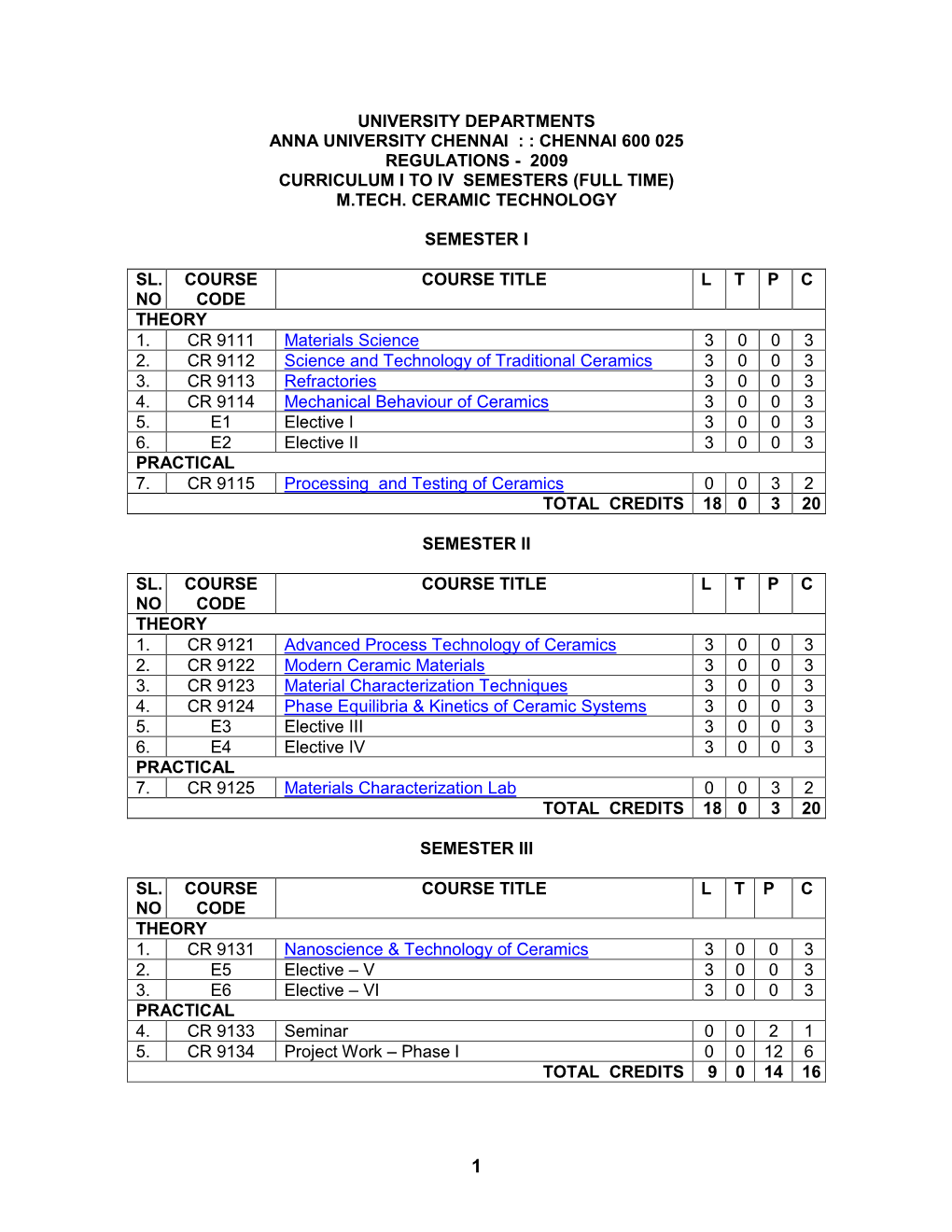

2009 Curriculum I to Iv Semesters (Full Time) M.Tech

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Ultradeep Fused Silica Glass Etching with an HF- Resistant Photosensitive Resist for Optical Imaging Applications

Ultradeep fused silica glass etching with an HF- resistant photosensitive resist for optical imaging applications John M Nagarah and Daniel A Wagenaar Broad Fellows Program and Division of Biology California Institute of Technology 1200 E. California Blvd. MC 216-76 Pasadena, CA 91125 [email protected] [email protected] Abstract Microfluidic and optical sensing platforms are commonly fabricated in glass and fused silica (quartz) because of their optical transparency and chemical inertness. Hydrofluoric acid (HF) solutions are the etching media of choice for deep etching into silicon dioxide substrates, but processing schemes become complicated and expensive for etching times greater than 1 hour due to the aggressiveness of HF migration through most masking materials. We present here etching into fused silica more than 600 μm deep while keeping the substrate free of pits and maintaining a polished etched surface suitable for biological imaging. We utilize an HF-resistant photosensitive resist (HFPR) which is not attacked in 49% HF solution. Etching characteristics are compared for substrates masked with the HFPR alone and the HFPR patterned on top of Cr/Au and polysilicon masks. We used this etching process to fabricate suspended fused silica membranes, 8–16 μm thick, and show that imaging through the membranes does not negatively affect image quality of fluorescence microscopy of biological tissue. Finally, we realize small through-pore arrays in the suspended membranes. Such devices will have applications in planar electrophysiology platforms, especially where optical imaging is required. 1. Introduction Glass and fused silica are appealing materials for constructing microelectromechanical systems (MEMS), lab-on-a-chip, and microfluidic platforms due to their chemical inertness, biocompatibility, optical transparency, mechanical rigidity, high melting point, electrical insulation, gas impermeability, and ability to bond to silicon, glass, and polydimethylsiloxane (PDMS) [1-3]. -

RTU Course "Chemistry and Technology of Glass"

Rīgas Tehniskā universitāte 25.09.2021 13:41 RTU Course "Chemistry and Technology of Glass" 14113 Department of Silicate, High Temperature and Inorganic Nanomaterials Technology General data Code ĶST554 Course title Chemistry and Technology of Glass Course status in the programme Compulsory/Courses of Limited Choice; Courses of Free Choice Responsible instructor Gundars Mežinskis Volume of the course: parts and credits points 1 part, 3.0 Credit Points, 4.5 ECTS credits Language of instruction LV, EN Annotation Theoretical principles of the melting and crystallization of glasses.The melting of glasses in conditions of industry. Principles and the equipment of the main technologies of glasses. The treatment and decoration of glassy materials. The characterisation of newest tendencies in the technology of glass and glassy materials. Goals and objectives of the course in terms of Understand the structural characteristics of the glass. To be competent in in glass compositions for competences and skills different application areas, glass characteristics and production technologies. Able to determine the most important glass properties. Structure and tasks of independent studies Using the compendium of lectures and literature data, the student prepares for its own laboratory work, after the execution of works presents laboratory reports, draw conclusions. Recommended literature 1.R.Švinka, V. Švinka. Silikātu materiālu ķīmija un tehnoloģija. Rīga, 1997. 192 lpp. 2.J.E.Shelby. Introduction to Glass Science and Technology. 2nd ed. The Royal Society of Chemistry, 2005. 291 p. 3.High-Performance Glasses. Ed. M.Cable and J.M.Parker . Blackie, Glasgow and London, 1992. 346 p. 4.В.С.Горшков, В.Г.Савельев, Н.Ф.Федоров. -

Opto-Fluidic Manipulation of Microparticles and Related Applications

University of South Florida Scholar Commons Graduate Theses and Dissertations Graduate School 11-10-2020 Opto-Fluidic Manipulation of Microparticles and Related Applications Hao Wang University of South Florida Follow this and additional works at: https://scholarcommons.usf.edu/etd Part of the Biomedical Engineering and Bioengineering Commons Scholar Commons Citation Wang, Hao, "Opto-Fluidic Manipulation of Microparticles and Related Applications" (2020). Graduate Theses and Dissertations. https://scholarcommons.usf.edu/etd/8601 This Dissertation is brought to you for free and open access by the Graduate School at Scholar Commons. It has been accepted for inclusion in Graduate Theses and Dissertations by an authorized administrator of Scholar Commons. For more information, please contact [email protected]. Opto-Fluidic Manipulation of Microparticles and Related Applications by Hao Wang A dissertation submitted in partial fulfillment of the requirements for the degree of Doctor of Philosophy in Biomedical Engineering Department of Medical Engineering College of Engineering University of South Florida Major Professor: Anna Pyayt, Ph.D. Robert Frisina, Ph.D. Steven Saddow, Ph.D. Sandy Westerheide, Ph.D. Piyush Koria, Ph.D. Date of Approval: October 30, 2020 Key words: Thermal-plasmonic, Convection, Microfluid, Aggregation, Isolation Copyright © 2020, Hao Wang Dedication This dissertation is dedicated to the people who have supported me throughout my education. Great appreciation to my academic adviser Dr. Anna Pyayt who kept me on track. Special thanks to my wife Qun, who supports me for years since the beginning of our marriage. Thanks for making me see this adventure though to the end. Acknowledgments On the very outset of this dissertation, I would like to express my deepest appreciation towards all the people who have helped me in this endeavor. -

Development of Elastomeric Optofluidic Devices for Lasing and Sensing

Development of Elastomeric Optofluidic Devices for Lasing and Sensing THÈSE NO 5451 (2012) PRÉSENTÉE LE 31 AOÛT 2012 À LA FACULTÉ DES SCIENCES ET TECHNIQUES DE L'INGÉNIEUR LABORATOIRE D'OPTIQUE PROGRAMME DOCTORAL EN PHOTONIQUE ÉCOLE POLYTECHNIQUE FÉDÉRALE DE LAUSANNE POUR L'OBTENTION DU GRADE DE DOCTEUR ÈS SCIENCES PAR Wuzhou SONG acceptée sur proposition du jury: Prof. C. Moser, président du jury Prof. D. Psaltis, directeur de thèse Prof. A. Kristensen, rapporteur Prof. J. Perruisseau-Carrier, rapporteur Prof. D. Rabus, rapporteur Suisse 2012 To my parents, to whom I owe what I am, to my sisters I could ever have had, to my teachers and friends, Many thanks! Acknowledge First of all, I would like to thank my thesis adviser Prof. Demetri Psaltis for giving me the opportunity to pursue research in his group. He can always motivate my research interest and strongly support my research activity. I also appreciate his valuable input in many aspects of science, life and human interaction. Absolutely my study in Switzerland is my precious experience in all my life. Meanwhile, many thanks go to all my colleagues in our lab, particularly to Dr. Andreas Vasdekis who gave me much guidance at beginning on the optofluidic dye laser projects, eventually we have built a deep friendship through our numeric discussions and arguments. Our lab is a big harmonic group; we often exchanged our different opinions, helped each other and we have shared a fruitful time in the past 4 years. I am grateful to CMI staffs for their patient and assistance in teaching me and helping to solve many technical issues. -

Micro-Hole Drilling on Glass Substrates—A Review

micromachines Review Micro-Hole Drilling on Glass Substrates—A Review Lucas A. Hof 1 and Jana Abou Ziki 2,* 1 Department of Mechanical & Industrial Engineering, Concordia University, 1455 de Maisonneuve Blvd. West, Montreal, QC H3G 1M8, Canada; [email protected] 2 Bharti School of Engineering, Laurentian University, Sudbury, ON P3E 2C6, Canada * Correspondence: [email protected]; Tel.: +1-705-675-1151 (ext. 2296) Academic Editors: Hongrui Jiang and Nam-Trung Nguyen Received: 14 November 2016; Accepted: 3 February 2017; Published: 13 February 2017 Abstract: Glass micromachining is currently becoming essential for the fabrication of micro-devices, including micro- optical-electro-mechanical-systems (MOEMS), miniaturized total analysis systems (µTAS) and microfluidic devices for biosensing. Moreover, glass is radio frequency (RF) transparent, making it an excellent material for sensor and energy transmission devices. Advancements are constantly being made in this field, yet machining smooth through-glass vias (TGVs) with high aspect ratio remains challenging due to poor glass machinability. As TGVs are required for several micro-devices, intensive research is being carried out on numerous glass micromachining technologies. This paper reviews established and emerging technologies for glass micro-hole drilling, describing their principles of operation and characteristics, and their advantages and disadvantages. These technologies are sorted into four machining categories: mechanical, thermal, chemical, and hybrid machining (which combines several machining methods). Achieved features by these methods are summarized in a table and presented in two graphs. We believe that this paper will be a valuable resource for researchers working in the field of glass micromachining as it provides a comprehensive review of the different glass micromachining technologies. -

Eindhoven University of Technology MASTER Optofluidic Control of Photonic Crystal Cavities Speijcken, N.W.L

Eindhoven University of Technology MASTER Optofluidic control of photonic crystal cavities Speijcken, N.W.L. Award date: 2012 Link to publication Disclaimer This document contains a student thesis (bachelor's or master's), as authored by a student at Eindhoven University of Technology. Student theses are made available in the TU/e repository upon obtaining the required degree. The grade received is not published on the document as presented in the repository. The required complexity or quality of research of student theses may vary by program, and the required minimum study period may vary in duration. General rights Copyright and moral rights for the publications made accessible in the public portal are retained by the authors and/or other copyright owners and it is a condition of accessing publications that users recognise and abide by the legal requirements associated with these rights. • Users may download and print one copy of any publication from the public portal for the purpose of private study or research. • You may not further distribute the material or use it for any profit-making activity or commercial gain Optofluidic control of photonic crystal cavities . Research group: Photonics and Semiconductor Nanophysics (PSN) Eindhoven University of Technology (TU/e) Supervisor: Dr. R.W. van der Heijden Dr. M. Dündar Professor: Prof. Dr. A. Fiore Abstract During the last decade, the combination of the fields of optics and micro‐fluidics has been investigated for their mutual benefits, which resulted in the emerging field of optofluidics. In this project the possibilities and applications of integrating fluids in photonic crystal (PhC) structures are explored. -

3-Dimensional Microstructural

View metadata, citation and similar papers at core.ac.uk brought to you by CORE provided by ScholarBank@NUS 3-DIMENSIONAL MICROSTRUCTURAL FABRICATION OF FOTURANTM GLASS WITH FEMTOSECOND LASER IRRADIATION TEO HONG HAI NATIONAL UNIVERSITY OF SINGAPORE 2009 3-DIMENSTIONAL MICROSTRUCTURAL FABRICATION OF FOTURANTM GLASS WITH FEMTOSECOND LASER IRRADIATION TEO HONG HAI (B. Eng. (Hons.), Nanyang Technological University) A THESIS SUBMITTED FOR THE DEGREE OF MASTER OF ENGINEERING DEPARTMENT OF ELECTRICAL AND COMPUTER ENGINEERING NATIONAL UNIVERSITY OF SINGAPORE 2009 Acknowledgement ACKNOWLEDGEMENTS I would like to take this opportunity to express my appreciation to my supervisor, Associate Professor Hong Minghui for his guidance during the entire period of my Masters studies. He has been encouraging particularly in trying times. His suggestions and advice were very much valued. I would also like to express my gratitude to all my fellow co-workers from the DSI-NUS Laser Microprocessing Lab for all the assistance rendered in one way or another. Particularly to Caihong, Tang Min and Zaichun for all their encouragement and assistance as well as to Huilin for her support in logistic and administrative issues. Special thanks to my fellow colleagues from Data Storage Institute (DSI), in particular, Doris, Kay Siang, Zhiqiang and Chin Seong for all their support. To my family members for their constant and unconditioned love and support throughout these times, without which, I will not be who I am today. i Table of Contents TABLE OF CONTENTS ACKNOWLEDGEMENTS -

Faculty of Fine Arts

FACULTY OF FINE ARTS Faculty of Fine Arts was established in 1983 as College of Applied Fine Arts with the law of 2809 and started accepting full time students in 1985-1986 academic year to the Departments of Graphics and Ceramics. The College assumed a new name in 1992 as Faculty of Fine Arts. The Faculty now has seven departments: Animation, Ceramic Arts, Graphic Arts, Interior Design, Painting, Printmaking Arts, and Sculpture. The Faculty strives to offer the best creative education to its students and houses laboratories, studios and up to date technical equipment to provide the best possible training and education to students. Before starting their freshman year the students go through a year of intensive English language program at the School of Foreign Languages. The objective of Fine Arts Faculty have pioneering graduates in their respective fields with aesthetic and creative training provided by the faculty. The graduates can be researchers as well as independent artists, designers or teachers (after receiving the teaching credential). Dean : Prof. Emel ŞÖLENAY Secretary of Faculty : Nazım Zeki ÖZTÜRK STAFF Professors: Mustafa AĞATEKİN, Zeliha AKÇAOĞLU, Rahmi ATALAY, Rıdvan COŞKUN, Münevver ÇAKI, Hüseyin ERYILMAZ, Hayri ESMER, Soner GENÇ, Saime HAKAN DÖNMEZER, F. Gonca İLBEYİ DEMİR, Gülbin KOÇAK, Sevim SELAMET, Sıdıka SEVİM, Hikmet SOFUOĞLU, Emel ŞÖLENAY, T. Fikret UÇAR, Bilgihan UZUNER, Leyla VARLIK ŞENTÜRK Associate Professors: Güldane ARAZ AY, Ezgi HAKAN MARTINEZ, Fethi KABA, Semih KAPLAN, Melike TAŞÇIOĞLU, Kemal ULUDAĞ, Nurbiye UZ Assistant professors: Sadettin AYGÜN, Ebru BARANSELİ, Sabahattin ÇALIŞKAN, Nurşen DİNÇ, Göktuğ GÜNKAYA, Duygu KAHRAMAN, Ekrem KULA, Çağlar OKUR, Cemalettin SEVİM, Çiğdem TAŞ ALİCENAP, Mehtap UYGUNGÖZ, N. -

2015 CHOICE BASED CREDIT SYSTEM M. Tech. CERAMIC TECHNOLOGY P

ANNA UNIVERSITY, CHENNAI UNIVERSITY DEPARTMENTS REGULATIONS – 2015 CHOICE BASED CREDIT SYSTEM M. Tech. CERAMIC TECHNOLOGY PROGRAMME EDUCATIONAL OBJECTIVES (PEOs) : I. To prepare students to excel in research or to succeed in Ceramic Technology profession through global, rigorous post graduate education. II. To provide students with a solid foundation in scientific and Technology fundamentals required to enrich Ceramic Technology. III. To train students with good scientific and engineering knowledge so as to comprehend, analyze, design, and create novel products and solutions for the real life problems. IV. To inculcate students in professional and ethical attitude, effective communication skills, teamwork skills, multidisciplinary approach, and an ability to relate Ceramic Technology issues to broader social context. V. To provide student with an academic environment aware of excellence, leadership, written ethical codes and guidelines, and the life-long learning needed for a successful professional career PROGRAMME OUTCOMES (POs): On successful completion of the programme, 1. Graduates will demonstrate knowledge of science and Technology. 2. Graduates will demonstrate an ability to identify, formulate and solve engineering problems. 3. Graduate will demonstrate an ability to design and conduct experiments, analyze and interpret data. 4. Graduates will demonstrate an ability to design a system, component or process as per needs and specifications. 5. Graduates will demonstrate an ability to visualize and work on laboratory and multidisciplinary tasks. 6. Graduate will demonstrate skills to use modern engineering tools, software and equipment to analyze problems. 7. Graduates will demonstrate knowledge of professional and ethical responsibilities. 8. Graduate will be able to communicate effectively in both verbal and written form. -

University of California Santa Cruz Hybrid Optofluidic

UNIVERSITY OF CALIFORNIA SANTA CRUZ HYBRID OPTOFLUIDIC BIOSENSORS A dissertation submitted in partial satisfaction of the requirements for the degree of DOCTOR OF PHILOSOPHY in ELECTRICAL ENGINEERING by Joshua W. Parks December 2016 The Dissertation of Joshua W. Parks is approved: Professor Holger Schmidt, Chair Professor Joel Kubby Professor Clair Gu Tyrus Miller Vice Provost and Dean of Graduate Studies Copyright © by Joshua W. Parks 2016 All rights reserved Table of Contents 1 Introduction ............................................................................................................ 1 2 Background ............................................................................................................ 5 2.1 Fluorophores and Fluorescence ....................................................................... 5 2.2 Fluorescent Reporters: Nucleic Acid Stains and Molecular Beacons ............. 8 2.3 ARROW Fundamentals ................................................................................. 12 2.3.1 Deriving the ARROW Condition ............................................................ 13 2.3.2 ARROW Device Fabrication .................................................................. 16 2.3.3 Fluorescence Based ARROW Detection ................................................ 20 2.4 PDMS Prototyping and Fabrication .............................................................. 24 3 Enhancement of ARROW Optofluidic Biosensors via Thermal Annealing ........ 29 3.1 Post Processing Low Temperature Thermal Annealing -

M.Tech. Ceramic Technology

UNIVERSITY DEPARTMENTS ANNA UNIVERSITY : : CHENNAI 600 025 REGULATIONS - 2013 I TO IV SEMESTERS CURRICULUM AND SYLLABUS (FULL TIME) M.TECH. CERAMIC TECHNOLOGY SEMESTER I COURSE COURSE TITLE L T P C CODE THEORY CR8101 Material Characterization Techniques 3 0 0 3 CR8102 Materials Science 3 0 0 3 CR8103 Mechanical Behaviour of Ceramics 3 0 0 3 CR8104 Traditional Ceramics 3 0 0 3 Elective I 3 0 0 3 Elective II 3 0 0 3 PRACTICAL CR8111 Material Characterization Lab 0 0 3 2 TOTAL CREDITS 18 0 3 20 SEMESTER II COURSE COURSE TITLE L T P C CODE THEORY CR8201 Advanced Ceramic Materials 3 0 0 3 CR8202 Ceramic Processing 3 0 0 3 CR8203 Phase Equilibria in Ceramic Systems 3 0 0 3 CR8204 Refractories 3 0 0 3 Elective III 3 0 0 3 Elective IV 3 0 0 3 PRACTICAL CR8211 Processing and Testing of Ceramics Lab 0 0 3 2 TOTAL CREDITS 18 0 3 20 SEMESTER III COURSE COURSE TITLE L T P C CODE THEORY CR8301 Nanoscience and Technology of Ceramics 3 0 0 3 Elective – V 3 0 0 3 Elective – VI 3 0 0 3 PRACTICAL CR8311 Industrial Training (Two weeks duration during II 0 0 0 1 Semester summer vacation) CR8312 Project Work – Phase I 0 0 12 6 CR8313 Seminar 0 0 2 1 TOTAL CREDITS 9 0 14 17 1 SEMESTER IV COURSE COURSE TITLE L T P C CODE PRACTICAL CR8411 Project Work – Phase II 0 0 24 12 TOTAL CREDITS 0 0 24 12 TOTAL NUMBER OF CREDITS TO BE EARNED FOR AWARD OF THE DEGREE 69 LIST OF ELECTIVES COURSE COURSE TITLE L T P C CODE CR8001 Abrasives 3 0 0 3 CR8002 Advanced Processing Techniques for Ceramics 3 0 0 3 CR8003 Advanced Refractory Engineering 3 0 0 3 CR8004 Bio-ceramics 3 -

Chemo-Thermal Micromachining of Glass: an Explorative Study

Chemo-Thermal Micromachining of Glass: An Explorative Study A thesis submitted to the Graduate School of the University of Cincinnati in partial fulfilment of the requirements for the degree of Master of Science In the Department of Mechanical Engineering of the College of Engineering and Applied Sciences by Arham Ali Bachelor of Technology in Mechanical Engineering Motilal Nehru National Institute of Technology Allahabad, India November 2018 Committee Chair: Dr. Murali Sundaram ABSTRACT Engineering materials such as glass and ceramics are finding numerous applications in electronics and communication, optics, chemical, aerospace and medical industries. Glass being a hard and brittle material poses huge machining challenges especially during micromachining. Traditional machining of glass by methods such as drilling or milling are generally difficult to achieve due to reasons ranging from excessive tool wear to abrupt breakage of glass. Chemical etching techniques can produce smooth machined surface on glass. Yet, chemical machining process is usually slow and often fail to produce high aspect ratio unless combined with some other additional masking techniques which are usually expensive. Laser beam machining when performed on glass produces micro-cracks along the machined edge due to uneven temperature distribution and residual stresses due to heat affected zones (HAZ). Wet laser beam machining, i.e. laser beam machining when performed under water instead of air results in considerable reduction in thermal defects. However, portion of laser energy is wasted in wet laser machining as heat loss in water. The motivation of this study is to use to minimize this loss and explore the possibility of utilizing this laser energy being absorbed by the medium to further increase machining.