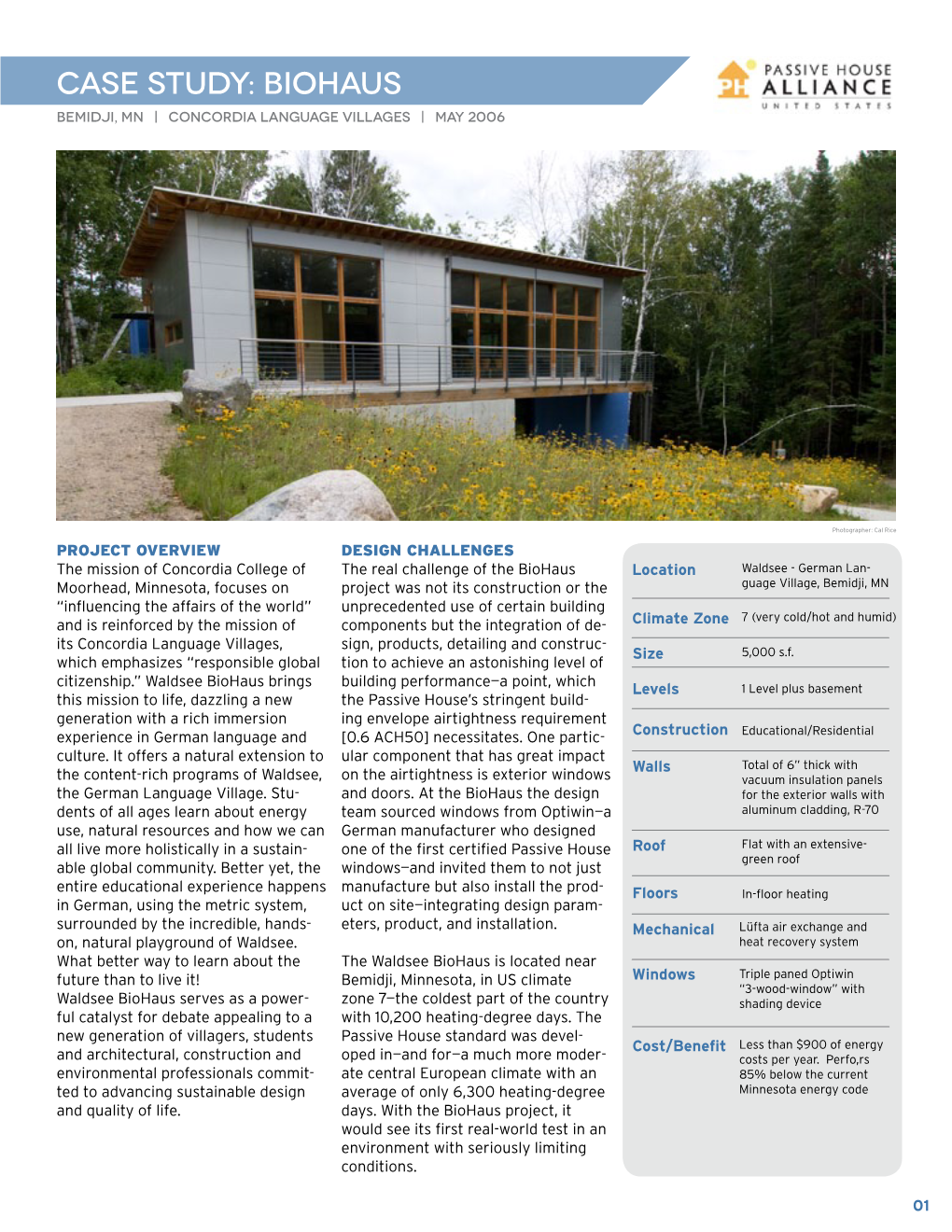

Case Study: Biohaus Bemidji, MN | Concordia Language Villages | May 2006

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Annual Report MESSAGE from the VICE PRESIDENT 2010 - 2011

2010 - 2011 Annual Report MESSAGE FROM THE VICE PRESIDENT 2010 - 2011 Dear Friends of Concordia Language Villages, Annual Report The summer of 2010 was marked by the momentous These improvements and developments are remarkable, celebrations of our 50th anniversary that provided an but only possible with the endorsement of the thousands opportunity to reflect on our successes while planning of friends who support our mission of promoting CONTENTS for our future. I personally enjoyed connecting with responsible citizenship in our global community. Thank many of the people who were instrumental in the you very much for your gifts, for sharing the Concordia 5 Concordia Language Villages & Waldsee Celebrate 50 Years growth of our program and the development of our Language Villages mission with your friends and 7 The Future of German community over the years. colleagues and for so many of you re-connecting and th re-engaging during our 50 celebration. 7 UN Dignitary Visits th While we celebrated our 50 , we also reflected on the sudden loss of a great advocate for the Language My very best, 8 The Healthy Camps Study Villages and global education. Pamela Jolicoeur passed away suddenly in June 2010 after completing her 11 Dakota Programs “Thank you very much for your sixth year as president of Concordia College. President 11 Italian Da Vinci Program gifts, for sharing the Concordia Jolicoeur was a visionary leader and an important Language Villages mission with partner as we strategically moved forward in the Christine Schulze, J.D. 13 STARTALK Russian Teachers your friends and colleagues and 21st century. -

2011-2012 U.S

CONCORDIA LANGUAGE VILLAGES ANNUAL REPORT | MAY 1, 2011–APRIL 30, 2012 The mission of Concordia Language Villages is to Looking Back, Moving Forward prepare young people for reponsible citizenship in Dear Friends of Concordia Language Villages, our global community. I would like to thank our many friends and supporters for another tremendous year at the Language Villages. This year we celebrated the 50th anniversary of our French Language Village, Lac du Bois (est. 1962), that featured summer festivities attended by staff and villagers from all five decades, along with great food, songs, and many memories. While we all had fun remembering the past, we also took the time to look ahead at what the future could be for Lac du Bois and the Language Villages. I’m pleased that many of the planners of the celebration have agreed to remain involved as we explore enrollment, development, and program opportunities NATIONAL ADVISORY COUNCIL going forward. Greg Cash Keith & Maria Johanneson Hugh & Linda Mullenbach Boston, Mass. Bemidji, Minn. Potomac, Md. Other notable highlights include new programs to assist Dakota language John Clemedtson Ilya Kastnelson David & Audrey Olsen educators in preserving and strengthening their language, STARTALK programs Moorhead, Minn. Copenhagen, Denmark Lake Elmo, Minn. for Russian, Portuguese and Arabic teachers, new soccer programs featuring Georg & Reidun Gauger Carolyn Lee Jon & Sophie Pederson coaches and referees from Germany at Waldsee, and, of course, another year of Mound, Minn. New York, N.Y. Spicer, Minn. welcoming almost 11,000 learners of all ages to our programs to learn a language Clinton Gilliland & Mary Turner Gilliland Margaret Cuomo Maier Steven Pollei & Solveig Storvick Pollei Menlo Park, Calif. -

2008 Annual Report Message from the Message from Executive Director the President

A pRogram of ConCoRdiA College, mooRheAd, minnesotA 2008 AnnuAl RepoRt Message From The Message From Executive Director The President Greetings from Concordia Language Villages, Greetings from Concordia College, In 2008 we recognize the launch of Mar e Floresta, the Portuguese In the past year we have seen a strengthening of Language Village, which represents our 15th language. We sincerely the collaboration between Concordia College and thank Dr. Rui Machete, President of the Luso-American Foundation, its Concordia Language Villages. From the Masters THE MISSION OF CONCoRDIA lANGUAGE VILLAGES for the significant financial contribution to Concordia Language program to the inauguration of a Chinese major on Villages for this new language offering and for ensuring a very campus to a variety of successful grants, the College successful first summer of operation. and the Villages are working together to enrich a IS TO pREPARe YOUNG PEOPLE FOR RESPONSIBLE number of key programs. The Villages are an integral In my introductory letter to our 2005 Annual Report, I cited the U.S. part of Concordia’s mission to prepare students for Department of State’s commitment to language education under the challenges of the world in which they will live and CITIZENSHIP IN OUR GLOBAl COMMUNITY. the National Security Language Initiative (NSLI). We were confident work. that this federal program would create new opportunities for the Language Villages – and it has. For example, we have been receiving We are looking forward to the 50th anniversary of the annual funding from STARTALK, a NSLI program, which provides Concordia Language Villages program with particular scholarships for students from across the country to attend our Arabic pride in the national and international stature the and Chinese Language Villages and for teachers of both languages Language Villages has attained. -

Four-Week High School Credit Programs Catalogue Accredited by Cognia

Concordia Language Villages Four-Week High School Credit Programs Catalogue Accredited by Cognia Concordia Language Villages offers high school students a variety of summer language and cultural immersion programs in 14 world languages for high school and college credit. Programs meet a variety of objectives related to linguistic proficiency, cultural competency, and positive engagement in local and global communities. The four-week high school credit programs are the equivalent of one year of high school language instruction. Students who are 18 years of age or younger and are entering grade 9, 10, 11, or 12 are eligible to enroll. A student who has graduated from high school and is still 18 years of age or younger, but who has not yet fully matriculated into college, is also eligible to register. High school credit programs support students’ learning needs in public and private schools, homeschooling environments, IB diploma programs, language immersion schools, and those seeking alternative learning environments and credentials, such as the Seal of Biliteracy and Global Education Achievement Certificate. The programs also boost skills beneficial for AP courses and exams. A minimum of 180 hours of direct instruction, along with significant language and culture practice, takes place within the context of a residential immersion setting. Participants learn in small groups that typically range in size from four to eight students. The credit program faculty and staff are native speakers or highly-proficient speakers in the target language, and all have teaching and leadership expertise with immersion methodology at the secondary and/or post-secondary levels. The high school credit programs are accredited by Cognia, a non-profit organization that conducts rigorous, on-site reviews of educational institutions to ensure all learners reach their full potential. -

Turtle River Lake International Retreat Center

TURTLE RIVER LAKE INTERNATIONAL RETREAT CENTER RENTAL RATES (Effective May 1, 2015 - April 30, 2016) We are currently taking ADULT RATE Full Day with 2 Basic Breaks $80.40 reservations for workshops, - Includes three meals, two breaks and lodging holiday dinners, overnight Full Day without Breaks $75.20 events, retreats, or luncheons. Daylong Workshop $19.45 - Includes one meal and two breaks Breakfast $8.95 Make your reservations today Brunch $12.00 at Concordia Language Villages Luncheon $14.25 Banquet $17.60 and call our toll free number at Lodging $34.40 1-800-450-2214. Or you may - Bedding, pillows and pillowcases and towels are provided - Adults will assume lodging only in the lower bunks contact the Special Events and Basic Breaks $2.60 Site Rental Coordinator directly - Coffee, hot tea, hot cocoa and one snack item at 218-586-8714 or via email, Standard Breaks $4.60 - Coffee, hot tea, hot cocoa, bottled water, soda and two snack [email protected]. items. The snack items are limited to one baked item (muffin, cookie or cake) and fruit or vegetables Deluxe Breaks $7.15 You may also write to: - Coffee, hot tea, hot cocoa, bottled water, soda and three snack items. The snack items are one baked item (muffin, cookie, cake Concordia Language Villages or caramel rolls), fruit and vegetables ATTN: Rental Groups Soda or Bottled Water $1.00 8659 Thorsonveien NE ** Minimums for a one-day workshop are 25 adult participants. Overnight requirements are a minimum of Bemidji, MN 56601 15 adult participants. ** LODGING: Overnight stays are required to order at least one meal (breakfast, lunch, or dinner). -

Summer at Concordia Language Villages

Welcome to Summer at Concordia Language Villages Dear Villager Family, Welcome to the 2018 summer learning adventure that is Concordia Language Villages! We know you have invested in this opportunity for your child because you strongly believe developing global competencies at an early age makes a real difference in who they become and how they see their future. And what better way to spend a childhood summer. We are honored to have your trust and confidence. Families and educators across the country continue to discuss 21st century skills and what is needed to prepare for a successful future. At Concordia Language Villages, we find a perfect complement between our mission and the 21st century skills of language learning, global awareness and environmental literacy, while encouraging the development of your child’s learning and innovation skills. A recent study requested by Congress on the state of learning language in the United States, released by the American Academy of Arts and Sciences, reinforces the urgency and importance of language learning for this and future generations. The ‘grand simulation’ of Concordia Language Villages programs creates a learning community that fosters curiosity, confidence and global competence in every “villager.” That learning community includes native speaking staff, culturally authentic food, games, music, sports, festivals, history, traditions and literature, all combining in the daily life of a Language Village. This fun and engaging learning community is comprised of people who have experienced exactly what your villager will be experiencing. A staff-to-villager ratio of 1:4 allows for individual attention and sets the tone for general supervision, while allowing for personal development and gaining independence. -

Low Energy Dwelling in Cold Conifer-Forested

ARCC 2010 ‐ The Place of Research / The Research of Place, Washington, D.C., 23‐26 June 2010 LOW ENERGY DWELLING IN COLD CONIFER-FORESTED MICROCLIMATES: A THERMAL EFFICIENCY CASE STUDY Keith Bickford1, and Frank Jacobus2 1The University of Idaho, Moscow, Idaho 2The University of Idaho, Moscow, Idaho ABSTRACT: A proposed carbon neutral dwelling in a cold region, alpine-forested microclimate is analyzed using a building energy analysis program and is redesigned to improve energy efficiency. The Passive House standard is used as a design guideline and a Passive House certified dwelling is used as a case study for comparison. By increasing thermal performance parameters of the proposed dwelling, energy costs are reduced by 67%. Achieving carbon neutrality in terms of building operation is now attainable. 1.0 INTRODUCTION insulation to cover apertures when there is no sunshine, while windows on non-southern walls must be minimized to With the initiation of the 2030 Challenge and the increasing avoid heat loss. threat of environmental instability due to CO2 emissions, in large part as a byproduct of the building sector, it is 2.0 PROJECT BACKGROUND imperative that engineers and architects work together to increase knowledge and awareness of design practices In 2006, an interdisciplinary group of faculty and students and principles that reduce building energy use and from the University of Idaho began designing a carbon continue to advance technologies that aid in a reduction of neutral campus at one of the university’s field sites in the burning of fossil fuels. McCall, Idaho. This campus houses the McCall Outdoor Science School (MOSS) and Environmental Learning This research analyzes thermal efficiency strategies for a Center. -

We Are Thrilled That You Will Be Joining Us Soon to Live the Language At

Dear Families, Welcome to Concordia Language Villages! We are thrilled that you will be joining us soon to Live the Language at a family- centered language and cultural immersion program! Whether you are attending a summer family week or family program during the school year, our promise is to engage you all in an enriching environment full of language learning adventures and discovery. Our goal is for each of you to leave with a sense of accomplishment and greater cross-cultural understanding. For your convenience, we have an on-line Family Program Handbook that will answer most of your questions and help prepare you for your Village experience. Please be sure to read the Family Handbook on our website and spend some time reviewing the program descriptions and policies, so you and your family members know what to expect when you arrive. We’ve included tips on how to prepare and have provided useful information about what each one of you will experience at the Language Villages. Be assured that with almost 60 years of experience, we’ve thought of just about everything to make sure your investment in this journey will be worthwhile. I hope that you, like many others, will be eager to come back year after year. Over the last decade of family programming, we have learned that children who experience a Language Village with other family members adapt quickly, gain independence, and often are eager to continue the language learning journey at the Villages on their own. After reading through the on-line handbook, if you have any questions prior to your arrival, do not hesitate to visit our Web site at www.ConcordiaLanguageVillages.org, email us at [email protected], or call us at (800) 222-4750. -

Escape Into Art? the Brücke Painters in the Nazi Period

Escape into Art? The Brücke Painters in the Nazi Period 14 April –11 August 2019 In 1937, the Nazis confiscated thousands Works from the Brücke-Museum collection materials. However, until the summer of of artworks from German museums, in- form the backbone of Escape into Art?, 1937 they were still exhibiting their works cluding key works by Karl Schmidt-Rottluff, supplemented by selected loans from the at galleries and art associations, and in Erich Heckel, Ernst Ludwig Kirchner, Max estates of the various artists and from pri- fact Pechstein continued to do so until Pechstein and Emil Nolde. In the propa- vate collectors. The exhibition also marks 1939. Their respective personal situation ganda exhibition entitled Degenerate Art, the first time the museum is opening out and stance during the Nazi era can thus public scorn was then poured on them. in spatial terms: While the period up to not be seen as some unchanging status, These aggressive attacks on their art have 1945 will be portrayed at Brücke-Museum, but must rather be construed as a dynamic tended to overshadow to this day how the the neighbouring Kunsthaus Dahlem will process. Brücke painters themselves experienced house the second part of the show and the Nazi regime. This focus on the events shed light on the immediate post-war era. It bears mentioning here that there were in the years 1937/38 has led to the artists Both galleries are united in their interest many artists who were victims of physical primarily being considered victims of the in a critical inquiry into the history of their persecution: Charlotte Salomon, Otto Nazi policy on art. -

Passive House

Passive house Passive house (German: Passivhaus) is a rigorous, voluntary standard for energy efficiency in a building, reducing its ecological footprint.[1] It results in ultra-low energy buildings that require little energy for space heating or cooling.[2][3] A similar standard, MINERGIE-P, is used in Switzerland.[4] The standard is not confined to residential properties; several office buildings, schools, kindergartens and a supermarket have also been constructed to the standard. Passive design is not an attachment or supplement to architectural design, but a design process that is integrated with architectural design.[5] Although it is mostly applied to new buildings, it has also been used for refurbishments. A building based on the passive house concept in Estimates of the number of Passivhaus buildings around the world in Darmstadt, Germany. late 2008 ranged from 15,000 to 20,000 structures.[6][7] As of August 2010, there were approximately 25,000 such certified structures of all types in Europe, while in the United States there were only 13, with a few dozen more under construction.[1] By 2017, that number has shot up to over 1,200 units totaling over one million square feet.[8] The vast majority of passive structures have been built in German-speaking countries andScandinavia .[6] Contents History First examples Further implementation and councils Standards Standards Recommendations Space heating requirement Construction costs Design and construction Passive solar design and landscape Superinsulation Advanced window technology -

Parent Handbook and All the Rules and Regulations Stated Therein

A program of CLANGUONCAGEORDIA VILLAGES CONCORDIA WELCOME TO LANGUAGE VILLAGES Dear Villager Family, We are delighted that you are joining us for a fun-filled immersion experience this summer, whether on site in northern Minnesota or in one of our Virtual Villages online. We are looking forward to this time together for language learning, adventure and being with friends. Each Village session encompasses a wide range of creative activities that will spark your curiosity about many parts of the world. You will learn to communicate in the language with confidence and cultural sensitivity, whether you are a beginner or an advanced speaker. You will actively explore historical events and delve deeply into current global issues, all geared for different age levels. You will make new friends and some of these friendships may last a lifetime. A staff-to-villager ratio of 1:4 allows for individual attention and sets the tone for general supervision, while allowing for personal development and gaining independence. Sincerely, Your account in MyVillage is your gateway to key information about your upcoming session at Concordia Language Villages. Please log into this site to access all of the forms and docu- ments that you will need before the start of your Virtual Village session. We are excited to be using CampDoc for all of our Jennifer Charlotte Speir | Group Director, Group C medical records this year. Watch for an email from CampDoc in late spring to complete your villager's health forms.This Parent Guidebook outlines our program expectations and our com- mitment to providing a safe, positive, and respectful learning experience for all villagers. -

Biohaus Environmental Living Center

BIOHAUS ENVIRONMENTAL LIVING CENTER Sustainable Building Technology Project Profile REHAU Helps Waldsee BioHaus Achieve North America’s First German Passivhaus Certification In creating its Waldsee BioHaus in Bemidji, MN, the first certified German Passivhaus in North America, Concordia Language Villages wanted to showcase Germany’s position as a leader in environmental practices, through a paradigm-changing green building design. The educational facility provides a level of energy efficiency beyond that of the US Green Building Council’s LEED (Leadership in Energy and Environmental Design) standard, using 85 percent less energy than comparable US structures. When it passed the official certification by Germany’s Passivhaus Institute, the BioHaus laid claim to being the nation’s tightest building – a notable achievement in light of the structure’s location in an extreme climate zone. Sustainable Design Dialogue The BioHaus at Waldsee is part of a larger effort by the Concordia Language Villages and Germany’s Deutsche Bundesstiftung Um- welt (DBU) – Europe’s largest environmental foundation dedicated Innovative Global Technologies to environmental practice, education and construction – to create Designed by lead architectural and consulting firm INTEP Planning, a “transatlantic green bridge” between German-speaking Europe with European offices in Munich, Germany, Zurich, Switzerland and (Austria, Germany and Switzerland) and the United States. It is ex- a satellite office in Minneapolis, MN that specializes in high-perfor- pected to promote a dialogue on and exchange of sustainable building mance and sustainable construction, the Waldsee BioHaus features components and technologies, as well as encourage the cooperative several innovative building systems and components. development of innovative educational curricula on sustainable build- ing practices.