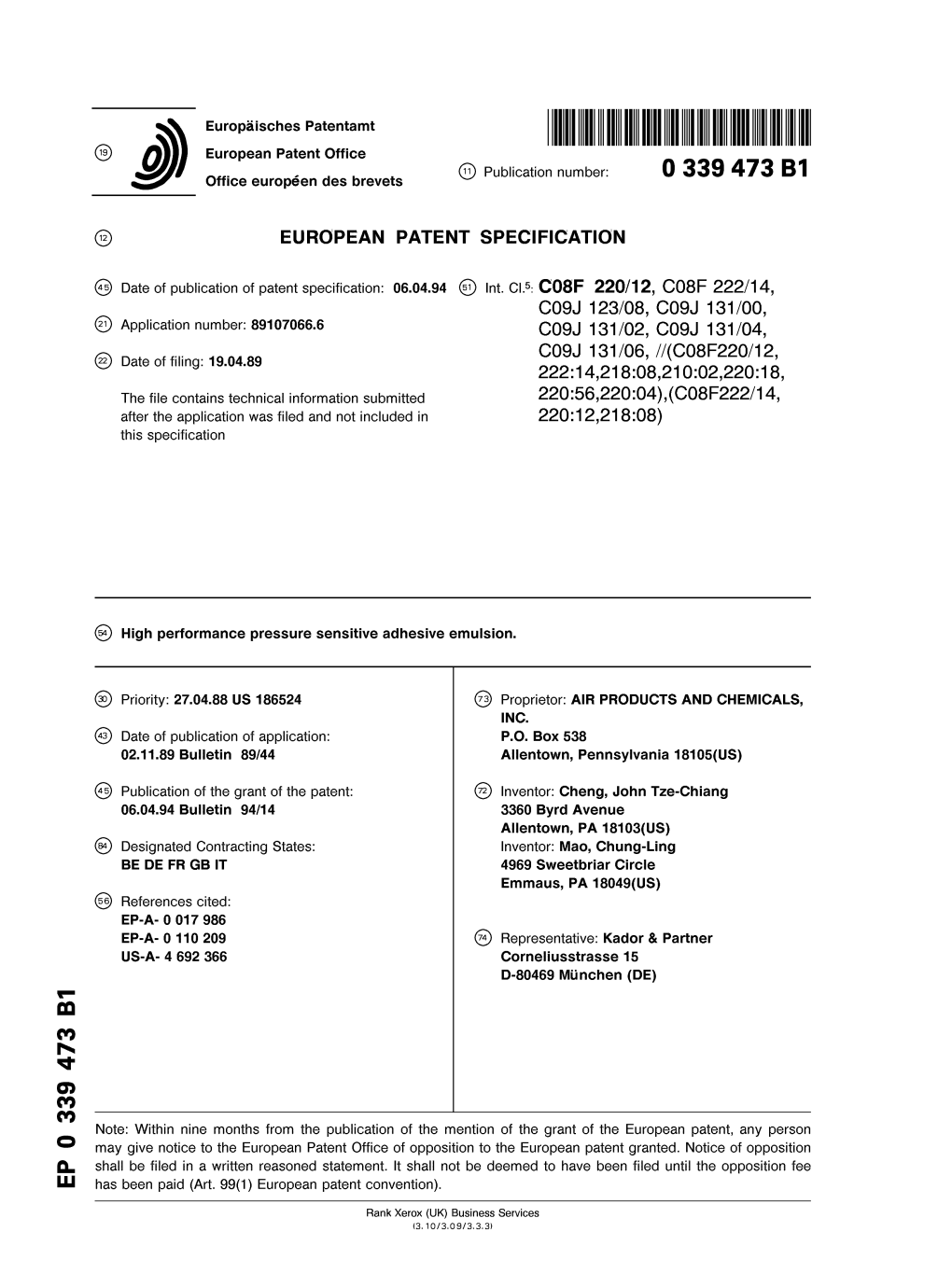

High Performance Pressure Sensitive Adhesive Emulsion

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Thèse Docteur De L'université De Haute-Alsace

UNIVERSITE DE HAUTE-ALSACE UNIVERSITE DE STRASBOURG Thèse Présentée pour l’obtention du grade de Docteur de l’Université de Haute-Alsace Ecole Doctorale : ED 222 - Sciences Chimiques Discipline : Chimie, Physique et Matériaux Présentée et soutenue publiquement par Franklin BAUER Le 30 novembre 2017 Une meilleure caractérisation des mécanismes d’action toxique à partir de la structure moléculaire. Thèse CIFRE Sous la Direction de : Directeur de thèse : Prof. Serge NEUNLIST Co-directeur de thèse : Dr. Samuel FOUCHARD Encadrée en entreprise par : Dr. Paul THOMAS Jury : Dr. Karine AUDOUZE, université Paris Diderot (Rapporteur) Dr. Patrice GONZALEZ, université de Bordeaux (Rapporteur) Prof. Jean-Philippe GODDARD, université de Haute-Alsace (Président) Prof. Eric PINELLI, université de Toulouse III Prof. Serge NEUNLIST, université de Haute-Alsace Dr. Samuel FOUCHARD, université de Haute-Alsace Dr. Paul THOMAS, KREATiS 3 Table des matières Table des figures .................................................................................................................. 6 Table des tableaux ............................................................................................................... 7 Liste des abréviations .......................................................................................................... 8 Remerciements ................................................................................................................. 10 Résumé de la thèse en anglais – Abstract ........................................................................ -

Evaluation of Maleate, Fumarate, and Succinate Diesters As Potential Green Plasticizers

Evaluation of maleate, fumarate, and succinate diesters as potential green plasticizers by Hanno Christian Erythropel A thesis submitted to McGill University in partial fulfillment of the requirements of the degree of Doctor of Philosophy Department of Chemical Engineering McGill University Montréal, Canada December 2015 ©Hanno C. Erythropel, 2015 Être homme, c’est précisément être responsable. C’est connaître la honte en face d’une misère qui ne semblait pas dépendre de soi. C’est être fier d’une victoire que les camarades ont remportée. C’est sentir, en posant sa pierre, que l’on contribue à bâtir le monde. -Antoine de Saint-Exupéry Gewidmet meinen lieben Eltern Eda & Karl-Heinz, sowie Thilo mit Marla. Abstract The industrial success of poly(vinyl chloride) (PVC) would not have been possible without compounds known as plasticizers, the most important class of additives to brittle polymers such as PVC. Plasticizers facilitate the processing of PVC and render the final product soft and flexible, and plasticizer content can reach up to 50 weight-percent. Due to the ever-increasing use of flexible PVC, plasticizers are produced in the range of several million metric tonnes per year. The most important class of plasticizers are phthalate diesters and di (2-ethylhexyl) phthalate (DEHP) is the most frequently used compound. The vast majority of plasticizers is simply blended with a polymer at elevated temperatures and thus is not bound to the polymer matrix, which results in their tendency to leach from the material over time, ultimately ending up in the environment. Once in the environment, the microbial biodegradation rates of phthalates are low, leading to their omnipresence in environmental samples. -

(12) United States Patent (10) Patent No.: US 6,620,949 B1 Sutton Et Al

USOO6620949B1 (12) United States Patent (10) Patent No.: US 6,620,949 B1 Sutton et al. (45) Date of Patent: Sep. 16, 2003 (54) PROCESS FOR THE SIMULTANEOUS 6,191,322 B1 2/2001 Bertola ....................... 568/864 PRODUCTION OF MALEC ANHYDRIDE 6.274,743 B1 * 8/2001 Tucket al. ................. 549/295 AND ITS HYDROGENATED DERVATIVES 6,380,402 B2 4/2002 Cho et al. ................... 549/325 6,433,193 B1 * 8/2002 Bertola et al. .............. 549/295 (75) Inventors: David Mark Sutton, 6,492,535 B1 * 12/2002 Castiglioni et al. ......... 549/325 Kingston-upon-Thames (GB); Andrew 6,515,148 B2 2/2003 Schiodt ...................... 549/326 George Hiles, Amersham (GB); Adrian FOREIGN PATENT DOCUMENTS Francis Backes, London (GB) GB 22O7914 2/1989 (73) Assignee: Davy Process Technology Limited, WO 9743234 11/1997 WO 9743242 11/1997 London (GB) WO 9948852 9/1999 (*) Notice: Subject to any disclaimer, the term of this patent is extended or adjusted under 35 * cited by examiner U.S.C. 154(b) by 0 days. Primary Examiner Deborah C. Lambkin (21) Appl. No.: 10/110,444 (74) Attorney, Agent, or Firm-Davidson, Davidson & Kappel, LLC (22) PCT Filed: Oct. 4, 2000 (57) ABSTRACT (86) PCT No.: PCT/GB00/03805 A proceSS is described for the co-production of maleic S371 (c)(1), anhydride and at least one C compound Selected from (2), (4) Date: Jul. 22, 2002 butane-1,4-diol, Y-butyrolactone, and tetrahydrofuran in (87) PCT Pub. No.: WO01/27058 which maleic anhydride is produced by partial oxidation of a hydrocarbon feedstock Selected from C. -

Poly(Lactic Acid) Science and Technology: Processing, Properties, Additives and Applications

Poly(lactic acid) Science and Technology Processing, Properties, Additives and Applications RSC Polymer Chemistry Series Editor-in-Chief: Ben Zhong Tang, The Hong Kong University of Science and Technology, Hong Kong, China Series Editors: Alaa S. Abd-El-Aziz, University of Prince Edward Island, Canada Stephen Craig, Duke University, USA Jianhua Dong, National Natural Science Foundation of China, China Toshio Masuda, Fukui University of Technology, Japan Christoph Weder, University of Fribourg, Switzerland Titles in the Series: 1: Renewable Resources for Functional Polymers and Biomaterials 2: Molecular Design and Applications of Photofunctional Polymers and Materials 3: Functional Polymers for Nanomedicine 4: Fundamentals of Controlled/Living Radical Polymerization 5: Healable Polymer Systems 6: Thiol-X Chemistries in Polymer and Materials Science 7: Natural Rubber Materials: Volume 1: Blends and IPNs 8: Natural Rubber Materials: Volume 2: Composites and Nanocomposites 9: Conjugated Polymers: A Practical Guide to Synthesis 10: Polymeric Materials with Antimicrobial Activity: From Synthesis to Applications 11: Phosphorus-Based Polymers: From Synthesis to Applications 12: Poly(lactic acid) Science and Technology: Processing, Properties, Additives and Applications How to obtain future titles on publication: A standing order plan is available for this series. A standing order will bring delivery of each new volume immediately on publication. For further information please contact: Book Sales Department, Royal Society of Chemistry, Thomas Graham -

156 Part 175—Indirect Food Addi

Pt. 175 21 CFR Ch. I (4–1–11 Edition) The Food and Drug Administration food in accordance with the following will exempt substances whose uses it prescribed conditions: determines meet the criteria in § 170.39 (1) The adhesive is prepared from one of this chapter from regulation as food or more of the optional substances additives and, therefore, a food addi- named in paragraph (c) of this section, tive petition will not be required for subject to any prescribed limitations. the exempted use. (2) The adhesive is either separated from the food by a functional barrier or [60 FR 36596, July 17, 1995] used subject to the following additional limitations: PART 175—INDIRECT FOOD ADDI- (i) In dry foods. The quantity of adhe- TIVES: ADHESIVES AND COMPO- sive that contacts packaged dry food NENTS OF COATINGS shall not exceed the limits of good manufacturing practice. Subpart A [Reserved] (ii) In fatty and aqueous foods. (a) The quantity of adhesive that contacts Subpart B—Substances for Use Only as packaged fatty and aqueous foods shall Components of Adhesives not exceed the trace amount at seams Sec. and at the edge exposure between pack- 175.105 Adhesives. aging laminates that may occur within 175.125 Pressure-sensitive adhesives. the limits of good manufacturing prac- tice. Subpart C—Substances for Use as (b) Under normal conditions of use Components of Coatings the packaging seams or laminates will 175.210 Acrylate ester copolymer coating. remain firmly bonded without visible 175.230 Hot-melt strippable food coatings. separation. 175.250 Paraffin (synthetic). (b) To assure safe usage of adhesives, 175.260 Partial phosphoric acid esters of pol- the label of the finished adhesive con- yester resins. -

Dr. Dennis Keefe Director of the Office of Food Additive Safety

NATURAL RESOURCES DEFENSE COUNCIL BREAST CANCER FUND CENTER FOR ENVIRONMENTAL HEALTH CENTER FOR FOOD SAFETY CENTER FOR SCIENCE IN THE PUBLIC INTEREST CHILDREN’S ENVIRONMENTAL HEALTH NETWORK CLEAN WATER ACTION ENVIRONMENTAL WORKING GROUP IMPROVING KIDS’ ENVIRONMENT October 17, 2014 (REVISED FROM VERSION FILED October 16, 2014) Dr. Dennis Keefe Director of the Office of Food Additive Safety (HFS-200) Center for Food Safety and Applied Nutrition 5100 Paint Branch Parkway College Park, MD 20740 Re: Petition seeking amended food additive regulation to remove FDA’s approval at 21 C.F.R. § 176.170 of the use of long-chain perfluorocarboxylate oil and grease repellents in paper and paperboard - Pre-Notification Consultation 1417 (PNC 1417) Dear Dr. Keefe: In 2010, the U.S. Food and Drug Administration’s (FDA) food additives toxicologists concluded that, in animal studies, long-chain perfluorinated compounds adversely affect fetal and newborn development and that one group of these compounds, long-chain perfluorocarboxylates1, adversely affect the male, and, possibly the female, reproductive systems.2 A ‘long-chain’ means the compound has eight or more carbons (“≥ C8”) connected together and the carbons are saturated with fluorine atoms. As the chain lengthens, FDA’s toxicologists noted that the chemical’s biopersistence, and hence potency, in the human body increases.3 These findings on long-chain perfluorocarboxylates expand on the toxicologist’s 2007 conclusion that carcinogenicity was a concern for chemicals that were structurally similar to the perfluorooctanoic acid (PFOA).4 The agency’s food additive toxicologists stated that “[d]ue to the considerable uncertainties remaining regarding the toxic effects of perfluorinated compounds as a class in humans, significant questions remain regarding the safe levels of dietary exposure to ≥ C8 perfluorinated 1 Including chemicals that may be converted to perfluorocarboxylates. -

Designing Green Plasticizers

DESIGNING GREEN PLASTICIZERS Hanno Erythropel Department of Chemical Engineering McGill University Montréal, Québec, Canada February 2011 This thesis is submitted to McGill University in partial fulfillment of the requirements of the degree of Master of Engineering © Hanno C. Erythropel, 2011 i Abstract Plasticizers are additives in poly (vinyl chloride) (PVC) formulations that render the material flexible. This is important for many applications. Because these plasticizers are not bound to the polymer chemically, they will eventually leach out upon disposal. Considering also the widespread use of flexible PVC, it is not surprising that some plasticizers, such as di(2-ethylhexyl) phthalate (DEHP), are considered ubiquitous contaminants in the environment. Previous studies have shown that DEHP, upon degradation, forms stable, toxic metabolites. Because of this and other concerns, DEHP and other phthalates have already been banned in certain products in Canada and other countries. Hence, there is a strong incentive to develop new, green plasticizers. A series of diesters based on maleic acid, which resembles a part of the phthalate chemical structure, was tested, along with other series based on the structural isomer of maleic acid, fumaric acid, and the saturated analogue, succinic acid. The alcohols used to form the ester bonds varied in length from ethanol to octanol and, also, included the branched 2-ethyl hexanol. Each of these diesters was incorporated into unplasticized PVC at about 30 weight-percent and then evaluated for plasticizer properties such as glass transition temperature Tg and tensile strength. These data were compared to each other and to results with DEHP. Pure samples of the diesters were tested for their biodegradability by the common soil bacterium Rhodococcus rhodocrous (ATCC 13808) while it was growing on hexadecane as a primary carbon source. -

Rossi Lars.Pdf

Submitted in partial fulfillment of the requirements for the degree of Master of Science Thermal treatment of drill cuttings Lars Martin Rossi Department of mathematics and natural science University of Stavanger June, 2016 Abstract Increased environmental stringency, and focus on cost efficiency, drives the oil & gas industry towards new and better solutions. Members of OSPAR have to follow strict discharge requirements for oil contaminated drill cuttings, based on the BAT, and BEP principles. The most successful technologies rely on thermal desorption. Only the TCC have received acceptance to treat and discharge OBM cuttings on the NCS, at a require- ment of 0:05 % oil by weight. Norwegian-Group AS is currently developing an integrated treatment solution for drilling fluids, waste water, and cuttings. In this thesis, thermal treatment of cuttings is investigated. The treatment concept rely on dielectric heating with microwaves, in combination with environmentally friendly, polar organic compounds. The initial study shows that glycols can be distilled without significant degradation, especially MEG. In addition to the benefits of increased process temperature, a significant reduction in energy requirement is possible. The energy required to vaporize MEG is in the order of magnitudes lower, than what is required to vaporize water. Due to a higher process temperature , the vapor pressure contribution from the oil was significantly increased. Drill cuttings was successfully treated to well below the OSPAR limit of 1 % oil by weight, by the use of susceptors. The presence of susceptors significantly increased the oil separation from cuttings, especially when the cuttings did not contain water. It is believed that the use of susceptors in combination with microwaves can challenge the TCC technology as BAT. -

Related Properties from Molecular Structures

Electronic Supplementary Material (ESI) for Green Chemistry. This journal is © The Royal Society of Chemistry 2021 1 SUPPORTING INFORMATION 2 A multi-task deep learning neural network for predicting flammability- 3 related properties from molecular structures 4 Ao Yang‡a,b, Yang Su‡c,a, Zihao Wanga, Saimeng Jina, Jingzheng Renb, Xiangping Zhangd, 5 Weifeng Shen*a and James H. Clarke 6 aSchool of Chemistry and Chemical Engineering, Chongqing University, Chongqing 400044, China 7 bDepartment of Industrial and Systems Engineering, The Hong Kong Polytechnic University, Hong 8 Kong SAR, China 9 cSchool of Intelligent Technology and Engineering, Chongqing University of Science and Technology, 10 Chongqing 401331, China 11 dBeijing Key Laboratory of Ionic Liquids Clean Process, CAS Key Laboratory of Green Process and 12 Engineering, Institute of Process Engineering, Chinese Academy of Sciences, Beijing, 100190, China 13 eGreen Chemistry Centre of Excellence, University of York, York YO105D, UK 14 *Correspondence should be addressed to: Weifeng Shen ([email protected]) 15 ‡These authors contributed equally to this work. 16 S1. Signature descriptors 17 The signature descriptor1 is an effective tool for encoding molecular structures with all 18 atomic neighborhood into strings. This descriptor involving two forms: the first one is the 19 atomic signatures generated at a specified root atom in a molecule, the other one is the molecular 20 signatures combined from all atom signatures linearly. The size of each atomic signature is 21 determined by a parameter named “height”, h. An atomic Signature is a tree subgraph including 22 all atoms/bonds extending out to the predefined distance h without backtracking. -

In-Situ Preparation of Polyaspartic Ester Mixture In-Situ Herstellung Von Polyasparaginestermischungen Preparation in Situ D’Un Melange D’Esters Polyaspartiques

Europäisches Patentamt *EP001208135B1* (19) European Patent Office Office européen des brevets (11) EP 1 208 135 B1 (12) EUROPEAN PATENT SPECIFICATION (45) Date of publication and mention (51) Int Cl.7: C08G 73/10 of the grant of the patent: 01.10.2003 Bulletin 2003/40 (86) International application number: PCT/US00/19808 (21) Application number: 00948828.9 (87) International publication number: (22) Date of filing: 21.07.2000 WO 01/007504 (01.02.2001 Gazette 2001/05) (54) IN-SITU PREPARATION OF POLYASPARTIC ESTER MIXTURE IN-SITU HERSTELLUNG VON POLYASPARAGINESTERMISCHUNGEN PREPARATION IN SITU D’UN MELANGE D’ESTERS POLYASPARTIQUES (84) Designated Contracting States: (72) Inventor: ROESLER, Richard, R. AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU Wexford, PA 15090 (US) MC NL PT SE (74) Representative: Bramer-Weger, Elmar et al (30) Priority: 23.07.1999 US 145451 P Bayer AG Konzernbereich RP, (43) Date of publication of application: Patente und Lizenzen 29.05.2002 Bulletin 2002/22 51368 Leverkusen (DE) (73) Proprietor: Bayer Corporation (56) References cited: Pittsburgh, PA 15205 (US) US-A- 5 502 117 US-A- 5 807 968 Note: Within nine months from the publication of the mention of the grant of the European patent, any person may give notice to the European Patent Office of opposition to the European patent granted. Notice of opposition shall be filed in a written reasoned statement. It shall not be deemed to have been filed until the opposition fee has been paid. (Art. 99(1) European Patent Convention). EP 1 208 135 B1 Printed by Jouve, 75001 PARIS (FR) EP 1 208 135 B1 Description FIELD OF THE INVENTION 5 [0001] The invention relates to a method for making polyaspartic esters. -

Graft Copolymers of Maleic Anhydride and Its Isostructural Analogues: High Performance Engineering Materials

International Review of Chemical Engineering, volume 3, o 2, March, 2011 Int. Rev.Chem. Eng., 3(2011) 153-215 Graft Copolymers of Maleic Anhydride and Its Isostructural Analogues: High Performance Engineering Materials Zakir M. O. Rzayev Institute of Science & Engineering, Division of anotechnology & anomedicine, Hacettepe University, Beytepe 06800 Ankara, Turkey E-mail: [email protected] Abstract – This review summarizes the main advances published over the last 15 years outlining the different methods of grafting, including reactive extruder systems, surface modification, grafting and graft copolymerization of synthetic and natural polymers with maleic anhydride and its isostructural analogues such as maleimides and maleates, and anhydrides, esters and imides of citraconic and itaconic acids, derivatives of fumaric acid, etc. Special attention is spared to the grafting of conventional and non-conventional synthetic and natural polymers, including biodegradable polymers, mechanism of grafting and graft copolymerization, in situ grafting reactions in melt by reactive extrusion systems, in solutions and solid state (photo- and plasma- induced graftings), and H-bonding effect in the reactive blend processing. The structural phenomena, unique properties and application areas of these copolymers and their various modifications and composites as high performance engineering materials have been also described. Keywords : Graft copolymers; Synthesis; Surface modification; Anhydride functionalities; Hydrogen-bonding; Reactive extrusion; Reactive in situ processing; Reactive blends; Reactive compatibilizers Contents 1. Introduction 2. Grafting of Polyolefins 2.1. Grafting in solution 2.2. Grafting in melt by reactive extrusion 2.3. Grafting in solid state 2.4. Photo-induced surface grafting 2.5. Plasma-induced surface grafting 3. Grafting of Styrene (Co)polymers 4. -

Polymer Additives and Plasticizers

Polymer Additives and Plasticizers Library Listing – 1,799 spectra This library is a valuable addition to any polymer chemist’s toolbox. It includes spectra of plastics and additives for polymers, rubbers, cosmetics, adhesives, sealants, and plasticizers. The Polymers, Polymer Additives and Plasticizers Library features 1,799 spectra collected by Chemir/Polytech Laboratories and Dr. John Kokosa. Samples were run by transmission using one of the following techniques: molded film, capillary film or KBr disk. Each spectrum in the library includes information on manufacturer, chemical name, product name, chemical abstract number, and category name, where available. Chemically, the classes of polymer compounds represented in the library include: thermoplastics, thermoset resins, engineering polymers, monomers, and catalysts. Additives represented include: plasticizers, mold release agents, inorganic fillers, antistatic agents, surfactants, and colorants. Polymer Additives and Plasticizers Index Compound Name Index Compound Name 873 (2,2-THIOBIS-T-OCTYL- 533 1:1 LAUREL DEA PHENOLATO))-N-BUTYLAMINE 416 2,2',4,4'-TETRAHYDROXY NICKEL BENZOPHENONE 916 (2,4-DIHYDROXYPHENOL)- 1643 2,2'-(ETHYLHEXANAMIDE) METHANONE DIETHYL ETHYLHEXANOATE 917 (2-HYDROXY-4-(OCTYLOXY) 744 2,2'-ETHYLIDENE-BIS(4,6-DI-TERT- PHENYL) PHENYL-METHANONE BUTYLPHENOL) 1209 (2-HYDROXY-4-(OCTYLOXY) 733 2,2'-METHYLENE-BIS(4-METHYL-6- PHENYL) PHENYLMETHANONE NONYLPHENOL) 918 (2-HYDROXY-4- 714 2,2'-METHYLENE-BIS(4-METHYL-6- METHOXYPHENYL) PHENYL- TERTIARYBUTYL PHENOL) #1 METHANONE 712