Sediment Grain Size Analysis Lab 1 Grain Size Boundary Sieve Sizes

Total Page:16

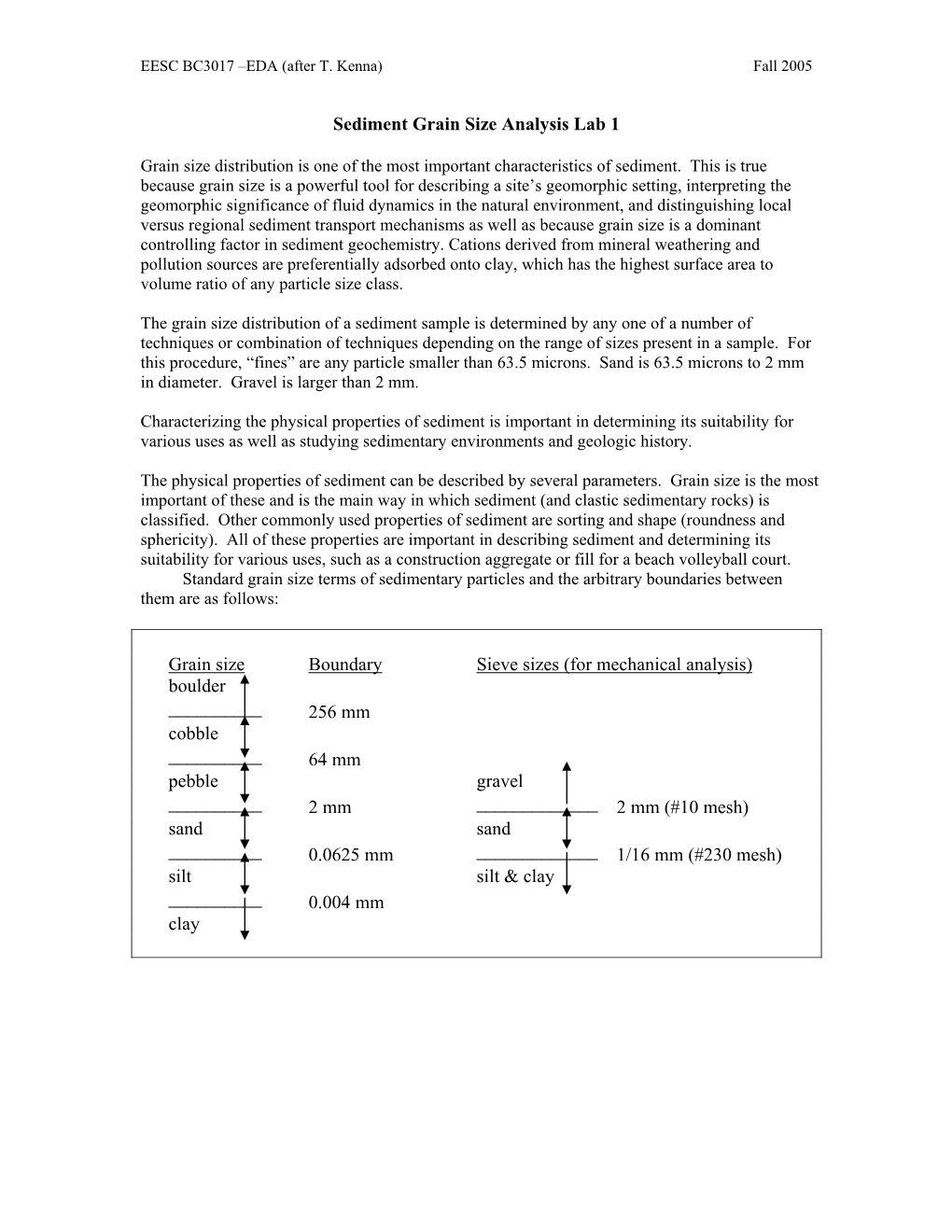

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Data Dictionary for Grain-Size Data Tables

Data Dictionary for Grain-Size Data Tables The table below describes the attributes (data columns) for the grain-size data tables presented in this report. The metadata for the grain-size data are not complete if they are not distibuted with this document. Attribute_Label Attribute_Definition SAMPLE ID Sediment Sample identification number DEPTH (cm) Sample depth interval, in centimeters Physical description of sediment textural group - describes the dominant grain size class of the sample (after Folk, 1954): SEDIMENT TEXTURE (Folk, 1954) Sand, Clayey Sand, Muddy Sand, Silty Sand, Sandy Clay, Sandy Mud, Sandy Silt, Clay, Mud, or Silt AVERAGED SAMPLE RUNS Number of sample runs (N) included in the averaged statistics or other relavant information MEAN GRAIN SIZE (mm) Mean grain size, in microns (after Folk and Ward, 1957) MEAN GRAIN SIZE STANDARD DEVIATION (mm) Standard deviation of mean grain size, in microns SORTING (mm) Sample sorting - the standard deviation of the grain size distribution, in microns (after Folk and Ward, 1957) SORTING STANDARD DEVIATION (mm) Standard deviation of sorting, in microns SKEWNESS (mm) Sample skewness - deviation of the grain size distribution from symmetrical, in microns (after Folk and Ward, 1957) SKEWNESS STANDARD DEVIATION (mm) Standard deviation of skewness, in microns KURTOSIS (mm) Sample kurtosis - degree of curvature near the mode of the grain size distribution, in microns (after Folk and Ward, 1957) KURTOSIS STANDARD DEVIATION (mm) Standard deviation of kurtosis, in microns MEAN GRAIN SIZE (ɸ) Mean -

Evolution and Grain Size Distribution of Bahamian Ooid Shoals From

Movement and grain size distribution of Bahamian sand shoals from remote sensing Kathryn M. Stack Michael Lamb, Ralph Milliken, Sebastien Leprince, John Grotzinger California Institute of Technology KISS Monitoring Earth Surface Changes From Space II 3/30/10 Motivation: Understand how sediment moves underwater Transport Grain size Implicaons Evoluon of shallow Petroleum and natural CO2 reservoirs bathymetry gas reservoirs 2 How remote sensing data can help • Obtain a 2-D snapshot of a modern day shallow carbonate environment • Build up a time series of morphology and grain size • Quantify the distribution and movement of sediment at a variety of temporal and spatial scales –Tides versus storms? • Use the modern to better understand the 3-D patterns of porosity and permeability in the rock record The Bahamas: A modern carbonate environment Florida The Atlantic Ocean The Bahamas Cuba 100 km Google Earth Tongue of the Ocean Schooner Cays 20 km 20 km Exumas Lily Bank 2 km 2 km Tongue of the Ocean 10 km 1 Crest spacing ~ 1‐10 km Google Earth 3 Crest spacing ~ 100 m 2 1 km Crest spacing ~ 1 km ASTER, Band 1 20 m Sediment transport and bedform migration Bedform spatial scales = 5-10 cm, 1 m, 10-100 m, 1-10 km Temporal scales = Hours, days, years Δy Δx Transport Ideal Imaging Campaign • High enough spatial resolution to see bedform crests on a number of scales - Sub-meter resolution - Auto-detection system • High enough temporal resolution to distinguish between slow steady processes and storms - Image collection every 3 to 6 hours • Spectral resolution depending on bedform scale of interest Also useful: • High resolution water topography (sub-meter resolution) • Track currents, tides, and water velocity Application of COSI-Corr • Use the COSI-Corr software developed by Leprince et al. -

The Effect of Variable Grain Size Distribution on Beach's

Delft University of Technology Faculty of Civil Engineering and Geosciences Department of Hydraulic Engineering MSc Thesis THE EFFECT OF VARIABLE GRAIN SIZE DISTRIBUTION ON BEACH’S MORPHOLOGICAL RESPONSE Graduation committee: Prof.dr.ir. A.J.H.M. Reniers Author: Dr.ir. Matthieu de Schipper Melike Koktas Ir. Tjerk Zitman Dr. Edith L. Gallagher May 2017 P a g e 2 | 67 EXECUTIVE SUMMARY Field studies with in-situ sediment sampling demonstrate the spatial variability in grain size on a sandy beach. However, conventional numerical models that are used to simulate the coastal morphodynamics ignore this variability of sediment grain size and use a uniform grain size distribution of mostly around and assumed fine grain size. This thesis study investigates the importance of variable grain size distribution in a beach’s morphological response. For this purpose, first a field experiment campaign was conducted at the USACE Field Research Facility (FRF) in Duck, USA, in the spring of 2014. This experiment campaign was called SABER_Duck as an acronym for ‘Stratigraphy And BEach Response’. During SABER_Duck, in-situ swash zone grain size distribution, the prevailing hydrodynamic conditions and the time-series of the cross-shore bathymetry data were collected. The data confirmed a highly variable grain size distribution in the swash zone both vertically and horizontally. Additionally, the two trench survey observations showed the existence of continuous layers of coarse and fine sands comprising the beach stratigraphy. Secondly, a process based numerical coastal morphology model, XBeach, was chosen to simulate the beach profile response to wave and tidal action. A 1D cross-shore profile model was built and tested with the bathymetry data and accompanying boundary conditions that were collected during SABER_Duck. -

Grain-Size Sorting in Grainflows at the Lee Side of Deltas

Sedimentology (2005) 52, 291–311 doi: 10.1111/j.1365-3091.2005.00698.x Grain-size sorting in grainflows at the lee side of deltas MAARTEN G. KLEINHANS Department of Physical Geography, Faculty of Geosciences, Universiteit Utrecht, PO Box 80115, 3508 TC Utrecht, The Netherlands (E-mail: [email protected]) ABSTRACT The sorting of sediment mixtures at the lee slope of deltas (at the angle of repose) is studied with experiments in a narrow, deep flume with subaqueous Gilbert-type deltas using varied flow conditions and different sediment mixtures. Sediment deposition and sorting on the lee slope of the delta is the result of (i) grains falling from suspension that is initiated at the top of the delta, (ii) kinematic sieving on the lee slope, (iii) grainflows, in which protruding large grains are dragged downslope by subsequent grainflows. The result is a fining upward vertical sorting in the delta. Systematic variations in the trend depend on the delta height, the migration celerity of the delta front and the flow conditions above the delta top. The dependence on delta height and migration celerity is explained by the sorting processes in the grainflows, and the dependence on flow conditions above the delta top is explained by suspension of fine sediment and settling on the lee side and toe of the delta. Large differences in sorting trends were found between various sediment mixtures. The relevance of these results with respect to sorting in dunes and bars in rivers and laboratory flumes is discussed and the elements for a future vertical sorting model are suggested. -

Coastal Processes Study at Ocean Beach, San Francisco, CA: Summary of Data Collection 2004-2006

Coastal Processes Study at Ocean Beach, San Francisco, CA: Summary of Data Collection 2004-2006 By Patrick L. Barnard, Jodi Eshleman, Li Erikson and Daniel M. Hanes Open-File Report 2007–1217 U.S. Department of the Interior U.S. Geological Survey U.S. Department of the Interior DIRK KEMPTHORNE, Secretary U.S. Geological Survey Mark D. Myers, Director U.S. Geological Survey, Reston, Virginia 2007 For product and ordering information: World Wide Web: http://www.usgs.gov/pubprod Telephone: 1-888-ASK-USGS For more information on the USGS—the Federal source for science about the Earth, its natural and living resources, natural hazards, and the environment: World Wide Web: http://www.usgs.gov Telephone: 1-888-ASK-USGS Barnard, P.L.., Eshleman, J., Erikson, L., and Hanes, D.M., 2007, Coastal processes study at Ocean Beach, San Francisco, CA; summary of data collection 2004-2006: U. S. Geological Survey Open-File Report 2007- 1217, 171 p. [http://pubs.usgs.gov/of/2007/1217/]. Any use of trade, product, or firm names is for descriptive purposes only and does not imply endorsement by the U.S. Government. Although this report is in the public domain, permission must be secured from the individual copyright owners to reproduce any copyrighted material contained within this report. ii Contents Executive Summary of Major Findings..................................................................................................................................1 Chapter 2 - Beach Topographic Mapping..............................................................................................................1 -

Maggie Williams Particle Size, Shape and Sorting: What Grains Can Tell Us

Particle size, shape and sorting: what grains can tell us Maggie Williams Most sediments contain particles that have a range of sizes, so the mean or average grain size is used in description. Mean grain size of loose sediments is measured by size analysis using sieves Grain size >2mm Coarse grain size (Granules<pebble<cobbles<boulders) 0.06 to 2mm Medium grain size Sand: very coarse-coarse-medium-fine-very fine) <0.06mm Fine grain size (Clay<silt) Difficult to see Remember that for sediment sizes > fine sand, the coarser the material the greater the flow velocity needed to erode, transport & deposit the grains Are the grains the same size of different? What does this tell you? If grains are the same size this tells you that the sediment was sorted out during longer transportation (perhaps moved a long distance by a river or for a long time by the sea. If grains are of different sizes the sediment was probably deposited close to its source or deposited quickly (e.g. by a flood or from meltwater). Depositional environments Environment 1 Environment 2 Environment 3 Environment 4 Environment 5 Environment 6 Sediment size frequency plots from different depositional environments • When loose sediment collected from a sedimentary environment is washed and then sieved it is possible to measure the grain sizes in the sediment accurately. • The grain size distribution may then be plotted as a histogram or as a cumulative frequency curve. • Sediments from different depositional environments give different sediment size frequency plots. This shows the grain size distribution for a river sand. -

Grain Size Characteristics of the Coleroon Estuary Sediments, Tamilnadu, East Coast of India

Carpathian Journal of Earth and Environmental Sciences, September 2011, Vol. 6, No. 2, p. 151 - 157 GRAIN SIZE CHARACTERISTICS OF THE COLEROON ESTUARY SEDIMENTS, TAMILNADU, EAST COAST OF INDIA Anithamary IRUDHAYANATHAN*, Ramkumar THIRUNAVUKKARASU & Venkatramanan SENAPATHI Department of Earth Sciences, Annamalai University. Annamalainagar. 608 002, India. *Corresponding author: [email protected] Abstract: The present study was carried out in order to study the textural characteristics of sediments, and their seasonal changes along with the Coleroon estuary. Samplings were done at different stations during two seasons from monsoon of 2009 to postmonsoon of 2010. Granulometric studies reveals that the grain size parameters at different Coleroon estuary locations. The differences between the seasons were larger than those between the geomorphological units. During the monsoon the mean size was medium to fine, sorting was moderately sorted to moderately well sorted in nature, and the distribution was more positively skewed. The major part of the sediment fall in a medium to fine grained category. with respect to spatial distribution sand is dominating in the upper estuarine region i.e. up to the station 7 silt, clay are mostly enriched in lower part of the estuary. Based on the CM pattern the sediment fall in rolling and suspension field. Keyword; Coleroon estuary, Granulometric, spatial, fluvial environment, Tamilnadu, east coast. 1. INTRODUCTION parameters are used to interpret sediment movement in Coleroon estuary. Estuaries are in a state of constant flux and their dynamic nature provides many ecological niches 2. STUDY AREA for diverse biota. The health status and biological diversity of Indian estuarine ecosystems are The study area is drained by Coleroon river and deteriorating day by day through multifarious man- its distributaries. -

Stratigraphic Heterogeneity of a Holocene Ooid Tidal Sand Shoal: Lily Bank, Bahamas

Stratigraphic heterogeneity of a Holocene ooid tidal sand shoal: Lily Bank, Bahamas by Andrew G. Sparks B.A., Franklin & Marshall College, 2008 Submitted to the Department of Geology and the Faculty of the Graduate School of The University of Kansas in partial fulfillment of the requirements for the degree of Master of Science 2011 Advisory Committee: ________________________ Eugene C. Rankey, Chair ________________________ Georgios P. Tsoflias ________________________ Krishnan Srinivasan Date Defended: ____________ The Thesis Committee for Andrew G. Sparks certifies that this is the approved version of the following thesis: Stratigraphic heterogeneity of a Holocene ooid tidal sand shoal: Lily Bank, Bahamas Advisory Committee: ________________________ Eugene C. Rankey, Chair Date Approved: ____________ ii ABSTRACT A central challenge in sedimentary geology is understanding three-dimensional architectural variability, and how it might be predicted. Ooid sand shoals, present in the stratigraphic record from Archean to recent, represent an economically important, but heterogeneous type of carbonate deposit. Whereas the processes influencing the deposition of ooid shoals are well examined and understood, the means by which distinct processes are recorded in the rock record are less constrained. The purpose of this thesis is to understand the relationship among processes, plan-view morphology and stratigraphic variability by examining Lily Bank, a modern tidally dominated Bahamian ooid shoal. Research focuses on two bar form end-members of Lily Bank: transverse shoulder bars oriented normal to flow and flood- and ebb-tide oriented parabolic bars. Results from integrating remote sensing imagery, high frequency seismic (Chirp) data and core characterization (sedimentary structures and granulometric analyses) reveal the stratigraphic record of geomorphic change. -

Sand Size Versus Beachface Slope — an Explanation Based on the Constructal Law

Geomorphology 114 (2010) 276–283 Contents lists available at ScienceDirect Geomorphology journal homepage: www.elsevier.com/locate/geomorph Sand size versus beachface slope — An explanation based on the Constructal Law A. Heitor Reis a,⁎, Cristina Gama b a Department of Physics and Geophysics Centre of Evora, University of Évora, R. Romão Ramalho 59, 7000-671 Evora, Portugal b Department of Geosciences and Geophysics Centre of Evora, University of Évora, R. Romão Ramalho 59, 7000-671 Evora, Portugal article info abstract Article history: The relationship between beachface slope and sand grain size has been established based on multiple Received 19 February 2009 observations of beach characteristics in many parts of the world. We show that this observational result may Received in revised 21 July 2009 be understood in the light of the Constructal Law (Bejan, 1997). A model of wave run-up and run-down Accepted 24 July 2009 along the beachface (swash) was developed to account for superficial flows together with flows through the Available online 3 August 2009 porous sand bed of average porosity 0.35, the permeability of which may be related to grain diameter and sphericity (0.9 for sand grains) through the Kozeny–Carmán equation. Then, by using the Constructal Law, Keywords: fi Beachface dynamics we minimized the time for completing a swash cycle, under xed wave height and sand grain diameter. As Sediment size the result, a relationship involving sand grain size, beachface slope and open ocean wave height has been Beach slope obtained, and then discussed and validated against experimental data. In addition, this relationship has also Constructal Law been used to illuminate beachface dynamic processes, namely the reshaping of sandy beachfaces in response to changes in wave height. -

The St. Bernard Shoals: an Outer Continental Shelf Sedimentary Deposit Suitable for Sandy Barrier Island Renourishment

The St. Bernard Shoals: an Outer Continental Shelf Sedimentary Deposit Suitable for Sandy Barrier Island Renourishment Chapter G of Sand Resources, Regional Geology, and Coastal Processes of the Chandeleur Islands Coastal System: an Evaluation of the Breton National Wildlife Refuge Scientific Investigations Report 2009–5252 U.S. Department of the Interior U.S. Geological Survey The St. Bernard Shoals: an Outer Continental Shelf Sedimentary Deposit Suitable for Sandy Barrier Island Renourishment By Bryan Rogers and Mark Kulp Chapter G of Sand Resources, Regional Geology, and Coastal Processes of the Chandeleur Islands Coastal System: an Evaluation of the Breton National Wildlife Refuge Edited by Dawn Lavoie In cooperation with the U.S. Fish and Wildlife Service Scientific Investigations Report 2009–5252 U.S. Department of the Interior U.S. Geological Survey U.S. Department of the Interior KEN SALAZAR, Secretary U.S. Geological Survey Marcia K. McNutt, Director U.S. Geological Survey, Reston, Virginia: 2009 This and other USGS information products are available at http://store.usgs.gov/ U.S. Geological Survey Box 25286, Denver Federal Center Denver, CO 80225 To learn about the USGS and its information products visit http://www.usgs.gov/ 1-888-ASK-USGS Any use of trade, product, or firm names is for descriptive purposes only and does not imply endorsement by the U.S. Government. Although this report is in the public domain, permission must be secured from the individual copyright owners to reproduce any copyrighted materials contained within this report. Suggested citation: Rogers, B., and Kulp, M., 2009, Chapter G. The St. Bernard Shoals—an outer continental shelf sedimentary deposit suitable for sandy barrier island renourishment, in Lavoie, D., ed., Sand resources, regional geology, and coastal processes of the Chandeleur Islands coastal system—an evaluation of the Breton National Wildlife Refuge: U.S. -

Grain-Size Distribution of Surface Sediments of Climbing and Falling Dunes in the Zedang Valley of the Yarlung Zangbo River, Southern Tibetan Plateau

J. Earth Syst. Sci. (2019) 128:11 c Indian Academy of Sciences https://doi.org/10.1007/s12040-018-1030-4 Grain-size distribution of surface sediments of climbing and falling dunes in the Zedang valley of the Yarlung Zangbo River, southern Tibetan plateau Jiaqiong Zhang1, Chunlai Zhang2,*, Qing Li2 and Xinghui Pan3 1State Key Laboratory of Soil Erosion and Dryland Farming on the Loess Plateau, Institute of Soil and Water Conservation, Northwest A&F University, Yangling 712100, Shaanxi, People’s Republic of China. 2State Key Laboratory of Earth Surface Processes and Resource Ecology, MOE Engineering Research Center of Desertification and Blown-Sand Control, Faculty of Geographical Science, Beijing Normal University, Beijing 100875, People’s Republic of China. 3Hydrology and Water Resources Survey Bureau of Weifang, Weifang 261061, Shandong, People’s Republic of China. *Corresponding author. e-mail: [email protected] MS received 24 March 2017; revised 24 January 2018; accepted 5 April 2018; published online 1 December 2018 Climbing and falling dunes are widespread in the wide valleys of the middle reaches of the Yarlung Zangbo River. Along a sampling transect running from northeast to southwest through 10 climbing dunes and two falling dunes in the Langsailing area, the surface sediments were sampled to analyse the grain-size characteristics, to clarify the transport pattern of particles with different grain sizes, and to discuss the effects of terrain factors including dune slope, mountain slope, elevation and transport distance to sand transport. Sand dunes on both sides of the ridge are mainly transverse dunes. Fine and medium sands were the main particles, with few very fine and coarse particles in the surface sediments. -

Particle Size Characterization of Historic Sediment Deposition from a Closed Estuarine Lagoon, Central California

Estuarine, Coastal and Shelf Science 126 (2013) 23e33 Contents lists available at SciVerse ScienceDirect Estuarine, Coastal and Shelf Science journal homepage: www.elsevier.com/locate/ecss Particle size characterization of historic sediment deposition from a closed estuarine lagoon, Central California Elizabeth Burke Watson a,*, Gregory B. Pasternack a, Andrew B. Gray a, Miguel Goñi b, Andrea M. Woolfolk c a Department of Land, Air & Water Resources, 228 Veihmeyer Hall, University of California, Davis, CA 95616, USA b College of Oceanic and Atmospheric Sciences, Oregon State University, 104 COAS Administration Building, Corvallis, OR 97331, USA c Elkhorn Slough National Estuarine Research Reserve, 1700 Elkhorn Rd., Watsonville, CA 95076, USA article info abstract Article history: Recent studies of estuarine sediment deposits have focused on grain size spectra as a tool to better Received 22 May 2012 understand depositional processes, in particular those associated with tidal inlet and basin dynamics. Accepted 2 April 2013 The key to accurate interpretation of lithostratigraphic sequences is establishing clear connections be- Available online 18 April 2013 tween morphodynamic changes and the resulting shifts in sediment texture. Here, we report on coupled analysis of shallow sediment profiles from a closed estuarine lagoon in concert with recent changes in Keywords: lagoon morphology reconstructed from historic sources, with a specific emphasis on the ability of suite sediment sorting statistics to provide meaningful insights into changes in sediment transport agency. We found that a sediment texture granulometry major reorganization in lagoon morphology, dating to the 1940s, was associated with a shift in sediment fi lagoon sedimentation deposition patterns. The restricted inlet was associated with deposition of sediments that were ner, less intermittently open estuaries negatively skewed, and less leptokurtic in distribution than sediments deposited while the lagoon had a ICOLL more open structure.