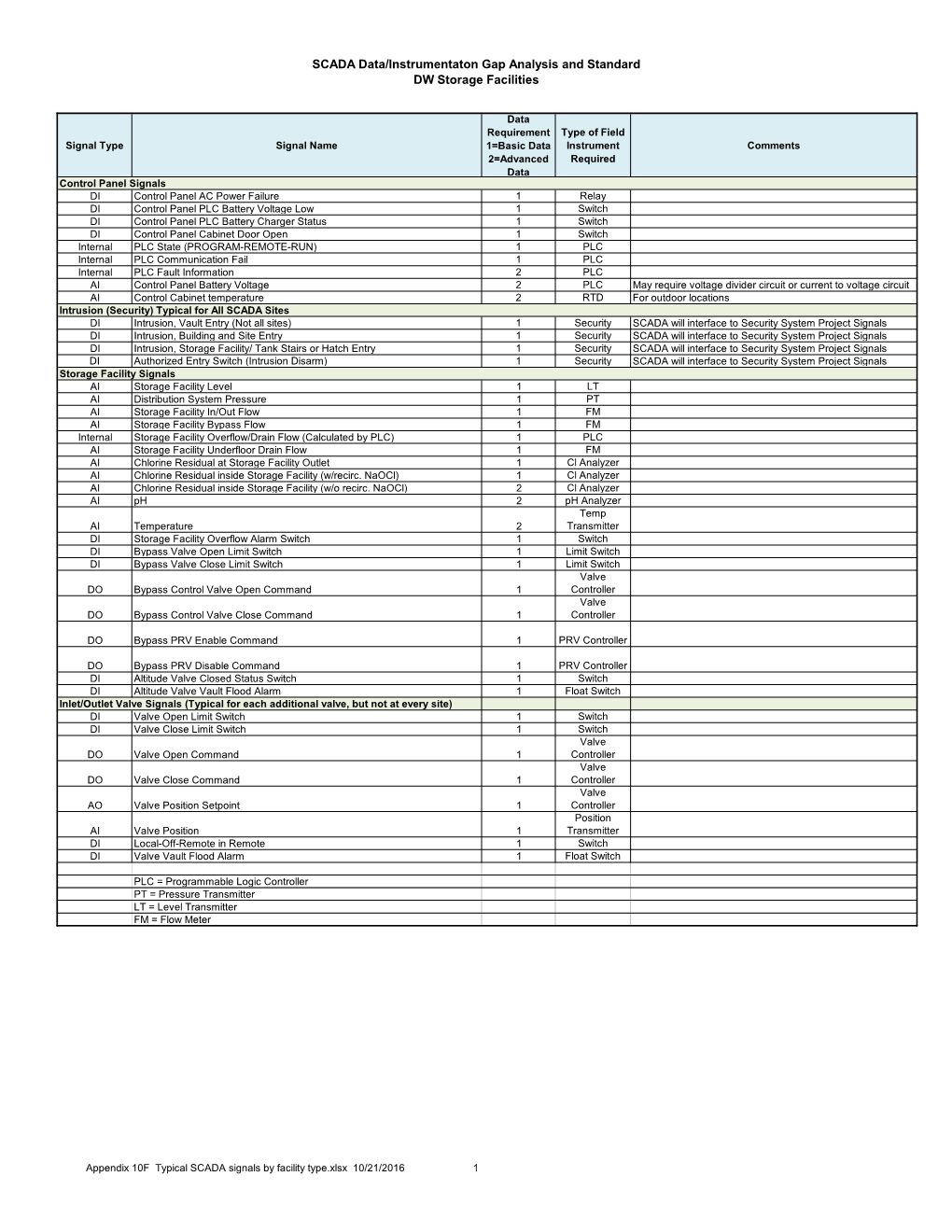

10F- Typical SCADA Signals by Facility Type

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Axis Control Valves PROFIBUS Firmware B99225-DV016-D-211

USER MANUAL FOR AXIS CONTROLVALVES WITH PROFIBUS INTERFACE FIRMWARE B99225-DV016-D-211 Rev. -, October 2015 OFFERING FLEXIBLE INTEGRATION AND ADVANCED MAINTENANCE FEATURES INCLUDING DIAGNOSTICS, MONITORING OF CHARACTERISTICS AND ABILITY TO DEFINE DYNAMIC BEHAVIORS WHAT MOVES YOUR WORLD Copyright © 2015 Moog GmbH Hanns-Klemm-Straße 28 71034 Boeblingen Germany Telephone: +49 7031 622-0 Fax: +49 7031 622-191 E-mail: [email protected] Internet: http://www.moog.com/Industrial All rights reserved. No part of these operating instructions may be reproduced in any form (print, photocopies, microfilm, or by any other means) or edited, duplicated, or distrib- uted with electronic systems without our prior written consent. Offenders will be held liable for the payment of damages. Subject to change without notice. B99225-DV016-D-211, Rev. -, October 2015 A Moog ACV with Profibus DP bus interface Table of contents Table of contents Copyright ................................................................................................................................................... A List of tables............................................................................................................................................ xvii List of figures ............................................................................................................................................xx 1 General information ..................................................................................1 1.1 About this manual ...................................................................................................................... -

Control Valve Handbook

CONTROL VALVE HANDBOOK Fifth Edition Emerson Automation Solutions Flow Controls Marshalltown, Iowa 50158 USA Sorocaba, 18087 Brazil Cernay, 68700 France Dubai, United Arab Emirates Singapore 128461 Singapore Neither Emerson, Emerson Automation Solutions, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance of any product. Responsibility for proper selection, use, and maintenance of any product remains solely with the purchaser and end user. The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are governed by our terms and conditions, which are available upon request. We reserve the right to modify or improve the designs or specifications of such products at any time without notice. Fisher is a mark owned by one of the companies in the Emerson Automation Solutions business unit of Emerson Electric Co. Emerson and the Emerson logo are trademarks and service marks of Emerson Electric Co. All other marks are the property of their respective owners. © 2005, 2019 Fisher Controls International LLC. All rights reserved. D101881X012/ Sept19 Preface Control valves are an increasingly vital component of modern manufacturing around the world. Properly selected and maintained control valves increase efficiency, safety, profitability, and ecology. The Control Valve Handbook has been a primary reference since its first printing in 1965. This fifth edition presents vital information on control valve performance and the latest technologies. Chapter 1 offers an introduction to control valves, including definitions for common control valve and instrumentation terminology. -

Automatic Control Valve Solutions

Types of Automatic Control Valves • Hydraulic • Electronic • Electronic with Hydraulic Back‐Up Line Pressure to Open Line Pressure to Close Flow Direction Control Valve Applications • Pressure Reducing • Pressure Relief/Sustaining • Pump Control • Rate‐of‐Flow Control • Level Control • Cavitation Control • Surge Anticipation • Electronic Control • Metering • Valve‐Based Power Generation Pressure Reducing Valves • Reduces a higher inlet pressure to a constant downstream pressure regardless of demand and supply pressure fluctuations • Enables delivery of water at safe pressures and adequate levels for customer needs • Installations: – Main line feeds – Distribution zones – Fire systems – Irrigation systems Pressure Relief/Pressure Sustaining Valves • Relieves excess pressure while maintaining a minimum upstream pressure • Prevents downstream demand from sacrificing supply of an upstream zone • Installations: – In‐line distribution piping – At booster pump stations 50-01 Pressure Relief Valve Rate of Flow Control Valves • Maintains a maximum flow rate setting downstream regardless of pressure changes • Installations: – Within distribution systems – Filter applications to distribution – Process control applications automatic control valve Example: Electronic Pressure Reducing • Application: Electronic Pressure Reducing/Pressure Sustaining Valve in packaged vault • Equipped with electronic actuator • Feeds community and elevated tank located 2+ miles from vault Hydraulic Level Control Valves • Designed to shut‐off when the reservoir reaches -

FOUNDATION™ FIELDBUS Positioner Type 3787

FOUNDATIONTM FIELDBUS Positioner Type 3787 Fig. 1 ⋅ Type 3787 Mounting and Operating Instructions EB 8383-1 EN Firmware R 1.4x/K 1.4x Edition November 2004 Contents Contents Page 1 Design and principle of operation . 8 1.1 Optional limit switches . 8 1.2 Communication . 8 2 Attachment to the control valve . 10 2.1 Direct attachment to Type 3277 Actuator . 10 2.2 Attachment acc. to IEC 60534-6 . 14 2.2.1 Mounting sequence . 14 2.2.2 Presetting the valve travel . 16 2.3 Attachment to rotary actuators . 17 2.3.1 Mounting the lever with feeler roll . 18 2.3.2 Mounting the intermediate piece . 18 2.3.3 Aligning and mounting the cam disk . 20 2.3.4 Reversing amplifier for double-acting actuators . 22 2.4 Fail-safe action of the actuator . 22 3 Connections . 24 3.1 Pneumatic connections . 24 3.1.1 Pressure gauge . 24 3.1.2 Supply air pressure . 25 3.2 Electrical connections . 25 3.2.1 Establishing communication . 28 4Operation . 29 4.1 LEDs . 29 4.2 Write protection and simulation switches . 30 4.3 Activate/deactivate forced venting function . 30 4.4 Default setting . 30 4.4.1 Adjusting mechanical zero . 30 4.4.2 Initialization . 31 4.5 Operation via TROVIS-VIEW . 33 4.5.1 Initialization . 33 4.5.2 Testing the control valve . 34 4.6 Setting the inductive limit switches . 34 2 EB 8383-1 EN Contents 5 Maintenance . 35 6 Servicing explosion-protected versions . 35 7 Parameter description . 36 7.1 General . -

Flowserve Control Valve Product Guide

Control Valve Product Guide Experience In Motion Experience In Motion Control valve solutions for all of your applications Performance!Nxt ™ CUSTOM ENGINEERED 6 24 Valve Sizing and Selection Suite Flowserve offers a comprehensive suite of custom- Performance!Nxt puts the power of on-demand control engineered solutions, as well as unique product valve selection and sizing at your fingertips. It’s the designs that meet your exacting specifications. right tool for finding the right product, every time. 30 POSITIONERS GENERAL SERVICE 8 Our portfolio of ultra-high precision positioners support Flowserve general service control valves combine plat- a range of communication protocols and hazardous form standardization, high-performance, and simplified area classifications to help facilitate dramatic improve- maintenance to deliver a lower total cost of ownership. ments in process uptime, reliability, and yield. SEVERE SERVICE 34 SALES AND SERVICE 16 Flowserve severe service products are engineered for Around the clock, around the world. Flowserve manu- durable functionality wherever harsh service conditions factures, sells, and services precision-quality pumps, exist. From extreme temperature and pressure differ- control valves, seals, and automation equipment for a entials, to cavitation, flashing, and beyond, our severe diverse range of industries. service solutions take the problem out of problematic applications. Accord™ Edward™ NAF ™ Valbart™ Anchor Darling™ Gestra™ Nobel Allloy™ Valtek™ Argus™ Kämmer™ Norbro™ Vogt™ Atomac™ Limitorque™ Nordstrom™ Worcester Controls™ Automax™ Logix™ PMV™ Durco™ McCANNA/MARPAC™ Serck Audco™ 2 flowserve.com Flowserve – Solutions to Keep You Moving Flowserve is one of the world’s leading providers of Flowserve markets are large, diverse, and worldwide. fluid motion and control products and services. -

Plantpax Distributed Control System (DCS) Demonstrator

PlantPAx™ Distributed Control System (DCS) Demonstrator - Pressure, Flow, Level, Temperature 8095450 (3531-V5) LabVolt Series Datasheet Festo Didactic en 230 V - 50 Hz * The product images shown in this document are for illustration purposes; actual products may vary. Please refer to the Specifications section of each product/item for all details. Festo Didactic reserves the right to change product images and specifications at any time without notice. 09/2021 PlantPAx™Distributed Control System (DCS) Demonstrator - Pressure, Flow, Level, Temperature, LabVolt Series Table of Contents General Description _________________________________________________________________________________ 2 PID Loop Tuning ____________________________________________________________________________________ 3 Features & Benefits _________________________________________________________________________________ 4 List of Equipment ___________________________________________________________________________________ 4 List of Manuals _____________________________________________________________________________________ 4 Table of Contents of the Manual(s) _____________________________________________________________________ 4 Equipment Description ______________________________________________________________________________ 5 General Description The Distributed Control System (DCS) Demonstrator is a modular demonstration unit capable of showing real- life process applications across a wide range of industries, including water and wastewater, oil refining, petrochemical, -

Control Valve Product Guide

Control Valve Product Guide Experience In Motion Experience In Motion Control valve solutions for all of your applications Performance!Nxt ™ CUSTOM ENGINEERED 6 24 Valve Sizing and Selection Suite Flowserve offers a comprehensive suite of custom- Performance!Nxt puts the power of on-demand control engineered solutions, as well as unique product valve selection and sizing at your fingertips. It’s the designs that meet your exacting specifications. right tool for finding the right product, every time. 30 POSITIONERS GENERAL SERVICE 8 Our portfolio of ultra-high precision positioners support Flowserve general service control valves combine plat- a range of communication protocols and hazardous form standardization, high-performance, and simplified area classifications to help facilitate dramatic improve- maintenance to deliver a lower total cost of ownership. ments in process uptime, reliability, and yield. SEVERE SERVICE 34 SALES AND SERVICE 16 Flowserve severe service products are engineered for Around the clock, around the world. Flowserve manu- durable functionality wherever harsh service conditions factures, sells, and services precision-quality pumps, exist. From extreme temperature and pressure differ- control valves, seals, and automation equipment for a entials, to cavitation, flashing, and beyond, our severe diverse range of industries. service solutions take the problem out of problematic applications. Accord™ Edward™ NAF ™ Valbart™ Anchor Darling™ Gestra™ Nobel Allloy™ Valtek™ Argus™ Kämmer™ Norbro™ Vogt™ Atomac™ Limitorque™ Nordstrom™ Worcester Controls™ Automax™ Logix™ PMV™ Durco™ McCANNA/MARPAC™ Serck Audco™ 2 flowserve.com Flowserve – Solutions to Keep You Moving Flowserve is one of the world’s leading providers of Flowserve markets are large, diverse, and worldwide. fluid motion and control products and services. -

Instrumentation & Process Control Automation Guidebook – Part 3

PDHonline Course E444 (7 PDH) _____________________________________________________ Instrumentation & Process Control Automation Guidebook – Part 3 Instructor: Jurandir Primo, PE 2014 PDH Online | PDH Center 5272 Meadow Estates Drive Fairfax, VA 22030-6658 Phone & Fax: 703-988-0088 www.PDHonline.org www.PDHcenter.com An Approved Continuing Education Provider www.PDHcenter.com PDH Course E444 www.PDHonline.org INSTRUMENTATION & PROCESS CONTROL AUTOMATION GUIDEBOOK – PART 3 CONTENTS: 1. INTRODUCTION 2. INSTRUMENTATION & CONTROL SYSTEMS 3. INSTRUMENTATION DESCRIPTION & APPLICATION 4. PROCESS CONTROL INSTRUMENTATION 5. CONDUCTIVITY & ANALYTICAL INSTRUMENTATION 6. CONTROL VALVES & INSTRUMENTATION 7. STANDARD & CONTROL VALVES APPLICATION 8. VALVES ACTUATORS, POSITIONERS & TRANSDUCERS 9. CONTROL SYSTEMS & FIELDBUS TECHNIQUES 10. DIAGNOSTICS & COMMUNICATION INTERFACES 11. HAZARDOUS CLASSIFICATION & PROTECTION TYPES 12. PROCESS & PIPING INSTRUMENTATION DIAGRAMS 13. PROCESS CONTROL & SOFTWARE SIMULATIONS 14. REFERENCES & LINKS ©2014 Jurandir Primo Page 1 of 91 www.PDHcenter.com PDH Course E444 www.PDHonline.org 1. INTRODUCTION: Instrumentation is the science of automated measurement and control, or can be defined as the sci- ence that applies and develops techniques for measuring and controls of equipment and industrial processes. Process control has a broad concept and may be applied to any automated systems such as, a complex robot or to a common process control system as a pneumatic valve controlling the flow of water, oil or steam in a pipe. A basic instrument consists of three elements: Sensor or Input Device Signal Processor Receiver or Output Device To measure a quantity, usually is transmitted a signal representing the required quantity to an indi- cating or computing device where either human or automated action takes place. If the controlling action is automated, the computer sends a signal to a final controlling device which then influences the quantity being measured. -

Configuration, Programming, Implementation, and Evaluation of Distributed Control System for a Process Simulator

Western University Scholarship@Western Electronic Thesis and Dissertation Repository 4-15-2015 12:00 AM Configuration, Programming, Implementation, and Evaluation of Distributed Control System for a Process Simulator Ximing Liu The University of Western Ontario Supervisor Jin Jiang The University of Western Ontario Graduate Program in Electrical and Computer Engineering A thesis submitted in partial fulfillment of the equirr ements for the degree in Master of Engineering Science © Ximing Liu 2015 Follow this and additional works at: https://ir.lib.uwo.ca/etd Part of the Controls and Control Theory Commons Recommended Citation Liu, Ximing, "Configuration, Programming, Implementation, and Evaluation of Distributed Control System for a Process Simulator" (2015). Electronic Thesis and Dissertation Repository. 2801. https://ir.lib.uwo.ca/etd/2801 This Dissertation/Thesis is brought to you for free and open access by Scholarship@Western. It has been accepted for inclusion in Electronic Thesis and Dissertation Repository by an authorized administrator of Scholarship@Western. For more information, please contact [email protected]. CONFIGURATION, PROGRAMMING, IMPLEMENTATION AND EVALUATION OF DISTRIBUTED CONTROL SYSTEM FOR A PROCESS SIMULATOR (Thesis format: Monograph) by Ximing Liu Graduate Program in Electrical and Computer Engineering A thesis submitted in partial fulfilment of the requirements for the degree of Master of Engineering Science School of Graduate and Postdoctoral Studies The University of Western Ontario London, Ontario, Canada © Ximing Liu, 2015 Abstract A common industrial distributed control system (DCS), DeltaV, is configured and programmed to control and monitor the Nuclear Process Control Test Facility (NPCTF). A cabinet which holds the hardware of the DelatV DCS system, including programmable logic controller (PLC), power supplies, input/output (I/O) cards, terminals, and relays are configured and wired to field devices of NPCTF. -

Key Considerations for Specifying Rotary Vs Globe Valves

AWC FC‐COC 2019:JP1.4 Key Considerations for Specifying Rotary vs. Globe Control Valves Jeff Peshoff AWC, Inc. jeff.peshoff@awc‐inc.com Steven Hocurscak Metso [email protected] AWC Flow Control COC 6655 Exchequer Drive Baton Rouge, LA 70809 April 12, 2019 AWC, Inc. shall not be responsible for statements or opinions contained in papers or printed in publications Keywords: Globe Control Valve, Rotary Control Valve (ball, segmented ball, rotary eccentric plug, offset butterfly), Rangeability, Permanent Pressure Loss, Pressure Recovery AWC FC‐COC 2019:JP1.4 Key Considerations for Specifying Rotary vs. Globe Control Valves It is not uncommon for engineers in the process industry to ask about selection criteria for specifying a linear (globe or sliding stem) control valve as opposed to a rotary (ex: eccentric plug, segmented ball, butterfly) control valve solution in a given application. Admittedly, engineering specification decisions are sometimes based upon past convention simply because selecting what has been used previously may be the least risky approach. No one wants to be the person asked why there was a deviation from past practice should something possibly go wrong. Ideally, all specifications should be based upon process requirements derived from process needs. Needs > Requirements > Specifications. If this is completed, the engineering design basis should be traceable and there should never be a question of why in a properly designed system. While technological obsolescence can cause a relatively short service life for process automation hardware, the properly specified control valve, in comparison, can have a much longer term of service, G Series Globe especially if the life cycle is managed optimally. -

Linecard 10/13

Valin Corporation, 6070 Corte Del Cedro, Carlsbad, CA 92011 Phone Number: (760) 438-4840 E-mail: [email protected] Fax Number: (760) 438-4836 Call Toll Free: 1-888-358-0030 or shop online at: www.TheValveShop.com We are a value added supplier and stocking distributor specializing in valves, automation, and process controls. Our products range from manually operated valves to fully automated valve systems. We offer you a large selection of high quality products from respected manufacturers at competitive prices. Valves Automation Controls Angle Valves Actuators & Kits Accumulators Ball Valves Chain Wheels Analog & Digital Butterfly Valves Double Acting Controllers Check Valves Electro-Hydraulic Fieldbus & Connectivity Control Valves Fail-Safe I/P Transducers Diaphragm Valves Gear Operators Instruments Float Valves Hand Wheels Pneumatics Gate Valves Limit Switches Process Filters Globe Valves Lockout Devices Pressure Gauges Plug Valves Modulating Process Switches Process Filters Motorized Electric Process Systems Regulators Pneumatic Regulators Relief Valves Rack & Pinion Sensors & Monitors Solenoid Valves Spring Return Transmitters Strainers & Traps Scotch Yoke Valve Positioners Y-Pattern Valves Travel Stops Wireless Devices BioPharm • Commercial • Industrial • Marine • OEM • Plastic • Sanitary • Water/Waste American • Apollo • Aquatrol • ASCO • Ashcroft • A-T Controls • AVCO • Babbitt • Banner Beric • Bonney Forge • BS&B • Cash Valve • Century • Check-All • Conbraco • Danfoss Flomatic • Dezurik • DK-Lok • Duo-Chek II • Dwyer • EMS -

Control Valves Selection Guide for Control Valves, Count on Azbil

CA2-8000 Industrial Control Valves Selection Guide For control valves, count on azbil. We have extensive experience in process automation at home and abroad. For over 80 years, since we made Japan’s first domestically produced control valves in 1936, we have delivered products to a wide variety of process automation sites inside and outside Japan. The technology we have accumulated through our abundant experience in the field is the heritage of each newly developed product, and is utilized to make ever more advanced general-purpose control valves with higher performance and greater reliability. In addition to general-purpose valves, we have developed a number of products for specific applications, such as high or low temperature, super high pressure, corrosion resistance, abrasion resistance, and environmental friendliness. In recent years, in order to create added value for plant operation by improving maintenance efficiency, reducing plant operating costs, etc., we acted quickly to make our valve positioners smart. These smart valve positioners, when connected with our PLUG-IN Valstaff control valve maintenance support system, provide new benefits throughout the control valve life cycle, such as assistance in preparing an efficient maintenance plan. Chemical plants Petrochemical plants Thermal power stations As a comprehensive supplier of control valves, the azbil Group continues to provide customers with added value in a variety of areas. Oil refineries Steel mills 2 Industrial Control Valves For control valves, count on azbil. We have extensive experience in process automation at home and abroad. For over 80 years, since we made Japan’s first domestically produced control valves in 1936, we have delivered products to a wide variety of process automation sites inside and outside Japan.