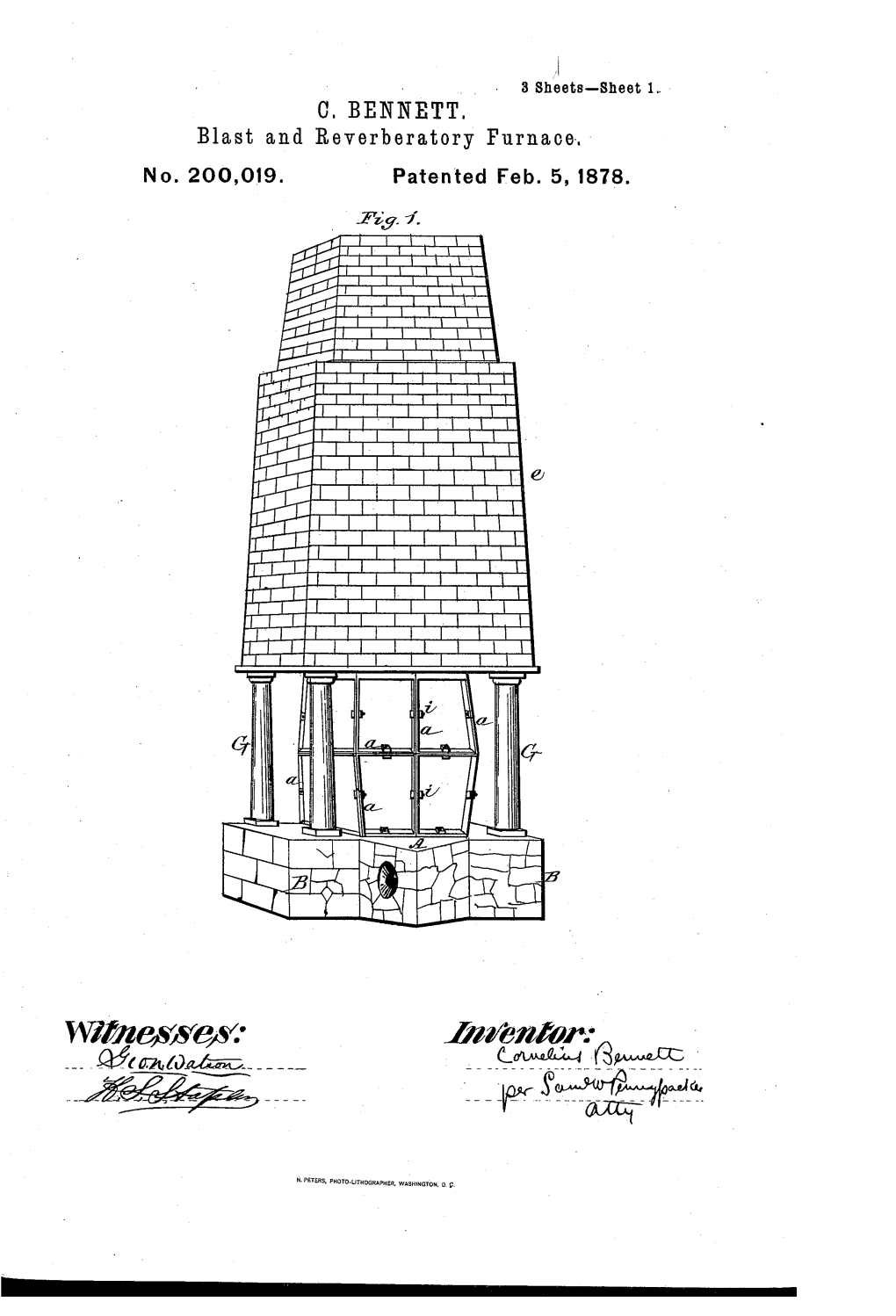

Blast and Reverberatory Furnace, No

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

ITP Metal Casting: Advanced Melting Technologies

Advanced Melting Technologies: Energy Saving Concepts and Opportunities for the Metal Casting Industry November 2005 BCS, Incorporated 5550 Sterrett Place, Suite 306 Columbia, MD 21044 www.bcs-hq.com Advanced Melting Technologies: Energy Saving Concepts and Opportunities for the Metal Casting Industry Prepared for ITP Metal Casting by BCS, Incorporated November 2005 Acknowledgments This study was a collaborative effort by a team of researchers from University of Missouri–Rolla, Case Western Reserve University, and Carnegie Mellon University with BCS, Incorporated as the project coordinator and lead. The research findings for the nonferrous casting industry were contributed by Dr. Jack Wallace and Dr. David Schwam, while the ferrous melting technologies were addressed by Dr. Kent Peaslee and Dr. Richard Fruehan. BCS, Incorporated researched independently to provide an overview of the melting process and the U.S. metal casting industry. The final report was prepared by Robert D. Naranjo, Ji-Yea Kwon, Rajita Majumdar, and William T. Choate of BCS, Incorporated. We also gratefully acknowledge the support of the U.S. Department of Energy and Cast Metal Coalition (CMC) in conducting this study. Disclaimer This report was prepared as an account of work sponsored by an Agency of the United States Government. Neither the United States Government nor any Agency thereof, nor any of their employees, makes any warranty, expressed or implied, or assumes any legal liability or responsibility for the accuracy, completeness, or usefulness of any information, apparatus, product, or process disclosed, or represents that its use would not infringe privately owned rights. Reference herein to any specific commercial product, process, or service by trade name, trademark, manufacturer, or otherwise does not necessarily constitute or imply its endorsement, recommendation, or favoring by the United States Government or any Agency thereof. -

AP-42, CH 12.9: Secondary Copper Smelting

12.9SecondaryCopperSmelting 12.9.1General1,2 Asof1992,morethan40percentoftheU.S.supplyofcopperisderivedfromsecondary sources,includingsuchitemsasmachineshoppunchings,turnings,andborings;manufacturingfacility defectiveorsurplusgoods;automobileradiators,pipes,wires,bushings,andbearings;and metallurgicalprocessskimmingsanddross.Thissecondarycoppercanberefinedintorelativelypure metalliccopper,alloyedwithzincortintoformbrassorbronze,incorporatedintochemicalproducts, orusedinanumberofsmallerapplications.Sixsecondarycoppersmeltersareinoperationinthe U.S.:3inIllinoisand1eachinGeorgia,Pennsylvania,andSouthCarolina.Alargenumberofmills andfoundriesreclaimrelativelypurecopperscrapforalloyingpurposes. 12.9.2ProcessDescription2,3 Secondarycopperrecoveryisdividedinto4separateoperations:scrappretreatment,smelting, alloying,andcasting.Pretreatmentincludesthecleaningandconsolidationofscrapinpreparationfor smelting.Smeltingconsistsofheatingandtreatingthescrapforseparationandpurificationofspecific metals.Alloyinginvolvestheadditionof1ormoreothermetalstocoppertoobtaindesirable qualitiescharacteristicofthecombinationofmetals.Themajorsecondarycoppersmeltingoperations areshowninFigure12.9-1;brassandbronzealloyingoperationsareshowninFigure12.9-2. 12.9.2.1Pretreatment- Scrappretreatmentmaybeachievedthroughmanual,mechanical,pyrometallurgical,or hydrometallurgicalmethods.Manualandmechanicalmethodsincludesorting,stripping,shredding, andmagneticseparation.Thescrapmaythenbecompressedintobricquettesinahydraulicpress. Pyrometallurgicalpretreatmentmayincludesweating(theseparationofdifferentmetalsbyslowly -

National Register of Historic Places Multiple Property

NFS Form 10-900-b 0MB No. 1024-0018 (Jan. 1987) United States Department of the Interior National Park Service National Register of Historic Places Multipler Propertyr ' Documentation Form NATIONAL This form is for use in documenting multiple property groups relating to one or several historic contexts. See instructions in Guidelines for Completing National Register Forms (National Register Bulletin 16). Complete each item by marking "x" in the appropriate box or by entering the requested information. For additional space use continuation sheets (Form 10-900-a). Type all entries. A. Name of Multiple Property Listing ____Iron and Steel Resources of Pennsylvania, 1716-1945_______________ B. Associated Historic Contexts_____________________________ ~ ___Pennsylvania Iron and Steel Industry. 1716-1945_________________ C. Geographical Data Commonwealth of Pennsylvania continuation sheet D. Certification As the designated authority under the National Historic Preservation Act of 1966, as amended, J hereby certify that this documentation form meets the National Register documentation standards and sets forth requirements for the listing of related properties consistent with the National Register criteria. This submission meets the procedural and professional requiremerytS\set forth iri36JCFR PafrfsBOfcyid the Secretary of the Interior's Standards for Planning and Evaluation. Signature of certifying official Date / Brent D. Glass Pennsylvania Historical & Museum Commission State or Federal agency and bureau I, hereby, certify that this multiple -

AP-42, CH 12.8: Secondary Aluminum Operations

12.8SecondaryAluminumOperations 12.8.1General1 Secondaryaluminumproducersrecyclealuminumfromaluminum-containingscrap,while primaryaluminumproducersconvertbauxiteoreintoaluminum.Thesecondaryaluminumindustry wasresponsiblefor27.5percentofdomesticaluminumproducedin1989.Thereareapproximately 116plantswitharecoverycapacityofapproximately2.4millionmegagrams(2.6milliontons)of aluminumperyear.Actualtotalsecondaryaluminumproductionwasrelativelyconstantduringthe 1980s.However,increaseddemandforaluminumbytheautomobileindustryhasdoubledinthelast 10yearstoanaverageof78.5kilograms(173pounds)percar.Recyclingofusedaluminumbeverage cans(UBC)increasedmorethan26percentfrom1986to1989.In1989,1.3millionmegagrams(1.4 milliontons)ofUBCswererecycled,representingover60percentofcansshipped.Recyclingaton ofaluminumrequiresonly5percentoftheenergyrequiredtorefineatonofprimaryaluminumfrom bauxiteore,makingthesecondaryaluminumeconomicallyviable. 12.8.2ProcessDescription Secondaryaluminumproductioninvolves2generalcategoriesofoperations,scrappretreatment andsmelting/refining.Pretreatmentoperationsincludesorting,processing,andcleaningscrap. Smelting/refiningoperationsincludecleaning,melting,refining,alloying,andpouringofaluminum recoveredfromscrap.Theprocessesusedtoconvertscrapaluminumtoproductssuchaslightweight aluminumalloysforindustrialcastingsarepresentedinFigure12.8-1Aand Figure12.8-1B.Someorallthestepsinthesefiguresmaybeinvolvedatanyonefacility.Some stepsmaybecombinedorreordered,dependingonscrapquality,sourceofscrap,auxiliaryequipment available,furnacedesign,andproductspecifications.Plantconfiguration,scraptypeusage,and -

Influence of High-Temperature Treatment of Melt on the Composition and Structure of Aluminum Alloy

ARCHIVES of ISSN (2299-2944) FOUNDRY ENGINEERING Volume 17 DOI: 10.1515/afe-2017-0131 Issue 4/2017 Published quarterly as the organ of the Foundry Commission of the Polish Academy of Sciences 61 – 66 Influence of High-Temperature Treatment of Melt on the Composition and Structure of Aluminum Alloy V.A. Grachev a, *, N.D. Turakhodjaev b a A.N. Frumkin Institute of Physical Chemistry and Electrochemistry of the Russian Academy of Sciences, 29 Bldg 1, Bolshaya Ordynka St., Suite # 104, 119017 Moscow, Russia b Tashkent State Technical University, Faculty of Mechanical University 2,Tashkent 100095, Republic of Uzbekistan, * Corresponding author. E-mail address: [email protected] Received 12.04.2017; accepted in revised form 23.06.2017 Abstract The aim of the current study was to examine the structure of an alloy treated at various temperatures up to 2,000–2,100 °C. Among research techniques for studying alloy structure there were the electron and optical microstructure, X-ray structure, and spectral analysis, and for studying the developed furnace geometric parameters the authors employed mathematical modeling method. The research was performed using aluminum smelting gas-fired furnaces and electric arc furnaces. The objects of the study were aluminum alloys of the brand AK7p and AK6, as well as hydrogen and aluminum oxide in the melt. For determining the hydrogen content in the aluminum alloy, the vacuum extraction method was selected. Authors have established that treatment of molten aluminum alloy in contact with carbon melt at high temperatures of 2,000–2,100 °C has resulted in facilitating reduction of hydrogen and aluminum oxide content in the melt by 40- 43% and 50-58%, respectively, which is important because hydrogen and aluminum oxide adversely affect the structure and properties of the alloy. -

Design and Fabrication of Waste Oil Fired Furnace

International Journal of Engineering and Advanced Technology (IJEAT) ISSN: 2249 – 8958, Volume-9 Issue-2, December, 2019 Design and Fabrication of Waste Oil Fired Furnace Navaneeth Kashyap K V, Yashas M S, Yogesh Kumar K J I. Fuel Fired Furnace Abstract: The study carried out a design and fabrication of an a. Gas Fired Furnace waste oil-fired furnace. The study focused on ensuring a high b . Oil Fired Furnace efficiency in melting of aluminium, by effectively minimizing c. Coke Fired Furnace heat losses, and maximizing heat generation. To achieve this, a d. Air Fired Furnace [Reverberatory Furnace] composite refractory material consisting of cement, asbestos, and clay was used, and waste oil was splashed which is used as II. Electrical Furnace fuel with the help of blower which is running at 3000 rpm and a. Electrical resistance furnace power rating of 1hp. The working pressure of furnace is 5.86 b. Electrical induction furnace x105 N/m2. Changes in the furnace geometry were negligible i. Low frequency indicating a long service life potential. With a useful heat input, ii. High frequency the furnace is able to melt aluminium at a pouring temperature c. Arc Furnace of 6600C. The design is considered safe since the working pressure does not exceed the working stress of its casing which is i. Direct arc electric furnace made of mild steel. ii. Indirect arc electric furnace Keywords : Oil-Fired Furnace, Refractory,Crucible, Furnace, II. LITERATURE REVIEW Refractory,Combustion. Through the comprehensive review of literature, the basic operations of oil fired furnace and importance of its I. -

12.8 Secondary Aluminum Operations 12.8.1 General Secondary

12.8 Secondary Aluminum Operations 12.8.1 General1 Secondary aluminum producers recycle aluminum from aluminum-containing scrap, while primary aluminum producers convert bauxite ore into aluminum. The secondary aluminum industry was responsible for 27.5 percent of domestic aluminum produced in 1989. There are approximately 116 plants with a recovery capacity of approximately 2.4 million megagrams (2.6 million tons) of aluminum per year. Actual total secondary aluminum production was relatively constant during the 1980s. However, increased demand for aluminum by the automobile industry has doubled in the last 10 years to an average of 78.5 kilograms (173 pounds) per car. Recycling of used aluminum beverage cans (UBC) increased more than 26 percent from 1986 to 1989. In 1989, 1.3 million megagrams (1.4 million tons) of UBCs were recycled, representing over 60 percent of cans shipped. Recycling a ton of aluminum requires only 5 percent of the energy required to refine a ton of primary aluminum from bauxite ore, making the secondary aluminum economically viable. 12.8.2 Process Description Secondary aluminum production involves 2 general categories of operations, scrap pretreatment and smelting/refining. Pretreatment operations include sorting, processing, and cleaning scrap. Smelting/refining operations include cleaning, melting, refining, alloying, and pouring of aluminum recovered from scrap. The processes used to convert scrap aluminum to products such as lightweight aluminum alloys for industrial castings are presented in Figure 12.8-1A and Figure 12.8-1B. Some or all the steps in these figures may be involved at any one facility. Some steps may be combined or reordered, depending on scrap quality, source of scrap, auxiliary equipment available, furnace design, and product specifications. -

Energy Efficiency and Cost Savings Opportunities For

Energy Efficiency and Cost Saving Opportunities for Metal Casting An ENERGY STAR® Guide for Energy & Plant Managers January 2016 Document Number 430-R-16-001 Office of Air Programs—Climate Protection Partnership Division Energy Efficiency and Cost Saving Opportunities for Metal Casting An ENERGY STAR® Guide for Energy and Plant Managers Katerina Kermeli, Utrecht University Richard Deuchler, Utrecht University Ernst Worrell, Utrecht University Eric Masanet, Northwestern University January 2016 Disclaimer This guide was prepared for the United States Government and is believed to contain correct information. Neither the United States Government nor any agency thereof, nor any persons or organizations involved in its development, makes any warranty, express or implied, or assumes any legal responsibility for the accuracy, completeness, or usefulness of any information, apparatus, product, or process disclosed, or represents that its use would not infringe on privately owned rights. Reference herein to any specific commercial product, process, or service by its trade name, trademark, manufacturer, or otherwise, does not necessarily constitute or imply its endorsement, recommendation, or favoring by the United States Government or any agency thereof, or any persons or organizations involved in its development. The views and opinions of authors expressed herein do not necessarily state or reflect those of the United States Government or any agency thereof. Development of this guide was funded by the U.S. Environmental Protection Agency. The research embodied in this report was initially supported by the U.S. Environmental Protection Agency through U.S. Department of Energy Contract No. DE-AC02-05CH11231 and was completed under the U.S. Environmental Protection Contract No. -

Colebrook's Involvement with the Iron Industry 1770-1810

Colebrook’s Involvement With the Iron Industry 1770-1810 Iron has been extracted from ore since prehistoric times. The earliest, of course, would have been metal residue found in the ashes of a fire that had burned in an enclosure consisting of rocks containing iron oxide. The carbon in the burning wood combined with the iron oxide and formed a metal that looked entirely different from the ore. Unbeknownst to the fire tender, two processes were taking place in his primitive campfire. The burning charcoal, which extracted the iron would inevitably carbonize some lumps of it, sometimes turning it into brittle and relatively useless cast iron, and some only far enough to convert it to steel, strong and very useful in its unhardened state. It is therefore almost certain that much of the earliest iron was in fact steel. There must have been a very long time between the discovery that this cold material from the campfire could be beaten into shapes after it had cooled; until the time it was discovered that it was much easier to beat it into shape while hot. The next step would seem to be the discovery that if this freshly beaten shape were suddenly cooled, it became hard and brittle. That knowledge would be taken to the next level by the discovery that gently re-heating this hard, brittle object would leave it hard, but remove the brittleness. Up until the 14th century in Europe, when a deposit of iron was discovered, the local smith converted it with the charcoal of the surrounding forest into wrought iron. -

The Paper of the Reverberatory Furnace by Dr. Kanno

World Cultural Heritage—Solving 10 Mysteries of Nirayama Reverberatory Furnace T. Kanno Kimura Chuzosho Co., Ltd., 1157 Shimizu-cho, Shizuoka Prefecture, Japan Key-Words: Nirayama reverberatory furnace, World Heritage, Cannon, Cast iron, Pig iron, Melting temperature, Bellows, Fuel, Firebrick 1. Introduction Nirayama reverberatory furnace is located in Izunokuni city, the Izu Peninsula, Shizuoka Prefecture. As shown in Fig. 1, they are composed of four furnaces in total: two pairs of twin towers, 15.6 m in height.1) Though the existing reverberatory furnace is also in Yamaguchi Prefecture, Nirayama’s is the only existing one which was actually used to melt cast iron in the world. Being one of the constituent properties of “Sites of Japan’s Meiji Industrial Revolution: Kyushu-Yamaguchi and related Areas,” it was decided to be the government’s recommendee for the World Heritage registration in 2015, on September 17th, 2013. Every year one site is selected in the aim of promoting domestic cultural properties for inclusion on the World Heritage List. This application aims to register as one of the group of “Heritages of Industrial Modernization in Kyushu area and Yamaguchi,” not Nirayama’s individually. The group is Fig. 1 Nirayama reverberatory furnace and 24 composed of 8 areas, 11 sites, and 23 properties, including pounder the castle town in Hagi city, Shuseikan in Kagoshima city, Nirayama reverberatory furnace in Izunokuni city, Hashino blast furnace in Kamaishi city, Mie Tsu Naval Training Center in Saga city, Hashima Coal Mine and Glover House in Nagasaki city, Miike Coal Mine in Arao city and Omuta city and Yahata Steel Works in Kitakyushu city. -

Lecture 11 Melting Practices Melting Is an Equally Important Parameter For

Lecture 11 Melting Practices Melting is an equally important parameter for obtaining a quality castings. A number of furnaces can be used for melting the metal, to be used, to make a metal casting. The choice of furnace depends on the type of metal to be melted. Some of the furnaces used in metal casting are as following:. Crucible furnaces Cupola Induction furnace Reverberatory furnace . Crucible Furnace. Crucible furnaces are small capacity typically used for small melting applications. Crucible furnace is suitable for the batch type foundries where the metal requirement is intermittent. The metal is placed in a crucible which is made of clay and graphite. The energy is applied indirectly to the metal by heating the crucible by coke, oil or gas. The heating of crucible is done by coke, oil or gas. Coke-Fired Furnace(Figure 13) . Primarily used for non-ferrous metals Furnace is of a cylindrical shape Also known as pit furnace Preparation involves: first to make a deep bed of coke in the furnace Burn the coke till it attains the state of maximum combustion Insert the crucible in the coke bed Remove the crucible when the melt reaches to desired temperature Figure 13: Coke Fired Crucible Furnace . Oil-Fired Furnace. Primarily used for non-ferrous metals Furnace is of a cylindrical shape Advantages include: no wastage of fuel Less contamination of the metal Absorption of water vapor is least as the metal melts inside the closed metallic furnace Cupola Cupola Cupola furnaces are tall, cylindrical furnaces used to melt iron and ferrous alloys in foundry operations. -

Comparison of Several Furnace Concepts for the Pyrometallurgical Refining of Secondary Copper

INSTITUT FÜR VERFAHRENSTECHNIK DES INDUSTRIELLEN UMWELTSCHUTZES Montanuniversität Leoben Peter-Tunner-Straße 15 Magisterarbeit Comparison of Several Furnace Concepts for the Pyrometallurgical Refining of Secondary Copper Montanuniversität Leoben Vorgelegt von: Betreuer: Paris Valdespino Gastprof.Dipl.-Ing.Dr.techn Hans Rinnhofer Matrikelnummer 0232253 Ao. Univ.Prof. Dipl.-Ing. Dr.mont. Helmut Antrekowitsch Leoben, November 2004 EIDESSTATTLICHE ERKLÄRUNG Ich erkläre an Eides statt, dass ich die vorliegende Magisterarbeit selbständig und ohne fremde Hilfe verfasst, andere als die angegebenen Quellen und Hilfsmittel nicht benutzt und die den benutzten Quellen wörtlich und inhaltlich entnommenen Stellen als solche erkenntlich gemacht habe. DANKSAGUNG Merci à mon Dieu, de l'occasion de la finition de ma maîtrise et de m'envoyer en Autriche où j'ai appris tellement. A mis padres Irma y Wilfrido por su apoyo incondicional en todos mis proyectos, por siempre infundirme confianza y por darme la oportunidad de estudiar la Universidad. Son mi gran orgullo. A mi hermano, a mis tios y primos por sus palabras de aliento y por siempre darme ánimos. A mis abuelos y en especial a Aquiles Valdespino Malagón que me ha dado el ejemplo de como un ingeniero tiene que ser. Ich danke auch meinem Berater, Herrn Dipl.-Ing. Dr. techn Hans Rinnhofer, für die Hilfe und Unterstützung dieser Arbeit, der mir den Zugang zu Ofenkonzepten und technische Daten der Öfen zur Verfügung stellte, ohne die ich diese Arbeit nicht hätte ausführen können sowie Herrn Univ. Prof. Dipl.-Ing. Dr. mont. Helmut Antrekowitsch, der mir die Grundlagen der Nichteisenmetallurgie vorstellte, die bei der Ausführung dieser Arbeit von großer Hilfe waren.