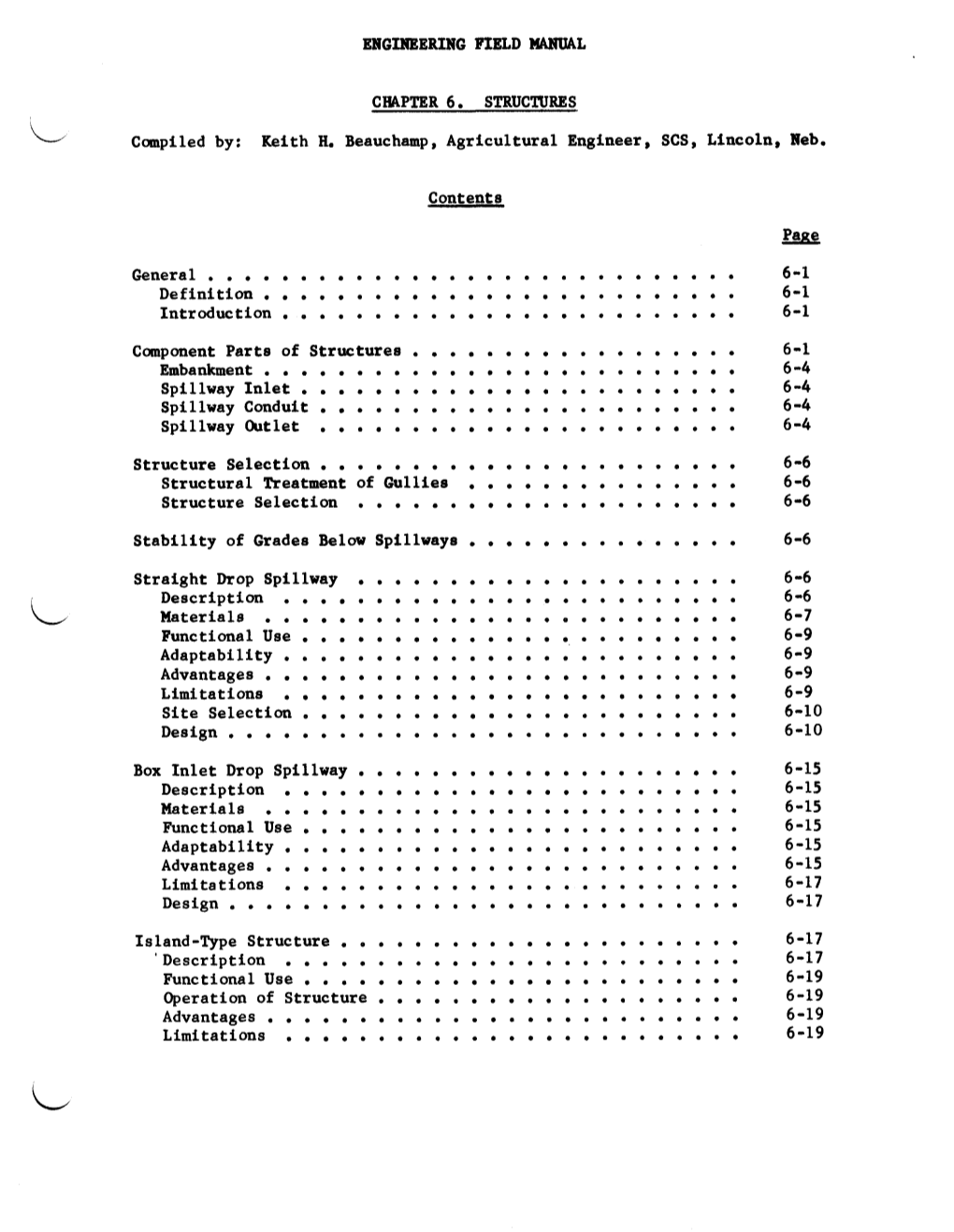

STRUCTURES Compiled By: Keith H

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Environmental Screening Of

Coachella Valley Stormwater Channel Improvement Project, Avenue 54 to Thermal Drop Structure Draft Environmental Impact Report / State Clearinghouse No. 2015111067 Appendices APPENDIX C Coachella Valley Stormwater Channel Improvement Project, Phase I Biological Resources Assessment & Coachella Valley Multiple Species Habitat Conservation Plan Compliance Report City of Coachella and Unincorporated Community of Thermal Submitted to: Terra Nova Planning & Research, Inc. 42635 Melanie Place, Suite 101 Palm Desert, CA 92211 Submitted by: Amec Foster Wheeler, Environment & Infrastructure, Inc. 3120 Chicago Avenue, Suite 110 Riverside, CA 92507 3 February 2016 Coachella Valley Water District C-1 Coachella Valley Stormwater Channel Improvement Project, Phase I Biological Resources Assessment & Coachella Valley Multiple Species Habitat Conservation Plan Compliance Report City of Coachella and Unincorporated Community of Thermal Riverside County, California Submitted to: Terra Nova Planning and Research, Inc. 42635 Melanie Place, Suite 101 Palm Desert, CA 92211 Contact: John Criste (760) 341-4800 [email protected] Submitted by: Amec Foster Wheeler, Environment & Infrastructure, Inc. 3120 Chicago Avenue, Suite 110 Riverside, CA 92507 Contact: John F. Green Senior Biologist (951) 369-8060 [email protected] 3 February 2016 Coachella Valley Stormwater Channel Improvement Project, Phase I Biological Resources Assessment & MSHCP Compliance Report February 2016 EXECUTIVE SUMMARY For the purposes of this assessment, analysis of the proposed Coachella Valley Stormwater Channel (CVSC) Improvement Project, Phase I (project) could include the following: Extension of existing and construction of new concrete-lined channel/levee banks, a fully concrete-lined channel from Airport Boulevard to the Thermal Drop Structure near Avenue 58, and construction of a bypass channel or combinations thereto. -

Chapter 10 Open Channels

Chapter 10 Open Channels Chapter 10 Open Channels Table of Contents 10-1 Introduction ...................................................................................................................................... 1 10-1-1 Chapter Overview ............................................................................................................. 1 10-1-2 Design Flows .................................................................................................................... 1 10-1-3 Channel Types .................................................................................................................. 2 10-1-4 Sediment Loads ................................................................................................................ 5 10-1-5 Permitting and Regulations ............................................................................................... 6 10-2 Natural Stream Corridors ............................................................................................................... 7 10-2-1 Functions and Benefits of Natural Streams ...................................................................... 8 10-2-2 Effects of Urbanization ..................................................................................................... 9 10-2-3 Preserving Natural Stream Corridors .............................................................................. 11 10-3 Stream Restoration Principles ..................................................................................................... -

Drainage and Erosion Control Design Manual

City of West Lake Hills Drainage and Erosion Control Design Manual May 2020 TABLE OF CONTENTS Chapter 1 Introduction ....................................................................................................... 1 1.1 Purpose and Scope ....................................................................................................... 1 1.2 Applicability .................................................................................................................... 1 1.3 Waivers ............................................................................................................................ 1 1.4 Amending the Manual .................................................................................................. 1 1.5 References and Definition of Terms ............................................................................ 1 Chapter 2 Drainage Criteria .............................................................................................. 3 2.1 Permit Submittal Components ..................................................................................... 3 2.1.1 Preliminary Drainage Plan ......................................................................................... 3 2.1.2 Type I Development Submittal ................................................................................. 4 2.1.3 Type II Development Submittal ................................................................................ 4 2.1.4 Type III Development Submittal .............................................................................. -

CHAPTER-6 Cross-Drainage and Drop Structures 6.1 Aqueducts and Canal Inlets and Outlets 6.1.1 Introduction

Cross-Drainage and Drop Structures CHAPTER-6 Cross-Drainage and Drop Structures 6.1 Aqueducts and canal inlets and outlets 6.1.1 Introduction The alignment of a canal invariably meets a number of natural streams (drains) and other structures such as roads and railways, and may sometimes have to cross valleys. Cross drainage works are the structures which make such crossings possible. They are generally very costly, and should be avoided if possible by changing the canal alignment and/or by diverting the drains. 6.1.2 Aqueducts An aqueduct is a cross-drainage structure constructed where the drainage flood level is below the bed of the canal. Small drains may be taken under the canal and banks by a concrete or masonry barrel (culvert), whereas in the case of stream crossings it may be economical to flume the canal over the stream (e.g. using a concrete trough, Fig. 6.1(a)). When both canal and drain meet more or less at the same level the drain may be passed through an inverted siphon aqueduct (Fig. 6.1(d)) underneath the canal; the flow through the aqueduct here is always under pressure. If the drainage discharge is heavily silt laden a silt ejector should be provided at the upstream end of the siphon aqueduct; a trash rack is also essential if the stream carries floating debris which may otherwise choke the entrance to the aqueduct. 6.1.3 Superpassage In this type of cross-drainage work, the natural drain runs above the canal, the canal under the drain always having a free surface flow. -

Lower Long Tom River Haibtat Improvement Project

Lower Long Tom River Habitat Improvement Plan 2018 Developed by: Confluence Consulting, LLC and Long Tom Watershed Council Lower Long Tom River Habitat Improvement Plan January 2018 1 | P a g e Table of Contents Executive Summary ............................................................................................................................................................................... 4 Introduction............................................................................................................................................................................................ 6 Study Goals and Opportunities ...................................................................................................................................................... 7 Stakeholders and Contributors ....................................................................................................................................................... 7 Background on the Lower Long Tom River .................................................................................................................................... 9 Long Tom Fisheries ............................................................................................................................................................................ 11 Fishery Background (excerpted from the US Army Corps of Engineers report “Long Term on the Long Tom,” February 2014) ............................................................................................................................................................................... -

1 Isaac River Condition, Condition Trajectory and Management

Memo Subject Response to information request from DEHP From Rohan Lucas Distribution BMA Date 12 February 2016 Project Broadmeadow EA amendment – Watercourse Subsidence 1 Isaac River condition, condition trajectory and management 1.1 Request The administering authority requires more information relating to the proactive management strategies that BMA will adopt to ensure the condition trajectory of the diversion is not negatively impacted by subsidence. 1.2 Response Understanding the incremental risk posed by subsidence The Isaac River diversion, constructed in the mid 1980’s was undertaken to a different standard to that which would be adopted today. The diversion underwent major erosional adjustment in the 1980’s and 1990’s (see Figure 2). Following some management intervention in the mid-late 1990’s (including timber pile fields) and a period without any major flow events from 1991 to 2007 (refer to Figure 1), the diversion underwent substantial recovery. This recovery included the deposition of benches against toe of bank and colonisation of those benches with riparian vegetation, providing a near continuous coverage along the diversion. These vegetated benches protect the near vertical, erodible upper banks from erosion in the majority of flow events (refer Figure 3). The diversion, which reduced river length by several kilometres, was constructed with two drop structures to compensate for the increase in gradient. One of these structures is now largely redundant and the other has been subject to damage from flow events and repair on numerous occasions. The remaining functional structure performs its design intent during smaller flows but is ineffective in larger flows in reducing energy conditions sufficiently. -

SEEDS) Sustainability Program Student Research Report

UBC Social Ecological Economic Development Studies (SEEDS) Sustainability Program Student Research Report Replacement of the Spiral Drain at the North End of UBC Campus Mona Dahir, Jas Gill, Danny Hsieh, Rachel Jackson, Michael Louws, Chris Vibe University of British Columbia CIVL 446 April 7th, 2017 Disclaimer: “UBC SEEDS Sustainability Program provides students with the opportunity to share the findings of their studies, as well as their opinions, conclusions and recommendations with the UBC community. The reader should bear in mind that this is a student research project/report and is not an official document of UBC. Furthermore, readers should bear in mind that these reports may not reflect the current status of activities at UBC. We urge you to contact the research persons mentioned in a report or the SEEDS Sustainability Program representative about the current status of the subject matter of a project/report”. UBC NORTH CAMPUS SPIRAL DRAIN REPLACEMENT Final Design Report PREPARED FOR: Client Representative: Mr. Doug Doyle, P.Eng Associate Director, Infrastructure and Planning Client: UBC Social Ecological Economic Development Studies (SEEDS) Project Team 24: Rachel Jackson Danny Hsieh Mona Dahir Michael Louws Jasninder Gill Chris Vibe April 7th, 2017 Executive Summary Vortex Consulting has prepared a detailed design report, as requested by UBC Social, Ecological, Economic Development Studies (SEEDS), for the replacement of UBC's current North Campus Stormwater Management facility, the spiral drain. This report intends to provide UBC SEEDS with an understanding of the design components, technical analysis and design, and project costs and construction sequencing, that are required to mitigate a 1 in 200 year storm event. -

Drop Structures

DROP STRUCTURES 1 DESCRIPTION OF TECHNIQUE Drop structures (also known as grade controls, sills, or weirs) are low-elevation structures that span the entire width of the channel, creating an abrupt drop in channel bed and water surface elevation in a downstream direction. Drop structures have been used extensively in Washington State to stabilize channel grades, improve fish passage, and to reduce erosion. Generally speaking, in fish bearing waters, vertical drops must not exceed 1 foot [WAC 220-110-070]; lesser drops are often required to accommodate certain species and age classes of fish. Drop Structures are designed to spill and direct flow such that there is a distinct drop in water surface elevation at normal low flows. The purpose of drop structures may include but is not limited to: • redistribute or dissipate energy; • stabilize the channel bed; • restore a step pool morphology to an altered channel • limit channel incision; • limit bank erosion by directing flow away from an eroding bank; • modify the channel bed profile and form by promoting collection, sorting and deposition of sediment; • create structural and hydraulic diversity in uniform channels; • improve fish passage over natural and artificial barriers by backwatering the upstream reach; • scour the channel bed, creating holding pools for fish and other aquatic life; • provide backwater (depth) in groundwater fed side channels; or • raise the bed of an incised stream to reconnect it with its floodplain. Drop structures may resemble porous weirs in appearance. But while drop structures direct water over the structure and are applied primarily to modify the profile of a channel, porous weirs allow water to flow through the structure and are applied primarily to redirect or concentrate flow. -

Drainage Design Manual

THE CITY OF SAN DIEGO Transportation & Storm Water Design Manuals Drainage Design Manual January 2017 Edition The City of San Diego | Drainage Design Manual | January 2017 Edition DRAINAGE DESIGN MANUAL THIS PAGE INTENTIONALLY LEFT BLANK FOR DOUBLE-SIDED PRINTING The City of San Diego | Drainage Design Manual | January 2017 Edition CONTENT Contents Contents ............................................................................................................................................................... i Figures ............................................................................................................................................................... vii Tables .................................................................................................................................................................. ix Equations ............................................................................................................................................................. x 1. Introduction.............................................................................................................................................. 1-1 Policies ............................................................................................................................................... 1-1 Basic Objectives ......................................................................................................................... 1-2 Exceptions to Design Standards ............................................................................................. -

Whitewater Park Toolkit

WHITEWATER PARK TOOLKIT A Paddler’s Guide to Championing a Local Project Every Project Needs a Local Champion Nationally, there are more than 1,000 rivers suitable for whitewater paddling, most of which are located off the beaten path and away from municipalities. Countless more, however, flow right through the heart of communities large and small. While many of these are not currently prone to paddling, with a little help they can be converted into destination whitewater play parks, becoming gathering places for their communities, enhancing the riparian zones, and even generating revenues for their towns. But it takes a champion and a little elbow grease. Most of today’s in-stream whitewater parks were the result of a paddler or group of paddlers that had a vision for a local park and the passion to get the ball rolling. Championing the development of a whitewater park for your community is not a simple process, nor is it the same from one community to the next. It takes tenacity, flexibility, and patience. Yet, armed with the right information and inspiration, you can be the spark that leads to a successful whitewater park in your community. The purpose of this Whitewater Park Toolkit is to serve as a guide for whitewater enthusiasts, anglers, and other community stakeholders to advocate for the development of a local in-stream whitewater park in their community. It provides a general understanding of the process, player, and costs involved in building a fun, safe, and environmentally S2O Design Whitewater Park Toolkit 01 CONTENTS 03 -

Site Visit and Conceptual Design Study Asheville Whitewater Park Asheville , N.C

Site Visit and Conceptual Design Study Asheville Whitewater Park Asheville , N.C. February 19, 2015 Prepared for: Ben Van Camp Asheville Parks and Greenway Foundation P.O. Box 2362 Asheville, NC, 28802 Prepared by: Scott Shipley, P.E. S2o Design and Engineering 318 McConnell Drive Lyons, CO, 80540 1 318 McConnell Drive | Lyons, CO | 80540 Contents Introduction: ................................................................................................................................................. 4 Section 1: Whitewater Parks ......................................................................................................................... 5 Whitewater Parks Defined ........................................................................................................................ 5 The Whitewater Design Process ............................................................................................................... 7 Design Factors for Whitewater Facilities: ................................................................................................. 8 Stability ................................................................................................................................................. 9 Costs .................................................................................................................................................... 10 Typical Economic Impacts of Whitewater Parks ..................................................................................... 10 Section 2: Site -

Floodplain Development in an Engineered Setting

EARTH SURFACE PROCESSES AND LANDFORMS Earth Surf. Process. Landforms 34, 291–304 (2009) Copyright © 2008 John Wiley & Sons, Ltd. Published online 9 December 2008 in Wiley InterScience (www.interscience.wiley.com) DOI: 10.1002/esp.1725 FloodplainJohnChichester,ESPEarthEARTHThe0197-93371096-9837Copyright20069999ESP1725Research Journal Wiley Surf.ScienceSurface SURFACE ArticleArticles ©Process. &UK of2006 Sons, Processes the PROCESSES JohnBritish Ltd.Landforms Wiley and Geomorphological Landforms AND & Sons, LANDFORMS Ltd. Research Group development in an engineered setting Floodplain development in an engineered setting Michael Bliss Singer1,2* and Rolf Aalto3,4 1 School of Geography and Geosciences, University of St Andrews, St Andrews, Fife, UK 2 Institute for Computational Earth System Science, University of California Santa Barbara, Santa Barbara, CA, USA 3 Department of Geography, Archaeology, and Earth Resources, University of Exeter, Exeter, UK 4 Department of Earth and Space Sciences, University of Washington, Seattle, WA, USA Received 25 February 2008; Revised 20 May 2008; Accepted 2 June 2008 * Correspondence to: Michael Bliss Singer, Institute for Computational Earth System Science, University of California Santa Barbara, Santa Barbara, CA, USA. E-mail: [email protected] ABSTRACT: Engineered flood bypasses, or simplified conveyance floodplains, are natural laboratories in which to observe floodplain development and therefore present an opportunity to assess delivery to and sedimentation within a specific class of floodplain. The effects of floods in the Sacramento River basin were investigated by analyzing hydrograph characteristics, estimating event-based sediment discharges and reach erosion/deposition through its bypass system and observing sedimentation patterns with field data. Sediment routing for a large, iconic flood suggests high rates of sedimentation in major bypasses, which is corroborated by data for one bypass area from sedimentation pads, floodplain cores and sediment removal reporting from a government agency.