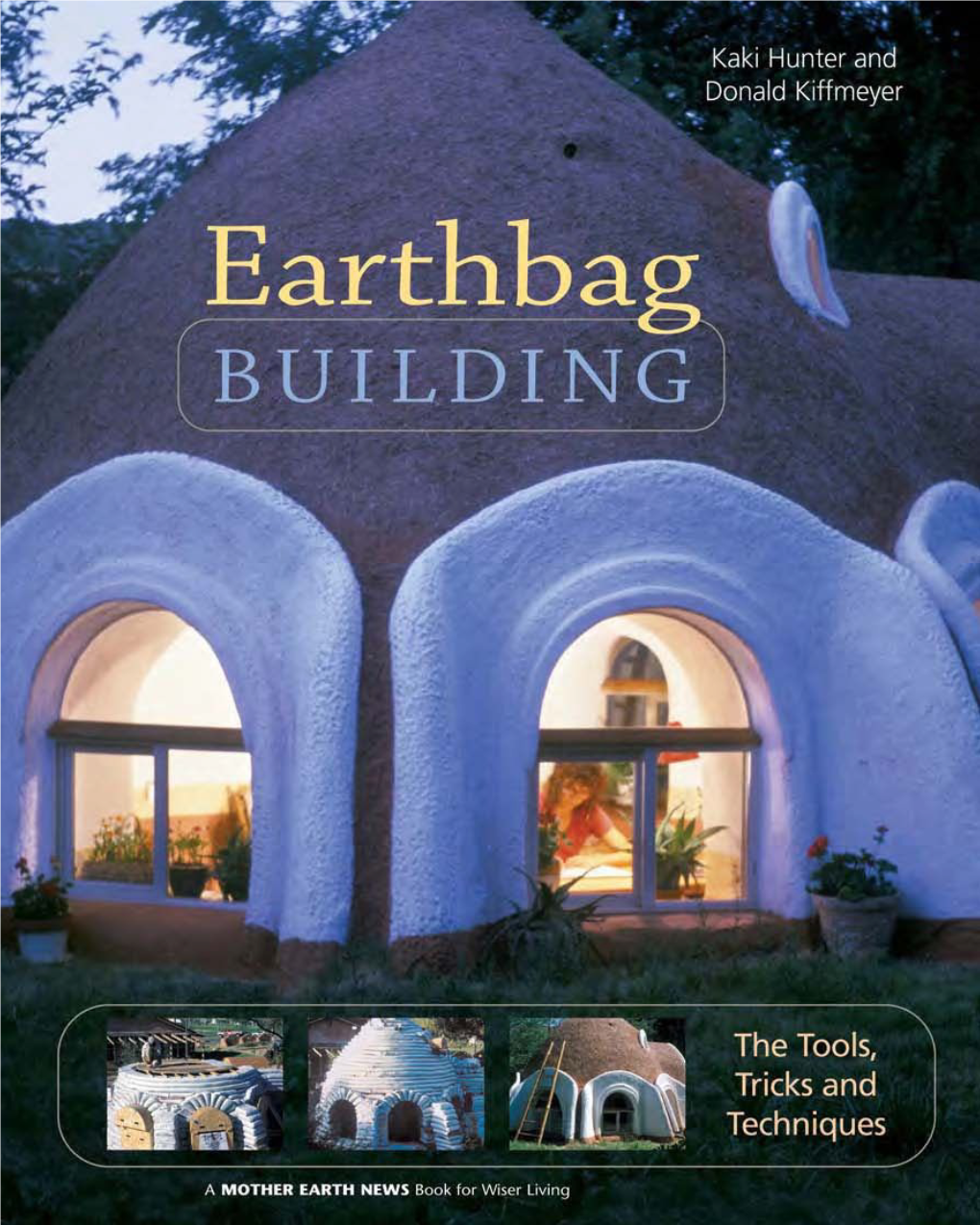

Earthbag Building the Tools,Tricks and Techniques

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Earthbag Technology - Simple, Safe and Sustainable

EARTHBAG TECHNOLOGY - SIMPLE, SAFE AND SUSTAINABLE Dr. Owen GEIGER1, Kateryna ZEMSKOVA2 1 Director of the Geiger Research Institute of Sustainable Building, USA Nepal Engineer's Association [email protected] Earthbag Technology - Simple, Safe and Sustainable 2 Co-Founder and President of Good Earth Nepal, a New York based non-profit organization, USA [email protected] Dr. Owen GEIGER Kateryna ZEMSKOVA Director of the Geiger Research Institute of Sustainable Co-Founder and President of Good Earth Nepal, Building, USA a New York based non-profit organization, USA [email protected] [email protected] ABSTRACT Earthbag technology is an inexpensive, simple and sustainable method for building structures. Having evolved from military bunker construction and flood control methods, Earthbag buildings are notable for their ability to endure fire, flood, wind, earthquake and vermin, and are used in disaster-prone zones all over the world. In Nepal, all 55 Earthbag buildings survived a 7.8 magnitude earthquake with no structural damage. Because Earthbag technology makes minimal use of cement, concrete, steel and timber, and the fuel needed to transport them. This technique is easy on the environment, and doesn’t deplete scarce natural resources. Earthbag technology also requires less expertise than other traditional building methods, and only the simplest of tools. I. INTRODUCTION Earthbag technology is a wall system with structures composed primarily of ordinary soil found at the construction site. The soil is stuffed inside polypropylene bags, which are then staggered like masonry and solidly tamped. Barbed wire is used between the layers of bags and serves as mortar. For seismically active zones reinforcements like buttresses, vertical rebars and bond beams are recommended. -

Initial Evidence of Plant and Animal-Origin Organic Additives from the Second-Century Bce Earthen Plaster of Rock-Cut Caves of Karla, India**

bs_bs_banner Archaeometry ••, •• (2019) ••–•• doi: 10.1111/arcm.12522 INITIAL EVIDENCE OF PLANT AND ANIMAL-ORIGIN ORGANIC ADDITIVES FROM THE SECOND-CENTURY BCE EARTHEN PLASTER OF ROCK-CUT CAVES OF KARLA, INDIA** B. DIGHE and M. R. SINGH† Department of Conservation, National Museum Institute, Janpath, Delhi, 110011, India Analytical investigations through phytochemical screening, scanning electron microscope (SEM) and light microscopic observation of the earthen plaster of Karla Caves of western India identified the presence of antifungal, antibacterial and insect repellent Careya arborea stem fibres as a vegetal additive. The scanning electron microscopy with energy-dispersive X-ray spectrometry (SEM-EDX) study also revealed the inclusion of rice (Oryza sativa) husk as a plant additive in the plaster. In the high rain-fed coastal regions of western India, the an- timicrobial, antioxidant and termite-resistance properties of C. arborea helped the survival of the plaster in unfavourable climatic conditions. Besides, the C. arborea and rice husk together played a role in reducing cracks, decreasing the density, and imparting a plasticity and a du- rability to the plaster. The liquid Fourier-transform infrared spectrometer (FTIR) of organic extracts revealed carboxylic acid (fatty acids)-based additives in the earthen plaster. From the gas chromatography-mass spectrometry (GC-MS) analysis of the plaster, the presence of animal milk fat, animal and vegetable fat, and vegetable oil was identified, and probably used to strengthen the earthen plaster for their resistance to tensile stress. The analysis also diag- noses the inclusion of methyl commate B, a resinous material obtained from the Burseraceae plant family, which has antimicrobial properties, through GC-MS analysis. -

Plastic Limit Analysis of Earthbag Structures

Plastic Limit Analysis of Earthbag Structures Student: Ralph Pelly Supervisor: Dr Andrew Heath Department of Architecture and Civil Engineering The University of Bath 2009 AR40223 MEng dissertation 1 Abstract In this paper, a detailed experimental analysis is carried out of the strength and structural performance of earthbag construction. An attempt at modelling the behaviour of earthbag arches using masonry arch plastic limit analysis is made, and conclusions drawn regarding its applicability to this method of construction. The relatively short history of earthbag construction is reviewed, and particular reference made to a planned earthbag dome project in the Namib Desert, Namibia. Constituent materials of polypropylene bags and sandy fill material are used to match expected conditions on this project, and material properties are defined in a series of tests. The compression strength, stiffness and friction coefficient of the earthbags are determined and used in further analysis on the structural system. Earthbag arches are tested, and it is shown that earthbag structures undergo large plastic deformations before ultimate collapse, and that properties can be improved significantly through the stabilisation of fill material. It is concluded that plastic limit analysis is appropriate only where stabilised fill material is employed. 2 Acknowledgements I would like to give my sincerest thanks and appreciation for all the support and advice I have received from so many people, not just in writing this paper but in studying for my degree over the last four years. It would not have been possible without them: Will Bazeley, Neil Price, Brian Purnell and Sophie Hayward, for their tireless and enduringly positive support through the entire experimental programme. -

Earthbag Housing: Structural Behaviour and Applicability in Developing Countries

EARTHBAG HOUSING: STRUCTURAL BEHAVIOUR AND APPLICABILITY IN DEVELOPING COUNTRIES by Bryce Callaghan Daigle A thesis submitted to the Department of Civil Engineering In conformity with the requirements for the degree of Master of Science in Engineering Queen’s University Kingston, Ontario, Canada September, 2008 Copyright © Bryce Callaghan Daigle, 2008 Abstract Global awareness of environmental issues such as climate change and resource depletion has grown dramatically in recent years. As a result, there has been a surge of interest in developing alternative building techniques and materials which are capable of meeting our structural needs with lower energy and material consumption. These technologies are particularly attractive for housing. Much of the global demand for housing is currently being driven by economic growth in developing countries. Additionally, natural disasters such as the 2004 Indian Ocean tsunami have destroyed houses in many countries where limited economic wealth makes reconstruction a challenge. This has resulted in shortages of permanent housing in these areas. This thesis explores the structural behaviour of earthbag housing under vertical compressive loading, in an attempt to broaden our quantitative understanding of this alternative building technique. Furthermore, this technique is assessed, along with other alternative construction techniques, for suitability in southern Sri Lanka, an area heavily damaged by the 2004 Indian Ocean tsunami. It was determined that the compressive strength of unplastered earthbag housing specimens meets or exceeds the vertical compressive strength of conventional stud-frame housing technology using a variety of fill materials, with the greatest strength being observed for soil- filled bags. Furthermore, the results of observational research from a site visit to Sri Lanka in 2006, combined with resource availability data and interviews with Sri Lankan citizens, suggest that earthbag housing is a very promising technique for housing construction in the southern coastal region. -

Analysis of Structural Components During Cyclical Loading of Steel Reinforced Earthbag Construction Noah Strong Santa Clara University

Santa Clara University Scholar Commons Civil Engineering Senior Theses Engineering Senior Theses Spring 2018 Analysis of Structural Components During Cyclical Loading of Steel Reinforced Earthbag Construction Noah Strong Santa Clara University Emil Huebner Santa Clara University Ethan Jensen Santa Clara University Follow this and additional works at: https://scholarcommons.scu.edu/ceng_senior Part of the Civil and Environmental Engineering Commons Recommended Citation Strong, Noah; Huebner, Emil; and Jensen, Ethan, "Analysis of Structural Components During Cyclical Loading of Steel Reinforced Earthbag Construction" (2018). Civil Engineering Senior Theses. 63. https://scholarcommons.scu.edu/ceng_senior/63 This Thesis is brought to you for free and open access by the Engineering Senior Theses at Scholar Commons. It has been accepted for inclusion in Civil Engineering Senior Theses by an authorized administrator of Scholar Commons. For more information, please contact [email protected]. 12 S H 613.2018 ANALYSIS OF STRUCTURAL COMPONENTS DURING CYCLICAL LOADING OF STEEL REINFORCED EARTHBAG CONSTRUCTION by Noah Strong Emil Huebner Ethan Jensen SENIOR DESIGN PROJECT REPORT Submitted to the Department of Civil Engineering of SANTA CLARA UNIVERSITY in partial fulfillment of the requirements for the degree of Bachelor of Science in Civil Engineering Santa Clara, California Spring 2018 ii ACKNOWLEDGEMENTS We would like to thank our Faculty Advisors, Dr. Tonya Nilsson and Dr. Mark Aschheim. Dr. Nilsson has guided, motivated, and assisted this design project the entire school year. Dr. Nilsson is an expert in alternative building methods and alternative building materials. Dr. Mark Aschheim designed and built the Three Degree-of-Freedom Test Frame and was vital in the testing success and data analysis. -

Analysis of the Thermal Behavior of an Earthbag Building in Mediterranean Continental Climate: Monitoring and Simulation

energies Article Analysis of the Thermal Behavior of an Earthbag Building in Mediterranean Continental Climate: Monitoring and Simulation Lídia Rincón, Ariadna Carrobé, Marc Medrano * , Cristian Solé, Albert Castell and Ingrid Martorell y SEMB Research Group, INSPIRES Research Centre, Universitat de Lleida, Pere de Cabrera s/n, 25001 Lleida, Spain; [email protected] (L.R.); [email protected] (A.C.); [email protected] (C.S.); [email protected] (A.C.); [email protected] (I.M.) * Correspondence: [email protected] Serra Húnter Fellow, Generalitat de Catalunya. y Received: 7 November 2019; Accepted: 24 December 2019; Published: 30 December 2019 Abstract: Nearly 30% of humanity lives in earthen dwellings. Earthbag is a sustainable, cheap, feasible and comfortable option for emergency housing. A comparative monitoring-simulation analysis of the hygrothermal behavior of an Earthbag dwelling in Mediterranean continental climate, designed under bioclimatic criteria, is presented. The dome shape Earthbag dwelling has a net floor area of 7.07 m2, a glass door facing south and two confronted windows in the east and west facades. A numerical model (EnergyPlus v8.8) was designed for comparison. Twenty-four hour cross ventilation, night cross ventilation, and no ventilation in free floating mode and a controlled indoor temperature were the tested scenarios. Comparisons between experimental data and simulation show a good match in temperature behavior for the scenarios studied. Reductions of 90% in summer and 88% in winter, in the interior thermal amplitude with respect to exterior temperatures are found. Position of the glazed openings was fundamental in the direct solar gains, contributing to the increase of temperature in 1.31 ◦C in winter and 1.37 ◦C in the equinox. -

STRAW-BALE AS a VIABLE, COST EFFECTIVE, and SUSTAINABLE BUILDING MATERIAL for USE in SOUTHEAST OHIO a Thesis Presented to the F

STRAW-BALE AS A VIABLE, COST EFFECTIVE, AND SUSTAINABLE BUILDING MATERIAL FOR USE IN SOUTHEAST OHIO A thesis presented to the faculty of the College of Arts and Sciences of Ohio University In partial fulfillment of the requirements for the degree Masters of Science Leanne R. Marks June 2005 This thesis entitled STRAW-BALE AS A VIABLE COST EFFECTIVE AND SUSTAINABLE BUILDING MATERIAL FOR USE IN SOUTHEAST OHIO by LEANNE R. MARKS has been approved for the Program of Environmental Studies and the College of Arts and Sciences by Christopher Boone Associate Professor of Geography Leslie A. Flemming Dean of College of Arts and Sciences Marks, Leanne R. M.S. June 2005. Environmental Studies. Straw-Bale as a Viable, Cost Effective, and Sustainable Building Material for use in Southeast Ohio. (118pp.) Director of Thesis: Christopher Boone In Southeast Ohio, the humidity is relatively high all year round; the maximum monthly average humidity readings exceeded 80% during the ten months of sampling. Precipitation levels, and its’ effect on moisture accumulation within straw-bale walls, had been a concern to individuals skeptical about the use of straw-bales as a viable building material. Athens County, Ohio, is located within the Appalachian region, a poverty stricken region that desperately requires livable, affordable housing. Throughout this document, it becomes evident that straw-bale construction is in fact, a viable, cost effective and sustainable and safe building method for use in southeast Ohio. Within the study the moisture content of three Athens County straw-bale homes were recorded during a ten-month period (Dec. 2001–Sept. -

David Bowie's Urban Landscapes and Nightscapes

Miranda Revue pluridisciplinaire du monde anglophone / Multidisciplinary peer-reviewed journal on the English- speaking world 17 | 2018 Paysages et héritages de David Bowie David Bowie’s urban landscapes and nightscapes: A reading of the Bowiean text Jean Du Verger Electronic version URL: http://journals.openedition.org/miranda/13401 DOI: 10.4000/miranda.13401 ISSN: 2108-6559 Publisher Université Toulouse - Jean Jaurès Electronic reference Jean Du Verger, “David Bowie’s urban landscapes and nightscapes: A reading of the Bowiean text”, Miranda [Online], 17 | 2018, Online since 20 September 2018, connection on 16 February 2021. URL: http://journals.openedition.org/miranda/13401 ; DOI: https://doi.org/10.4000/miranda.13401 This text was automatically generated on 16 February 2021. Miranda is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License. David Bowie’s urban landscapes and nightscapes: A reading of the Bowiean text 1 David Bowie’s urban landscapes and nightscapes: A reading of the Bowiean text Jean Du Verger “The Word is devided into units which be all in one piece and should be so taken, but the pieces can be had in any order being tied up back and forth, in and out fore and aft like an innaresting sex arrangement. This book spill off the page in all directions, kaleidoscope of vistas, medley of tunes and street noises […]” William Burroughs, The Naked Lunch, 1959. Introduction 1 The urban landscape occupies a specific position in Bowie’s works. His lyrics are fraught with references to “city landscape[s]”5 and urban nightscapes. The metropolis provides not only the object of a diegetic and spectatorial gaze but it also enables the author to further a discourse on his own inner fragmented self as the nexus, lyrics— music—city, offers an extremely rich avenue for investigating and addressing key issues such as alienation, loneliness, nostalgia and death in a postmodern cultural context. -

EARTHEN Natural Clay Plaster Can Also Help Moderate Temperature Swings - Wall Surfaces Remain Cool in Summer and Warm in Winter

NATURAL CLAY PLASTER - Adj. earthen - made of earth Clay as a construction material has been around for thousands of years. We have recognised these age old benefits, combined these with modern manufacturing, application, and colouring techniques to provide some very special qualities to enhance your living environment. Ideally suited for high comfort, modern buildings and historic building refurbishment. EARTHEN is a breathing surface in that it assists in regulating both humidity and temperature by absorbing and releasing vapour. It makes rooms more tolerable in humid weather, and when the weather becomes drier it releases moisture into the room helping to improve the air quality. EARTHEN is a hard, durable surface that can be repaired when damaged, re-surfaced and even completely recycled. If a colour change is required to update an interior you can maintain all the benefits of the EARTHEN plaster by simply painting with EARTHEN clay paint. EARTHEN Natural Clay plaster can also help moderate temperature swings - wall surfaces remain cool in summer and warm in winter. The more clay used in a room the greater the beneficial effects including acoustic. EARTHEN Clay is a natural product available in almost every corner of the earth, contains no VOC’s or cements. It is composed of fine white china clay, silica sands, and natural binders. This is then mixed with water to create a workable material for plastering. EARTHEN FEATURES v A more environmentally friendly choice than traditional gypsum plaster. v A 100% natural, breathable material. v Material naturally absorbs odours. v Mould resistant. v Natural properties are anti allergenic. -

The Scope of Hemp (Cannabis Sativa L.) Use in Historical Conservation in India

Indian Journal of Traditional Knowledge Vol. 17(2), April 2018, pp. 314-321 The scope of hemp (Cannabis sativa L.) use in Historical conservation in India M Singh 1*, Divija Mamania2 & Vasant Shinde3 1National Museum Institute, Janpath, New Delhi-110 011, India; 2IITian’s Pace and Pace Junior Science College, Mumbai-400 028, India; 3Deccan College Post Graduate and Research Institute, Pune-411 006, India E-mail: [email protected] Received 22 September 2017, revised 11 December 2017 Cannabis sativa L. (hemp) has preserved the ancient artwork in India’s sacred Ellora Caves for 1500 years. The long life of earthen plaster of Ellora, despite damaging environmental parameters, may be attributed to the material properties of hemp which is fibrous and durable as studied through stereo and scanning electron microscope. The properties of Cannabis sativa (hemp) including its ability to repel insects and regulate humidity must have been known to the ancient Indian technicians in 6th CE. Moreover, Cannabis has an excellent carbon dioxide sequestering capacity and is green house negative and these properties were exploited by ancient Indians in cave murals of Ellora. The finding could be applied in future construction technology, as well as conservation of historical structures, where more sustainable materials are being sought. However, it would be illegal in places where Cannabis is banned. The numerous useful properties of hemp can also be exploited for several environmental friendly applications. This paper deliberates upon the utilization of this plant from the ancient period to its present use to regulate green house impact. Keywords: Cannabis sativa L., Shiv, Greenhouse, Conservation IPC Int. -

Earthbag Building in the Humid Tropics

1 Earthbag Building in the Humid Tropics Earthbag Building in the Humid Tropics: Simple Structures 2nd edition Patti Stouter June 2011 Online version available at www.EarthbagBuilding.com and at www.Scribd.com/patti_stouter. Please share these free self-help guidelines and let us know how to improve them. 2 Earthbag Building in the Humid Tropics TABLE OF CONTENTS 3 About Earthbag 5 Types of Earthbag 7 ‘Raw’ Earth Versus Cement 11 Exterior Finishes STEP BY STEP: GENERAL PRINCIPLES 14 Soil Tests 15 Materials LAYOUTS FOR NON-HAZARDOUS AREAS 16 Buttress Corners 17 Piers at Corners, Straight Walls 18 Circles, Corrugated Walls, Wall Height & Thickness 19 Window & Door Openings, Window & Door Sizes, Windows without Arches 20 Roof INSTRUCTIONS 20 Placing Bags 22 Base Course, Openings 24 Bond Beam, Roof, Floor 26 Finishes 25 A Note About Working Across Cultures 28 Acknowledgements, About the Author, 29 Bibliography 3 Earthbag Building in the Humid Tropics In many parts of the world buildings must be extra strong for earthquakes or hurricanes and tsunamis. Other publications can help you plan for this.1 West Africa, northeastern South America and some parts of China and India do not have many earthquakes. Check the global seismic hazard assessment program (GSHAP) maps to be sure that your area is not at risk for earthquakes. If you live far enough inland where cyclones are not strong and tsunamis can't reach, these guidelines can help you try a new way of building simple structures with earth. Your buildings must resist termites and mold as well as be right for the climate, and for how people live. -

Natural Finishes Overview

Page 1 Natural Finishes Overview Natural plasters and finishes are a great alternative to the conventional finishing products that are available on the market. The ones that are just riddled with toxic chemicals! Most people don’t even realize the negative effects that these products have on their health. Indoor air pollution and toxic off gassing is a whole subject unto itself. But by using natural plasters and paints, you avoid the added toxicity of cement stucco, drywall, chemical paints, and the destructive industry that produces them all. Natural plasters and finishes can be applied to cob walls or even to drywall board! The majority of natural plasters and finishes are made from a combination of these simple ingredients: Clay, sand, straw, lime, kaolin clay, wheat paste, pigments, and water. Copyright 2015 - This Cob House LLC - All Rights Reserved Page 2 Plastering your cob home is like putting the icing on the cake. Once you have built your walls, built your roof, and installed the windows and doors then you can begin to plaster your building. The plaster will protect your walls from rain on the outside, and it will protect your cob walls from any crumbling off on the inside. A good foundation and a good roof overhang (a good hat and boots, as they say) will protect your cob home from most weather and rain. Some people decide not to plaster the exterior walls of their cob homes and they are fine in many cases, but you will still get deterioration. It is recommended to plaster your walls to protect them from driving rain and frost.