B) Ionic Polymerizations I) Anionic Polymerization the Active Center

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Cationic/Anionic/Living Polymerizationspolymerizations Objectives

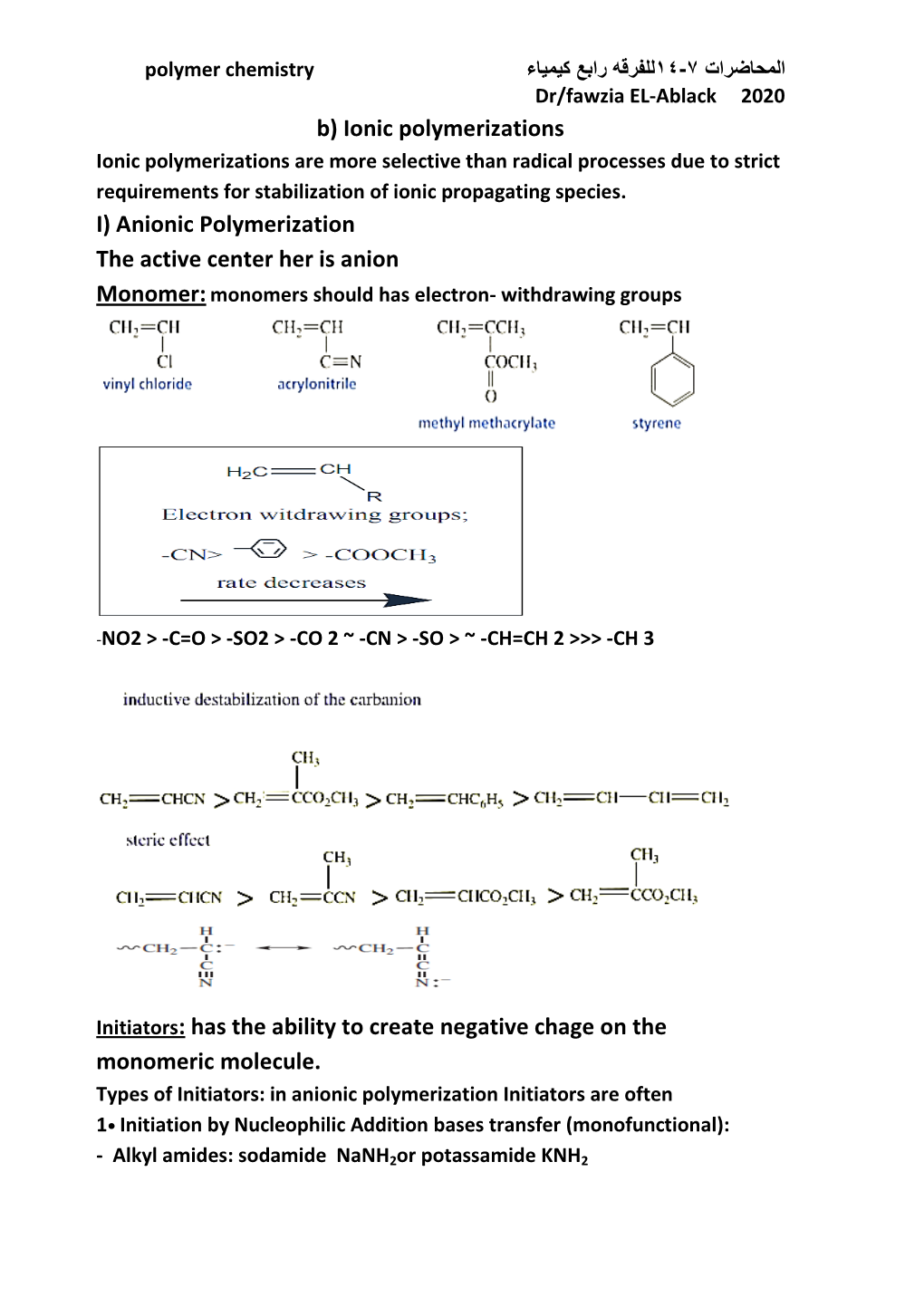

Chemical Engineering 160/260 Polymer Science and Engineering LectureLecture 1919 -- Cationic/Anionic/LivingCationic/Anionic/Living PolymerizationsPolymerizations Objectives • To compare and contrast cationic and anionic mechanisms for polymerization, with reference to free radical polymerization as the most common route to high polymer. • To emphasize the importance of stabilization of the charged reactive center on the growing chain. • To develop expressions for the average degree of polymerization and molecular weight distribution for anionic polymerization. • To introduce the concept of a “living” polymerization. • To emphasize the utility of anionic and living polymerizations in the synthesis of block copolymers. Effect of Substituents on Chain Mechanism Monomer Radical Anionic Cationic Hetero. Ethylene + - + + Propylene - - - + 1-Butene - - - + Isobutene - - + - 1,3-Butadiene + + - + Isoprene + + - + Styrene + + + + Vinyl chloride + - - + Acrylonitrile + + - + Methacrylate + + - + esters • Almost all substituents allow resonance delocalization. • Electron-withdrawing substituents lead to anionic mechanism. • Electron-donating substituents lead to cationic mechanism. Overview of Ionic Polymerization: Selectivity • Ionic polymerizations are more selective than radical processes due to strict requirements for stabilization of ionic propagating species. Cationic: limited to monomers with electron- donating groups R1 | RO- _ CH =CH- CH =C 2 2 | R2 Anionic: limited to monomers with electron- withdrawing groups O O || || _ -C≡N -C-OR -C- Overview of Ionic Chain Polymerization: Counterions • A counterion is present in both anionic and cationic polymerizations, yielding ion pairs, not free ions. Cationic:~~~C+(X-) Anionic: ~~~C-(M+) • There will be similar effects of counterion and solvent on the rate, stereochemistry, and copolymerization for both cationic and anionic polymerization. • Formation of relatively stable ions is necessary in order to have reasonable lifetimes for propagation. -

Poly(Ethylene Oxide-Co-Tetrahydrofuran) and Poly(Propylene Oxide-Co-Tetrahydrofuran): Synthesis and Thermal Degradation

Revue Roumaine de Chimie, 2006, 51(7-8), 781–793 Dedicated to the memory of Professor Mircea D. Banciu (1941–2005) POLY(ETHYLENE OXIDE-CO-TETRAHYDROFURAN) AND POLY(PROPYLENE OXIDE-CO-TETRAHYDROFURAN): SYNTHESIS AND THERMAL DEGRADATION Thomas HÖVETBORN, Markus HÖLSCHER, Helmut KEUL∗ and Hartwig HÖCKER Lehrstuhl für Textilchemie und Makromolekulare Chemie der Rheinisch-Westfälischen Technischen Hochschule Aachen, Pauwelsstr. 8, 52056 Aachen, Germany Received January 12, 2006 Copolymers of tetrahydrofuran (THF) and ethylene oxide (EO) (poly(THF-co-EO) and THF and propylene oxide (PO) (poly(THF-co-PO) were obtained by cationic ring opening polymerization of the monomer mixture at 0°C using boron trifluoride etherate (BF3.OEt2) as the initiator. From time conversion plots it was concluded that both monomers are consumed from the very beginning of the reaction and random copolymers are obtained. For poly(THF-co-PO) the molar ratio of repeating units was varied from [THF]/[PO] = 1 to 10; the molar ratio of monomers in the feed corresponds to the molar ratio of repeating units in the copolymer. Thermogravimetric analysis of the copolymers revealed that both poly(THF-co-EO) and poly(THF-co-PO) decompose by ca. 50°C lower than poly(THF) and by ca. 100°C lower than poly(EO); 50% mass loss is obtained at T50 = 375°C for poly(EO), T50 = 330°C for poly(THF) and at T50 = 280°C for both copolymers. The [THF]/[PO] ratio does not influence the decomposition temperature significantly as well. For the copolymers the activation energies of the thermal decomposition (Ea) were determined experimentally from TGA measurements and by density functional calculations on model compounds on the B3LYP/6-31+G* level of theory. -

Importance of Sulfate Radical Anion Formation and Chemistry in Heterogeneous OH Oxidation of Sodium Methyl Sulfate, the Smallest Organosulfate

Atmos. Chem. Phys., 18, 2809–2820, 2018 https://doi.org/10.5194/acp-18-2809-2018 © Author(s) 2018. This work is distributed under the Creative Commons Attribution 4.0 License. Importance of sulfate radical anion formation and chemistry in heterogeneous OH oxidation of sodium methyl sulfate, the smallest organosulfate Kai Chung Kwong1, Man Mei Chim1, James F. Davies2,a, Kevin R. Wilson2, and Man Nin Chan1,3 1Earth System Science Programme, Faculty of Science, The Chinese University of Hong Kong, Hong Kong, China 2Chemical Sciences Division, Lawrence Berkeley National Laboratory, Berkeley, CA, USA 3The Institute of Environment, Energy and Sustainability, The Chinese University of Hong Kong, Hong Kong, China anow at: Department of Chemistry, University of California Riverside, Riverside, CA, USA Correspondence: Man Nin Chan ([email protected]) Received: 30 September 2017 – Discussion started: 24 October 2017 Revised: 18 January 2018 – Accepted: 22 January 2018 – Published: 27 February 2018 Abstract. Organosulfates are important organosulfur 40 % of sodium methyl sulfate is being oxidized at the compounds present in atmospheric particles. While the maximum OH exposure (1.27 × 1012 molecule cm−3 s), only abundance, composition, and formation mechanisms of a 3 % decrease in particle diameter is observed. This can organosulfates have been extensively investigated, it remains be attributed to a small fraction of particle mass lost via unclear how they transform and evolve throughout their the formation and volatilization of formaldehyde. Overall, atmospheric lifetime. To acquire a fundamental under- we firstly demonstrate that the heterogeneous OH oxidation standing of how organosulfates chemically transform in of an organosulfate can lead to the formation of sulfate the atmosphere, this work investigates the heterogeneous radical anion and produce inorganic sulfate. -

Cationic Oligomerization of Ethylene Oxide

Polymer Journal, Vol. 15, No. 12, pp 883-889 (1983) Cationic Oligomerization of Ethylene Oxide Shiro KOBAYASHI, Takatoshi KOBAYASHI, and Takeo SAEGUSA Department of Synthetic Chemistry, Faculty of Engineering, Kyoto University, Kyoto 606, Japan (Received July 29, 1983) ABSTRACT: The oligomerization of ethylene oxide (EO) was investigated with several cationic catalysts to find a method for producing cyclic oligomers (crown ethers). The reactions were monitored by NMR spectroscopy (1 H and 19F) and gas chromatography. The composition of oligomers was found to change during the reactions, and the production of 1,4-dioxane increased at the later stage of the reactions. This indicates that the composition of oligomers is kinetically controlled. The formation of higher cyclic oligomers was favored by the addition of tetrahydro pyran or 1,4-dioxane to the system catalyzed by an oxonium salt; the maximum yield of cyclic tetramer was 16.8%. The effect of alkali metal salts was also examined. A template effect was observed to increase the amount of cyclic oligomer production. KEY WORDS Cationic Oligomerization I Ethylene Oxide I Cyclic Oligomers I Crown Ether I Kinetically Controlled Reaction I Additive Effects of Metal Salts I Template Effect I An extensive study was recently carried out on EXPERIMENTAL the cationic. polymerization of heterocyclic mono mers which, it was found, may lead to polymers Materials containing significant amounts of linear and cyclic All reagents were distilled under nitrogen. A oligomers.1 The most thoroughly studied monomer commercial sample of EO was distilled twice. was ethylene oxide (EO). Eastham et a!. observed Tetrahydropyran (THP) and DON were dried with that the cationic polymerization of EO resulted in sodium metal and distilled. -

Uncovering the Energies and Reactivity of Aminoxyl Radicals by Mass Spectrometry David Marshall University of Wollongong

University of Wollongong Research Online University of Wollongong Thesis Collection University of Wollongong Thesis Collections 2014 Uncovering the Energies and Reactivity of Aminoxyl Radicals by Mass Spectrometry David Marshall University of Wollongong Research Online is the open access institutional repository for the University of Wollongong. For further information contact the UOW Library: [email protected] Uncovering the Energetics and Reactivity of Aminoxyl Radicals by Mass Spectrometry A thesis submitted in (partial) fulfilment of the requirements for the award of the Degree Doctor of Philosophy from University of Wollongong by David Lachlan Marshall BNanotechAdv (Hons I) School of Chemistry April 2014 DECLARATION I, David L. Marshall, declare that this thesis, submitted in fulfilment of the requirements for the award of Doctor of Philosophy, in the School of Chemistry, University of Wollongong, is wholly my own work unless otherwise referenced or acknowledged. The document has not been submitted for qualifications at any other academic institution. David L. Marshall April 2014 i ACKNOWLDGEMENTS This PhD would not have been possible without the support of many people, and I am strongly indebted to each and every one of them. First and foremost, a big thankyou to my supervisors Prof. Stephen Blanksby and Dr. Philip Barker. Over the past 7 years, through undergraduate research, Honours and into a PhD, you have been a constant source of ideas, encouragement, and support. Phil, your passion for science is contagious, and hopefully I’ve learned a few Ninja skills along the way. Leaving Wollongong won’t feel right without your face greeting me from the side of a truck every day. -

Reactions of Aromatic Compounds Just Like an Alkene, Benzene Has Clouds of Electrons Above and Below Its Sigma Bond Framework

Reactions of Aromatic Compounds Just like an alkene, benzene has clouds of electrons above and below its sigma bond framework. Although the electrons are in a stable aromatic system, they are still available for reaction with strong electrophiles. This generates a carbocation which is resonance stabilized (but not aromatic). This cation is called a sigma complex because the electrophile is joined to the benzene ring through a new sigma bond. The sigma complex (also called an arenium ion) is not aromatic since it contains an sp3 carbon (which disrupts the required loop of p orbitals). Ch17 Reactions of Aromatic Compounds (landscape).docx Page1 The loss of aromaticity required to form the sigma complex explains the highly endothermic nature of the first step. (That is why we require strong electrophiles for reaction). The sigma complex wishes to regain its aromaticity, and it may do so by either a reversal of the first step (i.e. regenerate the starting material) or by loss of the proton on the sp3 carbon (leading to a substitution product). When a reaction proceeds this way, it is electrophilic aromatic substitution. There are a wide variety of electrophiles that can be introduced into a benzene ring in this way, and so electrophilic aromatic substitution is a very important method for the synthesis of substituted aromatic compounds. Ch17 Reactions of Aromatic Compounds (landscape).docx Page2 Bromination of Benzene Bromination follows the same general mechanism for the electrophilic aromatic substitution (EAS). Bromine itself is not electrophilic enough to react with benzene. But the addition of a strong Lewis acid (electron pair acceptor), such as FeBr3, catalyses the reaction, and leads to the substitution product. -

( 12 ) United States Patent

US009981991B2 (12 ) United States Patent (10 ) Patent No. : US 9 , 981, 991 B2 Castillo et al. ( 45 ) Date of Patent: May 29 , 2018 ( 54 ) SYNTHESIS AND ISOLATION OF Hitchcock et al ., “ The first crystalline alkali metal salt of a CRYSTALLINE ALKALIMETAL ARENE benzenoid radical anion without a stabilizing substituent and of a RADICAL ANIONS related dimer: X - ray structures of the toluene radical anion and of the benzene radical anion dimer potassium -crown ether salts . ” J . ( 71 ) Applicants : Efrain Maximiliano Castillo , El Paso , Am . Chem . Soc . , vol . 123 , No . 1 , 2001 , pp . 189 - 190 . TX (US ) ; Skye Fortier , El Paso , TX Rainis et al ., “ Disproportionation of the lithium , sodium , and potassium salts of anthracenide and perylenide radical anions in (US ) DME and THF, ” J. Am . Chem . Soc. , vol. 96 , No. 9 , 1974 , pp . 3008 - 3010 . ( 72 ) Inventors : Efrain Maximiliano Castillo , El Paso , Krieck et al ., “ Rubidium -mediated birch - type reduction of 1 , 2 TX (US ) ; Skye Fortier , El Paso , TX diphenylbenzene in tetrahydrofuran .” J . Am . Chem . Soc . , vol. 133 , (US ) No . 18 , 2011, pp . 6960 - 6963. (73 ) Assignee : THE BOARD OF REGENTS OF Zabula , “ A main group metal sandwich : five lithium cations jammed between two corannulene tetraanion decks .” Science, vol. 333 , No . THE UNIVERSITY OF TEXAS 6045 , 2011, pp . 1008 - 1011. SYSTEM , Austin , TX (US ) Connelly et al ., “ Chemical Redox Agents for Organometallic Chem istry ." Chem . Rev. , vol . 96 , No . 2 , 1996 , pp . 877 - 910 . ( * ) Notice : Subject to any disclaimer , the term of this Kowalczuk et al. , “ New reactions of potassium naphthalenide with patent is extended or adjusted under 35 B - , y - and d - lactones : an efficient route to a -alkyl y - and 8 - lactones U . -

Chemical Basis of Reactive Oxygen Species Reactivity and Involvement in Neurodegenerative Diseases

International Journal of Molecular Sciences Review Chemical Basis of Reactive Oxygen Species Reactivity and Involvement in Neurodegenerative Diseases Fabrice Collin Laboratoire des IMRCP, Université de Toulouse, CNRS UMR 5623, Université Toulouse III-Paul Sabatier, 118 Route de Narbonne, 31062 Toulouse CEDEX 09, France; [email protected] Received: 26 April 2019; Accepted: 13 May 2019; Published: 15 May 2019 Abstract: Increasing numbers of individuals suffer from neurodegenerative diseases, which are characterized by progressive loss of neurons. Oxidative stress, in particular, the overproduction of Reactive Oxygen Species (ROS), play an important role in the development of these diseases, as evidenced by the detection of products of lipid, protein and DNA oxidation in vivo. Even if they participate in cell signaling and metabolism regulation, ROS are also formidable weapons against most of the biological materials because of their intrinsic nature. By nature too, neurons are particularly sensitive to oxidation because of their high polyunsaturated fatty acid content, weak antioxidant defense and high oxygen consumption. Thus, the overproduction of ROS in neurons appears as particularly deleterious and the mechanisms involved in oxidative degradation of biomolecules are numerous and complexes. This review highlights the production and regulation of ROS, their chemical properties, both from kinetic and thermodynamic points of view, the links between them, and their implication in neurodegenerative diseases. Keywords: reactive oxygen species; superoxide anion; hydroxyl radical; hydrogen peroxide; hydroperoxides; neurodegenerative diseases; NADPH oxidase; superoxide dismutase 1. Introduction Reactive Oxygen Species (ROS) are radical or molecular species whose physical-chemical properties are well-known both on thermodynamic and kinetic points of view. -

Formation, Stability and Structure of Radical Anions of Chloroform, Tetrachloromethane and Fluorotrichloromethane in the Gas Phase

UvA-DARE (Digital Academic Repository) Formation, stability and structure of radical anions of chloroform, tetrachloromethane and fluorotrichloromethane in the gas phase Staneke, P.O.; Groothuis, G.; Ingemann Jorgensen, S.; Nibbering, N.M.M. DOI 10.1016/0168-1176(94)04127-S Publication date 1995 Document Version Final published version Published in International Journal of Mass Spectrometry and Ion Processes Link to publication Citation for published version (APA): Staneke, P. O., Groothuis, G., Ingemann Jorgensen, S., & Nibbering, N. M. M. (1995). Formation, stability and structure of radical anions of chloroform, tetrachloromethane and fluorotrichloromethane in the gas phase. International Journal of Mass Spectrometry and Ion Processes, 142, 83. https://doi.org/10.1016/0168-1176(94)04127-S General rights It is not permitted to download or to forward/distribute the text or part of it without the consent of the author(s) and/or copyright holder(s), other than for strictly personal, individual use, unless the work is under an open content license (like Creative Commons). Disclaimer/Complaints regulations If you believe that digital publication of certain material infringes any of your rights or (privacy) interests, please let the Library know, stating your reasons. In case of a legitimate complaint, the Library will make the material inaccessible and/or remove it from the website. Please Ask the Library: https://uba.uva.nl/en/contact, or a letter to: Library of the University of Amsterdam, Secretariat, Singel 425, 1012 WP Amsterdam, The Netherlands. You will be contacted as soon as possible. UvA-DARE is a service provided by the library of the University of Amsterdam (https://dare.uva.nl) Download date:29 Sep 2021 and Ion Processes ELSEVIER International Journal of Mass Spectrometry and Ion Processes 142 (1995) 83-93 Formation, stability and structure of radical anions of chloroform, tetrachloromethane and fluorotrichloromethane in the gas phase P.O. -

Chemical Redox Agents for Organometallic Chemistry

Chem. Rev. 1996, 96, 877−910 877 Chemical Redox Agents for Organometallic Chemistry Neil G. Connelly*,† and William E. Geiger*,‡ School of Chemistry, University of Bristol, U.K., and Department of Chemistry, University of Vermont, Burlington, Vermont 05405-0125 Received October 3, 1995 (Revised Manuscript Received January 9, 1996) Contents I. Introduction 877 A. Scope of the Review 877 B. Benefits of Redox Agents: Comparison with 878 Electrochemical Methods 1. Advantages of Chemical Redox Agents 878 2. Disadvantages of Chemical Redox Agents 879 C. Potentials in Nonaqueous Solvents 879 D. Reversible vs Irreversible ET Reagents 879 E. Categorization of Reagent Strength 881 II. Oxidants 881 A. Inorganic 881 1. Metal and Metal Complex Oxidants 881 2. Main Group Oxidants 887 B. Organic 891 The authors (Bill Geiger, left; Neil Connelly, right) have been at the forefront of organometallic electrochemistry for more than 20 years and have had 1. Radical Cations 891 a long-standing and fruitful collaboration. 2. Carbocations 893 3. Cyanocarbons and Related Electron-Rich 894 Neil Connelly took his B.Sc. (1966) and Ph.D. (1969, under the direction Compounds of Jon McCleverty) degrees at the University of Sheffield, U.K. Post- 4. Quinones 895 doctoral work at the Universities of Wisconsin (with Lawrence F. Dahl) 5. Other Organic Oxidants 896 and Cambridge (with Brian Johnson and Jack Lewis) was followed by an appointment at the University of Bristol (Lectureship, 1971; D.Sc. degree, III. Reductants 896 1973; Readership 1975). His research interests are centered on synthetic A. Inorganic 896 and structural studies of redox-active organometallic and coordination 1. -

Benzene Radical Anion in the Context of the Birch Reduction: When Solvation Is The

Benzene radical anion in the context of the Birch reduction: when solvation is the key Krystof Brezina,1, 2 Pavel Jungwirth,2 and Ondrej Marsalek1, a) 1)Charles University, Faculty of Mathematics and Physics, Ke Karlovu 3, 121 16 Prague 2, Czech Republic 2)Institute of Organic Chemistry and Biochemistry of the Czech Academy of Sciences, Flemingovo n´am. 2, 166 10 Prague 6, Czech Republic (Dated: 23 July 2020) The benzene radical anion is an important intermediate in the Dynamic Birch reduction of benzene by solvated electrons in liquid am- Jahn–Teller monia. Beyond organic chemistry, it is an intriguing subject of Effect spectroscopic and theoretical studies due to its rich structural and dynamical behavior. In the gas phase, the species appears as a metastable shape resonance, while in the condensed phase it remains stable. Here, we approach the system by ab initio molecular dynamics in liquid ammonia and demonstrate that the inclusion of solvent is crucial and indeed leads to stability. Beyond the mere existence of the radical anion species, our sim- ulations explore its condensed-phase behavior at the molecular level and offer new insights into its properties. These include the dynamic Jahn{Teller distortions, vibrational spectra in liq- Solvent Structure uid ammonia, and the structure of the solvent shell, including the motif of a π-hydrogen bond between ammonia molecules and the aromatic ring. One of the most prominent roles of the benzene radi- anion presents a challenge due to its need for both a •{ cal anion (C6H6 ) in organic chemistry is that of a re- large basis set and a sufficient level of electronic struc- active intermediate in the Birch process1{6 (Equation1) ture theory to accurately capture its properties in the used to reduce benzene or related derivatives into 1,4- gas phase. -

Radical Anions and Cations Derived from Ninhydrin and Alloxan Maria Chyang Young Iowa State University

Iowa State University Capstones, Theses and Retrospective Theses and Dissertations Dissertations 1966 Radical anions and cations derived from ninhydrin and alloxan Maria Chyang Young Iowa State University Follow this and additional works at: https://lib.dr.iastate.edu/rtd Part of the Organic Chemistry Commons Recommended Citation Young, Maria Chyang, "Radical anions and cations derived from ninhydrin and alloxan " (1966). Retrospective Theses and Dissertations. 2924. https://lib.dr.iastate.edu/rtd/2924 This Dissertation is brought to you for free and open access by the Iowa State University Capstones, Theses and Dissertations at Iowa State University Digital Repository. It has been accepted for inclusion in Retrospective Theses and Dissertations by an authorized administrator of Iowa State University Digital Repository. For more information, please contact [email protected]. This dissertation has been microiihned exactty as received g6—10,447 YOUNG, Maria Chyang, 1936- RADICAL ANIONS AND CATIONS DERIVED FROM NINHYDRIN AND ALLOXAN. Iowa State University of Science and Technology Ph.D., 1966 Chemistry, organic University Microfilms, Inc., Ann Arbor, Michigan RADICAL ANIONS AND CATIONS DERIVED FROM NINHYDRIN AND ALLOXAN by Maria Chyang Young A Dissertation Submitted to the Graduate Faculty in Partial Fulfillment of The Requirements for the Degree of DOCTOR OF PHILOSOPHY Major Subject: Organic Chemistry Approved; Signature was redacted for privacy. In Charge of Major Work Signature was redacted for privacy. Head of Major Department Signature