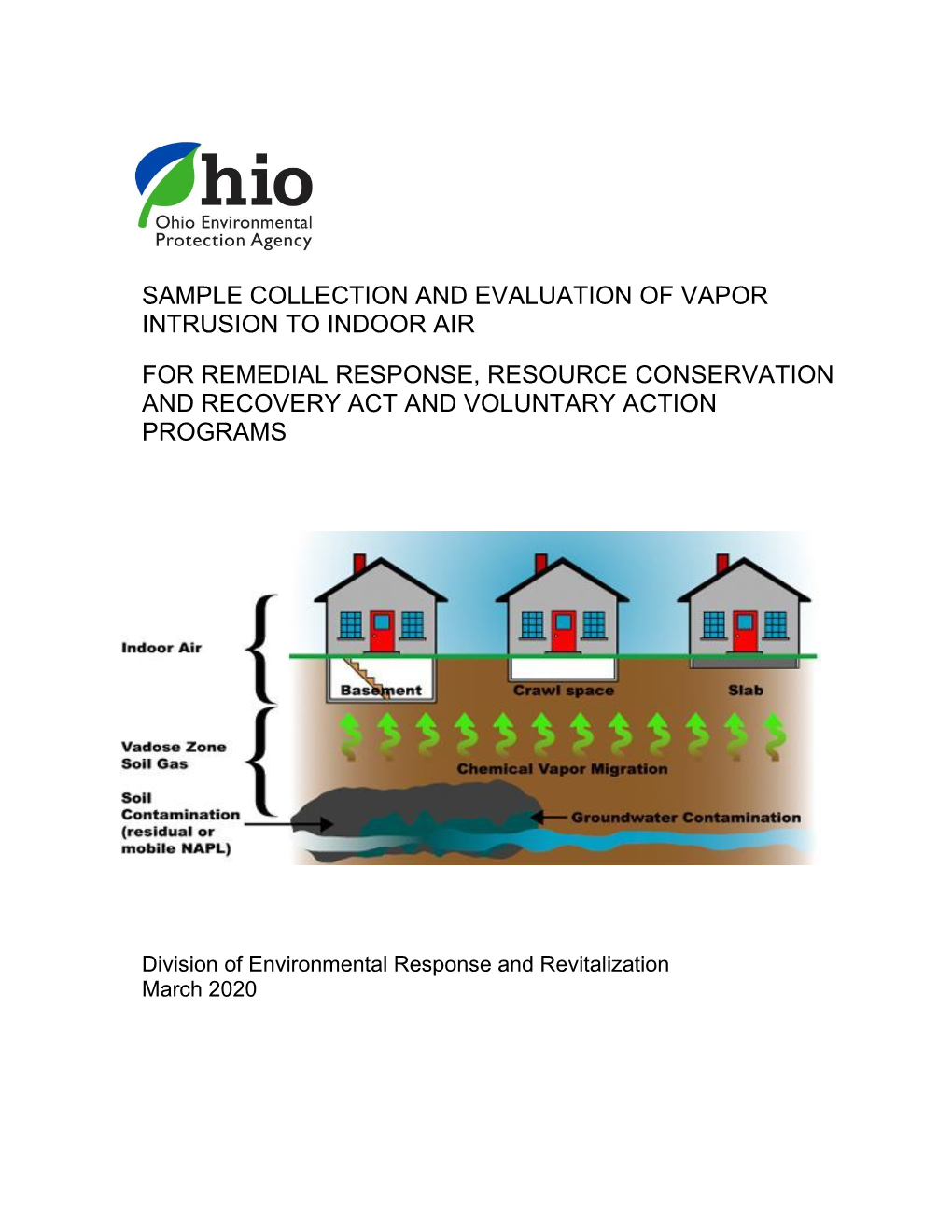

Sample Collection and Evaluation of Vapor Intrusion to Indoor Air for Remedial Response, Resource Conservation and Recovery Act and Voluntary Action Programs

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Palm Beach International Airport (PBI)

Agenda Item:~ PALM BEACH COUNTY BOARD OF COUNTY COMMISSIONERS AGENDA ITEM SUMMARY -===================================================================== Meeting Date: January 12, 2021 [ ] Consent [ X] Regular [ ] Ordinance [ ] Public Hearing Submitted By: Department of Airports ---------------------------------------------------------------------- I. EXECUTIVE BRIEF Motion and Title: Staff recommends motion to approve: a Contract for Air Service Development Consulting Services (Contract) with Ailevon Pacific Aviation Consulting LLC (Ailevon), a Florida limited liability company, commencing on February 1, 2021, and expiring on January 31, 2024, with one 24-month option to renew for an amount not to exceed $200,000 per contract year for a total not to exceed amount of $600,000 for the initial term. Summary: This Contract provides for professional and technical consulting services on an as-needed basis in support of the air service development program for the Palm Beach International Airport (PBI). Ailevon's principal place of business is Atlanta, GA. Air service development consulting services may include, but are not limited to, air service strategy and planning, airline route study and forecasting, competitive service analysis, business case development for new/expanded air service, development of incentive programs, catchment area demographic and leakage studies and analysis of air traffic demand and airfare data. The Contract provides for a not to exceed amount of $200,000 per contract year with an initial three-year term and an option to renew for an additional 24 months at the County's sole option. Due to lack of availability of qualified Small/Minority/Women Owned Business Enterprises providing the services required by this Contract, the Office of Equal Business Opportunity issued a waiver of Affirmative Procurement Initiatives on July 30, 2020. -

Chapter 3 Equations of State

Chapter 3 Equations of State The simplest way to derive the Helmholtz function of a fluid is to directly integrate the equation of state with respect to volume (Sadus, 1992a, 1994). An equation of state can be applied to either vapour-liquid or supercritical phenomena without any conceptual difficulties. Therefore, in addition to liquid-liquid and vapour -liquid properties, it is also possible to determine transitions between these phenomena from the same inputs. All of the physical properties of the fluid except ideal gas are also simultaneously calculated. Many equations of state have been proposed in the literature with either an empirical, semi- empirical or theoretical basis. Comprehensive reviews can be found in the works of Martin (1979), Gubbins (1983), Anderko (1990), Sandler (1994), Economou and Donohue (1996), Wei and Sadus (2000) and Sengers et al. (2000). The van der Waals equation of state (1873) was the first equation to predict vapour-liquid coexistence. Later, the Redlich-Kwong equation of state (Redlich and Kwong, 1949) improved the accuracy of the van der Waals equation by proposing a temperature dependence for the attractive term. Soave (1972) and Peng and Robinson (1976) proposed additional modifications of the Redlich-Kwong equation to more accurately predict the vapour pressure, liquid density, and equilibria ratios. Guggenheim (1965) and Carnahan and Starling (1969) modified the repulsive term of van der Waals equation of state and obtained more accurate expressions for hard sphere systems. Christoforakos and Franck (1986) modified both the attractive and repulsive terms of van der Waals equation of state. Boublik (1981) extended the Carnahan-Starling hard sphere term to obtain an accurate equation for hard convex geometries. -

Top 40 Singles Top 40 Albums

12 May 2008 CHART #1616 Top 40 Singles Top 40 Albums Forever Don't Hold Back Unbreakable: 2008 NZ Tour Edition 50th Anniversary 1 Chris Brown 21 The Potbelleez 1 Westlife 21 Gray Bartlett Last week 5 / 3 weeks SBME Last week 22 / 12 weeks MOS/Universal Last week 10 / 22 weeks Platinum x1 / SBME Last week 17 / 3 weeks EMI Take A Bow Stop And Stare Rockferry Past, Present, Future 2 Rihanna 22 OneRepublic 2 Duffy 22 Tiki Taane Last week 4 / 2 weeks Universal Last week 18 / 17 weeks Universal Last week 3 / 5 weeks Gold x1 / Universal Last week 22 / 25 weeks Gold x1 / DirtyDub/Rhythm/DRM... Love In This Club Tattoo Flight Of The Conchords Rejoice 3 Usher feat. Young Jeezy 23 Jordin Sparks 3 Flight Of The Conchords 23 Katherine Jenkins Last week 1 / 10 weeks Gold x1 / SBME Last week 36 / 2 weeks SBME Last week 1 / 3 weeks Gold x1 / SubPop/Rhythmethod Last week 32 / 3 weeks Universal No Air Sorry Believe Legend: The Very Best Of 4 Jordin Sparks feat. Chris Brown 24 Buckcherry 4 Geoff Sewell 24 Willie Nelson Last week 2 / 10 weeks Platinum x1 / SBME Last week 26 / 6 weeks Universal Last week 2 / 4 weeks Gold x1 / SewellMusic/Ode Last week 18 / 6 weeks Gold x1 / SBME Lollipop What Is It? Back To Black: Deluxe Edition E=MC2 5 Lil Wayne 25 Baby Bash feat. Sean Kingston 5 Amy Winehouse 25 Mariah Carey Last week 6 / 3 weeks Universal Last week 33 / 6 weeks SBME Last week 6 / 49 weeks Platinum x2 / Universal Last week 20 / 3 weeks Universal 4 Minutes Party People The Swing Sessions Watershed 6 Madonna feat. -

Air Automated Manifest System

AIR AUTOMATED MANIFEST SYSTEM FREQUENTLY ASKED QUESTIONS 1. Systems to be Used 2 2. Required and Voluntary Participation 2 3. When Air AMS Filing Required 4 4. Participant Procedures 4 5. Bond Requirements 5 6. Air AMS Documentation 6 7. Compliance Dates 7 8. Enforced Compliance Procedures – Phase 1 7 9. Enforced Compliance Procedures – Phase 2 9 10. Delivery Authorization 9 11. Split Shipments 10 12. Cargo that Fails to Arrive in the United States 11 13. Consolidated Shipments 11 14. Order of Receipt of Master and House Air Waybill 12 15. Simple and Master Air Waybill Format 12 16. House Air Waybill Format 13 17. In-bond Authorization 13 18. Permits to Transfer (Local Transfer) 15 19. Incomplete House Air Waybills 16 20. Manifest Holds 17 21. Foreign Cargo Remaining On Board (FROB) 17 22. Flights Without Cargo 18 23. Air AMS Problem Resolution 18 24. Scheduled Air AMS Downtime 19 25. Presentation of Documents 20 26. Manifest Discrepancy Reporting 20 27. Freight Report Inbound and Freight Report Change 20 28. Carrier Nomination/Agent Field 21 29. Emergency/Forced Landings 21 30. Location of Data Input 22 31. Duplicate Air Waybills 22 32. Quantity to Be Reported 22 33. Freight Status Information Messages 24 34. Carrier Codes 24 35. Company Material/Postal Mail/Letters and Documents 25 36. Code-Share Flights 25 37. Shipper/Consignee Information 27 38. Express Consignment Operations 29 1 Updated 07/25/2005 Updated Questions # 36 U.S. Customs and Border Protection (CBP) has received numerous questions concerning the regulations promulgated pursuant to the Trade Act of 2002. -

Liquid-Vapor Equilibrium in a Binary System

Liquid-Vapor Equilibria in Binary Systems1 Purpose The purpose of this experiment is to study a binary liquid-vapor equilibrium of chloroform and acetone. Measurements of liquid and vapor compositions will be made by refractometry. The data will be treated according to equilibrium thermodynamic considerations, which are developed in the theory section. Theory Consider a liquid-gas equilibrium involving more than one species. By definition, an ideal solution is one in which the vapor pressure of a particular component is proportional to the mole fraction of that component in the liquid phase over the entire range of mole fractions. Note that no distinction is made between solute and solvent. The proportionality constant is the vapor pressure of the pure material. Empirically it has been found that in very dilute solutions the vapor pressure of solvent (major component) is proportional to the mole fraction X of the solvent. The proportionality constant is the vapor pressure, po, of the pure solvent. This rule is called Raoult's law: o (1) psolvent = p solvent Xsolvent for Xsolvent = 1 For a truly ideal solution, this law should apply over the entire range of compositions. However, as Xsolvent decreases, a point will generally be reached where the vapor pressure no longer follows the ideal relationship. Similarly, if we consider the solute in an ideal solution, then Eq.(1) should be valid. Experimentally, it is generally found that for dilute real solutions the following relationship is obeyed: psolute=K Xsolute for Xsolute<< 1 (2) where K is a constant but not equal to the vapor pressure of pure solute. -

From the Outside, You Can't See Any Difference Between a Run-Flat Tire

FEATURE Few 10 Tech Drive wer blowouts Run-Flats Offer Convenience and Peace of Mind. If you had X-ray vision, you could see that the sidewall on a 3 Series run-flat is different from that of a conventional tire. Few things are more frightening to a driver than a blowout because several bad things start happening all at once. A trained, experienced driver may be able to bring his or her vehicle to a safe stop after a blowout. However, many drivers just hang on and hope for the best, or, worse, slam on the brakes. Even for an experienced driver, a blowout while driving on a highway with other vehicles nearby is scary. “Run-flat” tires, which still support the car and provide control even when air pressure is lost, greatly reduce the danger of a blowout. Although run-flats have been available for many years, interest in these tires has surged recently. BMW has offered run-flat tires as standard or optional equipment on selected models since the late 1990s. Equipped with run-flats, a BMW can be driven some distance even though the tire has no air in it. However, the maximum recommended speed for a run-flat without air is 50 mph. So, your customer can drive to your shop for tire replace - ment, just not at high speed. In addition to their other benefits, run-flats eliminate the hassle and potential risk of pulling onto the shoulder of a busy highway to replace a flat tire. These tires even offer a convenience benefit, freeing up trunk space because a spare tire and jack are not necessary with run-flats. -

Answer Document for Practice Test 1

11_559400 ch05.qxd 6/30/04 1:59 PM Page 113 - Answer Document for Practice Test 1 English Language Arts 1 A B C D 6 F G H J 11 A B C D 16 F G H J 21 A B C D 26 F G H J 2 F G H J 7 A B C D 12 F G H J 17 A B C D 22 F G H J 27 A B C D 3 A B C D 8 F G H J 13 A B C D 18 F G H J 23 A B C D 28 F G H J 4 F G H J 9 A B C D 14 F G H J 19 A B C D 24 F G H J 5 A B C D 10 F G H J 15 A B C D 20 F G H J 25 A B C D 29 30 31 - CUT HERE - 36 F G H J 41 A B C D 46 F G H J 51 A B C D 32 F G H J 37 A B C D 42 F G H J 47 A B C D 33 A B C D 38 F G H J 43 A B C D 48 F G H J 34 F G H J 39 A B C D 44 F G H J 49 A B C D 35 A B C D 40 F G H J 45 A B C D 50 F G H J 1 Use a lined 8 ⁄2 × 11 sheet of paper to write your essay. -

New Guidance for Residential Air Cleaners- ASHRAE Journal Sep 2019

TECHNICAL FEATURE ©ASHRAE www.ashrae.org. Used with permission from ASHRAE Journal at www.epa.gov. This article may not be copied nor distributed in either paper or digital form without ASHRAE’s permission. For more information about ASHRAE, visit www.ashrae.org. New Guidance for Residential Air Cleaners BY LEW HARRIMAN, FELLOW/LIFE MEMBER ASHRAE; BRENT STEPHENS, PH.D, MEMBER ASHRAE; TERRY BRENNAN, MEMBER ASHRAE As HVAC&R professionals, we in the ASHRAE community are sometimes asked ques- tions about residential indoor air quality (IAQ) and how to improve it. What contami- nants are most hazardous? How do I get rid of a particular smell? Should I use this air cleaner or that filter? Sadly, our friends and family generally lose patience when we helpfully suggest: “Well, it’s complicated. But just read Chapters 46, 60 and 62 in the ASHRAE Handbook—HVAC Applications, because there’s great information in there.” In general, we find that information seekers are frustrated by such helpful advice. Usually, the question is repeated (with some heat) in a form such as: “You’re the professional. Can’t you boil it down? What should I DO in my HOUSE?” Fortunately, two new resources can help you better mainstream and social media. When you get questions answer such questions. First, the ASHRAE Residential from friends and family about residential air filtration Indoor Air Quality Guide1 is a comprehensive summary of and air cleaners, you may find the U.S. Enivronmental IAQ for homes and apartments, written by our mem- Protection Agency’s recently updated publications help- ber colleagues and published by ASHRAE in 2018. -

Vip Hospitality

SYNDICATED SUITE PACKAGE FRIDAY 18TH DECEMBER International RnB superstar Chris Brown is coming to New Zealand for his One Hell Of A Nite tour with special guest August Alsina. Brown last performed in New Zealand in 2008 with Rihanna at Vector Arena, selling over 20,000 tickets - the first show selling out in minutes. Brown has had huge success here with four No. 1 singles - “Yeah 3x” (2010), “With You” (2007), “Forever”(2008) and “Run It” (2005); as well as two collaborative No.1 singles – “Kiss Kiss” (with T-Pain in 2007) and “No Air” (with Jordin Sparks in 2007). This Grammy Award-winning and multi-platinum-selling singer/songwriter has had six albums reach the NZ top 10, with 2012’s Fortune debuting at No.1. Adding the coveted Grammy Award to his collection, Brown is the recipient of more than 40 awards, including a Billboard Music Award for Top RnB Artist, in addition to the 2012 BET Awards for Best Male RnB Artist and the 2012 MTV Video Music Awards for Best Male Video and Best Choreography for “Turn Up the Music”. Chris Brown is currently performing at sold-out shows on his One Hell Of A Nite tour in the States, bringing incredible dancing and singing to ecstatic audiences. Don’t miss your chance to see this superstar who will be performing all of his hits in this energy-packed, must-see live show! Our SYNDICATED VIP packages are available for individuals or groups. Available only on selected shows (dependent on interest). Package includes: • Two hour pre-show hosting in shared VIP suite with other like minded people • Gold Concert tickets • Complimentary drink on arrival • Chef’s delicious themed gourmet menu • Souvenir VIP lanyard • Official VIP merchandise • Red carpet entry to your VIP suite • Dedicated event hosts $359 + gst per guest Please contact Rebecca Widdison to book: 09 358 1250, [email protected] VIP HOSPITALITY. -

Understanding Vapor Diffusion and Condensation

uilding enclosure assemblies temperature is the temperature at which the moisture content, age, temperature, and serve a variety of functions RH of the air would be 100%. This is also other factors. Vapor resistance is commonly to deliver long-lasting sepa- the temperature at which condensation will expressed using the inverse term “vapor ration of the interior building begin to occur. permeance,” which is the relative ease of environment from the exteri- The direction of vapor diffusion flow vapor diffusion through a material. or, one of which is the control through an assembly is always from the Vapor-retarding materials are often Bof vapor diffusion. Resistance to vapor diffu- high vapor pressure side to the low vapor grouped into classes (Classes I, II, III) sion is part of the environmental separation; pressure side, which is often also from the depending on their vapor permeance values. however, vapor diffusion control is often warm side to the cold side, because warm Class I (<0.1 US perm) and Class II (0.1 to primarily provided to avoid potentially dam- air can hold more water than cold air (see 1.0 US perm) vapor retarder materials are aging moisture accumulation within build- Figure 2). Importantly, this means it is not considered impermeable to near-imperme- ing enclosure assemblies. While resistance always from the higher RH side to the lower able, respectively, and are known within to vapor diffusion in wall assemblies has RH side. the industry as “vapor barriers.” Some long been understood, ever-increasing ener- The direction of the vapor drive has materials that fall into this category include gy code requirements have led to increased important ramifications with respect to the polyethylene sheet, sheet metal, aluminum insulation levels, which in turn have altered placement of materials within an assembly, foil, some foam plastic insulations (depend- the way assemblies perform with respect to and what works in one climate may not work ing on thickness), and self-adhered (peel- vapor diffusion and condensation control. -

Pdf, 639.57 KB

00:00:00 Music Music “Oh No, Ross and Carrie! Theme Song” by Brian Keith Dalton. A jaunty, upbeat instrumental. 00:00:09 Ross Host Hello! And welcome to Oh No Ross and Carrie—the show where Blocher we don’t just report on fringe science, spirituality, and claims of the paranormal, but we take part ourselves! 00:00:17 Carrie Host Yep! When they make the claims, we show up, so you don’t have Poppy to. I’m Ross Blocher. 00:00:21 Ross Host And I’m… Carrie Poppy. 00:00:23 Carrie Host [Laughs.] Begrudgingly. 00:00:25 Ross Host Well, now I’m gonna get it. 00:00:26 Crosstalk Crosstalk Ross: You know, “You are not Carrie Poppy!” Carrie: From that one little girl. [They laugh.] 00:00:29 Ross Host You know, I think—I think it happened once before camp, and she just resumed right where she left off. 00:00:34 Carrie Host [Laughing.] Ooh, okay. 00:00:36 Ross Host “You are not Carrie Poppy!” 00:00:37 Carrie Host I’ll be honest, this is not the episode for that little girl, anyway. 00:00:40 Ross Host A fair point. Well, actually—that’s a—that’s a good transition. So, we’re—in this episode, we’re very excited. [Carrie agrees.] We’ve got an interview guest that we hinted at that we might have. Isis Aquarian. 00:00:52 Carrie Host Isis was the archivist and historian and a ranking member of the Source family. 00:00:57 Ross Host You may have listened to our episode on the Source family reunion dinner, held at Gratitude in Beverly Hills. -

Sub-Slab Vapor Sampling Procedures

Sub-Slab Vapor Sampling Procedures RR-986 July 2014 Table of Contents I. Introduction .......................................................................................................................... 2 II. Sub-Slab Sample Ports .......................................................................................................... 2 A. Distribution of sub-slab probes ...................................................................................... 3 B. Permanent vs. temporary sub-slab probes .................................................................... 4 C. Tubing used in the sample train ..................................................................................... 4 D. Abandonment of sub-slab probes .................................................................................. 4 E. Sub-slab vapor samples collected from a sump pit ....................................................... 4 III. Leak Testing and Collecting a Sub-slab Sample .................................................................... 5 A. Shut-in test ..................................................................................................................... 6 B. Helium shroud ................................................................................................................ 7 C. Other leak detection methods for probe seals .............................................................. 7 D. Sample collection after leak testing ............................................................................... 8