$Sxxx2%Snssnn.S.Nysssns (Ssn

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Sodium-Bismuthate

He a lt h 2 0 Fire 0 2 0 Re a c t iv it y 0 Pe rs o n a l Pro t e c t io n J Material Safety Data Sheet Sodium bismuthate MSDS Section 1: Chemical Product and Company Identification Product Name: Sodium bismuthate Contact Information: Catalog Codes: SLS3700, SLS1480 Sciencelab.com, Inc. 14025 Smith Rd. CAS#: 12232-99-4 Houston, Texas 77396 RTECS: VZ1750000 US Sales: 1-800-901-7247 International Sales: 1-281-441-4400 TSCA: TSCA 8(b) inventory: Sodium bismuthate Order Online: ScienceLab.com CI#: Not available. CHEMTREC (24HR Emergency Telephone), call: Synonym: 1-800-424-9300 Chemical Name: Not available. International CHEMTREC, call: 1-703-527-3887 Chemical Formula: NaBiO3 For non-emergency assistance, call: 1-281-441-4400 Section 2: Composition and Information on Ingredients Composition: Name CAS # % by Weight Sodium bismuthate 12232-99-4 100 Toxicological Data on Ingredients: Sodium bismuthate LD50: Not available. LC50: Not available. Section 3: Hazards Identification Potential Acute Health Effects: Hazardous in case of eye contact (irritant), of inhalation. Potential Chronic Health Effects: Hazardous in case of eye contact (irritant), of inhalation. CARCINOGENIC EFFECTS: Not available. MUTAGENIC EFFECTS: Not available. TERATOGENIC EFFECTS: Not available. DEVELOPMENTAL TOXICITY: Not available. The substance is toxic to lungs, mucous membranes. Repeated or prolonged exposure to the substance can produce target organs damage. Section 4: First Aid Measures Eye Contact: Check for and remove any contact lenses. Do not use an eye ointment. Seek medical attention. Skin Contact: No known effect on skin contact, rinse with water for a few minutes. -

Using Sodium Bismuthate As an Oxidant and Sym-Diphenylcarbazide As a Complexing Agent

Chem. Anal. (Warsaw), 49, 405 (2004) Flow-Injection System for the Spectrophotometric Determination of Mn (II) Using Sodium Bismuthate as an Oxidant and Sym-diphenylcarbazide as a Complexing Agent by M. Noroozifar* and M. Khorasani-Motlagh Department of Chemistry, Sistan and Baluchestan University, Zahedan P.O. Box 98165-181, Iran Key words: flow-injection, manganese determination, sodium bismuthate reactor, sym-diphenylcarbazide Flow-injection spectrophotometric determination of manganese in aqueous solution, using a solid sodium bismuthate reactor has been presented. Manganese (Mn2+) can be determi- ned spectrophotometrically at 308 nm after its on-line oxidation to MnO at the room 4 temperature. In acidic media permanganate immediately reacts with sym-diphenylcarbazide to form a complex, the absorbance of which is measured. The linear range of the method was 5 × 10-71 × 10-4 mol L-1 with a detection limit (3σ) of 6 × 10-8 mol L-1. The proposed procedure was applied to the determination of Mn2+ in effluents and food, with a relative standard deviation better than 1.85%. The sampling frequency as high as 110 h-1 could be achieved. Zaproponowano spektrofotometryczn¹ metodê oznaczania manganu w wodnych roztworach w uk³adzie przep³ywowo-wstrzykowym z zastosowaniem reaktora z bizmutanem sodu. Mangan (Mn2+) oznaczano spektrofotometrycznie po uprzednim utlenieniu on-line, w temperaturze pokojowej, do MnO. W rodowisku kwanym nadmanganian natychmiast 4 reaguje z sym-difenylokarbazydem tworz¹c kompleks, którego absorbancja by³a mierzona. Zakres liniowoci metody wynosi³ 5 × 10-71 × 10-4 mol L-1, a granica wykrywalnoci (3σ) 6 × 10-8 mol L-1. Proponowan¹ metodê zastosowano do oznaczania Mn2+ w ciekach i ¿ywnoci uzyskuj¹c wzglêdne odchylenie standardowe lepsze ni¿ 1,85%. -

Sodium Bismuthate

Sodium bismuthate sc-203272 Material Safety Data Sheet Hazard Alert Code Key: EXTREME HIGH MODERATE LOW Section 1 - CHEMICAL PRODUCT AND COMPANY IDENTIFICATION PRODUCT NAME Sodium bismuthate STATEMENT OF HAZARDOUS NATURE CONSIDERED A HAZARDOUS SUBSTANCE ACCORDING TO OSHA 29 CFR 1910.1200. NFPA FLAMMABILITY0 HEALTH2 HAZARD INSTABILITY0 SUPPLIER Company: Santa Cruz Biotechnology, Inc. Address: 2145 Delaware Ave Santa Cruz, CA 95060 Telephone: 800.457.3801 or 831.457.3800 Emergency Tel: CHEMWATCH: From within the US and Canada: 877-715-9305 Emergency Tel: From outside the US and Canada: +800 2436 2255 (1-800-CHEMCALL) or call +613 9573 3112 PRODUCT USE Used in analysis (testing for manganese in iron, steel and ores). Used as a reagent and in pharmaceuticals. SYNONYMS Bi-Na-O3 Section 2 - HAZARDS IDENTIFICATION CHEMWATCH HAZARD RATINGS Min Max Flammability: 0 Toxicity: 2 Body Contact: 2 Min/Nil=0 Low=1 Reactivity: 0 Moderate=2 High=3 Chronic: 2 Extreme=4 CANADIAN WHMIS SYMBOLS 1 of 11 EMERGENCY OVERVIEW RISK Harmful if swallowed. Irritating to eyes, respiratory system and skin. POTENTIAL HEALTH EFFECTS ACUTE HEALTH EFFECTS SWALLOWED ! Accidental ingestion of the material may be harmful; animal experiments indicate that ingestion of less than 150 gram may be fatal or may produce serious damage to the health of the individual. ! Owing to limited gastro-intestinal absorption, administration of insoluble bismuth compounds by mouth does not usually give rise to acute toxic effects. They are excreted in the faeces. Stomatitis (ulceration of mouth parts) may result following ingestion. ! Absorbed bismuth salts permeate the body fluids and tissues and are excreted mainly in the urine but some bismuth is retained in tissues. -

Safety Data Sheet According to OSHA Hazard Communication Standard, 29 CFR 1910.1200 Initial Preparation Date: 01.15.2018 Page 1 of 8 Sodium Bismuthate

Safety Data Sheet According to OSHA Hazard Communication Standard, 29 CFR 1910.1200 Initial preparation date: 01.15.2018 Page 1 of 8 Sodium Bismuthate, SECTION 1: Identification Product identifier Product name: Sodium Bismuthate, Product code: S25534 Recommended use of the product and restriction on use Relevant identified uses: Not determined or not applicable. Uses advised against: Not determined or not applicable. Reasons why uses advised against: Not determined or not applicable. Manufacturer or supplier details Manufacturer: Supplier: AquaPhoenix Scientific Fisher Science Education 860 Gitts Run Road 6771 Silver Crest Road Hanover Nazareth PA 17331 PA 18064 (717) 632-1291 800 955-1177 Emergency telephone number: United States Emergency Telephone No.: 800-255-3924 SECTION 2: Hazard(s) identification GHS classification: Acute toxicity (oral), category 4 Label elements Hazard pictograms: Signal word: Warning Hazard statements: H302 Harmful if swallowed Precautionary statements: P264 Wash skin thoroughly after handling P270 Do not eat, drink or smoke when using this product P301+P330+P312 IF SWALLOWED: Rinse mouth. Call a POISON CENTER or doctor/physician if you feel unwell. P405 Store locked up P501 Dispose of contents and container as instructed in Section 13 Hazards not otherwise classified: None SECTION 3: Composition/information on ingredients Identification Name Weight % Generated by SDSPublisher (patent-pending) www.GSMSDS.com, 1-813-435-5161 Safety Data Sheet According to OSHA Hazard Communication Standard, 29 CFR 1910.1200 Initial preparation date: 01.15.2018 Page 2 of 8 Sodium Bismuthate, CAS number: Sodium Bismuthate 100 12232-99-4 Additional Information: None SECTION 4: First aid measures Description of first aid measures General notes: Not determined or not applicable. -

Hanford Tank Waste Information Enclosure 1

Hanford Tank Waste Information Enclosure 1 Hanford Tank Waste Information 1.0 Summary This information demonstrates the wastes in the twelve Hanford Site tanks meet the definition of transuranic (TRU) waste as set forth in the Waste Isolation Pilot Plant (WIPP) Land Withdrawal Act of 1996, as amended. The wastes in these twelve (12) tanks are not high-level waste (HLW), and contain more than 100 nanocuries of alpha-emitting TRU isotopes per gram with half-lives greater than 20 years. The Department’s plan for these wastes is to remove these wastes from these tanks, dewater, package, certify, and then dispose of these TRU wastes at WIPP. Once dewatered and packaged, wastes from these twelve (12) tanks will meet all shipping and disposal requirements imposed by the WIPP. Waste from nine (9) of these twelve (12) tanks will be contact-handled TRU waste (i.e., container surface dose rate less than or equal to 200-mrem per hour), and waste from the other three (3) tanks will be remote-handled TRU waste (i.e., container surface dose rate greater than 200-mrem per hour). The fission product (i.e., Cs137 and Sr90) content of these wastes is consistent with the fission product content of other TRU wastes already stored or planned for storage in the WIPP. The following sections provide a description of waste generation and management activities conducted at the Hanford Site to demonstrate how these wastes were generated and segregated and why these wastes are expected to meet the requirements for TRU waste, and thus, be eligible for disposal at WIPP. -

Spectrophotometric Determination of Chromiumin(III) in Water Using Sodium Bismuthate As an Oxidizing Reagent

IOSR Journal of Applied Chemistry (IOSR-JAC) e-ISSN: 2278-5736.Volume 13, Issue 1 Ser. I (January. 2020), PP 30-33 www.iosrjournals.org Spectrophotometric Determination of Chromiumin(III) in Water Using Sodium Bismuthate as an Oxidizing Reagent N. LAL, A. Tiwari, A. K. Dixit and D. K. Singh* Department of Chemistry, VSSD College, CSJM University, Kanpr-208002, India. * Ex-Professor, Department of chemistry, H. B. Technological Institute, Kanpur-208002 (India) Corresponding Author: N. Lal, A. Tiwari Abstract: A simple, sensitive, inexpensive and rapid spectrophotometric method for the determination of trace amounts of chromium (III) in water through oxidation using sodium bismuthate (NaBiO3) is described. NaBiO3 is found to be an effective oxidizing agent for aforesaid oxidation and carries advantages such as easy handling, non-toxic and eco-friendly. Chromium (VI) forms a pink/purple colored complex with diphenyl carbazide (DPC) having λmax 540 nm. Major cations and anions did not show any interference. Beer’s law is applicable under concentration range 20.8 – 104.0 µg/l of chromium. The method is highly reproducible and has been tested for chromium estimation in synthetic water samples. The correlation coefficient R2 is greater than 0.999. Key words: Spectrophotometric determination; Chromium(III); Sodium bismuthate; Diphenyl carbazide ----------------------------------------------------------------------------------------------------------------------------- ---------- Date of Submission: 10-01-2020 Date of Acceptance: 27-01-2020 -------------------------------------------------------------------------------------------------------------------------------------- I. Introduction Chromium compounds have numerous applications in industry; however their discharge into ground water is of great concern due to their hazardous effect. Chromium is an essential nutritional supplement for humans and animals. It plays an important role in glucose metabolism1,2In nature, chromium is found usually in trivalent and hexavalent states. -

Chemical Disposition of Plutonium in Hanford Site Tank Wastes

PNNL-23468 Rev. 1 WTP-RPT-234 Rev. 1 Chemical Disposition of Plutonium in Hanford Site Tank Wastes CH Delegard SA Jones May 2015 PNNL-23468 Rev. 1 WTP-RPT-234 Rev. 1 Chemical Disposition of Plutonium in Hanford Site Tank Wastes CH Delegard SA Jones May 2015 Prepared for the U.S. Department of Energy Under Contract DE-AC05-76RL01830 Pacific Northwest National Laboratory Richland, Washington 99352 WTP-RPT-234 Rev 1 Summary This report examines the chemical disposition of plutonium (Pu) in Hanford Site tank wastes, by itself and in its observed and potential interactions with the neutron absorbers aluminum (Al), cadmium (Cd), chromium (Cr), iron (Fe), manganese (Mn), nickel (Ni), and sodium (Na). Consideration also is given to the interactions of plutonium with uranium (U). No consideration of the disposition of uranium itself as an element with fissile isotopes is considered except tangentially with respect to its interaction as an absorber for plutonium. The report begins with a brief review of Hanford Site plutonium processes, examining the various means used to recover plutonium from irradiated fuel and from scrap, and also examines the intermediate processing of plutonium to prepare useful chemical forms. The paper provides an overview of Hanford tank defined-waste–type compositions and some calculations of the ratios of plutonium to absorber elements in these waste types and in individual waste analyses. These assessments are based on Hanford tank waste inventory data derived from separately published, expert assessments of tank disposal records, process flowsheets, and chemical/radiochemical analyses. This work also investigates the distribution and expected speciation of plutonium in tank waste solution and solid phases. -

Chemical Capabilities Listing Laboratory, R&D, Industrial and Manufacturing Applications

Page 1 of 3 Chemical Capabilities Listing Laboratory, R&D, Industrial and Manufacturing Applications Acacia, Gum Arabic Barium Oxide Chromium Trioxide Acetaldehyde Bentonite, White Citric Acid, Anhydrous Acetamide Benzaldehyde Citric Acid, Monohydrate Acetanilide Benzoic Acid Cobalt Oxide Acetic Acid Benzoyl Chloride Cobaltous Acetate Acetic Anhydride Benzyl Alcohol Cobaltous Carbonate Acetone Bismuth Chloride Cobaltous Chloride Acetonitrile Bismuth Nitrate Cobaltous Nitrate Acetyl Chloride Bismuth Trioxide Cobaltous Sulfate Aluminium Ammonium Sulfate Boric Acid Cottonseed Oil Aluminon Boric Anhydride Cupferron Aluminum Chloride, Anhydrous Brucine Sulfate Cupric Acetate Aluminum Chloride, Hexahydrate n-Butyl Acetate Cupric Bromide Aluminum Fluoride n-Butyl Alcohol Cupric Carbonate, Basic Aluminum Hydroxide tert-Butyl Alcohol Cupric Chloride Aluminum Nitrate Butyric Acid Cupric Nitrate Aluminum Oxide Cadmium Acetate Cupric Oxide Aluminum Potassium Sulfate Cadmium Carbonate Cupric Sulfate, Anhydrous Aluminum Sulfate Cadmium Chloride, Anhydrous Cupric Sulfate, Pentahydrate 1-Amino-2-Naphthol-4-Sulfonic Acid Cadmium Chloride, Hemipentahydrate Cuprous Chloride Ammonium Acetate Cadmium Iodide Cuprous Oxide, Red Ammonium Bicarbonate Cadmium Nitrate Cyclohexane Ammonium Bifluoride Cadmium Oxide Cyclohexanol Ammonium Bisulfate Cadmium Sulfate, Anhydrous Cyclohexanone Ammonium Bromide Cadmium Sulfate, Hydrate Devarda's Alloy Ammonium Carbonate Calcium Acetate Dextrose, Anhydrous Ammonium Chloride Calcium Carbide Diacetone Alcohol Ammonium Citrate -

The Kinetic and Thermodynamic Properties of the Dissolution

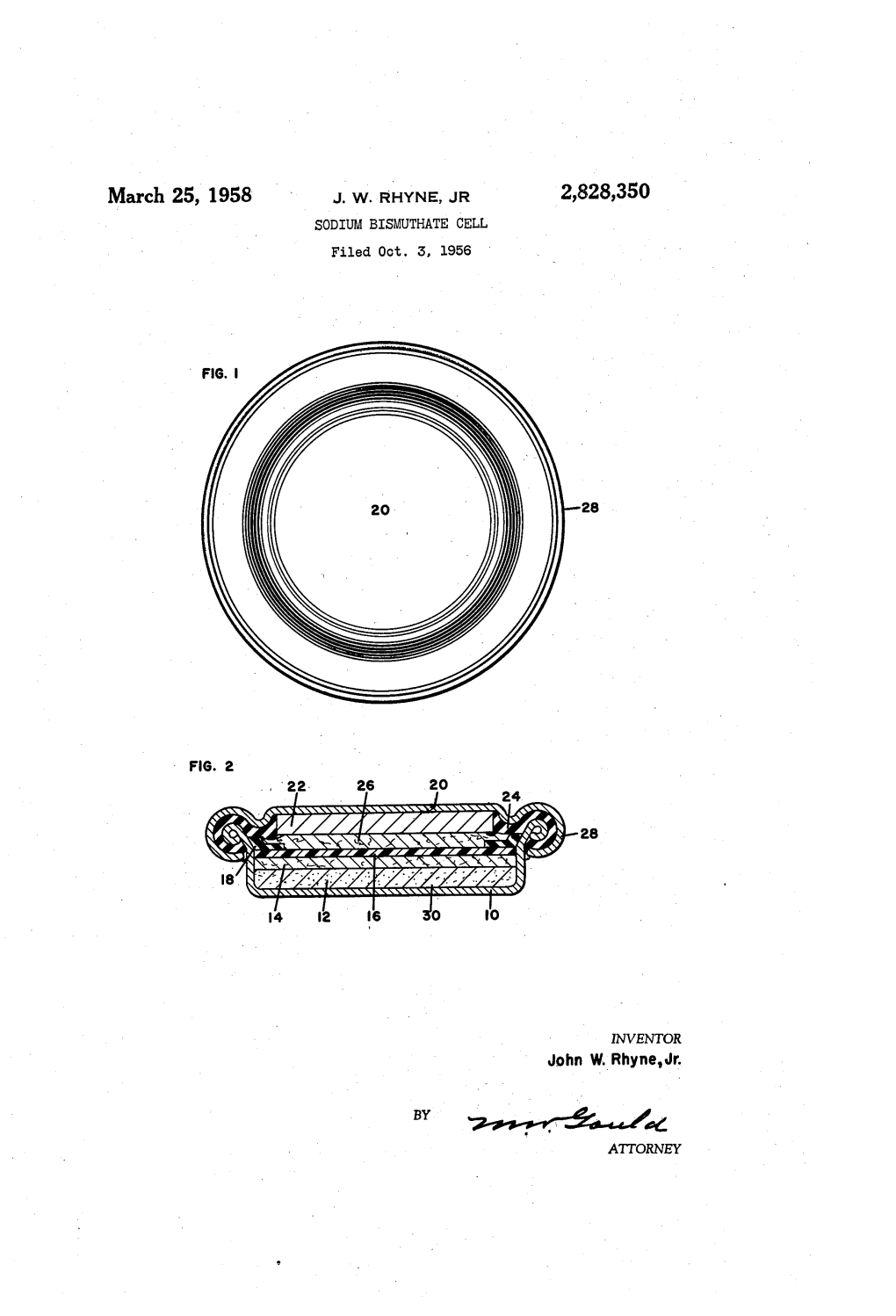

THE KINETIC AND THERMODYNAMIC PROPERTIES OF THE DISSOLUTION OF SODIUM BISMUTHATE A Thesis by ANDREW JOHN WILCOX Submitted to the Office of Graduate and Professional Studies of Texas A&M University in partial fulfillment of the requirements for the degree of MASTER OF SCIENCE Chair of Committee, Sunil S. Chirayath Co-Chair of Committee, Jonathan D. Burns Committee Members, Charles M. Folden III Head of Department, Yassin A. Hassan May 2018 Major Subject: Nuclear Engineering Copyright 2018 Andrew J. Wilcox ABSTRACT The development of a group actinide separation of U, Pu, Np, and Am could significantly simplify the closure of the nuclear fuel cycle, while reducing the amount of nuclear waste produced. To perform this group extraction the difficult separation of Am3+ from Cm3+ and the trivalent lanthanides must be addressed. Higher oxidation states of Am have been observed but require a high oxidizing potential to achieve. NaBiO3 has been shown to be capable of oxidation of Am(III)/Am(VI) in highly concentrated nitric acid and is known to be a cost effective and easily produced oxidizing agent. The slow dissolution kinetics of sodium bismuthate that have been observed, as well as its low solubility in nitric acid, represent some concerns in adoption of a process in which it is implemented. For this reason a thorough investigation of these properties as a function of nitric acid concentrations was undertaken. In addition, the effect of having other metal ions present in solution, like Cs+, Sr2+, Nd3+, Zr4+, Ce3+/4+, or 2+ UO2 on the dissolution behavior of sodium bismuthate was determined. -

Safety Data Sheet Release 1.1 Revision 01/18/2021 Date of Issue 05/29/2021 Page 1 of 6

Safety Data Sheet Release 1.1 Revision 01/18/2021 Date of issue 05/29/2021 page 1 of 6 1 Identification of the substance Identification of the substance Identification of the Sodium bismuthate substance Additional identification Bismuth sodium trioxide Biosynth catalog no. FS52639 REACH No. A registration number is not available for this substance as the substance or its uses are exempted from registration or the annual tonnage does not require a registration. Use of the substance/preparation Identified uses other biochemicals Restriction on use not for food or drug use, for laboratory use only Company Carbosynth Ltd 8&9 Old Station Business Park GB-COMPTON RG20 6NE Phone +44 1635 578444 Mail [email protected] Emergency Number Phone Office hours: +44 1635 578444 2 Hazards identification Health Hazards serious irritation (Category 2) serious irritation (Category 2) acute toxicity (Category 4) (single exposure), STOT SE3 Enviromental Hazards not classified Physical Hazards not classified Possible Hazards (Summary) GHS Labeling Regulatory List EC1272/08 Regulation (EC) 1272/2008 (GHS/CLP) Symbol GHS07 exclamation mark Pictogram Safety Data Sheet FS52639 page 2 of 6 Signal Word Warning Warning Hazard Statement H302 Harmful if swallowed. H315 Causes skin irritation. H319 Causes serious eye irritation. H335 May cause respiratory irritation. Precautionary Statement P270 Do no eat, drink or smoke when using this product. P280 Wear protective gloves/protective clothing/eye protection/face protection. P501 Dispose of contents / container in accordance with local / regional / national / international regulations. P301+P312 IF SWALLOWED: Call a POISON CENTER or doctor/physician if you feel unwell. P302+P352 IF ON SKIN: Wash with plenty of soap and water. -

Determination of Manganese As Sulphate and by the Sodium

DETERMINATION OF MAN$ ANESE AS SULPHATE AND B$ THE SODIUM BISMUTHATE METHOD By William Blum CONTENTS Im n u m n n s m n ns 1 . porta ce of acc rate a ga e e deter i atio u s in v m m s 2 . So rce of error gra i etric ethod ur s in v u m m s 3 . So ce of error ol etric ethod THE B IS M UTHATE METHO D . Ou tline of m ethod H st m t . 2 . i ory of e hod n n z n s u . 3 . Sta dardi atio of ol tio (a) Discu ssion o f m ethods ‘ (b) Evidence b ased o n redu ction and reoxidation P n m s and s u ns 4 . reparatio of aterial ol tio (a) Water . (d) Potassiu m perm anganate (f ) Stab ility of perm anganate solu tions (g) Manganou s su lphate . (h) Sodiu m ox alate . s— b (i) Ferrou s su lphate solu tion Sta ility . (j) Nitric acid . (k) B ismu thate . ‘ (l) F erric nitrate (m ) Use of weight b u rettes Standardiz ation of perm anganate with sodiu m ox alate Standardiz ation of perm anganate With manganou s sulphate (a) Standardi z ation of m anganou s su lphate solu tions (b) Efie ct of conditions u pon the standardiz ations with m anga nou s su lphate - ( 1 ) F errou s su lphate permanganate ratio . m n m n n i m n (2 ) A ou t of a ganese prese t n a deter i ation . -

The Journal of Industrial and Engineering Chemistry I9

Jan., 1918 THE JOURNAL OF INDUSTRIAL AND ENGINEERING CHEMISTRY I9 THE DETERMINATlON OF MANGANESE IN STEEL IN the weight of the sample has been added as chromate THE PRESENCE OF CHROMIUM AND VANADIUM immediately before titrating. Under the usual BY ELECTROMETRIC TITRATION conditions of analysis most of the chromium is present By G. L. RELLBY, M. G. SPBNCBR,C. B ILLINGWORTHAND T. GRAY as chromic salt and such amounts of chromium in Received July 14, 1917 this state make the end-point obscure. In the pres- The determination of manganese in steel in the ence of 5 per cent or more of chromium all of these presence of chromium and vanadium has long offered methods, except those which involve the separation difficulties to the analyst in steel works laboratories. of manganese, are extremely uncertain. Numerous methods have been developed with the object of alleviating or overcoming these difficulties. In this paper we describe a method which has suffi- cient :accuracy for all technical purposes and which, Cain' and \Tatters2 recommend devices for the separa- without the separation of chromium and vanadium, tion of the manganese. Cornelius3 and Dedericks,* is not interfered with by these elements under the con- although not particularly concerned with the analysis of+'steel, have recommended procedures available for ditions of analysis. The oxidation of the manganese the quantitative separation of manganese from chro- in this method may be accomplished either by the bis- muthate or persulfate procedures, and titration is mium and vanadium. Talminger6 has proposed a method of the latter type, using von Knorre's procedure, made electrometrically, using mercurous nitrate as the viz., the precipitation of manganese by ammonium reducing agent.