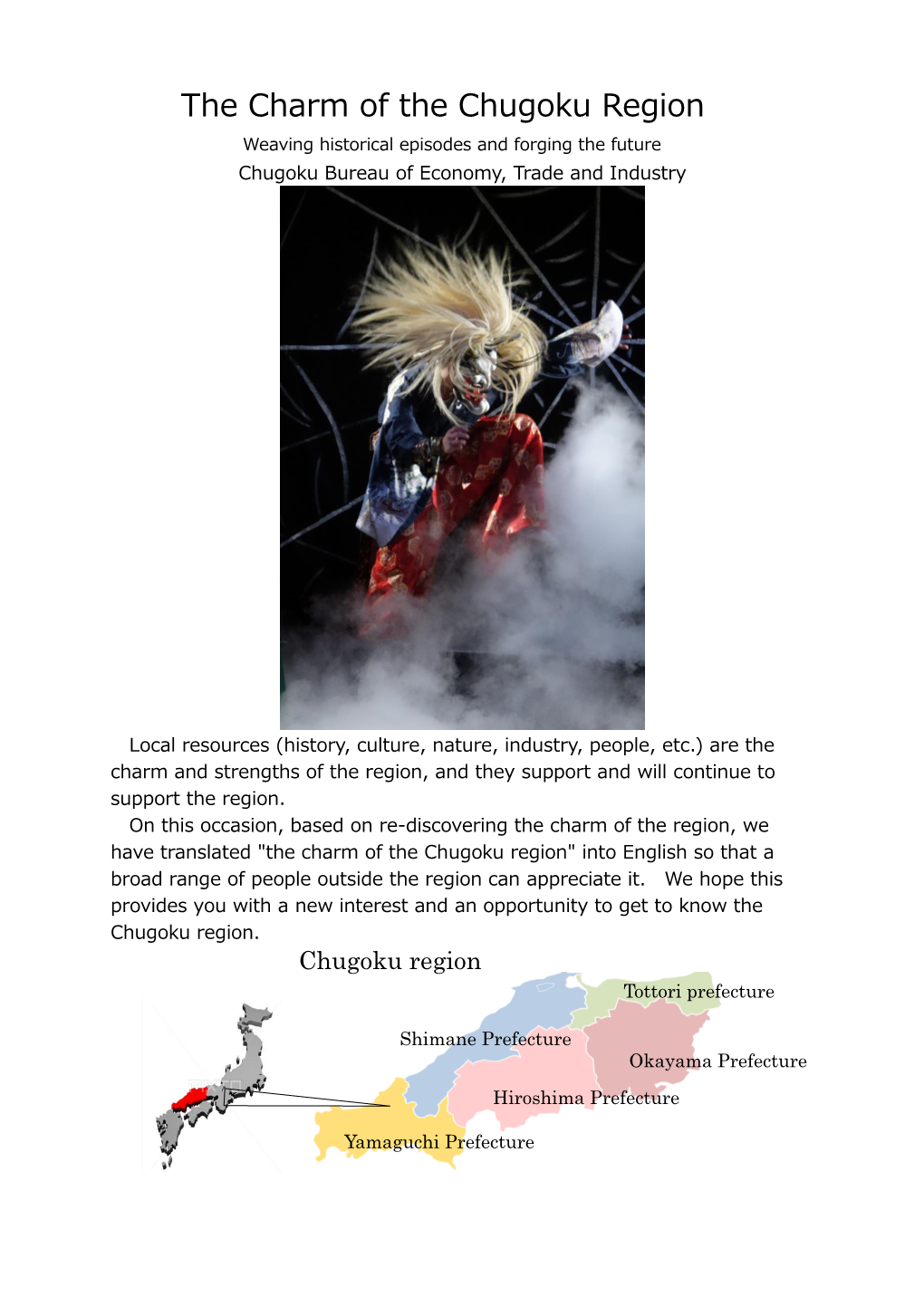

The Charm of the Chugoku Region Weaving Historical Episodes and Forging the Future Chugoku Bureau of Economy, Trade and Industry

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

615. Miyazaki Fumiko and Duncan Williams

Japanese Journal of Religious Studies 2001 28/3–4 The Intersection of the Local and the Translocal at a Sacred Site The Case of Osorezan in Tokugawa Japan MIYAZAKI Fumiko and Duncan WILLIAMS Osorezan is often portrayed today as a remote place in the Shimokita Peninsula, a borderland between this world and the other world, where female mediums called itako communicate with the dead. This article is an attempt to sketch the historical development of Osorezan with evidence from local archives, travel records, temple collections, and inscriptions from stone monuments. With newly available local historical data, despite what temple pamphlets claim, we will establish that the cult of Jizõ (and the death-associated rituals associated with the bodhisattva) was a late Tokugawa-period development and that the female mediums who have made the site so famous only began their communications with the dead at the mountain in the twentieth century. Indeed, what the historical evi- dence suggests is that Osorezan was a complex site that developed late for a major pilgrimage destination, in which the other-worldly concern with the dead (through the worship of Jizõ) was only one aspect of the Osorezan cult. Major patrons of Osorezan in the Tokugawa period prayed for the success of their commercial enterprises there and local people viewed the site primarily as a place of hot spring cures. This article will examine the his- tory of Osorezan from its emergence as a local religious site during the mid- seventeenth until the end of the Tokugawa period, when it became a pilgrimage destination known throughout Japan. -

Local Dishes Loved by the Nation

Sapporo 1 Hakodate 2 Japan 5 3 Niigata 6 4 Kanazawa 15 7 Sendai Kyoto 17 16 Kobe 10 9 18 20 31 11 8 ocal dishes Hiroshima 32 21 33 28 26 19 13 Fukuoka 34 25 12 35 23 22 14 40 37 27 24 29 Tokyo loved by 41 38 36 Nagoya 42 44 39 30 Shizuoka Yokohama 43 45 Osaka Nagasaki 46 Kochi the nation Kumamoto ■ Hokkaido ■ Tohoku Kagoshima L ■ Kanto ■ Chubu ■ Kansai 47 ■ Chugoku ■ Shikoku Naha ■ Kyushu ■ Okinawa 1 Hokkaido 17 Ishikawa Prefecture 33 Okayama Prefecture 2 Aomori Prefecture 18 Fukui Prefecture 34 Hiroshima Prefecture 3 Iwate Prefecture 19 Yamanashi Prefecture 35 Yamaguchi Prefecture 4 Miyagi Prefecture 20 Nagano Prefecture 36 Tokushima Prefecture 5 Akita Prefecture 21 Gifu Prefecture 37 Kagawa Prefecture 6 Yamagata Prefecture 22 Shizuoka Prefecture 38 Ehime Prefecture 7 Fukushima Prefecture 23 Aichi Prefecture 39 Kochi Prefecture 8 Ibaraki Prefecture 24 Mie Prefecture 40 Fukuoka Prefecture 9 Tochigi Prefecture 25 Shiga Prefecture 41 Saga Prefecture 10 Gunma Prefecture 26 Kyoto Prefecture 42 Nagasaki Prefecture 11 Saitama Prefecture 27 Osaka Prefecture 43 Kumamoto Prefecture 12 Chiba Prefecture 28 Hyogo Prefecture 44 Oita Prefecture 13 Tokyo 29 Nara Prefecture 45 Miyazaki Prefecture 14 Kanagawa Prefecture 30 Wakayama Prefecture 46 Kagoshima Prefecture 15 Niigata Prefecture 31 Tottori Prefecture 47 Okinawa Prefecture 16 Toyama Prefecture 32 Shimane Prefecture Local dishes loved by the nation Hokkaido Map No.1 Northern delights Iwate Map No.3 Cool noodles Hokkaido Rice bowl with Tohoku Uni-ikura-don sea urchin and Morioka Reimen Chilled noodles -

Chugoku・Shikoku Japan

in CHUGOKU・SHIKOKU JAPAN A map introducing facilities related to food and agriculture in the Chugoku-Shikoku Tottori Shimane Eat Okayama Hiroshima Yamaguchi Stay Kagawa Tokushima Ehime Kochi Experience Rice cake making Sightseeing Rice -planting 疏水のある風景写真コンテスト2010 Soba making 入選作品 題名「春うらら」 第13回しまねの農村景観フォトコンテスト入賞作品 第19回しまねの農村景観フォトコンテスト入賞作品 Chugoku-shikoku Regional Agricultural Administration Office Oki 26 【Chugoku Region】 7 13 9 8 Tottori sand dunes 5 3 1 Bullet train 14 2 25 4 16 17 11 Tottori Railway 36 15 12 6 Izumo Taisha 41 Matsue Tottori Pref. Shrine 18 Kurayoshi Expressway 37 10 Shimane Pref. 47 24 45 27 31 22 42 43 35 19 55 28 Iwami Silver Mine 48 38 50 44 29 33 34 32 30 Okayama Pref. 39 23 20 54 53 46 40 49 57 Okayama 21 Okayama 52 51 Kurashiki Korakuen 59 Hiroshima Pref. 60 64 79 75 76 80 62 Hiroshima Fukuyama Hagi 61 58 67 56 Atom Bomb Dome Great Seto Bridge 74 Yamaguchi Pref.Yamaguchi Kagawa Pref. 77 63 Miyajima Kintaikyo 68 69 Bridge Tokushima Pref. Shimonoseki 66 65 72 73 Ehime Pref. 70 71 78 Tottori Prefecture No. Facility Item Operating hours Address Phone number・URL Supported (operation period) Access language Tourism farms 1206Yuyama,Fukube-cho,Tottori city Phone :0857-75-2175 Mikaen Pear picking No holiday during 1 English 味果園 (Aug.1- early Nov.) the period. 20 min by taxi from JR Tottori Station on the Sanin http://www.mikaen.jp/ main line 1074-1Hara,Yurihama Town,Tohaku-gun Phone :0858-34-2064 KOBAYASHI FARM Strawberry picking 8:00~ 2 English 小林農園 (early Mar.- late Jun.) Irregular holidays. -

Local Cuisine Around Japan: Vol. 4 Hokkaido Genghis Khan from Hokkaido

Japan Local Government Centre (CLAIR, Sydney) This issue includes: 1 Local Cuisine around Japan 4 Vice Governor of Okayama visited Sydney 2 CLAIR Forum 2017 4 Article from Toowoomba: 2 The Kyushu Big Four at Matsuri Japan Festival Toowoomba Takatsuki Celebrating 25 years 3 Japan-Australia Tourism Seminar by JNTO 5 JETAA International Meeting in Tokyo 3 CLAIR Forum Magazine Interviews 7 From the Director Local Cuisine around Japan: Vol. 4 Hokkaido Genghis Khan from Hokkaido An island on its own, Hokkaido takes up nearly a quarter of the entire country. With its vast land and nature, Hokkaido is known to many tourists as a treasure trove of food, including seafood, agriculture, dairy products, wine, and sake. Of all the edible wonders this prefecture offers, there is one unique item that is not only popular among tourists, but is also a staple for locals: Genghis Khan. Genghis Khan is a lamb/mutton barbeque that uses uniquely-shaped skillets. One of the most common skillet shapes is that of a soldier’s helmet. The meat is grilled in the centre of the skillet, which rises in the middle like a mountain, and fresh local vegetables—common choices are bean sprouts, cabbage, onions, and pumpkin slices—are steamed on the rims with the juice that flows from the meat on top. Genghis Khan is often prepared in a cook-your-own style: diners grill the meat and vegetables by themselves, whether they are at home or in a restaurant. This makes Genghis Khan a great social opportunity as well, and even locals often go out to enjoy grilling up some Genghis Khan with glasses of local beer in hand. -

Provenance of Kiseru in an Ainu Burial at the Iruekashi Site, Hokkaido

Cultural contact and trade between the Ainu and Japanese prior to 1667: Provenance of kiseru in an Ainu burial at the Iruekashi site, Hokkaido FU K ASAWA Yuriko1 ABSTRACT Focusing on the production and circulation of kiseru (Japanese smoking devices), the aim of this paper is to discuss cultural contact and trade between the Ainu and Japanese in the 17th century. The archaeological discovery of several examples of kiseru, at the Iruekashi site including an Ainu burial that predates 1667, implies that these artefacts were diffused to Ainu by as early as the first half of the 17th century. Furthermore, results of a comparative chronological study on the morphological characteristics of artefacts suggest that they most likely originated from Kyoto. Ethnographic and historical sources have elucidated a long history of the production of such handicrafts in Kyoto, where metal materials were manufactured at specialized workshops concentrated in a specific area. Data from historical documents and archaeological excavations have also revealed how processes of technological production have changed over time. Finally, the results of this study indicate that a marine trade route connecting western Japan and Hokkaido along the cost of the Japan Sea was already in use by the middle of the 17th Century, before the establishment of the Kitamaebune trade route to the North. KEYWORDS: kiseru, smoking device, Ainu, Iruekashi site, Kyoto handicrafts, 1667 Introduction All over the world, the presence of devices for smoking including kiseru, European and clay pipes are significant in an archaeological context in order to understand cultural contact, trade, and the diffusion of cultural commodities. -

KAKEHASHI Project (Canada) Inbound Program for Young Leaders Program Report

KAKEHASHI Project (Canada) Inbound program for Young Leaders Program Report 1. Program Overview Under the “KAKEHASHI Project” of Japan’s Friendship Ties Program, 9 participants from Canada visited Japan from November 17 to November 24, 2019 to participate in the program aimed at promoting their understanding of Japan with regard to Japanese politics, economy, society, culture, history, and foreign policy. Through the lectures, observations and interactions with Japanese people etc., the participants enjoyed a wide range of opportunities to improve their understanding of Japan. 【Participating Countries and Numbers of Participants】 Canada: 9 participants 【Prefectures Visited】 Tokyo, Hiroshima 2. Program Schedule 11/17(Sun) 【Arrival】 11/18(Mon) 【Orientation】 【Observation】Meiji Jingu Shrine 【Lecture】The North American Affairs Bureau, Ministry of Foreign Affairs 【Observation】Kabukiza Gallery, Ginza 11/19(Tue) 【Observation】Fujitsu netCommunity 【Observation】The National Diet Building 11/20(Wed) 【Observation】Senso-ji Temple, Nakamise 【Cultural Experience】Tea Ceremony (Chadogu Kaki Kakinuma) 【Opinion Exchange】Keidanren (Japan Business Federation) Committee on Canada Move to Hiroshima from Tokyo 11/21(Thu) 【Courtesy Call】Hiroshima Prefecture 【Opinion Exchange】The Hiroshima Chamber of Commerce and Industry 【Observation】Chugoku Jozo Co., Ltd. 【Observation】Hiroshima Yokagura (sacred music and dance) 11/22(Fri) 【Observation】Mazda Museum 【Observation】Miyajima, Itsukushima Shrine 1 11/23(Sat) 【Observation】Hiroshima Peace Memorial Park, Hiroshima Peace Memorial Museum, Testimony of Atomic Bomb survivor Move to Tokyo from Hiroshima 11/24 (Sun) 【Individual observation】 【Departure】 3. Program Photos 11/18 【Lecture】The North American Affairs 11/19【Observation】 Bureau, Ministry of Foreign Affairs The National Diet Building 11/20【Cultural Experience】Tea 11/21【Courtesy Call】Hiroshima Ceremony (Chadogu Kaki Kakinuma) Prefecture 11/21【Observation】 11/23【Lecture】 Chugoku Jozo Co., Ltd. -

Deepwater Archaeology Off Tobishima Island of Northern Japan

Deepwater Archaeology off Tobishima Island of Northern Japan Hayato Kondo1 and Akifumi Iwabuchi2 Abstract Tobishima island on the Japan sea, belonging to Yamagata prefecture, lies about 40 kilometres to the northwest of mainland Japan. Although the island itself is relatively small, it has been on seaborne trading routes since ancient times. Trawl fishermen occasionally find earthenware pots of the 8th century by accident around the seabed. From the late 17th to the 19th centuries Tobishima island was an important islet of call for Kitamaebune, which were wooden cargo ships trading along the northern coast of Japan. According to local legends, the southeastern waters just in front of the main port is a kind of ships’ graveyard hallowed by sacred memories. Contrariwise, no reliable historical record on maritime disasters or shipwrecks exists. In February 2011 Tokyo University of Marine Science & Technology (TUMSAT) and the Asian Research Institute of Underwater Archaeology (ARIUA) conducted the preliminary submerged survey around these waters, utilising a multibeam sonar system and a Remotely Operated Vehicle (ROV). The research team succeeded in recording fine-resolution bathymetries and video images of a few shipwrecks lying between 60 and 85 metres. One looks modern, but one seems to be potentially older. For the next step, an Autonomous Underwater Vehicle (AUV), which has been designed and developed by TUMSAT, is planned to be employed for the visual mappings. The AUV is able to hover for observation by approaching very close to specified objects, and is equipped with high definition cameras. Two-dimensional and three-dimensional photo mosaics will be obtained, while accurate bathymetry data shall be recorded using sonar and an optical ranging system mounted on the vehicle in order to creat fully-covered and detailed site plans. -

Molluscan Fauna of The“ Miocene” Namigata Formation in the Namigata Area, Okayama Prefecture, Southwest Japan

Jour. Geol. Soc. Japan, Vol. 119, No. 4, p. 249–266, April 2013 JOI: DN/JST.JSTAGE/geosoc/2012.0048 doi: 10.5575/geosoc.2012.0048 Molluscan fauna of the“ Miocene” Namigata Formation in the Namigata area, Okayama Prefecture, southwest Japan Abstract Takashi Matsubara The molluscan fauna of the Namigata Formation, traditionally ac- cepted to be of Miocene age, are reexamined taxonomically, and the Received 27 February, 2012 geologic age of the formation and its paleogeographic implications Accepted 12 June, 2012 are discussed. The formation is subdivided into the main part and two new members (the Senjuin Shell-Sandstone and Ônishi Con- Division of Natural History, Museum of Na- glomerate members). The Namigata Formation yielded 13 species of ture and Human Activities Hyogo, 6 Yayoiga- Gastropoda, 16 species of Bivalvia and 1 species of Scaphopoda. The oka, Sanda 669-1546, Japan occurrences of Molopophorus watanabei Otuka, Acila (Truncacila) nagaoi Oyama and Mizuno, Chlamys (Nomurachlamys?) namiga- Corresponding author: T. Matsubara, [email protected] taensis (Ozaki), and Isognomon (Hippochaeta) hataii Noda and Fu- ruichi indicate that the molluscan age should be revised to the late Late Eocene–Early Oligocene. Taking account of the latest elasmo- branch data and preliminary strontium isotope ratio, the age of the formation is confined to the late Late Eocene. The present and recent results show that the First Seto Inland Sea was actually composed of two sea areas that existed at different times: the Paleogene sea area is estimated to have been an open sea facing south to the Pacific Ocean, whereas that in the Miocene is thought to have been an em- bayment connected to the northwest to the Sea of Japan. -

What Is Dewa Sanzan? the Spiritual Awe-Inspiring Mountains in the Tohoku Area, Embracing Peopleʼs Prayers… from the Heian Period, Mt.Gassan, Mt.Yudono and Mt

The ancient road of Dewa Rokujurigoegoe Kaido Visit the 1200 year old ancient route! Sea of Japan Yamagata Prefecture Tsuruoka City Rokujurigoe Kaido Nishikawa Town Asahi Tourism Bureau 60-ri Goe Kaido Tsuruoka City, Yamagata Prefecture The Ancient Road “Rokujuri-goe Kaido” Over 1200 years, this road has preserved traces of historical events “Rokujuri-goe Kaido,” an ancient road connecting the Shonai plain and the inland area is said to have opened about 1200 years ago. This road was the only road between Shonai and the inland area. It was a precipitous mountain road from Tsuruoka city to Yamagata city passing over Matsune, Juo-toge, Oami, Sainokami-toge, Tamugimata and Oguki-toge, then going through Shizu, Hondoji and Sagae. It is said to have existed already in ancient times, but it is not clear when this road was opened. The oldest theory says that this road was opened as a governmental road connecting the Dewa Kokufu government which was located in Fujishima town (now Tsuruoka city) and the county offices of the Mogami and Okitama areas. But there are many other theories as well. In the Muromachi and Edo periods, which were a time of prosperity for mountain worship, it became a lively road with pilgrims not only from the local area,but also from the Tohoku Part of a list of famous places in Shonai second district during the latter half of the Edo period. and Kanto areas heading to Mt. Yudono as “Oyama mairi” (mountain pilgrimage) custom was (Stored at the Native district museum of Tsuruoka city) booming. -

May 31St Message from the Governor to All Citizens of Shimane

May 31st Message from the Governor To all citizens of Shimane Prefecture, On May 28th, the length of the state of emergency was changed, as well as the length of “priority measures to prevent the spread of infections.” In addition, the basic policy for dealing with COVID-19 has changed. Therefore, I request the following to all citizens. For travel to and from Gunma Prefecture, Ishikawa Prefecture, and Kumamoto Prefecture, these requests shall be applicable until June 13th 2021. For other regions, these requests shall be applicable until June 20th 2021. (Regarding Travel Between Prefectures) 1. Please refrain from travel between Shimane Prefecture and areas under a state of emergency—namely, Hokkaido, Tokyo Metropolitan Area, Aichi Prefecture, Kyoto Prefecture, Osaka Prefecture, Hyogo Prefecture, Okayama Prefecture, Hiroshima Prefecture, Fukuoka Prefecture, and Okinawa Prefecture. Please refrain from travel between Shimane Prefecture and “areas under priority measures to prevent the spread of infections”—namely, Gunma Prefecture, Saitama Prefecture, Chiba Prefecture, Kanagawa Prefecture, Ishikawa Prefecture, Gifu Prefecture, Mie Prefecture, and Kumamoto Prefecture. In addition, there are areas where the prefectural governments are requesting that citizens refrain from non-essential, non-urgent outdoor travel as well non-essential, non-urgent travel across prefectural borders—namely, Fukushima Prefecture, Tochigi Prefecture, Toyama Prefecture, Fukui Prefecture, Shizuoka Prefecture, Wakayama Prefecture, Yamaguchi Prefecture, Kagawa Prefecture, Ehime Prefecture, Saga Prefecture, Nagasaki Prefecture, Oita Prefecture, Miyazaki Prefecture, Kagoshima Prefecture, etc. Please carefully reconsider travel plans to these areas. In particular, please refrain from travel if you have symptoms such as a fever. Except if you have symptoms such as a fever, you do not need to refrain from travel if the purpose includes work, job relocation, job hunting, funerals, nursing care, etc. -

Hiroshima Port Tourist Information

Hiroshima Port Tourist Information http://www.mlit.go.jp/kankocho/cruise/ Oysters・Oyster Hut Hiroshima is known throughout Japan for its large and flavorful oysters. Whether you prefer them grilled, fried, boiled or raw, we are certain to have the dish for you. An Oyster Hut offers visitors the casual experience of trying oysters from Hiroshima as a limited time offer, in an atmosphere unique to the Seto Inland Sea area. 1-chome Ujinakaigan, Hiroshima Minami-ku, Location/View Hiroshima ,734-0011 Access 20 min. walk from port(1.5km) Season WinterLate October - Late March Oysters(Explore Hiroshima ) https://www.hiroshima-navi.or.jp/en/gourmet/cooking/oyster Related links .html Contact Us【Hiroshima Prefecture Tourism Federation】 E-MAIL [email protected] l Website :http://visithiroshima.net/ Hiroshima-style Okonomiyaki Okonomiyaki is Soul food in Hiroshima. It has its roots in a pre-war children’s snack of a water-flour mixture grilled on an iron hot plate with toppings including spring onion. After the war this snack was treasured as a staple food when rice could not be obtained. As recovery progressed, cabbage, noodles, eggs and other ingredients were added to make the current style of Okonomiyaki. There are more than 900 Okonomiyaki restaurants in the Hiroshima city. Location/View Access Season Year-round Hiroshima-style Okonomiyaki(Explore Hiroshima) https://www.hiroshima-navi.or.jp/en/gourmet/cooking/okonomiyaki.html Related links Try Hiroshima soul food "Okonomiyaki"!(The Official HIROSHIMA Prefecture Tourism Site VISIT HIROSHIMA) http://visithiroshima.net/plan_your_trip/tour_plans/okonomiyaki.html Contact Us【Hiroshima Prefecture Tourism Federation】 E-MAIL [email protected] l Website :http://visithiroshima.net/ Grilled eel on rice Charcoal grilled eel seasoned with soy sauce and mirin served on boiled rice.The aroma that rises from the cooking eel is mouthwatering. -

Okayama University(Okayama Prefecture)

Okayama University (Okayama Prefecture) This program aims at deepening your comprehension of Japanese language, culture, economy, law, and education. The program offers the following classes; (1)Japanese language classes with various levels and topics, (2) Special courses on Japanese culture, economy, law, and education, (3)Courses at the Faculties of Letters, Law, Economics and Education Characteristics of Okayama Prefecture Number of Students to be Accepted: 5 ■University Overview (4 recommended by Embassy and Okayama Prefecture is in the Chugoku region, which is Characteristics and Overview of Okayama 1 recommended by University) located in the western part of the Japanese Islands, and faces University the Seto Inland Sea. The Mizushima Industrial District and Qualifications and Requirements: 1) Characteristics and History manufacturing industry are prosperous. It is also famous for Candidates are expected to have Japanese Okayama University was founded in 1949 on farm products and marine products. Okayama city, where language ability equivalent to the N2 Level or the basis of its predecessors Okayama Okayama University is located, is the capital of Okayama above of the Japanese Proficiency Test (6,000 Medical College and Sixth High School, which Prefecture and one of major political, economic, commercial, words, 1,000 kanji) . were founded in 1922 and 1900 respectively. educational and cultural centers of the Chugoku region. Now, it has 11 faculties and 7 graduate Okayama city's population is approximately 720,000. Purpose of the Course: schools and is one of the biggest national It is a convenient key city in the transportation network. By The aims of the courses are to aid students in universities in Japan.