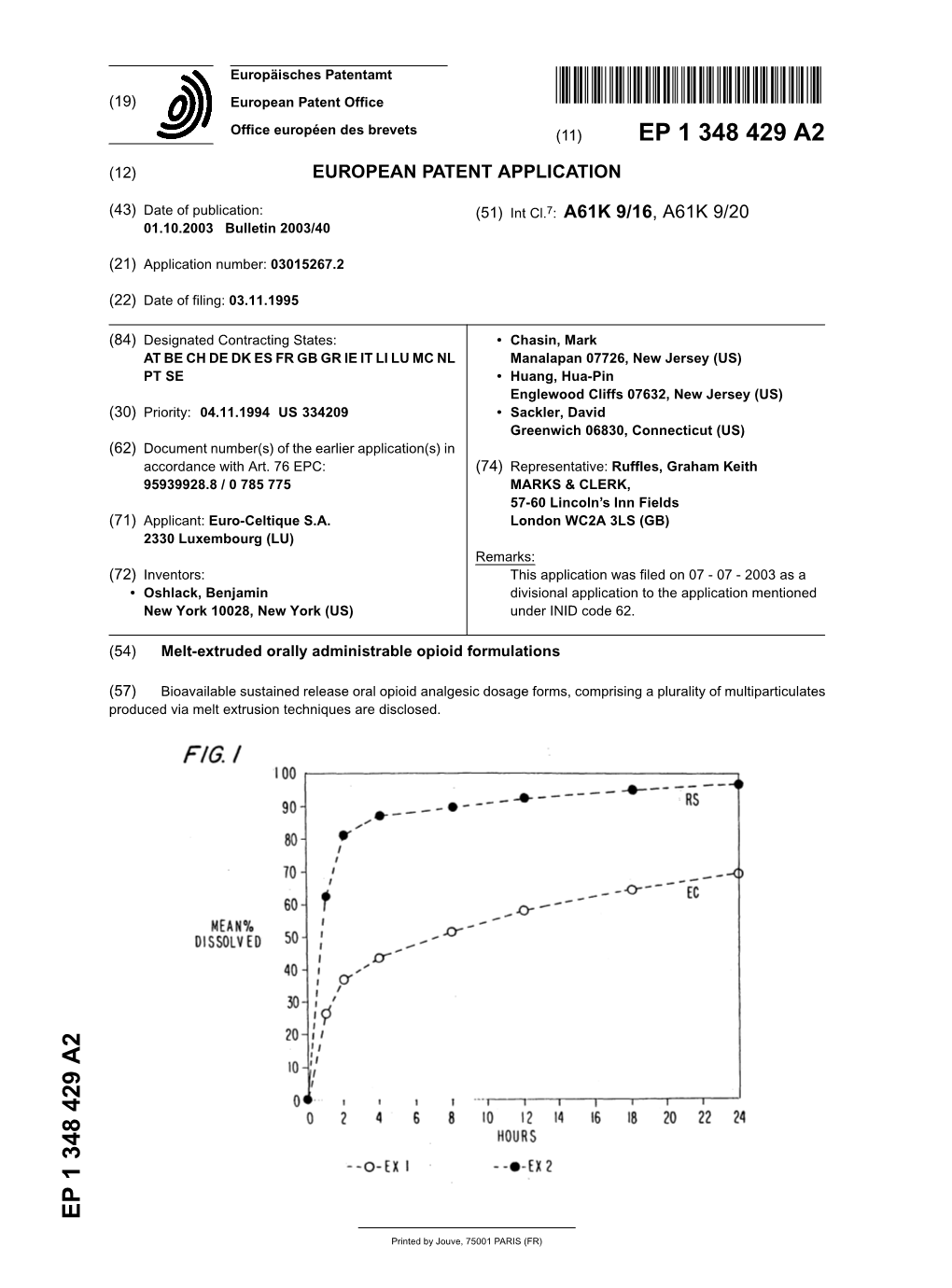

Melt-Extruded Orally Administrable Opioid Formulations

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Title 16. Crimes and Offenses Chapter 13. Controlled Substances Article 1

TITLE 16. CRIMES AND OFFENSES CHAPTER 13. CONTROLLED SUBSTANCES ARTICLE 1. GENERAL PROVISIONS § 16-13-1. Drug related objects (a) As used in this Code section, the term: (1) "Controlled substance" shall have the same meaning as defined in Article 2 of this chapter, relating to controlled substances. For the purposes of this Code section, the term "controlled substance" shall include marijuana as defined by paragraph (16) of Code Section 16-13-21. (2) "Dangerous drug" shall have the same meaning as defined in Article 3 of this chapter, relating to dangerous drugs. (3) "Drug related object" means any machine, instrument, tool, equipment, contrivance, or device which an average person would reasonably conclude is intended to be used for one or more of the following purposes: (A) To introduce into the human body any dangerous drug or controlled substance under circumstances in violation of the laws of this state; (B) To enhance the effect on the human body of any dangerous drug or controlled substance under circumstances in violation of the laws of this state; (C) To conceal any quantity of any dangerous drug or controlled substance under circumstances in violation of the laws of this state; or (D) To test the strength, effectiveness, or purity of any dangerous drug or controlled substance under circumstances in violation of the laws of this state. (4) "Knowingly" means having general knowledge that a machine, instrument, tool, item of equipment, contrivance, or device is a drug related object or having reasonable grounds to believe that any such object is or may, to an average person, appear to be a drug related object. -

(12) United States Patent (10) Patent No.: US 8,541,026 B2 Qiu Et Al

USOO8541026B2 (12) United States Patent (10) Patent No.: US 8,541,026 B2 Qiu et al. (45) Date of Patent: Sep. 24, 2013 (54) SUSTAINED RELEASE FORMULATIONS OF 4,612,008 A 9/1986 Wong et al. OPOD AND NONOPOD ANALGESCS 4,663,149 A 5, 1987 Eckenhoff et al. 4,681.583 A 7/1987 Urquhartet al. 4,717,569 A 1/1988 Harrison et al. (75) Inventors: Yihong Qiu, Vernon Hills, IL (US); 4,763,405 A 8, 1988 E" Cheri E. Klein, Northbrook, IL (US) 4,765,989 A 8/1988 Wong et al. 4,777,049 A 10/1988 Magruder et al. (73) Assignee: AbbVie Inc., North Chicago, IL (US) 4,783,337 A 1 1/1988 Wong et al. 4,786,503 A 11/1988 Edgren et al. (*) Notice: Subject to any disclaimer, the term of this 4,806.3594,801.461 A 2/19891/1989 RadebaughHamel et al. etal patent is extended or adjusted under 35 48 16,470 A 3, 1989 Dowle et al. U.S.C. 154(b) by 1219 days. 4,820,522 A 4, 1989 Radebaugh et al. 4,844,907 A 7/1989 Elger et al. (21) Appl. No.: 11/737,914 4,847,077 A 7, 1989 Raghunathan 4,892,778 A 1/1990 Theeuwes et al. 1-1. 4.915,949 A 4/1990 Wong et al. (22) Filed: Apr. 20, 2007 4.915,954. A 4/1990 Ayer et al. O O 4,931,285 A 6/1990 Edgren et al. (65) Prior Publication Data 4,940,465. -

(12) Patent Application Publication (10) Pub. No.: US 2004/0024006 A1 Simon (43) Pub

US 2004.0024006A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2004/0024006 A1 Simon (43) Pub. Date: Feb. 5, 2004 (54) OPIOID PHARMACEUTICAL May 30, 1997, now abandoned, and which is a COMPOSITIONS continuation-in-part of application No. 08/643,775, filed on May 6, 1996, now abandoned. (76) Inventor: David Lew Simon, Mansfield Center, CT (US) Publication Classification Correspondence Address: (51) Int. Cl. ................................................ A61K 31/485 David L. Simon (52) U.S. Cl. .............................................................. 514/282 P.O. Box 618 100 Cemetery Road (57) ABSTRACT Mansfield Center, CT 06250 (US) The invention is directed in part to dosage forms comprising a combination of an analgesically effective amount of an (21) Appl. No.: 10/628,089 opioid agonist analgesic and a neutral receptor binding agent or a partial mu-opioid agonist, the neutral receptor binding (22) Filed: Jul. 25, 2003 agent or partial mu-opioid agonist being included in a ratio Related U.S. Application Data to the opioid agonist analgesic to provide a combination product which is analgesically effective when the combina (63) Continuation-in-part of application No. 10/306,657, tion is administered as prescribed, but which is leSS analge filed on Nov. 27, 2002, which is a continuation-in-part Sically effective or less rewarding when administered in of application No. 09/922,873, filed on Aug. 6, 2001, excess of prescription. Preferably, the combination product now Pat. No. 6,569,866, which is a continuation-in affects an opioid dependent individual differently from an part of application No. 09/152,834, filed on Sep. -

(12) Patent Application Publication (10) Pub. No.: US 2010/0129443 A1 Pettersson (43) Pub

US 20100129443A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2010/0129443 A1 Pettersson (43) Pub. Date: May 27, 2010 (54) NON-ABUSABLE PHARMACEUTICAL Publication Classification COMPOSITION COMPRISING OPODS (51) Int. Cl. A69/20 (2006.01) (76) Inventor: Anders Pettersson, Uppsala (SE) A6IR 9/14 (2006.01) Correspondence Address: 3. ?t C RYAN KROMHOLZ & MANION, S.C. (2006.01) POST OFFICE BOX 266.18 A6IP 25/00 (2006.01) MILWAUKEE, WI 53226 (US) (52) U.S. Cl. ......... 424/465; 424/489: 514/329; 514/282: 424/464 (21) Appl. No.: 12/312,995 (57) ABSTRACT (22) PCT Filed: Dec. 3, 2007 There is provided pharmaceutical compositions for the treat ment of pain comprising a pharmacologically-effective (86). PCT No.: PCT/GB2OOTFOO4627 amount of an opioid analgesic, or a pharmaceutically-accept S371 (c)(1) able salt thereof, presented in particulate form upon the sur (2), (4) Date: Jan. 12, 2010 faces of carrier particles comprising a pharmacologically s e -la?s effective amount of an opioid antagonist, or a O O pharmaceutically-acceptable Salt thereof, which carrier par Related U.S. Application Data ticles are larger in size than the particles of the opioid anal (60) Provisional application No. 60/872,496, filed on Dec. gesic. The compositions are also useful in prevention of 4, 2006. opioid abuse by addicts. US 2010/0129443 A1 May 27, 2010 NON-ABUSABLE PHARMACEUTICAL ing opioid analgesics, which may be administered by a con COMPOSITION COMPRISING OPODS Venient route, for example transmucosally, particularly, as is usually the case, when such active ingredients are incapable of being delivered perorally due to poor and/or variable bio 0001. -

Drug and Medication Classification Schedule

KENTUCKY HORSE RACING COMMISSION UNIFORM DRUG, MEDICATION, AND SUBSTANCE CLASSIFICATION SCHEDULE KHRC 8-020-1 (11/2018) Class A drugs, medications, and substances are those (1) that have the highest potential to influence performance in the equine athlete, regardless of their approval by the United States Food and Drug Administration, or (2) that lack approval by the United States Food and Drug Administration but have pharmacologic effects similar to certain Class B drugs, medications, or substances that are approved by the United States Food and Drug Administration. Acecarbromal Bolasterone Cimaterol Divalproex Fluanisone Acetophenazine Boldione Citalopram Dixyrazine Fludiazepam Adinazolam Brimondine Cllibucaine Donepezil Flunitrazepam Alcuronium Bromazepam Clobazam Dopamine Fluopromazine Alfentanil Bromfenac Clocapramine Doxacurium Fluoresone Almotriptan Bromisovalum Clomethiazole Doxapram Fluoxetine Alphaprodine Bromocriptine Clomipramine Doxazosin Flupenthixol Alpidem Bromperidol Clonazepam Doxefazepam Flupirtine Alprazolam Brotizolam Clorazepate Doxepin Flurazepam Alprenolol Bufexamac Clormecaine Droperidol Fluspirilene Althesin Bupivacaine Clostebol Duloxetine Flutoprazepam Aminorex Buprenorphine Clothiapine Eletriptan Fluvoxamine Amisulpride Buspirone Clotiazepam Enalapril Formebolone Amitriptyline Bupropion Cloxazolam Enciprazine Fosinopril Amobarbital Butabartital Clozapine Endorphins Furzabol Amoxapine Butacaine Cobratoxin Enkephalins Galantamine Amperozide Butalbital Cocaine Ephedrine Gallamine Amphetamine Butanilicaine Codeine -

Naturopathic Physicians Regulation

PROPOSED AMENDMENTS – NATUROPATHIC PHYSICIANS REGULATION Health Professions Act NATUROPATHIC PHYSICIANS REGULATION PROPOSED TO REPLACE B.C. REG. 282/2008 Contents 1 Definitions 2 College name 3 Reserved titles 4 Scope of practice 5 Restricted activities 6 Limits or conditions on services and restricted activities 7 Patient relations program 8 Health profession corporations 1 PROPOSED AMENDMENTS – NATUROPATHIC PHYSICIANS REGULATION Definitions 1 In this regulation: "Act" means the Health Professions Act; "compound" means (a) in respect of a drug, to mix with one or more other ingredients, and (b) in respect of a therapeutic diet, to mix two or more ingredients; "dispense" has the same meaning as in the Pharmacy Operations and Drug Scheduling Act, but excludes a sale, as defined in that Act; "drug" means, except in the definition of "substance", a drug (a) specified in Schedule I of the Drug Schedules Regulation, B.C. Reg. 9/98, other than a drug set out in the Schedule of this regulation, or (b) specified in Schedule II of the Drug Schedules Regulation; "enteral instillation" means instillation directly into the gastrointestinal tract; "minor surgery" means a surgical procedure that (a) is performed, for a diagnostic or therapeutic purpose, on a superficial anatomical structure, and (b) does not involve (i) sedation, general anaesthesia or respiratory assistance, or (ii) a material risk to life; "naturopathic medicine" means the health profession in which a person provides the services of prevention, assessment and treatment of an individual's -

Codeine and Its Alternates for Pain and Cough Relief* 2

Bull. Org. mond. Sante Bull. Wid Hith Org. J 1969, 40. 1-53 Codeine and its Alternates for Pain and Cough Relief* 2. Alternates for Pain Relief NATHAN B. EDDY, M.D.,1 HANS FRIEBEL, Dr med.,2 KLAUS-J)RGEN HAHN, Dr med.3 & HANS HALBACH, Dr med. Dr-Ing. 4 This report-the second of a series on codeine and its alternates for pain and cough relief-contains a detailed evaluation of experimental and clinical data on newer sub- stances having analgesic properties comparable to and in approximately the same range as those ofcodeine. The data are discussed under the headings: analgesic effects in animals; clinical usefulness; side-effects with particular reference to dependence andabuse liability. CONTENTS CARISOPRODOL ............... 1 PRODILIDINE ........... ... .. 42 DEXTROPROPOXYPHENE ........... 6 INDANES .................. 44 DHYDROCODEINE ............... 22 PHTHALIMIDES ............... 44 ETHOHEPTAZINE ............... 24 PYRROLIDINES .......... .... 45 ETYMIDE.. .............. 29 SPECIFIC OPIATE ANTAGONISTS .... 45 FENYRAMIDOL ............... 32 Risum .................... 47 METOFOLINE. .............. 33 REFERENCES ............. ... 48 CARISOPRODOL 5 propanediol carbamate isopropyl carbamate) was evaluated initially for paralysis of the intact animal, After the discovery and development of mepro- depression of spinal reflexes, anticonvulsant effect bamate, further exploitation of the dicarbamate molecule resulted in the preparation of substances 0 which differed widely in their pattern of activity. CH3-CH2-CH2 CH2-O-C-NHCH (CH3)2 One of these, carisoprodol (2-methyl-2-propyl-1,3- \I/ c * This review of the analgesic and antitussive effects of CH3 CH2-0-C-NH2 codeine and its alternates is being published in the Bulletin of the World Health Organization in five instalments. The first, devoted to an assessment of codeine as a pain reliever, was published in Bull. -

A Study of Efficacy of Intramuscular Injection

A STUDY OF EFFICACY OF INTRAMUSCULAR INJECTION TRAMADOL AS LABOUR ANALGESIC AND LABOUR ACCELERATOR IN 400 PRIMIGRAVIDA PATIENTS IN LATENT PHASE OF FIRST STAGE OF LABOUR A Dissertation Submitted to THE TAMILNADU DR. M.G.R MEDICAL UNIVERSITY CHENNAI In Partial Fulfilments of the Regulations for the Award of the Degree of M.S. (OBSTETRICS & GYNAECOLOGY) - BRANCH – II GOVERNMENT STANLEY MEDICAL COLLEGE CHENNAI April – 2014 BONAFIDE CERTIFICATE This is to certify that this dissertation is the bonafide work of Dr.MUTHULAKSHMI.N on ‘‘A STUDY OF EFFICACY OF INTRAMUSCULAR INJECTION TRAMADOL AS LABOUR ANALGESIC AND LABOUR ACCELERATOR IN 400 PRIMIGRAVIDA PATIENTS IN LATENT PHASE OF FIRST STAGE OF LABOUR” during her M.S.,(Obstetrics and Gynaecology) course from April 2011 to April 2014 at the Government Stanley medical college and Raja Sir Ramasamy Mudaliar Lying-in Hospital,Chennai. PROF.DR.V.KALAIVANI, M.D., DGO., Professor and Head Of the Department, Dept. of Obstetrics & Gynaecology, Govt. Stanley Medical College & Govt. RSRM Lying In Hospital, Chennai – 600013. PROF. Dr.S.GEETHALAKSHMI, M.D., Ph.D., THE DEAN, GOVT. STANLEY MEDICAL COLLEGE & HOSPITAL, CHENNAI-1 DECLARATION I, Dr. MUTHULAKSHMI.N solemnly declare that the dissertation ‘‘A STUDY OF EFFICACY OF INTRAMUSCULAR INJECTION TRAMADOL AS LABOUR ANALGESIC AND LABOUR ACCELERATOR IN 400 PRIMIGRAVIDA PATIENTS IN LATENT PHASE OF FIRST STAGE OF LABOUR” is a bona fide work done by me at Government R.S.R.M Lying in Hospital, under supervision and guidance of Prof. Dr. V. KALAIVANI, M.D., DGO in Department of Obstetrics and Gynaecology, Government Stanley Medical College, Chennai. This thesis is submitted to The Tamil Nadu Dr .M.G.R. -

ABSTRACT This Material Provides Documentation for Users of the Micro-Data Files of the 2000 National Hospital Ambulatory Medical

2000 NHAMCS MICRO-DATA FILE DOCUMENTATION PAGE 1 ABSTRACT This material provides documentation for users of the micro-data files of the 2000 National Hospital Ambulatory Medical Care Survey (NHAMCS). The NHAMCS is a national probability sample survey of visits to hospital outpatient and emergency departments, conducted by the National Center for Health Statistics, Centers for Disease Control and Prevention. The survey is a component of the National Health Care Survey, which measures health care utilization across a variety of health care providers. There are two micro-data files produced from the NHAMCS, one for outpatient department records and one for emergency department records. Section I of this documentation, “Description of the National Hospital Ambulatory Medical Care Survey,” includes information on the scope of the survey, the sample, field activities, data collection procedures, medical coding procedures, and population estimates. Section II provides detailed descriptions of the contents of each file’s data record by location. Section III contains marginal data for selected items on each file. The appendixes contain sampling errors, instructions and definitions for completing the Patient Record forms, and lists of codes used in the survey. PAGE 2 2000 NHAMCS MICRO-DATA FILE DOCUMENTATION THIS PAGE HAS BEEN LEFT BLANK INTENTIONALLY. 2000 NHAMCS MICRO-DATA FILE DOCUMENTATION PAGE 3 Table of Contents Page I. Description of the National Hospital Ambulatory Medical Care Survey A. Introduction ..........................................................5 -

Disposal Systems of Transdermal Delivery Devices to Prevent Misuse of the Active Agents Contained Therein

(19) & (11) EP 1 837 023 A1 (12) EUROPEAN PATENT APPLICATION (43) Date of publication: (51) Int Cl.: 26.09.2007 Bulletin 2007/39 A61K 31/485 (2006.01) A61K 9/70 (2006.01) A61K 31/445 (2006.01) B09B 3/00 (2006.01) (2006.01) (21) Application number: 07003694.2 A61F 13/00 (22) Date of filing: 10.06.2003 (84) Designated Contracting States: (72) Inventors: AT BE BG CH CY CZ DE DK EE ES FI FR GB GR • Baker, Carl J. HU IE IT LI LU MC NL PT RO SE SI SK TR Middletown, NY 10941-5004 (US) Designated Extension States: • Shevchuck, Ihor AL LT LV MK Yonkers, NY 10710 (US) (30) Priority: 10.06.2002 US 387800 P (74) Representative: Maiwald Patentanwalts GmbH Elisenhof, (62) Document number(s) of the earlier application(s) in Elisenstrasse 3 accordance with Art. 76 EPC: 80335 München (DE) 03757468.8 / 1 513 532 Remarks: (71) Applicant: EURO-CELTIQUE S.A. This application was filed on 22 - 02 - 2007 as a 2330 Luxembourg (LU) divisional application to the application mentioned under INID code 62. (54) Disposal systems of transdermal delivery devices to prevent misuse of the active agents contained therein (57) The present invention relates to a transdermal at least one deactivating agent to chemically alter, to de- delivery device disposal system for disposing of a grade, and/or to deactivate the active component (s) con- transdermal delivery device containing at least one phar- tained in the transdermal delivery device, such as an opi- maceutically active component. The disposal system oid antagonist or an opioid agonist deactivating agent so contains -

2021 Equine Prohibited Substances List

2021 Equine Prohibited Substances List . Prohibited Substances include any other substance with a similar chemical structure or similar biological effect(s). Prohibited Substances that are identified as Specified Substances in the List below should not in any way be considered less important or less dangerous than other Prohibited Substances. Rather, they are simply substances which are more likely to have been ingested by Horses for a purpose other than the enhancement of sport performance, for example, through a contaminated food substance. LISTED AS SUBSTANCE ACTIVITY BANNED 1-androsterone Anabolic BANNED 3β-Hydroxy-5α-androstan-17-one Anabolic BANNED 4-chlorometatandienone Anabolic BANNED 5α-Androst-2-ene-17one Anabolic BANNED 5α-Androstane-3α, 17α-diol Anabolic BANNED 5α-Androstane-3α, 17β-diol Anabolic BANNED 5α-Androstane-3β, 17α-diol Anabolic BANNED 5α-Androstane-3β, 17β-diol Anabolic BANNED 5β-Androstane-3α, 17β-diol Anabolic BANNED 7α-Hydroxy-DHEA Anabolic BANNED 7β-Hydroxy-DHEA Anabolic BANNED 7-Keto-DHEA Anabolic CONTROLLED 17-Alpha-Hydroxy Progesterone Hormone FEMALES BANNED 17-Alpha-Hydroxy Progesterone Anabolic MALES BANNED 19-Norandrosterone Anabolic BANNED 19-Noretiocholanolone Anabolic BANNED 20-Hydroxyecdysone Anabolic BANNED Δ1-Testosterone Anabolic BANNED Acebutolol Beta blocker BANNED Acefylline Bronchodilator BANNED Acemetacin Non-steroidal anti-inflammatory drug BANNED Acenocoumarol Anticoagulant CONTROLLED Acepromazine Sedative BANNED Acetanilid Analgesic/antipyretic CONTROLLED Acetazolamide Carbonic Anhydrase Inhibitor BANNED Acetohexamide Pancreatic stimulant CONTROLLED Acetominophen (Paracetamol) Analgesic BANNED Acetophenazine Antipsychotic BANNED Acetophenetidin (Phenacetin) Analgesic BANNED Acetylmorphine Narcotic BANNED Adinazolam Anxiolytic BANNED Adiphenine Antispasmodic BANNED Adrafinil Stimulant 1 December 2020, Lausanne, Switzerland 2021 Equine Prohibited Substances List . Prohibited Substances include any other substance with a similar chemical structure or similar biological effect(s). -

(12) Patent Application Publication (10) Pub. No.: US 2005/0163856A1 Maloney Et Al

US 2005O163856A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2005/0163856A1 Maloney et al. (43) Pub. Date: Jul. 28, 2005 (54) ABUSE-RESISTANTSUSTAINED-RELEASE Related U.S. Application Data OPOD FORMULATION (63) Continuation of application No. 10/264,020, filed on Oct. 3, 2002, which is a continuation-in-part of appli (75) Inventors: Ann Maloney, Dublin, OH (US); cation No. 10/085,597, filed on Feb. 27, 2002, now Debra Marie Murwin, Orient, OH abandoned, and which is a continuation of application (US); Michael Jay Schobelock, Grove No. 09/626,584, filed on Jul. 27, 2000, now aban City, OH (US) doned. (60) Provisional application No. 60/146,298, filed on Jul. Correspondence Address: 29, 1999. MICHAEL P. MORRIS Publication Classification BOEHRINGER INGELHEM CORPORATION 900 RIDGEBURY ROAD (51) Int. CI.7. ... A61K 31/485; A61K 9/14 PO BOX 368 (52) U.S. Cl. ............................................ 424/486; 514/282 RIDGEFIELD, CT 06877-0368 (US) (57) ABSTRACT (73) Assignee: Roxane Laboratories, Inc., Columbus, A method for reducing the abuse potential of an oral dosage OH form of an opioid extractable by commonly available house hold Solvents Said method comprising combining a thera (21) Appl. No.: 11/087,154 peutically effective amount of the opioid compound, or a Salt thereof, a matrix-forming polymer and an ionic exchange (22) Filed: Mar. 23, 2005 resin. US 2005/0163856 A1 Jul. 28, 2005 ABUSE-RESISTANTSUSTAINED-RELEASE after repeated administration of the drug, a given dose of the OPOD FORMULATION drug produces a decreased effect, or conversely, when increasingly larger doses of the drug must be administered RELATED APPLICATIONS to obtain effects observed with the original dose.