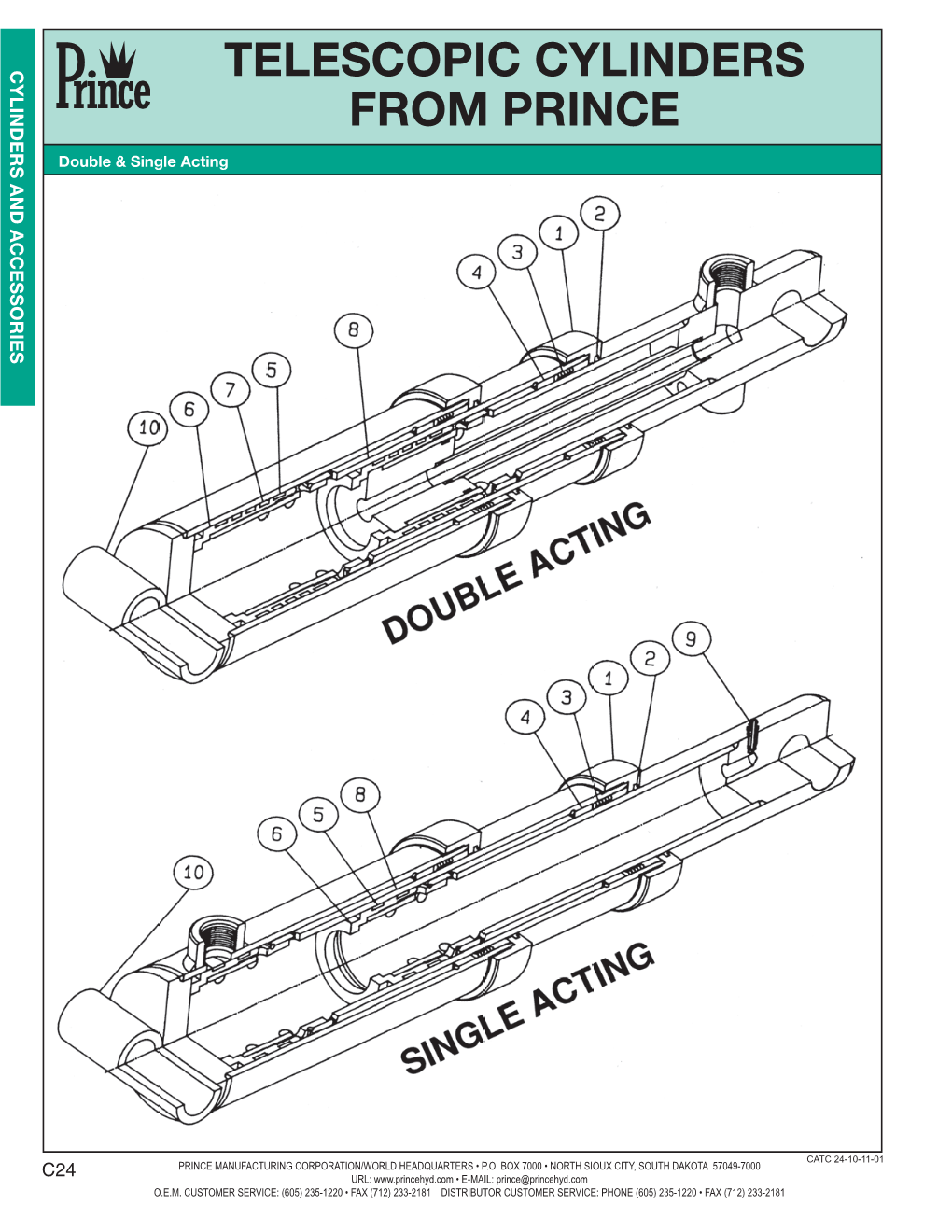

Double Acting Telescopic Cylinder Specifications Code No

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Introduction to Hydraulic Actuators

Introduction to hydraulic actuators By - Kamalesh 16-11-2012 History and definition Inventor Joseph Bramah of England invented Hydraulic press and was issued a patent on this press in 1795. Pressurized hydraulic fluid used to transfer energy from flow and pressure to drive hydraulic machinery. 01 Principle of hydraulic system Pascal's law is the basis of hydraulic drive systems. 02 Basic hydraulic system Hydraulic jack 03 Hydraulic actuators 1. Hydraulic motors 2. Hydraulic cylinders 04 Hydraulic motors A hydraulic motor is a mechanical actuator that converts hydraulic pressure and flow into torque and angular displacement (rotation). 05 Hydraulic cylinders A Hydraulic cylinder (also called a linear hydraulic motor) is a mechanical actuator that is used to give a unidirectional force through a unidirectional stroke. Single acting vs. double acting 1. Single acting cylinders are economical and the simplest design. Hydraulic fluid enters through a port at one end of the cylinder, which extend the rod by means of area difference. An external force returns or gravity returns the piston rod. 2. Double acting cylinders have a port at each end, supplied with hydraulic fluid for both the retraction and extension. 06 Components of a hydraulic cylinder 1. Cylinder barrel 2. Cylinder base or cap 3. Cylinder head 4. Piston 5. Piston rod 6. Seal gland 7. Seals (nitrile rubber, Polyurethane or Fluorocarbon Viton) 07 Cylinder designs Telescopic cylinder These are multistage cylinders which can fit in the smaller dimensions of machine. Plunger cylinder An hydraulic cylinder without a piston or with a piston without seals is called a plunger cylinder. -

![Lecture 14 HYDRAULIC ACTUATORS [CONTINUED]](https://docslib.b-cdn.net/cover/7003/lecture-14-hydraulic-actuators-continued-1667003.webp)

Lecture 14 HYDRAULIC ACTUATORS [CONTINUED]

Lecture 14 HYDRAULIC ACTUATORS [CONTINUED] 1. 7 First-, Second- and Third-Class Lever Systems Many mechanisms use hydraulic cylinders to transmit motion and power. Among these, lever mechanisms such as toggles, the rotary devices and the push--pull devices use a hydraulic cylinder. In this section, the mechanics of cylinder loading used in first-class, second-class and third-class lever systems is being discussed. 1. 7.1 First-Class Lever System Fixed Cylinder hinge pin rod pin Fixed hinge pin Cylinder Figure 1. 21 First-class lever system In this lever system, the fixed-hinge point is located in between the cylinder and the loading point. The schematic arrangement of a first-class lever system with a hydraulic cylinder is shown in Fig.1. 21. In this system, the downward load acts at the lever end. The cylinder has to apply a downward force to lift the load. The cylinder has a clevis mounting arrangement; it pivots about its eye-end center through an angle. However, the effect of this angle (around 10° to 15°) is negligible on the force and hence cannot be considered. Here, Fload = load to be operated, Fcyl = load to be exerted by a hydraulic cylinder, L1 = distance from the rod end to the pivot point, L2 = distance from the pivot point to the loading point and θ = inclination of the lever measured with respect to the horizontal line at the hinge. When the load is being lifted, the cylinder force rotates the lever in an anticlockwise direction about the pivot point. Due to this, a moment acts in the anticlockwise direction. -

Hydraulic Cylinders – Engineered and Made in Germany

Hydraulic cylinders Engineered and made in Germany. OUR VISION As a forward-thinking traditional manufacturer, we are expanding our leading position as preferred supplier for hydraulic cylinders of well- known producers in the construction machine, crane and specialty machine industry. We focus on our core competencies and branch into new markets through investment. We are committed to our Black Forest location as shown by the modernization and expansion of our facility there. Andreas Riem, CEO WHO WE ARE Customers at center stage Your partner for demanding tasks Hengstler Zylinder GmbH is a leading manufacturer of high- We have the values of a traditional, medium-sized company, quality, customer-specific hydraulic cylinders. With over 80 and our customers and employees are at the heart of what years of experience we know our customers better than we do. On this basis we develop products and strategies almost anybody else. This individual support is valued and that are successful today and for the future. This makes has added to our reliability and fairness over many years. us a preferred partner for demanding tasks and bespoke solutions involving hydraulic cylinders. Our guiding principle We give customers more than they expect. From the initial idea right through to the finished product, we work closely with our customers. We put the focus on their individual needs, from advice about technology, through to production and customer service, to create win-win solutions. 2 WHAT SETS US APART? Solid expertise Quality awareness and customer Our strength is our specialized knowledge of the design, con- orientation at every level struction and manufacture of premium hydraulic cylinders Reliable quality, cooperative collaboration and mutual trust for construction machines, cranes and specialty machines. -

Master Brochure 2020 Updated.Indd

TABLE OF CONTENTS RAM........................................................................................ 1 RAM Cylinder Applications........................................... 2 RAM Quality......................................................................... 3 RAM Hydraulic Cylinders YORK Series (Standard Welded) Cross Tube................................................. 7 Clevis.............................................................. 10 Heavy Duty Cross Tube......................... 11 Heavy Duty Clevis..................................... 11 Stabilizer................................................................... 13 Standard Solid Locking Nut................ 15 Standard Split Locking Nut................. 17 Ball End Solid Locking Nut................... 18 Ball End Split Locking Nut................... 19 Thumb....................................................................... 20 Custom Heavy Duty............................................. 22 Custom Oversized................................................ 24 Piggy-Back............................................................... 26 Smart Sensor........................................................ 28 Telescopic Standard Single Acting........................ 30 Standard Double Acting...................... 32 Truck & Trailer Hoist............................. 36 Mast Raising.............................................. 40 Custom......................................................... 42 Synchronizing (Rephasing)............................... 44 RAMLok Wirelock............................................... -

Understanding Truck Mounted Hydraulic Systems

EIGHTH EDITION UNDERSTANDING TRUCK-MOUNTED HYDRAULIC SYSTEMS Corporate Headquarters • Muncie, Indiana Manufacturing Division • Tulsa, Oklahoma MUNCIE POWER PRODUCTS QUALITY POLICY Muncie Power Products is dedicated to providing quality products and services that will satisfy the needs and expectations of our customers. We are committed to the continual improvement of our products and processes to achieve our quality objectives, minimize costs to our customers and realize a reasonable profit that will provide a stable future for our employees. TABLE OF CONTENTS UNDERSTANDING TRUCK-MOUNTED Section 8 HYDRAULIC SYSTEMS ........................................ 2 OIL FILTERS ........................................................ 20 Suction strainers Section 1 Suction filters PRINCIPLES OF HYDRAULICS ........................... 3 Pressure filters Pascal’s law Return filters Four pressures Filter carts Atmospheric Neutral system Section 9 Pump operating HOSE AND FITTINGS ......................................... 21 Relief Pressure The Society of Automotive Engineers Hydraulic system efficiency Hose working pressures Open and closed center hydraulic systems Hose routing tips Open center Section 10 Closed center HYDRAULIC OILS ............................................... 24 Section 2 Viscosity PRIME MOVER ....................................................... 6 Lubricity Power take-offs Chemical contamination Engine crankshaft driven Particulate contamination Auxiliary engines Built-in contamination Belt driven pumps Inducted contamination -

Lecture 12 HYDRAULIC ACTUATORS

Lecture 12 HYDRAULIC ACTUATORS Learning Objectives Upon completion of this chapter, the student should be able to: Explain the classification of hydraulic actuators. Explain various types of hydraulic cylinders. Describe the construction and working of double-acting cylinders. Derive an expression for force, velocity and power for hydraulic cylinders. Analyze various lever systems using hydraulic cylinders. Explain the importance of cylinder cushioning. Explain various types of cylinder mountings used in fluid power. Evaluate the performance of hydraulic systems using cylinders. 1.1 Introduction Hydraulic systems are used to control and transmit power. A pump driven by a prime mover such as an electric motor creates a flow of fluid, in which the pressure, direction and rate of flow are controlled by valves. An actuator is used to convert the energy of fluid back into the mechanical power. The amount of output power developed depends upon the flow rate, the pressure drop across the actuator and its overall efficiency. Thus, hydraulic actuators are devices used to convert pressure energy of the fluid into mechanical energy. Depending on the type of actuation, hydraulic actuators are classified as follows: 1. Linear actuator: For linear actuation (hydraulic cylinders). 2. Rotary actuator: For rotary actuation (hydraulic motor). 3. Semi-rotary actuator: For limited angle of actuation (semi-rotary actuator). Hydraulic linear actuators, as their name implies, provide motion in a straight line. The total movement is a finite amount determined by the construction of the unit. They are usually referred to as cylinders, rams and jacks. All these items are synonymous in general use, although ram is sometimes intended to mean a single-acting cylinder and jack often refers to a cylinder used for lifting. -

Dynamic Simulation of the Harvester Boom Cylinder

machines Article Dynamic Simulation of the Harvester Boom Cylinder Rongfeng Shen *, Xiaozhen Zhang and Chengjun Zhou School of Transportation and Civil Engineering, Fujian Agriculture and Forestry University, Fuzhou 350002, China; [email protected] (X.Z.); [email protected] (C.Z.) * Correspondence: [email protected]; Tel.: +158-0607-7197 Academic Editor: Robert Parkin Received: 25 December 2016; Accepted: 17 March 2017; Published: 17 April 2017 Abstract: Based on the complete dynamic calculation method, the layout, force, and strength of harvester boom cylinders were designed and calculated. Closed simulations for the determination of the dynamic responses of the harvester boom during luffing motion considering the cylinder drive system and luffing angle position control have been realized. Using the ADAMS mechanical system dynamics analysis software, six different arm poses were selected and simulated based on the cylinder as the analysis object. A flexible model of the harvester boom luffing motion has been established. The movement of the oil cylinder under different conditions were analyzed, and the main operation dimensions of the harvester boom and the force condition of the oil cylinder were obtained. The calculation results show that the dynamic responses of the boom are more sensitive to the luffing acceleration, in comparison with the luffing velocity. It is seen that this method is very effective and convenient for boom luffing simulation. It is also reasonable to see that the extension of the distance of the bottom of the boom is shortened by adjusting the initial state of the boom in the working process, which can also effectively reduce the workload of the boom—thus improving the mechanical efficiency. -

Hydraulic Cylinders Catalog

HYDRAULIC CYLINDERS CATALOG DESIGN MANUFACTURE INTEGRATION INNOVATIVE MOBILE SOLUTIONS 1 87DESIGN7 382-285 0 MANUFACTUREEAGLE-HYDRAULIC.COM INTEGRATE 1 877 382-2850 EAGLE-HYDRAULIC.COM- INNOVATIVE MOBILE SOLUTIONS Eagle Hydraulic Inc. is a Canadian based manufacturer of custom and standard hydraulic solutions. OUR CAPABILITIES We manufacture hydraulic cylinders, hydraulic power OEM HYDRAULIC CYLINDERS units and pumps as well as engineer and integrate more than 500,000 other hydraulic components such as motors, 1 valves, manifolds, and many more options. STANDARD HYDRAULIC CYLINDERS Serving the mobile equipment industry for decades, our products are designed and supported from our head 2 office located in Mirabel, Quebec, Canada to exceed North American standards. HYDRAULIC POWER UNITS - AC We own and operate two hydraulic cylinder manufacturing - DC facilities located in China. Our manufacturing operations 3 are certified ISO TS16949. We are also a certified OEM production supplier to many large North American based HYDRAULIC COMPONENTS corporations. - Pumps - Manifolds - Motors - Filters Our services include custom components or system 4 - Valves - Remotes design, on-site visits, continuous support, flexible delivery - Tanks - Wireless controllers and stocking programs, inventory updates, many warranty - Toolboxes - ... options, and responsive service. We strive to provide you the best experience and deliver SYSTEM INTEGRATION high-quality merchandise faster than expected. 5 Eagle Hydraulic adds value through innovation, quality, respect, -

Cylinder Catalog 13Th Edition

Cylinder Catalog 13th Edition 3236 IRVING BOULEVARD DALLAS, TX 75247 (214) 351-1251 Toll Free (877)-838-7325 Fax (214) 214-351-3949 [email protected] WWW.HDDISTRIBUTORS.COM TABLE OF CONTENTS INTRODUCTION Introduction, Online Ordering, Catalog Offerings and Freight Information ..................................................ii - v Hercules Ordering Information and Terms and Conditions ....................................................................... vi - vii Credit Application ........................................................................................................................................... viii CYLINDERS Index .................................................................................................................................................................1 Hercules Brand Cylinders - Tie Rod and Welded ..................................................................................... 2 - 12 Snow Plow Cylinders ......................................................................................................................................13 Prince Cylinders ...................................................................................................................................... 14 - 19 Telescopics ........................................................................................................................................ 12, 20 - 27 Power Units ............................................................................................................................................ -

Hydraulic Actuators

LECTURE 12 TO 14 – HYDRAULIC ACTUATORS SELF EVALUATION QUESTIONS AND ANSWERS 1A pump supplies oil at 0.002 m3/s to a 50mm diameter double acting cylinder and a rod diameter is 20mm. If the load is 6000N both in extending and retracting, find a. Piston velocity during the extension stroke and retraction stroke b. Pressure during the extension stroke and retraction stroke c. Power during the extension stroke and retraction stroke 2A hydraulic cylinder has to move a table of weight 13kN. Speed of the cylinder is to be accelerated up to a velocity of 0.13m/s in 0.5 seconds and brought to stop within a distance of 0.02m. Assume coefficient of sliding friction as 0.15 and cylinder bore diameter as 50mm. Calculate the surge pressure. 3.A cylinder has a bore of 80mm diameter and a rod of 45mm diameter. It drives a load of 7000N, travelling at a velocity of 15m/min. The load slides on a flat horizontal surface having a coefficient of friction of 0.12. The load is to be decelerated to rest within a cushion length of 20mm. If the relief valve is set at 50 bar, compute the fluid pressure developed in the cushion. Load Pressure force Declaration Force Figure 1 for the Problem No 3 4.A cylinder has a bore of 125mm diameter and a rod of 70mm diameter. It drives a load of 2000 kg vertically up and down at a maximum velocity of 3 m/s. The load is slowed down to rest in the cushion length of 50mm. -

Unit 2. ACTUATORS and Power Unit Introduction: an Actuator Is a Component of Machines That Is Responsible for Moving Or Controlling a Mechanism Or System

Unit 2. ACTUATORS and Power Unit Introduction: An Actuator is a component of machines that is responsible for moving or controlling a mechanism or system. The supplied main energy source may be electric current, hydraulic fluid pressure, or pneumatic pressure. When the control signal is received, the actuator responds by converting the energy into mechanical motion. It is a device which converts fluid power into rotary power or converts fluid pressure into torque or linear power. Introduction- . They extract energy from a fluid, and convert it to mechanical energy to perform useful work. Hydraulic cylinders, also called linear actuators provide a force that drives an external load along a straight line. Hydraulic motors, also called rotary actuators, provide a torque that drives an external load along a circular path. Hydraulic F x v System Hydraulic Cylinder V x I P x Q Electric T x ω Hydraulic Motor Pump T x ω Hydraulic Motor Difference between Hydraulic Motor and Hydraulic Pump Hydraulic Motor Hydraulic Pump It is a device for delivering torque at a It is a device for delivering flow at a given pressure. The main emphasis is on given pressure. The main emphasis is on mechanical efficiency and torque that volumetric efficiency and flow. can be transmitted. Motors usually operate over a wide Pumps usually operate at high RPM. range of speed, from a low RPM to high RPM. Most motors are designed for In most situations, pumps usually bidirectional applications such as operate in one direction. braking loads, rotary tables. Motors may be idle for long time Pumps usually operate continuously.