A Review on Fatigue Behaviour of Connecting Rod Made of Austempered Ductile Iron

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Wärtsilä 32 PRODUCT GUIDE © Copyright by WÄRTSILÄ FINLAND OY

Wärtsilä 32 PRODUCT GUIDE © Copyright by WÄRTSILÄ FINLAND OY COPYRIGHT © 2021 by WÄRTSILÄ FINLAND OY All rights reserved. No part of this booklet may be reproduced or copied in any form or by any means (electronic, mechanical, graphic, photocopying, recording, taping or other information retrieval systems) without the prior written permission of the copyright owner. THIS PUBLICATION IS DESIGNED TO PROVIDE AN ACCURATE AND AUTHORITATIVE INFORMATION WITH REGARD TO THE SUBJECT-MATTER COVERED AS WAS AVAILABLE AT THE TIME OF PRINTING. HOWEVER, THE PUBLICATION DEALS WITH COMPLICATED TECHNICAL MATTERS SUITED ONLY FOR SPECIALISTS IN THE AREA, AND THE DESIGN OF THE SUBJECT-PRODUCTS IS SUBJECT TO REGULAR IMPROVEMENTS, MODIFICATIONS AND CHANGES. CONSEQUENTLY, THE PUBLISHER AND COPYRIGHT OWNER OF THIS PUBLICATION CAN NOT ACCEPT ANY RESPONSIBILITY OR LIABILITY FOR ANY EVENTUAL ERRORS OR OMISSIONS IN THIS BOOKLET OR FOR DISCREPANCIES ARISING FROM THE FEATURES OF ANY ACTUAL ITEM IN THE RESPECTIVE PRODUCT BEING DIFFERENT FROM THOSE SHOWN IN THIS PUBLICATION. THE PUBLISHER AND COPYRIGHT OWNER SHALL UNDER NO CIRCUMSTANCES BE HELD LIABLE FOR ANY FINANCIAL CONSEQUENTIAL DAMAGES OR OTHER LOSS, OR ANY OTHER DAMAGE OR INJURY, SUFFERED BY ANY PARTY MAKING USE OF THIS PUBLICATION OR THE INFORMATION CONTAINED HEREIN. Wärtsilä 32 Product Guide Introduction Introduction This Product Guide provides data and system proposals for the early design phase of marine engine installations. For contracted projects specific instructions for planning the installation are always delivered. Any data and information herein is subject to revision without notice. This 1/2021 issue replaces all previous issues of the Wärtsilä 32 Project Guides. Issue Published Updates 1/2021 15.03.2021 Technical data updated. -

ME1402 Dynamics of Machinery: Practice

National Institute Technology Jamshedpur Mechanical Engineering Department Program: B.Tech. (Hons.) in Mechanical Engineering, Semester: IV, Session: Spring 2019-20, Course: ME1402 Dynamics of Machinery, Instructor: Dr. A. K. Mandal Practice Problems IV : Dynamic Force and Motion Analysis 1. (i) Figure1 shows a mechanism where link 2 is driving link 4 with the help of a rigid, uniform coupler of negligible mass. The angular velocity !2 at the instant shown is 10 rad/s. If a moment M of magnitude 500 N-m is applied on 2, as shown, determine the acceleration of link 2. The 2 2 moments of inertia of links 2 and 4 about O2 and O4 are 0.5 kg:m and 1.0 kg:m , respectively. Given O2O4 = 25 cm, AO2 = 35 cm, and BO4 = 50 cm. (ii) What will be the acceleration of link 2 if the coupler has a mass 2 kg and the mechanism is in a horizontal plane? Figure 1: 2. For the mechanism shown in Fig.2, the sliding blocks weigh 45 N each. Both connecting rods are uniform, each being 50.8 cm long. The length of the crank is 15.3 cm and is rigid with a mass 10 kg at its end. All links weigh 172 N/m. (i) If a force of 450 N is applied to the slider A as shown in the figure, what will be the acceleration of the slider B at the instant when the force is applied, assuming the mechanism to be initially at rest? (ii) Instead of being at rest, if the crank possesses an angular velocity of 300 rad/s in the counter-clockwise direction, what will be the acceleration of the slider B at the instant 3. -

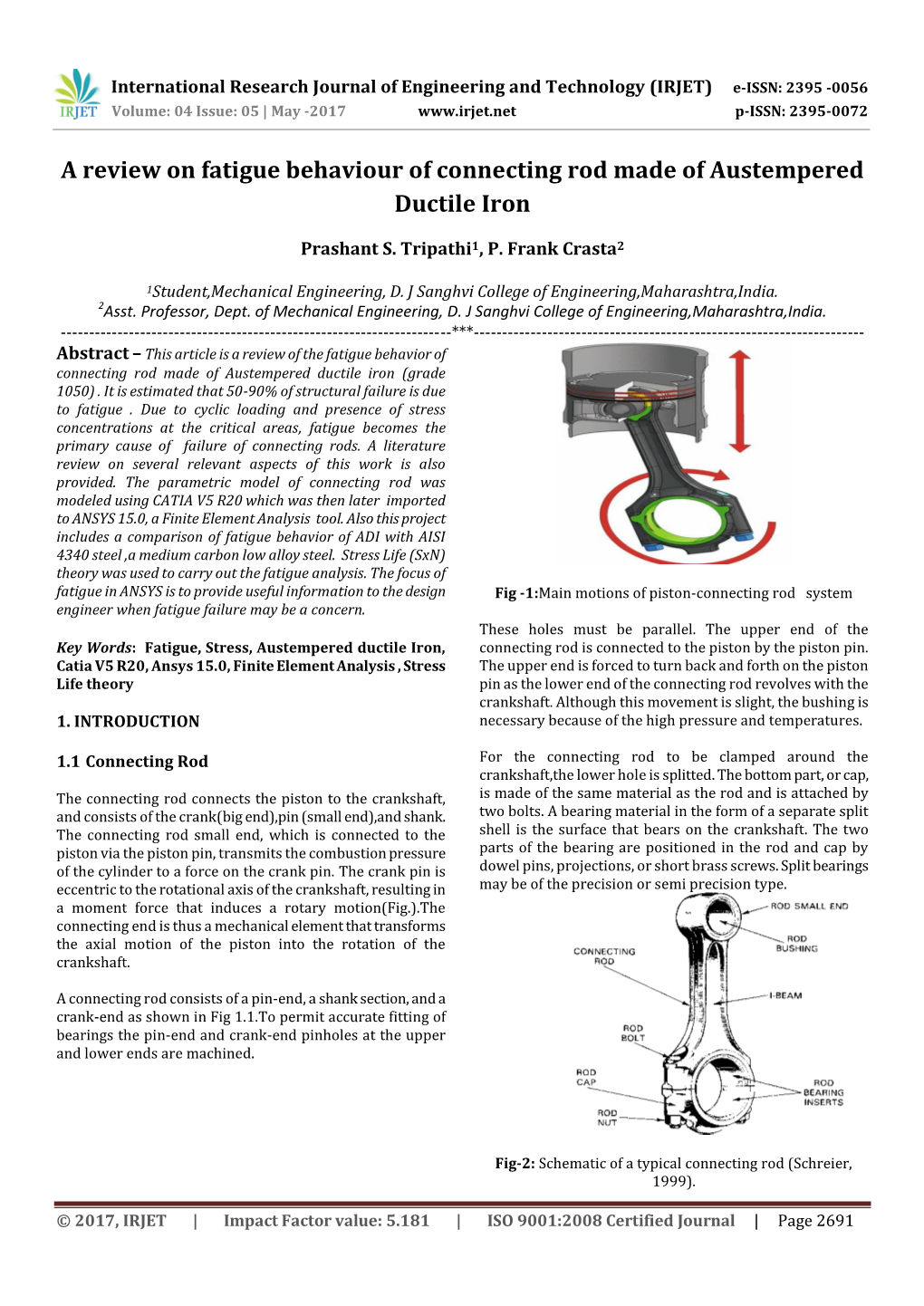

Weight-Optimized Bushingless Connecting Rods: Improving the Tribological Performance of a Gudgeon Pin/Connecting Rod System by Using the Triboconditioning® Process

Journal of Materials Science and Engineering A 7 (1-2) (2017) 25-36 doi: 10.17265/2161-6213/2017.1-2.004 D DAVID PUBLISHING Weight-Optimized Bushingless Connecting Rods: Improving the Tribological Performance of a Gudgeon Pin/Connecting Rod System by Using the Triboconditioning® Process Jonas Lundmark1, Boris Zhmud1, Boris Brodmann2, Dietmar Schorr3 and Urban Morawitz4 1. Applied Nano Surfaces Sweden AB, Uppsala SE-75323, Sweden 2. OptoSurf GmbH, Ettlingen D-76275, Germany 3. Steinbeis Transfer Center Tribology, Karlsruhe D-76133, Germany 4. Ford Motor Company, Cologne D-50735, Germany Abstract: The risk of failures associated with a distressed pin/connecting rod bearing contact without forced pin oiling is exaggerated due to ever increasing power density and torque output of modern TSI (turbocharged straight injection) and TDI (turbocharged direct injection) engines, in combination with the introduction of low-viscosity low-SAPS (sulfated ash, phosphorus, sulfur) lubricants and general engine downsizing resulting in fewer cylinders to bear the load. This forces OEMs (original equipment manufacturer) to look for innovative cost-efficient solutions to promote bushingless connecting rods without impacting reliability. One such solution is the Triboconditioning® process. Triboconditioning is an industrial surface finishing process which attempts to carry out running-in of components during their manufacture. The present paper provides an in-depth analysis of the tribological effects of Triboconditioning® on the pin/conrod contact. Key words: Triboconditioning, mechanochemical finishing, connecting rod, wear, tribology. 1. Introduction to a minimum. For instance, in motor sports, H-shaped shanks are preferred for this particular reason. Use of a The connecting rod connects the piston to the bushingless pin bearing in the small end is another crankshaft, transforming the axial motion of the piston way to reduce oscillating masses, which is of increasing into the rotation of the crankshaft. -

ACP 33 Volume 3 For

Amendment List Date Amended by Incorporated No Date 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 i ACP 33 FLIGHT CONTENTS Volume 1 ................. History of Flight Volume 2 ................. Principles of Flight Volume 3 ................ Propulsion Volume 4 ................. Airframes Volume 3 Propulsion Chapter 1 ................ The Piston Engine Chapter 2 ................ Carburation Chapter 3 ................ Ignition Chapter 4 ................ Lubrication and Cooling Chapter 5 ................ Propellers Chapter 6 ................ The Jet Engine Chapter 7 ................ Rockets Instructors’ Guide ISSUED 2000 ii ACKNOWLEDGEMENT Chapter 6 - “The Jet Engine” is a reproduction of a publication “How a Jet Engine Works”, produced and supplied by Rolls-Royce Limited. We gratefully acknowledge their permission to print and other help given. iii THE PISTON ENGINE CHAPTER 1 THE PISTON ENGINE Introduction How it all started 1. In 1903, the Wright brothers made history with the first powered aeroplane that could carry a man. Their flying machine was powered by a piston engine - and today, nearly a century later, piston engines are still used in hundreds of thousands of aircraft all over the world. Basic Principles Piston Engine Design 2. There are many types of piston engine - one example is the old type of railway engine, where solid fuel (coal or wood) is burnt externally in a firebox, to turn water into steam which is then piped to the engine to drive the pistons. These external combustion engines are much too heavy for aviation, so we use the internal combustion engine, which obtains its power by burning liquid fuel inside the engine, where the pistons are located. -

Section 1 – Engine & Exhaust

• -, - SICTIOfl , 0 , , , , , U , , , • • • • " • " • •• COJO'i:)i1'S Peg. D"eriptfoD ... .. .. .. , Gene,,"l data .. .. 8 L\lbr jell t i 011 eyat .. De.cril'tion ... .. .. I'''"O&U''' r"lier "alYe •• .. .. ,." Re .. eving ,.0 !"elHUIIR P"UIUNI reliaf vlllv •... ,. Adjusting .. , oil p.. aalRlre •• , ... .. ... 26 W&inteUAuall ... .. .. 26 111gb" oil .. .. ... .. 27 Chltngillll ". ,il .. ... .. .. 27 01' tilUr (Jull ClIIW typeD) Description ... .. Sel"Vieing (Tocalllllli t ) .. ... ... " SIIM'icillll (Yok.es) ... .. ... lilt ...",,] oil coollll' ... ... " External oil (1001 01' " Description .. .. ... Inatalling ... .. .. " all"'ov; .. , .. , ,.erHtlng .. .. ... " Oil P'''' " Description .. .. · .. RamoYing ." refUting ... .. · .. .. " Dis=.ntl llll .. .. · .. " Iupct<,tioll .. , 1'........ lIIOblll1l1 · .. .. • •• " Cylhlder h ••cI D.,crlptloll .. .. ... " Romoving .. , pgUttin.. ... .. ... ,~ " Valve cloarll"c88 ... ... .. Dilill&J\ t I IllS' .. .. ·..... .. "48 hapllctloll NI-<!ondt t 1011111 11 · .. .. ... Rflplacllli 'f--,... lv e fU tel .. .. .. ... .. " Replaoflli rock.r buab .. .. .. .. ) Ro ...... n.CIb ling ... ... .. ... " Cylinder bloci< " De scriptlOIl ... ... , .. Ro-borillg .. ... ... ... " ( SIC1IOII 1. -, - Cr8.D.tahatt OueriptlCla .. ... ... · · • • · • R..owlPI aad rerlttlp, • · · • • · " Iup'ctioll ... • · · " Waia beariDg •... ... "60 riUllI, ... Ia burIDI' .. · · 60 Re-grlodllll ••• . •. " · · · J'lywheel aod atarter rial · · · " J'lywh.. I ... • .• • • CODAectiDi rod. 8.D.d pi.tOIlI · " Vucriptfoa · · · "64 R&mowiDi -

Experimental Study on Connecting Rod Structure Behavior Using Modal Analysis R

Journal of Chemical and Pharmaceutical SciencesISSN: 0974-2115 Experimental study on Connecting rod structure behavior using Modal Analysis R. Jaganathan, S. Dinesh* Department of Automobile Engineering, Saveetha School of Engineering, Saveetha University, Chennai 602 105 *Corresponding author: E-Mail: [email protected] ABSTRACT The connecting rod is the intermediate member between the piston and the Crankshaft. Its primary function is to transmit the push and pull from the piston pin to the crank pin, thus converting the reciprocating motion of the piston into rotary motion of the crank. This study incorporates modal analysis and experimental modal analysis of connecting rod. A model of Connecting rod is modeled and modal analysis is carried out by using dewesoft Software. Modal analysis method is used to determine natural frequencies of a connecting rod and compare results with FFT analyzer. FFT analysis is done by hanging the connecting rod at small end and further the experimental results were compared with FEA. KEY WORDS: Connecting rod, Dewesoft Software, FFT analyzer. 1. INTRODUCTION A Connecting rod is the link between the reciprocating piston and rotating crank shaft. Small finish of the connecting rod is hooked up to the piston by the use of gudgeon pin. The colossal finish of the connecting rod is connected to the crankshaft. The operation of the connecting rod is to convert the reciprocating movement of the piston into the rotary movement of the crankshaft. A blend of axial and bending stresses act on the rod in operation. The axial stresses are product due to cylinder fuel strain and the inertia force bobbing up on account of reciprocating motion. -

4.0 & 4.6 Litre V8 Engine Overhaul Manual

4.0 & 4.6 LITRE V8 ENGINE OVERHAUL MANUAL These engines having Serial No. Prefix 42D, 46D, 47D, 48D, 49D, 50D or 51D are fitted to the following models: New Range Rover Discovery - North American Specification - 1996 MY Onwards Defender - North American Specification - 1997 MY Onwards Defender V8i Automatic Publication Part No. LRL 0004ENG - 3rd Edition Published by Rover Technical Communication 1998 Rover Group Limited INTRODUCTION CONTENTS Page INFORMATION INTRODUCTION...................................................................................................... 1 REPAIRS AND REPLACEMENTS........................................................................... 2 SPECIFICATION...................................................................................................... 2 INTRODUCTION INTRODUCTION References How to use this Manual With the engine and gearbox assembly removed, the crankshaft pulley end of the engine is referred to To assist in the use of this Manual the section title is as the front. References to RH and LH banks of given at the top and the relevant sub-section is given cylinders are taken viewing from the flywheel end of at the bottom of each page. the engine. This manual contains procedures for overhaul of the Operations covered in this Manual do not include V8 engine on the bench with the gearbox, clutch, reference to testing the vehicle after repair. It is inlet manifold, exhaust manifolds, coolant pump, essential that work is inspected and tested after starter motor, alternator, and all other ancillary -

Service Manual

•^ Service Manual Section 2 (21) Reconditioning engine Repairs B 27, B 28 and maintenance 260 1975-1983 *# books4cars.com 4850 37th Avenue South Seattle, WA 98118 U.SA B27A-B27E-B27F-B28A-B28E-B28F 1 What do these designations mean? B28E A = carburetted engine E = fuel injected engine F = fuel injected engine "USA models" 1 28(27) = ce pacity • B = petrol (g«jsoline ) Engine type Model year B27A 1976-1979 B28A 1980-1982 B27E 1975-1980 The B 28 is in principle a B 27 with a larger bore. B28E 1981-1983 B27F 1976-1979 B28F 1980-1982 Volvos are sold in versions adapted for different markets. These adaptions depend on many factors including legal, taxation and market requirements. This manual may therefore show illustrations and text which do not apply to cars in your country. Group 21 Reconditioning engine Contents Contents Page Important information ... 2 Specifications ... 2 Special tools .. 11 Operation Thread repairs A 1-14 14 Reconditioning engine Disassembly B 1-19 20 r Cleaning and inspection C 1-41 26 Assembly D 1-35 38 Cylinder head, reconditioning E 1-26 46 Assembly (cont.) F 1-33 52 Index page 62 This manual deals exclusively with the overhaul of the engine. r For work carried out on the engine when fitted in the car, and for engine removal and installation, please refer to the separate manuals. r Order number: TP 30447/1 We reserve the right to make alterations. Group 21 Reconditioning engine Important information Important information Tightening torques Nearly all of the B 27/28 engine is made of aluminium alloy. -

Gudgeon Pin Locations \

i-. ,. I “* -.. ,, * o prevent damage to cylinder walls, the gudgeon pins of T an engine must be located Gudgeon against axial movement or pro- vided with soft end wads to avoid unprotected contact-which, in the \ case of a mishap, produces score marks or grooves resulting in loss Pin of compression and power, to rectify which either reboring or sleeving is necessary. Depending on the constructor’s ideas and what may be most con- Locations venient, a gudgeon pin can be fixed in the piston with the small end of the connecting rod forming the bearing; or the pin can be fully By GEOMETER floating with bearings in both con- necting iod and piston; or again, it can be fixed in the connecting rod tab-type locking washer. This type with bearings formed in the piston of gudgeon pin must always be below bosses. the side of the piston, when, for A tied-in-the-piston gudgeon pin testing, the latter is oscillated by hand is generally located by a screw, as at on the pin and pushed side to side A (left) and may be used on industrial for the bosses to abut to the con- engines and models. One boss of the necting rod. piston is drilled and tapped, and An arrangement where a gudgeon the gudgeon pin drilled to accept the pin is located one way and protected parallel turned end of the screw. In the other is as at D. The piston bosses the larger sizes of application, the are of different sizes and the pin , screw head can be drilled for a split stepped to suit, the larger end carrying pin, which prevents unscrewing by an end wad. -

Design and Manufacturing of Gudgeon Pin: a Review Paper Miss Kranti Kharade ,Miss Rucha Kamble ,Miss Deepali Veer,Miss Nandini Maher Prof.R.G.Maske

© 2019 JETIR April 2019, Volume 6, Issue 4 www.jetir.org (ISSN-2349-5162) Design and manufacturing of gudgeon pin: A Review Paper Miss Kranti Kharade ,Miss Rucha Kamble ,Miss Deepali Veer,Miss Nandini Maher Prof.R.G.Maske ‘student mechanical engineering ,SKNCOE,PUNE “Professor ,Mechanical engineering, SKNCOE,PUNE Vadagaon budruk,pune 411041 Abstract- Premature wear of the Gudgeon pin is the major concern for the company Gudgeon pin connects the piston and the small end of the connecting rod of IC engines. This paper deals with Stress analysis and Fatigue analysis of Gudgeon pin used in diesel engine. In stress analysis frictional stresses and Von-Misses stresses coming on Pin are determined using finite element analysis tool ANSYS 16. Effect of different factors on frictional stresses and Von-Misses stresses such as change in internal diameter of pin and application of diamond-like carbon (DLC) coating are analyzed. In Fatigue analysis, fatigue life of Pin is determined using fatigue analysis tool FEMFAT 5.0 b. Effect of change in surface roughness of connecting rod small end bush and change in internal diameter of pin on fatigue life is analyzed. Keywords- Gudgeon pin,various stresses,ANSYS and CATIA V5 INTRODUCTION Excessive premature wear of the Gudgeon pins initiated this FEA investigation. The purpose was to develop a design variation that would remove this failure mode. Piston pin or Gudgeon pin or wrist pin connects the piston and the small end of the connecting rod of IC engines. Gudgeon pin is generally hollow and made from case hardening steel heat treated to produce a hard ware resisting surface. -

The Engines in This Book Are Those Made After Such Wonderful Pieces of Equipment

How to be an Engine Expert on MGs MG Engines from 1935 to 1998 Neil Cairns Engines for M.G.s Their Story after 1935 by Neil Cairns Copyright Neil Cairns • December1997 Edition 2 • ammended 26.09.98 1 Covering the XPAG series BMC ‘A’ Series BMC ‘B’ Series With their relative units such as the Twin Cam, BMC ‘C’ series, Rover V8, some early Morris units, the ‘O’, ‘R’, ‘S’ and ‘K’ series till 1998 A study of engines fitted to MG cars from 1935 to 1998 The cover Photo is that of a K1 Magnette, using a derivate of the Wolsley Hornet Engine. The engines in this book are those made after such wonderful pieces of equipment. 2 M.G. Engines 1935–1998 Of all the engines M.G. used, perhaps the most romantic is the XPAG shown below, as it powered the majority of the ‘T’ type Midgets, on their spindly wheels with flowing wings. The version below is the unit destined for the M.G. ‘One and a Quarter Litre’ saloon of 1947, the huge air silencer above the engine and its single SU H2 carburettor being identifying signs, with its early oil filter. 3 Contents Introduction . 5 An Engine . 7 Chapter One, M.G. Engines Care of Morris . 8 Chapter Two, The TA Onwards . 12 Chapter Three, ‘X’ Series of Engines. 25 Chapter Four, XPAG State of the Art . 46 Chapter Five, BMC ‘A’ Series & Triumph . 56 Chapter Six, BMC ‘B’ Series . 84 Chapter Seven, Big ‘B’ Series . 112 Chapter Eight, ‘C’, & ‘K’ series, & Rover V8’s . -

GLOBAL JOURNAL of ENGINEERING SCIENCE and RESEARCHES a REVIEW PAPER on EVALUATION of OPTIMUM DESIGN PARAMETER for CONNECTING ROD USING FEA Savita S.Shinde1, Prof

[Shinde, TECHNOPHILIA: February 2016] ISSN 2348 – 8034 Impact Factor- 3.155 GLOBAL JOURNAL OF ENGINEERING SCIENCE AND RESEARCHES A REVIEW PAPER ON EVALUATION OF OPTIMUM DESIGN PARAMETER FOR CONNECTING ROD USING FEA Savita S.Shinde1, Prof. Hredeya Mishra2 *1PG Student, Department of Mechanical Engineering, Jaihind College of Engineering, Kuran, Pune- 410511 2Assistant Professor, Department of Mechanical Engineering, Jaihind College of Engineering, Kuran, Pune-410511 ABSTRACT The automobile engine connecting rod is highly volume production and critical component. It connects to rotating crankshaft to reciprocating piston. It transmits the thrust of the piston to the crankshaft. Every vehicle that uses internal combustion engine which requires one connecting rod depending upon the number of cylinders in the engine. Connecting rod is automobile application are typically manufactured by either from wrought steel or powdered metal. Keywords: connecting rod- I-section, rectangular section I. INTRODUCTION Connecting rod is a component of internal combustion engine and it is classified under function of machine. It is used to in between piston and crank shaft. The main function of connecting rod is to transmit the reciprocating motion of piston to rotational motion of crank shaft. The functions of the connecting rod also transmit the thrust of the piston to the crankshaft. Connecting rod has three main zones. The piston pin end, the centre shank and the big end. The piston pin end is called the small end, the crank end is the big end and the centre shank is of I-cross section/Rectangular section. Connecting rod is a pin jointed in which more weight is concentrated towards the big end.