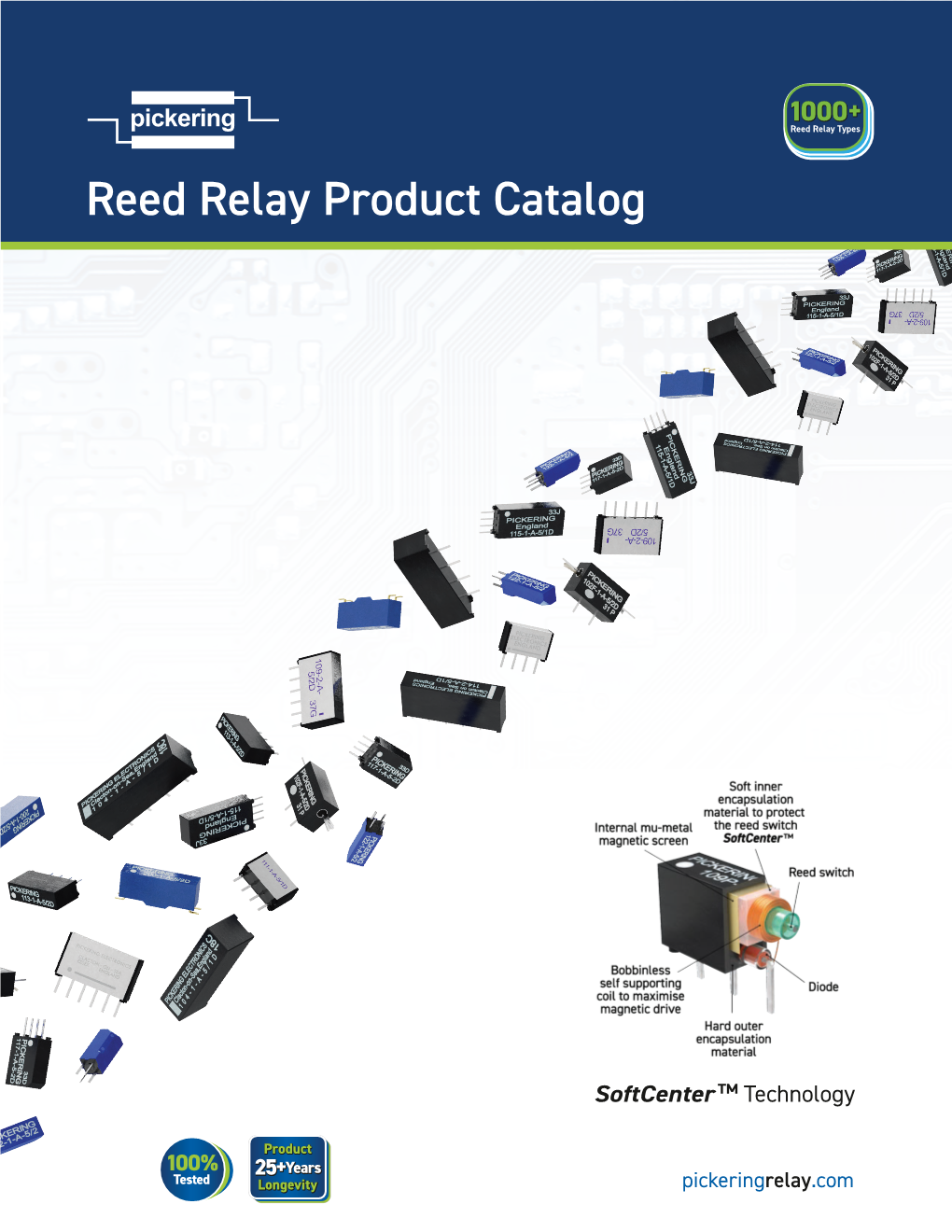

Reed Relay Product Catalog Pickering | Reed Relay Product Catalog | Pickering Relay .Com

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Pickering 20-525 Manual

Full-service, independent repair center -~ ARTISAN® with experienced engineers and technicians on staff. TECHNOLOGY GROUP ~I We buy your excess, underutilized, and idle equipment along with credit for buybacks and trade-ins. Custom engineering Your definitive source so your equipment works exactly as you specify. for quality pre-owned • Critical and expedited services • Leasing / Rentals/ Demos equipment. • In stock/ Ready-to-ship • !TAR-certified secure asset solutions Expert team I Trust guarantee I 100% satisfaction Artisan Technology Group (217) 352-9330 | [email protected] | artisantg.com All trademarks, brand names, and brands appearing herein are the property o f their respective owners. Find the Pickering 20-525-902-LS1 at our website: Click HERE USER MANUAL pickering Model No. 20-520/20-525 R.F. Matrix Module with Self-Test Designed & Manufactured by:- Pickering Interfaces Limited. Stephenson Road Clacton-on-Sea Essex CO15 4NL England Tel: 01255-428141 +44 1255-428141 (International) Fax: 01255-475058 +44 1255-475058 (International) Internet: www.pickering.co.uk E Mail: [email protected] Issue 2.00 June. 1996 © Copyright (1996) Pickering Interfaces Ltd. All Rights Reserved 20-520/20-525 pickering R.F. SWITCHING MATRIX MODULE 1 HELP!!! If you need assistance with your Pickering Interfaces Switching System: Switching problems, Programming or Integration within your Test System. – Please ring Pickering Interfaces and ask for “Technical Support”. Alternatively you may fax, email or connect to our Internet Web Site. A full set of operating manuals, application notes and software drivers is available on CD ROM. 20-520/20-525 pickering 2 SWITCHING MATRIX MODULE Contents Section 1 High Density Matrix Modules .................................................................................... -

Historical Perspectives of Development of Antique Analog Telephone Systems Vinayak L

Review Historical Perspectives of Development of Antique Analog Telephone Systems Vinayak L. Patil Trinity College of Engineering and Research, University of Pune, Pune, India Abstract—Long distance voice communication has been al- ways of great interest to human beings. His untiring efforts and intuition from many years together was responsible for making it to happen to a such advanced stage today. This pa- per describes the development time line of antique telephone systems, which starts from the year 1854 and begins with the very early effort of Antonio Meucci and Alexander Graham magnet core Bell and ends up to the telephone systems just before digiti- Wire 1Coil with permanent Wire 2 zation of entire telecommunication systems. The progress of development of entire antique telephone systems is highlighted in this paper. The coverage is limited to only analog voice communication in a narrow band related to human voice. Diaphragm Keywords—antique telephones, common battery systems, cross- bar switches, PSTN, voice band communication, voice commu- nication, strowger switches. Fig. 1. The details of Meucci’s telephone. 1. Initial Claims and Inventions Since centuries, telecommunications have been of great cally. Due to this idea, many of the scientific community interest to the human beings. One of the dignified per- consider him as one of the inventors of telephone [10]. sonality in the field of telecommunication was Antonio Boursuel used term “make and break” telephone in his Meucci [1]–[7] (born in 1808) who worked relentlessly for work. In 1850, Philip Reis [11]–[13] began work on tele- communication to distant person throughout his life and in- phone. -

Replacement Parts with Drawings in .Pdf Format

REPLACEMENT PARTS CATALOG This catalog contains part numbers for the most common replacement parts for QMARK heaters shown in the Table of Contents. Additional parts for these heaters may be available - consult factory for availability. Parts for QMARK heaters not listed in the Table of Contents may be available - consult factory for availability. NOTE: Parts longer than 8’ in length cannot ship UPS. Consult factory for shipping information. TABLE OF CONTENTS BASEBOARD CEILING HEATERS CRN ..............................................................20 Baseboard Accessories ..................................2 CDF ................................................................9 ARL ..............................................................21 CBD ................................................................3 EFF..................................................................9 CHRR............................................................23 HBB ................................................................3 QCH ................................................................8 QMK (2500 Series) ........................................2 BUILDER PRODUCTS QMKC..............................................................2 UNIT HEATERS BATH VENTS ................................................37 MUH..............................................................11 WHOLE HOUSE FANS ..................................41 WALL HEATERS MUH35..........................................................14 RESIDENTIAL CEILING FANS........................43 -

The Great Telecom Meltdown for a Listing of Recent Titles in the Artech House Telecommunications Library, Turn to the Back of This Book

The Great Telecom Meltdown For a listing of recent titles in the Artech House Telecommunications Library, turn to the back of this book. The Great Telecom Meltdown Fred R. Goldstein a r techhouse. com Library of Congress Cataloging-in-Publication Data A catalog record for this book is available from the U.S. Library of Congress. British Library Cataloguing in Publication Data Goldstein, Fred R. The great telecom meltdown.—(Artech House telecommunications Library) 1. Telecommunication—History 2. Telecommunciation—Technological innovations— History 3. Telecommunication—Finance—History I. Title 384’.09 ISBN 1-58053-939-4 Cover design by Leslie Genser © 2005 ARTECH HOUSE, INC. 685 Canton Street Norwood, MA 02062 All rights reserved. Printed and bound in the United States of America. No part of this book may be reproduced or utilized in any form or by any means, electronic or mechanical, including photocopying, recording, or by any information storage and retrieval system, without permission in writing from the publisher. All terms mentioned in this book that are known to be trademarks or service marks have been appropriately capitalized. Artech House cannot attest to the accuracy of this information. Use of a term in this book should not be regarded as affecting the validity of any trademark or service mark. International Standard Book Number: 1-58053-939-4 10987654321 Contents ix Hybrid Fiber-Coax (HFC) Gave Cable Providers an Advantage on “Triple Play” 122 RBOCs Took the Threat Seriously 123 Hybrid Fiber-Coax Is Developed 123 Cable Modems -

Sensors and Transducers

Sensors and Transducers Sensors and Transducers Third edition Ian R. Sinclair OXFORD AUCKLAND BOSTON JOHANNESBURG MELBOURNE NEW DELHI Newnes An imprint ofButterworth-Heinemann Linacre House, Jordan Hill, Oxford OX2 8DP 225 Wildwood Avenue, Woburn, MA 01801-2041 A division ofReed Educational a nd Professional Publishing Ltd A member ofthe Reed Elsevier plc group First published by BSP Professional Books 1988 Reprinted by Butterworth-Heinemann 1991 Second edition published by Butterworth-Heinemann 1992 Third edition 2001 # I. R. Sinclair 1988, 1992, 2001 All rights reserved. No part ofthis publication may be reproduced in any material form (including photocopying or storing in any medium by electronic means and whether or not transiently or incidentally to some other use ofthis publication) without the written permission ofthe copyright holder except in accordance with the provisions ofthe Copyright, Designs and Patents Act 1988 or under the terms ofa licence issued by the Copyright Licensing Agency Ltd, 90 Tottenham Court Road, London, England W1P 9HE. Applications for the copyright holder's written permission to reproduce any part ofthis publication should be addressed to the publishers British Library Cataloguing in Publication Data A catalogue record for this book is available from the British Library ISBN0750649321 Typeset by David Gregson Associates, Beccles, Su¡olk Printed and bound in Great Britain Contents Preface to Third Edition vii Preface to First Edition ix Introduction xi 1 Strain and pressure 1 2 Position, direction, distance -

Elecsys Watchdog Scout / SCT-N3-20 Quick-Start Guide

Elecsys Watchdog Scout / SCT-N3-20 Quick-Start Guide Package contents: Scout Monitoring unit with cable harness and connectors (communication terminal w/ brackets & cable on satellite units); 100A interruption relay; AC detect probe; 120/240VAC - 12/24VAC step-down isolation transformer w/ plastic safety guards; set of 2 mounting brackets w/fasteners; 1 1/4” threaded connector for mounting directly to the rectifier enclosure. *Please inspect package contents and immediately notify Elecsys Technical Support at (913)825-6366 or email [email protected] if there are any discrepancies. Recommended: Watchdog Installation Supplies Kit -- WD-48-0002-00 (includes 1” flexible conduit, cable to run from rectifier to Scout unit, connectors, mounting hardware, and conduit fittings); Depending on the type of installation, the following may be necessary: Lag bolts & washers for mounting unit; conduit (approx. 4’ per site); 1” conduit connectors; #4 welding cable (ap- prox.. 5’ per site – depending on max amps of rectifier could use 16ga to #4 wire for connecting the relay); 18” of 16ga. 2 wire cable (preferably with White and Black insulated wires) to connect the incoming commercial power to the input of the Isolation transformer; a split bolt splice and electrical tape can be used for larger gauge wires, the yellow connectors will usually work for smaller gauge wires on the relay circuit; 8 x ½” hex head self-tapping screws to mount the relay and transformer inside the rectifier; assortment of red, blue, and yellow butt splice conns, ring conns, disconnects conns, and fork conns; plastic zip-ties. Important Installation Notes: Do not connect directly to high voltage AC. -

Switching Relations: the Rise and Fall of the Norwegian Telecom Industry

View metadata, citation and similar papers at core.ac.uk brought to you by CORE provided by NORA - Norwegian Open Research Archives Switching Relations The rise and fall of the Norwegian telecom industry by Sverre A. Christensen A dissertation submitted to BI Norwegian School of Management for the Degree of Dr.Oecon Series of Dissertations 2/2006 BI Norwegian School of Management Department of Innovation and Economic Organization Sverre A. Christensen: Switching Relations: The rise and fall of the Norwegian telecom industry © Sverre A. Christensen 2006 Series of Dissertations 2/2006 ISBN: 82 7042 746 2 ISSN: 1502-2099 BI Norwegian School of Management N-0442 Oslo Phone: +47 4641 0000 www.bi.no Printing: Nordberg The dissertation may be ordered from our website www.bi.no (Research - Research Publications) ii Acknowledgements I would like to thank my supervisor Knut Sogner, who has played a crucial role throughout the entire process. Thanks for having confidence and patience with me. A special thanks also to Mats Fridlund, who has been so gracious as to let me use one of his titles for this dissertation, Switching relations. My thanks go also to the staff at the Centre of Business History at the Norwegian School of Management, most particularly Gunhild Ecklund and Dag Ove Skjold who have been of great support during turbulent years. Also in need of mentioning are Harald Rinde, Harald Espeli and Lars Thue for inspiring discussion and com- ments on earlier drafts. The rest at the centre: no one mentioned, no one forgotten. My thanks also go to the Department of Innovation and Economic Organization at the Norwegian School of Management, and Per Ingvar Olsen. -

Five Signs That It Is Time to Replace the Mercury Based Relays and Switches in Your Industrial Application

• white paper • white paper • white paper • white paper • industry: industrial process heating author: brian bettini Five Signs That it is Time to Replace the Mercury Based Relays and Switches in Your Industrial Application And What to Look for in a Suitable Replacement Summary: Mercury relays have been used in industrial applications for decades, most commonly for power switching. For example, in applications that use process heating, mercury relays are traditionally used to power on and off of electric heaters efficiently. But these kinds of relays are being replaced for several reasons. The latest generation of mercury relay/mercury switch alternatives is safer and more accurate and just as durable. • white paper • white paper • The background: mercury in industry U.S. patents for a mercury-based relay can be found as far back as 1937, and they have been used in industry for decades.1 They were first developed for applications where contact erosion could present a challenge for more conventional relay contacts, or where constant cycling was needed (such as heating operations). Mercury relays have been known to overheat, however, and there have been known cases of relays exploding and sending vaporized mercury into the workspace. This can potentially create a serious environmental and safety issue, not to mention the need for costly clean-up. But even with that risk, and with the EPA and the European Union placing bans on the use of mercury, some manufacturers are still using mercury relays or similar outdated switching devices. Why? Some industrial engineers claim to prefer mercury relays because they believe them to be durable and capable of handling difficult and dirty environments. -

Capacitors, Fixed, Chips, Ceramic Dielectric, Types I

Page 1 of 33 CAPACITORS, LEADLESS SURFACE MOUNTED, TANTALUM, SOLID ELECTROLYTE, ENCLOSED ANODE CONNECTION ESCC Generic Specification No. 3012 Issue 4 September 2020 Document Custodian: European Space Agency – see https://escies.org ESCC Generic Specification PAGE 2 No. 3012 ISSUE 4 LEGAL DISCLAIMER AND COPYRIGHT European Space Agency, Copyright © 2020. All rights reserved. The European Space Agency disclaims any liability or responsibility, to any person or entity, with respect to any loss or damage caused, or alleged to be caused, directly or indirectly by the use and application of this ESCC publication. This publication, without the prior permission of the European Space Agency and provided that it is not used for a commercial purpose, may be: − copied in whole, in any medium, without alteration or modification. − copied in part, in any medium, provided that the ESCC document identification, comprising the ESCC symbol, document number and document issue, is removed. ESCC Generic Specification PAGE 3 No. 3012 ISSUE 4 DOCUMENTATION CHANGE NOTICE (Refer to https://escies.org for ESCC DCR content) DCR No. CHANGE DESCRIPTION 1233, 1257 Specification up issued to incorporate changes per DCR. ESCC Generic Specification PAGE 4 No. 3012 ISSUE 4 TABLE OF CONTENTS 1 INTRODUCTION 8 1.1 SCOPE 8 1.2 APPLICABILITY 8 2 APPLICABLE DOCUMENTS 8 2.1 ESCC SPECIFICATIONS 8 2.2 OTHER (REFERENCE) DOCUMENTS 9 2.3 ORDER OF PRECEDENCE 9 3 TERMS, DEFINITIONS, ABBREVIATIONS, SYMBOLS AND UNITS 9 4 REQUIREMENTS 10 4.1 GENERAL 10 4.1.1 Specifications 10 4.1.2 Conditions -

Reed Relaymate from Pickering Electronics

Reed RelayMate from Pickering Electronics Pickering Electronics Ltd. Tel (Int): +(44) 1255 428141 Stephenson Road Tel (UK): 01255 428141 Clacton-on-Sea E-Mail: [email protected] CO15 4NL United Kingdom © Copyright (2021) Pickering Electronics Ltd. All Rights Reserved. Pickering Electronics maintains a commitment to continuous product development, consequently we reserve the right to vary from the descriptions given in this catalogue. Edition 1b Reed RelayMate This book provides an overview of how reed relays work how they are constructed and how to interpret their specifications and make best use of them in their applications. It is intended to be a practical book about reed relays aimed at engineers. It requires little or no theoretical knowledge about the materials they are constructed from, all the issues are dealt with in a practical manner. With the information supplied in this book we hope users will better understand the efforts that go into designing what in principle is a simple component but which in practice is a complicated product full of engineering compromises and best value judgements. Created by the team at Pickering Electronics, April 2011 About Pickering Electronics Pickering Electronics was formed in January 1968 to design and manufacture high quality reed relays, intended principally for use in instrumentation and automatic test equipment. Pickering Electronics offer an extensive range of high quality instrumentation grade reed relays designed for applications requiring the highest levels of performance and reliability at an affordable price. Through the experience of supporting the most demanding manufacturers of large ATE systems with high relay counts the company has refined its assembly and quality control methods to optimise its manufacturing methods. -

Picosecond Pulse Generators Using Microminiature Mercury Switches

NBSIR 74-377 PICOSECOND PULSE GENERATORS USING MICROMINIATURE MERCURY SWITCHES James R. Andrews Electromagnetics Division Institute for Basic Standards National Bureau of Standards Boulder, Colorado 80302 March 1974 Final Report Prepared for Department of Defense Calibration Coordination Group 72-66 NBSIR 74-377 PICOSECOND PULSE GENERATORS USING MICROMINIATURE MERCURY SWITCHES James R. Andrews Electromagnetics Division Institute for Basic Standards National Bureau of Standards Boulder, Colorado 80302 March 1974 Final Report Prepared for Department of Defense Calibration Coordination Group 72-66 U.S. DEPARTMENT OF COMMERCE, Frederick B. Dent, Secretary NATIONAL BUREAU OF STANDARDS Richard W Roberts Director TABLE OF CONTENTS Page I. INTRODUCTION 1 II. FLAT PULSE GENERATOR CONCEPT 5 III. PRELIMINARY WORK 6 IV. ALTERNATE SWITCH CONFIGURATIONS STUDIED 7 V. COMMERCIAL STRIPLINE SWITCH EVALUATION 8 VI. NBS STRIPLINE SWITCH 13 VII. CLASSICAL MERCURY SWITCH PULSE GENERATOR 16 VIII. CONCLUSIONS 17 REFERENCES 18 LIST OF FIGURES Figure Page 2-1 Diode switch flat pulse generator 21 2- 2 Mercury switch flat pulse generator 21 3- 1 Basic SPDT microminiature mercury wetted switch 22 3-2 DIP IC mercury switch pulse generator 23 3-3 Transition time measurement set-up 24 3-4 Transient step response of measurement set-up. Hori- zontal scale is 100 ps/div. 24 3- 5 Pulse output from DIP IC mercury switch pulse generator. Horizontal scale is 200 ps/div. 25 4- 1 Microminiature mercury switched mounted in a 14 mm insertion unit 26 4- 2 Pulse output of a microminiature switch mounted in a 14 mm insertion unit. Horizontal scale is 100 ps/div.- 26 5- 1 Microminiature mercury switch in commercial strip line package 27 5-2 TDR characteristics of commercial stripline micro- miniature mercury switch, (a) Port 2 to Port 1. -

TURBINE PROTECTION SYSTEM PERFORMANCE by Margaret C

TURBINE PROTECTION SYSTEM PERFORMANCE by Margaret C. Campbell Project Engineer Foster-Miller, Incorporated Waltham, Massachussetts based control, the majority of the installed turbine protection As a Project Mechanical Engineer with systems rely on the high pressure pneumatic EHC system. To Foster-Miller,Incorporated, in Waltham, supplement the protection afforded by the this system, most Massachusetts, Margaret C. Campbell suppliers also provide a comprehensive package of turbine provides engineering and managerial sup supervisory instrumentation (TSI) systems. These TSI systems port to power industry related programs. can be designed, at the request of the customer, to initiate pro Her work has included reliability studies of tective actions. nuclear turbine protection systems,design Power plant experience indicates that the turbine protection of pneumatic systems fo r robotic controls, systems often initiate turbine trips when operating conditions and designof innovative naturalgas piping do not warrant a trip. In Table 1, the Institute of Nuclear Power systems. Operations (INPO) reports the listing of subsystems and compo Before joining Foster-Miller, Ms. Camp nents that are typically associated with turbine trip events [2]. bell was employed with Stone and Webster Engineering Corpora tion,where she was a Systems engineer involved in such activities Table 1. Subsystems and Components TypicallyAssociated with as the startup of auxiliary boilers and associated systems at the Thrbine Trip Events. Millstone III Nuclear Power Plant. Percent ofTotal Ms. Campbell received a B.S.M.E. degree in 1982,from the Subsystem Turbine Trip Events University of Massachusetts. EHC System 47 Governor/Control Valves 9 Intercept/StopValves 6 ABSTRACT Instruments 5 The need to protect a turbine generator from abnormal Pressure Regulator 5 operating condidtions is a given.