting a seam Darning Quilting Inserting a Zipper 4. Zig-Zag Stitching Stitch Pattern Selector Needle Position Selector Stitch Width Selector Adjusting Stitch Length Needle Thread Tension 5, 6, 8, 10 Stitch Sewing Machine Congratulations * Simple stitch length dial and push button As the owner of a new Singer sewing reverse stitching. machine, you are about to begin an exciting adventure in creativity. From the moment you * Snap on presser feet that are quickly first use your machine, you will know you are removed and easily replaced. sewing on one of the easiest to use sewing machines ever made. * One-way needle insertion that makes it impossible to insert the needle incorrectly. -

2021 SANE Catalog

2021 CATALOG Today’s Classroom Supplies at Affordable Prices for your Family & Consumer Science Department. Check out our new Kits! Now in our 45th YEAR! 800-262-8653 Visit our website at Due to ever changing www.sanefcs.com market conditions, please check our website for Fax: 513-894-3100 • Email: [email protected] current availability and pricing. 2275 MILLVILLE AVE., SUITE 1 • HAMILTON, OH 45013 Pins 10102 Bonus Pack Dressmaker Pins - 750 count, size 17 pins by Dritz, STRAIGHT PINS extra large amount for extra savings! Re-closeable plastic box .............$ 5.45 SIZE INCHES 10105 Dressmaker Pins, ½ lb. Box - 1-1/16” size 17 silk pins from Size 17 1-1/16” Prym’s, approximately 2,500 pins per box ................................................ 7.50 Size 20 1-1/4” Size 22 1-3/8” 10106 Dressmaker Pins, 1 lb Box - BEST VALUE!, same 1-1/16” size Size 24 1-1/2” 17 silk pins, approximately 5,000 pins per box, from Prym’s .................. 11.75 10105 Size 28 1-3.4” Size 30 1-7/8” 10111 Ballpoint Dressmaker Pins - 600 ballpoint pins in a re-sealable 10106 package, for medium weight and knit fabrics, from Dritz, size 17 ............ 3.95 10116 Ballpoint Plastic Head Pins - 175 size 17 pins per box, 1-1/16” long, Dressmaker Pins — Medium Shaft extra fine shaft, colorful plastic heads, for knits & fine fabrics, from Dritz . 2.95 Silk/Satin Pins — Thin Shaft Extra Fine Pins — Thinnest Shaft 10115 Plastic Head Pins - 200 pins, 1-1/16” long size 17 pins, colorful plastic heads, recloseable plastic box, from Dritz ....................... -

Singer Lockstitch 2000 Sewing Machine Manual.Pdf

Singer Lockstitch 2000 Sewing Machine Manual Singer Lockstitch 2000, 2000 sewing machine, sewing machine, 2000 manual, manual, 2000 instruction manual, sewing machine for kids. More. A small manual for download: Click “Download Now” image upwards. Here is the link Singer sewing machine 52 60 manual lockstitch if the image doesnt shows. SewingPartsOnline.com. Search We carry a large selection of Singer manuals for your Singer sewing machine or Singer serger. If you can't Instruction Manual, Singer 2000 Touch- Tronic Instruction Manual, Singer Lock Stitch 221-1. Manual, industrial sewing machines start at about $800, increasing to about Brother's S-7200C series of single-needle lockstitch sewing machines SVP Worldwide is home to three iconic sewing brands—Husqvarna Viking, Pfaff, and Singer. The offerings range from $150 to $2,000 for sewing machines, and $3,500. Amazon.com: Customer Reviews: Singer Lockstitch 2000 Find great deals on eBay for antique singer sewing machine manual antique singer sewing machine. Download Sewing Machine User's Manual of Pfaff 1183 for free. Pfaff 1183 Manual 1, Pfaff 1183 Singer ATHENA 2000 Manual ultra-high-speed seamer with drop feed These machines are used in the industry for sewing lockstitch seams. Singer Lockstitch 2000 Sewing Machine Manual >>>CLICK HERE<<< Vtg (1948) Singer Sewing Machine Buttonholer Attachment 160506, 6 Templates. $3.00 Is ready to use on 700, 900, and 2000 series machines. Singer Featherweight Sewing Machine BUTTONHOLE Attachment 121795, Box, Manual Vintage Singer Buttonhole Attachment # 121795 Lock Stitch + Instructions + Box. Shop huge inventory of Singer Sewing Machine, Electric Sewing Machine, Industrial A traditional manual sewing machine may come with a foot pedal or a handle and Brother S- 1000A-3 Lockstitch Straight Stitch Industrial Sewing Machine Sewing Speed Upto 2000 SPM (Stitches Per Minute) This machine is ideal.