Technical Letter | 05

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

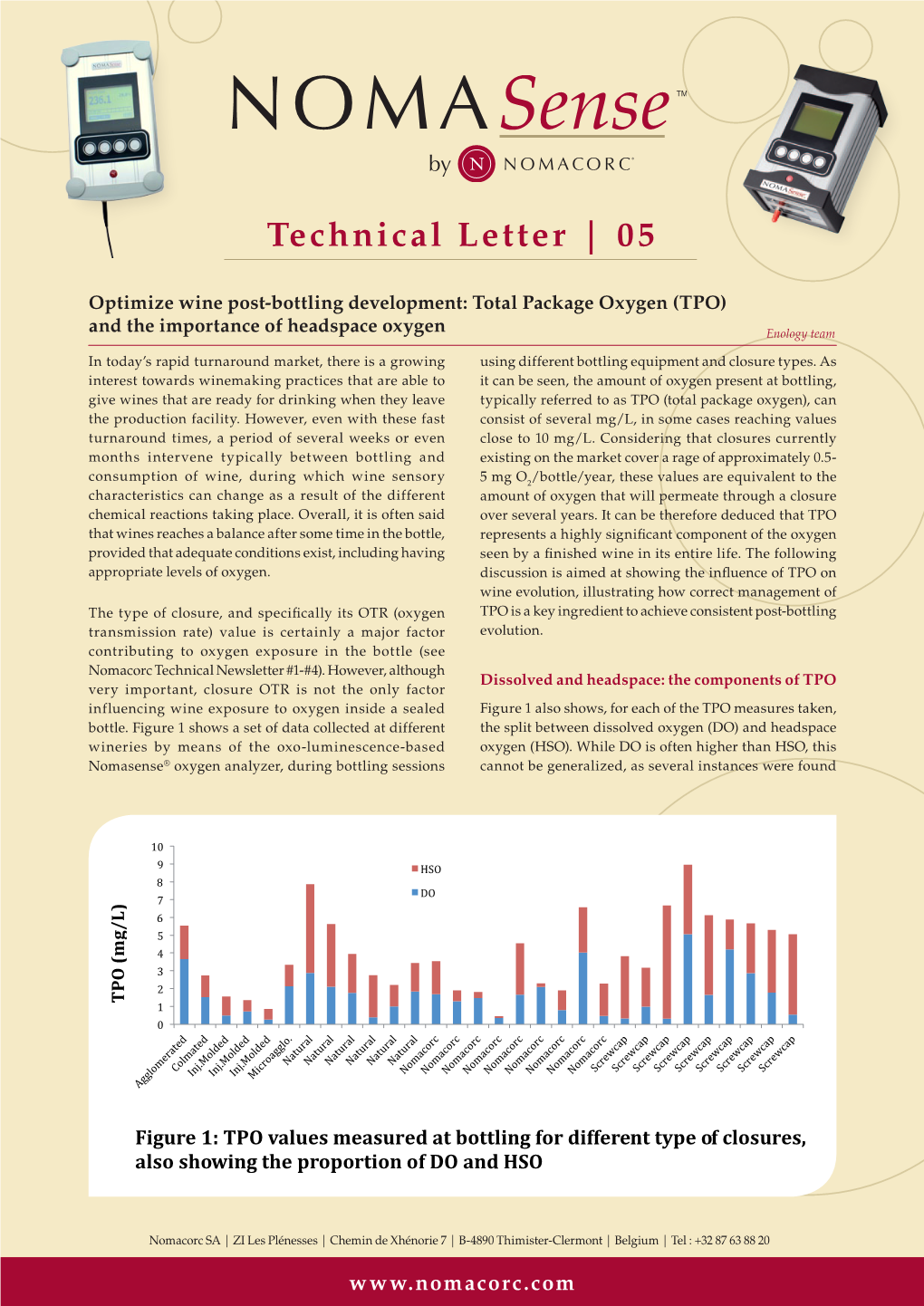

-

Wine Flavor 101C: Bottling Line Readiness Oxygen Management in the Bottle

Wine Flavor 101C: Bottling Line Readiness Oxygen Management in the Bottle Annegret Cantu [email protected] Andrew L. Waterhouse Viticulture and Enology Outline Oxygen in Wine and Bottling Challenges . Importance of Oxygen in Wine . Brief Wine Oxidation Chemistry . Physical Chemistry of Oxygen in Wine . Overview Wine Oxygen Measurements . Oxygen Management and Bottling Practices Viticulture and Enology Importance of Oxygen during Wine Production Viticulture and Enology Winemaking and Wine Diversity Louis Pasteur (1822-1895): . Discovered that fermentation is carried out by yeast (1857) . Recommended sterilizing juice, and using pure yeast culture . Described wine oxidation . “C’est l’oxygene qui fait le vin.” Viticulture and Enology Viticulture and Enology Viticulture and Enology Importance of Oxygen in Wine QUALITY WINE OXIDIZED WINE Yeast activity Color stability + Astringency reduction Oxygen Browning Aldehyde production Flavor development Loss of varietal character Time Adapted from ACS Ferreira 2009 Viticulture and Enology Oxygen Control during Bottling Sensory Effect of Bottling Oxygen Dissolved Oxygen at Bottling . Low, 1 mg/L . Med, 3 mg/L . High, 5 mg/L Dimkou et. al, Impact of Dissolved Oxygen at Bottling on Sulfur Dioxide and Sensory Properties of a Riesling Wine, AJEV, 64: 325 (2013) Viticulture and Enology Oxygen Dissolution . Incorporation into juices & wines from atmospheric oxygen (~21 %) by: Diffusion Henry’s Law: The solubility of a gas in a liquid is directly proportional to the partial pressure of the gas above the liquid; C=kPgas Turbulent mixing (crushing, pressing, racking, etc.) Increased pressure More gas molecules Viticulture and Enology Oxygen Saturation . The solution contains a maximum amount of dissolved oxygen at a given temperature and atmospheric pressure • Room temp. -

Sparkling Wine and Brandy Production

4/29/2014 Tonight’s Lecture History of sparkling wine Sparkling Wine and Definition of sparkling wine Champagne vs. sparkling wine Brandy Production Types of sparkling wine Wine 3 Production methods Introduction to Enology Méthode Champenoise How to serve sparkling wine Brandy production 4/29/2013 1 2 Sparkling Wine and Brandy What is sparkling wine? Basically its wine (usually white) with bubbles. These are two completely different beverages, In the U.S., the legal definition is based on but they are similar in that they are both CO2 content. made from wine. Still wine < 3.92 g/L In both products a simple, clean base wine is Effervescent >3.92 g/L first made and then the unique flavors come 1 g/L = 1000 PPM from the processing after the primary Most still wines have 0.5 to 1.5 g/L CO fermentation. 2 3 4 Champagne vs. sparkling wine Champagne vs. sparkling wine True Champagne is French sparkling wine from the Champagne region of France. Most US producers call it sparkling wine but occasionally even some French-owned In the US, Champagne can be used as a generic California wineries accidently refer to their term for sparkling wine if labeled with region of product as Champagne. origin (California champagne). You also must have used the term prior to 2006 to be grandfathered in. 5 6 Sparkling & Brandy 1 4/29/2014 Types of Sparkling Wine Types of Sparkling Wine French sparkling wine made outside the Champagne region is called Vins Mousseux Sekt (pronounced Zehkt) is the German (pronounced Moo-sur). -

Layout Copy 9

mericans have always used the packaging that wine comes in as A an indicator of its quality. In the past, jug and boxed wines usually meant cheap, bottom of the barrel wines, but that has all changed in the past couple of years. Not only have more and more alternative forms of wine packaging hit the market, but consumers can now trust that the wine inside will be good quality. From screw cap closures, to boxes and Tetra Paks, the evolution of wine packaging is underway. SCREW CAPS While natural cork still dominates with 80% market share, according to Wine Business Monthly’s 2007 Closure Survey, screw caps have increased their position over the prior year by almost 25%. The most commonly found wines in screw cap are white wines, imports and wines priced between $8 and $11.99. However, Boisset America’s De Loach’s Sonoma Stage Pinot Noir 2005, which retails for $85, is the first ultra premium wine to have a high-end screw cap called Stelvin Lux+, which Jean Charles Boisset, president of Boisset-America and vice presi- dent of Boisset La Famille des Grands Vins, says, “offers a slight oxygenation of the wine through the seal, allowing it to age with tremendous results.” While nationally screw cap sales account for 4% of the total 750 ml table wine sales, at www.wine.com it is 17.5%. Rich Bergsund, CEO of www.wine.com, attributes this growth to suppliers pushing screw caps “because they don’t want to see up to 5% of their efforts wasted due to cork taint. -

Wine Tasting, Second Edition: a Professional Handbook

Wine Tasting: A Professional Handbook Second Edition Food Science and Technology International Series Series Editor Steve L. Taylor University of Nebraska – Lincoln, USA Advisory Board Ken Buckle The University of New South Wales, Australia Mary Ellen Camire University of Maine, USA Roger Clemens University of Southern California, USA Hildegarde Heymann University of California – Davis, USA Robert Hutkins University of Nebraska – Lincoln, USA Ron S. Jackson Quebec, Canada Huub Lelieveld Bilthoven, The Netherlands Daryl B. Lund University of Wisconsin, USA Connie Weaver Purdue University, USA Ron Wrolstad Oregon State University, USA A complete list of books in this series appears at the end of this volume. Wine Tasting: A Professional Handbook Second Edition Ronald S. Jackson Cool Climate Oenology and Viticulture Institute, Brock University, St. Catharines, Ontario, Canada Academic Press is an imprint of Elsevier 30 Corporate Drive, Suite 400, Burlington, MA 01803, USA 525 B Street, Suite 1900, San Diego, California 92101-4495, USA 84 Theobald’s Road, London WC1X 8RR, UK Copyright # 2009, Elsevier Inc. All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopy, recording, or any information storage and retrieval system, without permission in writing from the publisher. Permissions may be sought directly from Elsevier’s Science & Technology Rights Department in Oxford, UK: phone: (þ44) 1865 843830, fax: (þ44) 1865 853333, E-mail: [email protected] You may also complete your request online via the Elsevier homepage (http://elsevier.com), by selecting “Support & Contact” then “Copyright and Permission” and then “Obtaining Permissions.” Library of Congress Cataloging-in-Publication Data APPLICATION SUBMITTED British Library Cataloguing-in-Publication Data A catalogue record for this book is available from the British Library. -

HOW RED WINES AGE What Happens When a Red Wine Ages in the Bottle? Lots! Three Processes Cause Changes to Colour, Mouthfeel and Flavour

HOW RED WINES AGE What happens when a red wine ages in the bottle? Lots! Three processes cause changes to colour, mouthfeel and flavour. 1. Colour from anthocyanin molecules, gradually lightens and changes from ruby-purple red towards more of a brick red, as the anthocyanin molecules polymerize (join up) with tannin molecules. With extended ageing the anthocyanin-tannin molecules can become so large that they no longer remain soluble in the wine and precipitate as a deposit. This natural deposit that forms in red wines often means that an old red is best decanted when serving to avoid having the sediment in the glass. 2. Mouthfeel – as the tannin molecules become larger, they take on a silky or velvety quality and mouthfeel becomes softer. 3. Flavour is enhanced – as many aroma precursors are released by acid hydrolysis in the wine as it ages, slowly over time. Wines contain many aroma compounds that are formed in the grape. However a proportion of these are formed in such a way that we cannot smell them. Remember that wine flavour is mainly due to what we can smell in the wine, either by smelling the wine’s bouquet in the glass or as we taste the wine in our mouth. As grapes ripen, many of the aroma compounds formed in the grapes are chemically bonded to glucose molecules* and in this form we can’t smell them even though they are in the young wine. (*The reason for this is unknown but could be related to the grape skin cells needing to store these compounds in a form that is less disruptive to cell membranes, or needing to store them in this “preserved” way until the grape seeds have fully formed.) During wine maturation the natural organic acids in the wine eventually break the bond between the aroma compounds and their glucose components, thus transforming the aroma compound into a form that can be smelt. -

Mitton-EU-Private-Portfolio.Pdf

Mitton International Wines GmbH was established in Berlin in 2002. We supply leading hotels, clubs and restaurants in Central Europe with carefully selected, hand-made, value for money wines imported from family-owned, boutique wineries in Australia, Argentina, South Africa and New Zealand. We have selected regionally diverse wines from important wine growing regions that highlight the styles of these varied terroirs and winemakers. Our main office is located in Berlin, Germany and we have storage facilities and delivery partners in Milan, Monte Carlo, Prague and Warsaw. Our partners are supported by our main office with promotions and sales and in turn deliver promptly and efficiently in these regions. Before moving to Germany, Managing Director Bradley Mitton worked for eleven years in the food and beverage industry in Asia. His experiences include working in the hospitality and wine trade in Australia, Hong Kong, Thailand, Philippines and South Korea. His passion for excellence was generated through working with and meeting great vintners in particular Robert Mondavi, Trimbach of Alsace, Drouhin of Burgundy, Chapoutier of the Rhone Valley and other iconic new world wine figures. Bradley travels throughout Europe training and educating hotel and restaurant employees in the diversity and regionality of New World wines. In conjunction with our gourmet club concept “Club Vivanova” (www.clubvivanova.com), we organise various events around Europe with creative concepts that offer our consumers the chance to taste wines in a fun and informative atmosphere. In combining these events with other co-sponsoring corporations, we offer excellent networking and socialising opportunities. Current Brand Distribution Eden Mill Gin . -

Contents Section 1 - for the Love of Wine

For the Love of Wine – Basic Wine Knowledge Contents Section 1 - For the love of wine ........................................................................................................................................ 2 For the love of wine ...................................................................................................................................................... 2 History of wine .............................................................................................................................................................. 2 History of wine in Australia ........................................................................................................................................... 3 Wine Making Process .................................................................................................................................................... 3 What gives wine its colour? .......................................................................................................................................... 4 Wine Terminology ......................................................................................................................................................... 5 Section 2 – Varieties and Regions ................................................................................................................................... 10 Wine Varieties ............................................................................................................................................................ -

The Australian Wine Research Institute Annual Report 2001 T

The Australian Wine Research Institute Annual Report 2001 T Council Members Registered office Mr D.J. McWilliam, BSc, MSc Waite Road, Urrbrae, SA 5064 Chairman—Elected a Postal Address: member under Clause 6(e) PO Box 197, Glen Osmond, SA 5064 of the Articles of Association t (08) 83 03 66 00 f (08) 83 03 66 01 Mr R.E. Day, BAgSc, BAppSc Elected a member under Clause 6(e) of the Articles The Company of Association The Australian Wine Research Institute was incorporated under Mr R.L. Gibson, the South Australian Companies Act on 27 April 1955. It is BAppSc, BAppSc a company limited by guarantee, it does not have a share Elected a member under capital and it has been permitted, under licence, to omit the Clause 6(e) of the Articles word ‘limited’ from its registered name. of Association The Memorandum of Association of The Australian Wine Mr P.F. Hayes, Research Institute sets out in broad terms the aims of the BSc, BAppSc, MSc, DipEd Institute and the Report of the Committee of Review for the Elected a member under Institute published in March 1977 identified the following Clause 6(e) of the Articles specific aims: of Association 1. To carry out applied research in the field of oenology. 2. To service the extension needs of the winemakers of Australia. Professor P.B. Høj, 3 To be involved in the teaching of oenology at both MSc, PhD undergraduate and postgraduate levels. Ex officio under Clause 6(d) 4. To assume responsibility for the co-ordination of oenological of the Articles of Association activities, and the collection, collation and dissemination as Director of the Institute of information on oenological and viticultural research to the benefit of the Australian wine industry. -

July 1, 2001 Page 1 of 5 2000 Scherrer Zinfandel Futures Offering

July 1, 2001 Page 1 of 5 2000 Scherrer Zinfandel Futures Offering & 1999 Fall Releases We are happy to announce the 2000 Zinfandel futures offering (our tenth vintage) as well as our first fall wine releases. Over the past few years, the number of wines we produce each year has grown to nearly a dozen. Some of these wines beg for more time in bottle before release, so it seems natural to go to two releases per year (spring and fall) despite the difficulty in managing the paperwork so close to harvest. The 2000 growing season was punctuated by several very hot periods. The early heat reduced the crop size, as well as the homogeneity of ripening of the Zinfandel (generally and issue). Where 1999 gave us Zinfandel with few shriveled berries and raisins, 2000 yielded many shriveled and raisined berries along with perfectly ripened ones on the same cluster. Our destemmer is modified to deal with this, so the majority of raisins stick to the stems and are discarded. Then a hot streak at harvest dehydrated most of the berries, pushing the alcohol levels to just over 15%. This is now commonplace with other producers, yet unusual for us. The resulting 2000 Zinfandels are a bit more generous, jammy and smoother than usual for us at this point, particularly compared to the 1999=s. The alcohol level shows after drinking about half a bottle, so be careful. I bet some critics will give our 2000=s better marks for these very reasons. Stylistically, this vintage breaks new ground for us. -

April 2020 Ogen

OHIO GRAPE-WINE ELECTRONIC NEWSLETTER Edited by: Dr. Maria Smith April / 2020 Photo: Early bud break variety ‘Marquette’, Georgetown, OH on 08 Apr 2020. Photo credit: Phil Weber IN THIS ISSUE: 2020 Spring Freeze 2020 Spring Freeze ............................ 2 The 2020 growing season commenced at the end of March for REMINDER! 2019 Grape production southern Ohio and late April for northern Ohio. Due to a major and pricing survey ............................... 5 cold snap in mid-April, many growers experienced freeze injury to emerging shoots in the South. We have provided a recap of Wooster Vineyard Update ................. 6 those events and a guide on how to proceed in this issue of Enology COVID update ...................... 8 OGEN. Dissolved oxygen during bottling .... 12 For wineries, Todd Steiner has provided guidance towards Wines & Vines News ........................... 15 managing wine oxygen during bottling. Contact us! ............................................. 16 Lastly, if you grow grapes and have not yet responded to the 2019 Grape Production and Pricing survey, please do so. It will be open until May 15, 2020. -Maria and the OSU V&E team Vineyard management following the April 2020 spring freeze events By: Imed Dami and Maria Smith, HCS-OSU Following a mild winter, early bud break grape varieties across southern Ohio suffered shoot injury following several days of below freezing temperatures during the week of April 12, 2020. April freeze events across the state Several days of below freezing (32°F) temperatures arrived during the week of April 12, with the coldest temperatures occurring on the morning of April 16, 2020 (Table 1; Fig. 1). On April 16, temperatures across the state ranged between 25.3°F at Piketon in south-central Ohio to 29.5°F in the northeastern Lake Erie region (Table 1). -

Pinotfile Vol 10 Issue 5

Pinot Noir Brings You Closer to God Volume 10, Issue 5 February 26, 2015 Celebrating the 50th Anniversary of Papa Pinot’s Legacy I was fortunate to be one of the 250 people who attended The Eyrie Vineyards Fiftieth Anniversary Vertical Tasting in Portland, Oregon, this past February 22, 2015, hosted by Diana and Jason Lett. This momentous event commemorated fifty years since David Lett planted the first Pinot Noir vines in the Willamette Valley of Oregon on February 22, 1965. I have been enthralled with the story of David Lett and wrote extensively about the first plantings of Willamette Valley Pinot Noir in a previous issue (“Oregon Pinot Noir: Who Planted First?”: www.princeofpinot.com/article/ 1090/). It was not surprising then that I could not contain my enthusiasm for this occasion that was enlivened by cherished memories, abundant applause, lively toasts and extraordinary wines. Speaking to an avid crowd of family, friends, customers, wine press, sommeliers, and winemakers from around the world, Diana Lett led off the festivities describing her first meeting with David Lett at a book publisher’s conference in the Midwest in 1965. After David had planted his first Pinot Noir cuttings in early 1965, he sold college textbooks to support himself, and this led to the couple’s fortuitous meeting. Three months after their chance meeting, they were married, and Diana found herself in a muddy field in the Dundee Hills in a yellow raincoat, helping David establish the first Eyrie vineyard. The remainder of the afternoon was orchestrated by Jason Lett, who provided his personal insight into the origins of The Eyrie Vineyards, the establishment of the vineyards and winery, the transition upon David’s passing in 2013, and the present challenges of the winery. -

A Look at Wine Closures

Innovative Packaging for the Wine Industry: A Look at Wine Closures By Denise Gardner Virginia Tech Food Science and Technology Duck Pond Dr. Blacksburg, VA 24061 2008 At an International Screwcap Symposium in November 2004, Peter Goddon from the Australian Wine Research Institute (AWRI) was quoted, “Closure variation may have a greater impact on wines and wine quality than the widely discussed and debated terroir issues. After about a month in the bottle, wines under different types of closures will never be the same.” Since the Australian industry first published consumer results of using different closure types on wines, the debate on closures has blown open. As of about ten years ago, natural cork was still the dominant closure type used for wine bottles (Phillips, 2007c). But since the age of technology has provided choices for winemakers in how they close their bottles, a range of synthetic corks to screw caps are now provided. The following report will highlight the history of wine closure packaging, five closure packaging possibilities used in the wine industry, their problems and benefits, and conclude with some insight what the future of wine packaging may entail. WINE CLOSURE HISTORY Wine. The word sounds simple enough, but in the past few decades, the scientific knowledge of the wine process has become so extensive that today’s winemakers are faced with a number of choices from the vineyard to the bottle. Wine closures are used to inhibit the extensive contact with oxygen, which causes oxidation of the wine (Robinson, 2006). Since wine has been manufactured, a number of different closure and bottle styles have been present through history.