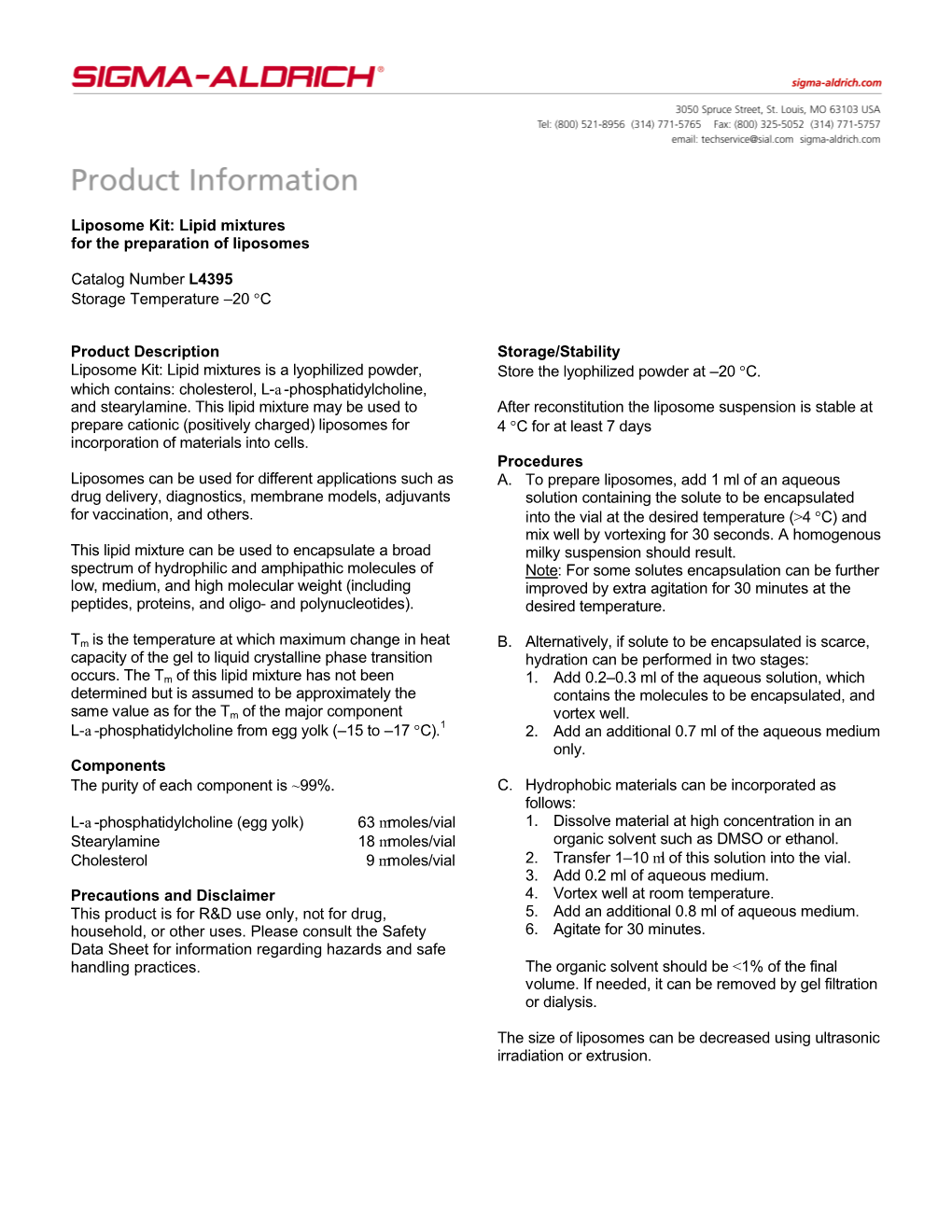

Liposome Kit: Lipid Mixtures (L4395)

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Using Rheology Measurement As a Potentially Predictive Tool for Solder Paste Transfer Efficiency and Print Volume Consistency

USING RHEOLOGY MEASUREMENT AS A POTENTIALLY PREDICTIVE TOOL FOR SOLDER PASTE TRANSFER EFFICIENCY AND PRINT VOLUME CONSISTENCY Mitch Holtzer, Karen Tellefsen and Westin Bent Alpha Assembly Solutions South Plainfield, NJ, USA [email protected] ABSTRACT Commercially available solder pastes use an upper and Industry standards such as J-STD-005 and JIS Z 3284-1994 lower limit for viscosity. Generally, this viscosity is call for the use of viscosity measurement(s) as a quality measured at one shear rate, typically the shear associated assurance test method for solder paste. Almost all solder with a spiral viscometer rotating at 10 revolutions per paste produced and sold use a viscosity range at a single minute (RPM). If the powder contained in solder paste is shear rate as part of the pass fail criteria for shipment and dissolved by the acid activator in the solder paste flux, the customer acceptance respectively. viscosity of the solder paste will quickly increase. If the viscosity increases more than 20 to 30% above the upper As had been reported many times, an estimated 80% of the limit of the specification, poor printing results will be highly defects associated with the surface mount technology likely. The solder paste will not roll evenly over the stencil process involve defects created during the printing process. and apertures in the stencil will remain unfilled, causing Viscosity at a single shear rate could predict a fatal flaw in skips in the paste printing pattern. the printability of a solder paste sample. However, false positive single shear rate viscosity readings are not The purpose of the study was to determine if there is a unknown. -

Effect of Liposome Composition and Other Factors on the Targeting of Liposomes to Experimental Tumors: Biodistribution and Imaging Studies1

(CANCER RESEARCH SO.6371-6378. October I. 1990] Effect of Liposome Composition and Other Factors on the Targeting of Liposomes to Experimental Tumors: Biodistribution and Imaging Studies1 Alberto Gabizon,2 David C. Price, John Huberty, Robert S. Bresalier, and Demetrios Papahadjopoulos Cancer Research Institute ¡A.(j., I). P.] and Department of Radiology, [D. C. P., J. H.J, L'nirersity of California, San Francisco, California 9414}; (iastroinlestinal Research Laboratories, I eteram Administration Medical Center, and Department of Medicine, I 'nirersity of California, San Francisco, California 94121 [R. S. B.J; and Liposome Technology Inc., Mento Park, California 94025 ¡A.CiJ ABSTRACT temperature, cholesterol, and careful size control result in in hibition of RES uptake with concomitant enhancement of We have examined the distribution of radiolabeled liposomes in tumor- tumor uptake (5). bearing mice after i.v. injection. Two mouse tumors (B16 melanoma, In this report, we describe tissue distribution and imaging J6456 lymphoma) and a human tumor (LS174T colon carcinoma) inoc ulated i.m., S.C.,or in the hind footpad were used in these studies. When studies with transplantable mouse and human tumor models various liposome compositions with a mean vesicle diameter of ~ 100 nm using 3 different radiolabels of liposomes. The findings here were compared using a radiolabel of gallium-67-deferoxamine, optimal indicate that the concentration of liposome-encapsulated radio- tumor localization was obtained with liposomes containing a phosphati- labels in tumors is well above that of most other tissues and dylcholine of high phase-transition temperature and a small molar frac approximates the values obtained in the liver. -

Orally Inhaled & Nasal Drug Products

ORALLY INHALED & NASAL DRUG PRODUCTS: INNOVATIONS FROM MAJOR DELIVERY SYSTEM DEVELOPERS www.ondrugdelivery.com 00349_GF_OnDrugDelivery349_GF_OnDrugDelivery PulmonaryPulmonary NasalNasal NovemberNovember 2010.indd2010.indd 1 330/11/100/11/10 111:32:331:32:33 “Orally Inhaled & Nasal Drug Products: Innovations from Major Delivery CONTENTS System Developers” This edition is one in the ONdrugDelivery series of pub- Innovation in Drug Delivery by Inhalation lications from Frederick Furness Publishing. Each issue focuses on a specific topic within the field of drug deliv- Andrea Leone-Bay, Vice-President, Pharmaceutical ery, and is supported by industry leaders in that field. Development, Dr Robert Baughman, Vice-President, Clinical Pharmacology & Bioanalytics, Mr Chad EDITORIAL CALENDAR 2011: Smutney, Senior Director, Device Technology, February: Prefilled Syringes Mr Joseph Kocinsky, Senior Vice-President, March: Oral Drug Delivery & Advanced Excipients Pharmaceutical Technology Development April: Pulmonary & Nasal Drug Delivery (OINDP) MannKind Corporation 4-7 May: Injectable Drug Delivery (Devices Focus) June: Injectable Drug Delivery (Formulations Focus) Current Innovations in Dry Powder Inhalers September: Prefilled Syringes Richard Sitz, Technical Manager, DPI Technology October: Oral Drug Delivery Platform Leader November: Pulmonary & Nasal Drug Delivery (OINDP) 3M Drug Delivery Systems 10-12 December: Delivering Biologics (Proteins, Peptides & Nucleotides) Pulmonary Delivery & Dry-Powder Inhalers: SUBSCRIPTIONS: Advances in Hard-Capsule -

An Introduction to Fast Dissolving Oral Thin Film Drug Delivery Systems: a Review

Muthadi Radhika Reddy /J. Pharm. Sci. & Res. Vol. 12(7), 2020, 925-940 An Introduction to Fast Dissolving Oral Thin Film Drug Delivery Systems: A Review Muthadi Radhika Reddy1* 1School of pharmacy, Gurunanak Institute of Technical Campus, Hyderabad, Telangana, India and Department of Pharmacy, Gandhi Institute of Technology and Management University, Vizag, Andhra Pradesh, India INTRODUCTION 2. Useful in situations where rapid onset of action Fast dissolving drug delivery systems were first developed required such as in motion sickness, allergic attack, in the late 1970s as an alternative to conventional dosage coughing or asthma forms. These systems consist of solid dosage forms that 3. Has wide range of applications in pharmaceuticals, Rx disintegrate and dissolve quickly in the oral cavity without Prescriptions and OTC medications for treating pain, the need of water [1]. Fast dissolving drug delivery cough/cold, gastro-esophageal reflux disease,erectile systems include orally disintegrating tablets (ODTs) and dysfunction, sleep disorders, dietary supplements, etc oral thin films (OTFs). The Centre for Drug Evaluation [4] and Research (CDER) defines ODTs as,“a solid dosage 4. No water is required for the administration and hence form containing medicinal substances which disintegrates suitable during travelling rapidly, usually within a matter of seconds, when placed 5. Some drugs are absorbed from the mouth, pharynx upon the tongue” [2]. USFDA defines OTFs as, “a thin, and esophagus as the saliva passes down into the flexible, non-friable polymeric film strip containing one or stomach, enhancing bioavailability of drugs more dispersed active pharmaceutical ingredients which is 6. May offer improved bioavailability for poorly water intended to be placed on the tongue for rapid soluble drugs by offering large surface area as it disintegration or dissolution in the saliva prior to disintegrates and dissolves rapidly swallowing for delivery into the gastrointestinal tract” [3]. -

Liposome-Based Drug Delivery Systems in Cancer Immunotherapy

pharmaceutics Review Liposome-Based Drug Delivery Systems in Cancer Immunotherapy Zili Gu 1 , Candido G. Da Silva 1 , Koen van der Maaden 2,3, Ferry Ossendorp 2 and Luis J. Cruz 1,* 1 Department of Radiology, Leiden University Medical Center, Albinusdreef 2, 2333 ZA Leiden, The Netherlands 2 Tumor Immunology Group, Department of Immunology, Leiden University Medical Center, Albinusdreef 2, 2333 ZA Leiden, The Netherlands 3 TECOdevelopment GmbH, 53359 Rheinbach, Germany Received: 1 October 2020; Accepted: 2 November 2020; Published: 4 November 2020 Abstract: Cancer immunotherapy has shown remarkable progress in recent years. Nanocarriers, such as liposomes, have favorable advantages with the potential to further improve cancer immunotherapy and even stronger immune responses by improving cell type-specific delivery and enhancing drug efficacy. Liposomes can offer solutions to common problems faced by several cancer immunotherapies, including the following: (1) Vaccination: Liposomes can improve the delivery of antigens and other stimulatory molecules to antigen-presenting cells or T cells; (2) Tumor normalization: Liposomes can deliver drugs selectively to the tumor microenvironment to overcome the immune-suppressive state; (3) Rewiring of tumor signaling: Liposomes can be used for the delivery of specific drugs to specific cell types to correct or modulate pathways to facilitate better anti-tumor immune responses; (4) Combinational therapy: Liposomes are ideal vehicles for the simultaneous delivery of drugs to be combined with other therapies, including chemotherapy, radiotherapy, and phototherapy. In this review, different liposomal systems specifically developed for immunomodulation in cancer are summarized and discussed. Keywords: liposome; drug delivery; cancer immunotherapy; immunomodulation 1. The Potential of Immunotherapy for the Treatment of Cancer Cancer immunotherapy has been widely explored because of its durable and robust effects [1]. -

Mometasone Powder Rationale for Inclusion In

MOMETASONE POWDER RATIONALE FOR INCLUSION IN PA PROGRAM Background Mometasone is a corticosteroid demonstrating potent anti-inflammatory activity able to decrease inflammation through a mechanism of action that is not known. However, corticosteroids are thought to act by the induction of phospholipase A2, which leads to the inhibition of a common precursor for potent inflammatory mediators. Topical corticosteroids can be absorbed from normal intact skin. Inflammation and/or other disease processes in the skin increase percutaneous absorption (1). Mometasone is commercially available in the following dosage forms: topical cream, topical lotion, topical ointment, nasal spray and as a powder for inhalation. Regulatory Status FDA approved topical indication: Mometasone is a corticosteroid indicated for the relief of inflammatory and pruritic manifestations of corticosteroid-responsive dermatoses in patients 2 years of age and older (1). The safety and efficacy of mometasone have not been established in pediatric patients below 2 years of age (1). Summary Topical steroids have anti-inflammatory, antipruritic, and vasoconstrictive properties. Mometasone is FDA-approved for inflammatory and pruritic manifestations of corticosteroid- responsive dermatoses in patients 2 years of age and older. The safety and efficacy of mometasone have not been established in pediatric patients below 2 years of age (1). Mometasone is commercially available in the following dosage forms: topical cream, topical lotion, topical ointment, nasal spray and as powder for inhalation. Mometasone powder may be considered medically necessary in a topical formulation for patients 2 years of age or older for the treatment of inflammatory and pruritic manifestations of corticosteroid-responsive dermatoses. Mometasone powder may be considered investigational in a topical formulation for patients Mometasone Powder FEP Clinical Rationale MOMETASONE POWDER under the age of 2 years, or in patients without a diagnosis of inflammatory and pruritic manifestations of corticosteroid-responsive dermatoses. -

SODIUM POLYSTYRENE SULFONATE, USP Cation-Exchange Resin

Kayexalate® SODIUM POLYSTYRENE SULFONATE, USP Cation-Exchange Resin DESCRIPTION Kayexalate, brand of sodium polystyrene sulfonate is a benzene, diethenyl-polymer, with ethenylbenzene, sulfonated, sodium salt and has the following structural formula: The drug is a cream to light brown finely ground, powdered form of sodium polystyrene sulfonate, a cation-exchange resin prepared in the sodium phase with an in vitro exchange capacity of approximately 3.1 mEq (in vivo approximately 1 mEq) of potassium per gram. The sodium content is approximately 100 mg (4.1 mEq) per gram of the drug. It can be administered orally or in an enema. CLINICAL PHARMACOLOGY As the resin passes along the intestine or is retained in the colon after administration by enema, the sodium ions are partially released and are replaced by potassium ions. For the most part, this action occurs in the large intestine, which excretes potassium ions to a greater degree than does the small intestine. The efficiency of this process is limited and unpredictably variable. It commonly approximates the order of 33 percent but the range is so large that definitive indices of electrolyte balance must be clearly monitored. Metabolic data are unavailable. INDICATION AND USAGE Kayexalate is indicated for the treatment of hyperkalemia. CONTRAINDICATIONS Kayexalate is contraindicated in the following conditions: patients with hypokalemia, patients with a history of hypersensitivity to polystyrene sulfonate resins, obstructive bowel disease, neonates with reduced gut motility (postoperatively or drug induced) and oral administration in neonates (see PRECAUTIONS). WARNINGS Intestinal Necrosis: Cases of intestinal necrosis, which may be fatal, and other serious gastrointestinal adverse events (bleeding, ischemic colitis, perforation) have been reported in association with Kayexalate use. -

Direct-Write Fabrication of Pb(Nb,Zr,Ti)O3 Devices: Influence of Paste Rheology on Print Morphology and Component Properties

journal J. Am. Ceram. Soc., 84 [11] 2462–68 (2001) Direct-Write Fabrication of Pb(Nb,Zr,Ti)O3 Devices: Influence of Paste Rheology on Print Morphology and Component Properties Sherry L. Morissette*,† and Jennifer A. Lewis* Department of Materials Science and Engineering, University of Illinois, Urbana, Illinois 61801 Paul G. Clem,* Joseph Cesarano III,* and Duane B. Dimos* Sandia National Laboratories, Albuquerque, New Mexico 87185 Lead niobium zirconate titanate (PNZT) pastes with tailored required before deposition of additional layers, this direct-write rheological properties have been developed for direct-write approach yields significant advantages over the conventional fabrication of thick-film capacitor elements in highly inte- method for producing multilayer devices, such as those based on grated, multifunctional electroceramic devices. Such pastes lamination of tape-cast layers with screen-printed elements, in- exhibited pseudoplastic behavior with a low shear apparent cluding the ability to modify patterned designs on-line during .viscosity of roughly 1 ؋ 106 cP. On aging, the degree of shear printing and to incorporate multiple materials in individual layers thinning and the low shear apparent viscosity decreased. The rheological requirements of thick film pastes for micropen Pastes prepared from as-received powders attained printable, printing and screen printing are nearly identical.7–9,11–17 Hence, -steady-state viscosities of ϳ2 ؋ 105 cP after 50 days of aging. commercially available screen printing pastes (e.g., silver–palla In contrast, pastes prepared from dispersant-coated powders dium conductor, ruthenium oxide resistor, and dielectric pastes) showed no measurable rheological changes after 1 day of can be readily utilized in this direct-write approach. -

Entrapment of Citrus Limon Var. Pompia Essential Oil Or Pure Citral in Liposomes Tailored As Mouthwash for the Treatment of Oral Cavity Diseases

pharmaceuticals Article Entrapment of Citrus limon var. pompia Essential Oil or Pure Citral in Liposomes Tailored as Mouthwash for the Treatment of Oral Cavity Diseases 1, 1, 2 3 Lucia Palmas y , Matteo Aroffu y, Giacomo L. Petretto , Elvira Escribano-Ferrer , Octavio Díez-Sales 4, Iris Usach 4, José-Esteban Peris 2, Francesca Marongiu 1, Mansureh Ghavam 5, Sara Fais 6, Germano Orrù 6, Rita Abi Rached 7, Maria Letizia Manca 1,* and Maria Manconi 1 1 Department of Scienze della Vita e dell’Ambiente, Drug Science Division, University of Cagliari, 09124 Cagliari, Italy; [email protected] (L.P.); matteo.aroff[email protected] (M.A.); [email protected] (F.M.); [email protected] (M.M.) 2 Department of Chemistry and Pharmacy, University of Sassari, 07100 Sassari, Italy; [email protected] (G.L.P.); [email protected] (J.-E.P.) 3 Biopharmaceutics and Pharmacokinetics Unit, Institute for Nanoscience and Nanotechnology, University of Barcelona, 08193 Barcelona, Spain; [email protected] 4 Department of Pharmacy, Pharmaceutical Technology and Parasitology, University of Valencia, Burjassot, 46100 Valencia, Spain; [email protected] (O.D.-S.); [email protected] (I.U.) 5 Department of Range and Watershed Management, Faculty of Natural Resources and Earth Sciences, University of Kashan, Kashan 8731753153, Iran; [email protected] 6 Department of Surgical Science, University of Cagliari, Molecular Biology Service Lab (MBS), Via Ospedale 40, 09124 Cagliari, Italy; [email protected] (S.F.); [email protected] (G.O.) 7 Centre d’Analyses et de Recherche, Unité de Recherche TVA, Laboratoire CTA, Faculté des Sciences, Université Saint-Joseph, B.P. -

RECONSTITUTION, DOSING and ADMINISTRATION of VELCADE® (Bortezomib) 3.5 Mg Vial for Subcutaneous (SC) and Intravenous (IV) Use

Important information regarding RECONSTITUTION, DOSING AND ADMINISTRATION of VELCADE® (bortezomib) 3.5 mg vial for Subcutaneous (SC) and Intravenous (IV) use Prescribing Information can be found within this document Important information regarding RECONSTITUTION, DOSING AND ADMINISTRATION of VELCADE® (bortezomib) 3.5 mg vial for Subcutaneous (SC) and Intravenous (IV) use CORRECT RECONSTITUTION Avoiding the potential risk FOR SC AND IV ADMINISTRATION of administration errors VELCADE® (bortezomib) 3.5 mg powder for solution for injection In order to avoid dosing errors, caution is required when preparing ® is available for intravenous (IV) or subcutaneous (SC) administration. VELCADE as the volume required for reconstitution for the SC route is lower (1.4 ml) than that used for IV route (3.5 ml) giving a higher concentration of diluted drug (details are shown in tables 1 and 2). As the drug concentration after reconstitution differs between the Subcutaneous or Intravenous use only. SC and IV preparations, special care is required when calculating the Do not give by other routes. volume of reconstituted drug, which will be delivered to the patient Intrathecal administration has resulted in death. according to the prescribed dose. Please see pages 8-10 for examples of dosing for the different routes. VELCADE® must be reconstituted by a Health Care Professional. Aseptic technique must be strictly observed throughout the handling of VELCADE® since no preservative is present. 2 3 Important information regarding RECONSTITUTION, DOSING AND ADMINISTRATION of VELCADE® (bortezomib) 3.5 mg vial for Subcutaneous (SC) and Intravenous (IV) use SUBCUTANEOUS ROUTE OF The reconstituted solution should be clear and colourless. ADMINISTRATION The reconstituted solution must be inspected visually for particulate matter and discolouration prior to administration. -

In Vitro Release Test Methods for Drug Formulations for Parenteral Applications

dx.doi.org/10.14227/DT250418P8 Reprinted with permission. Copyright 2018. The United States Pharmacopeial Convention. All rights reserved. In Vitro Release Test Methods for Drug Formulations for Parenteral Applications Vivian Gray,a Susan Cady,b David Curran,c James DeMuth,d Okponanabofa Eradiri,e Munir Hussain,f Johannes Krämer,g John Shabushnig,h Erika Stippler,i,j a V. A. Gray Consulting, Inc, Hockessin, DE. b Boehringer Ingelheim Animal Health, North Brunswick, NJ. c GlaxoSmithKline R&D, King of Prussia, PA. d University of Wisconsin, Madison, WI. e Food and Drug Administration, Silver Spring, MD.—The views presented in this article do not necessarily reflect those of the FDA. No official support or endorsement by the Food and Drug Administration is intended or should be inferred. f Bristol-Myers Squibb Company, New Brunswick, NJ. (Retired). g PHAST, Homburg, Germany. h Insight Pharma Consulting, LLC, Marshall, MI. i United States Pharmacopeia, Rockville, MD. j Correspondence should be addressed to: Desmond G Hunt, Principal Scientific Liaison, US Pharmacopeial Convention, 12601 Twinbrook Parkway, Rockville, MD 20852-1790; tel: +1.301.816.8341; email: [email protected] ABSTRACT In vitro drug release testing for parenteral drug formulations could benefit from more regulatory guidance and compendial information as this testing is a part of current expectations for drug product approval. This Stimuli article discusses in vitro drug release methods for those parenteral drug formulations that are not solutions and explores the challenges involved in using these methods for each formulation type. INTRODUCTION particulate matter, sterility, bacterial endotoxins, water his Stimuli article is the work of some members of the content, aluminum content, and content uniformity. -

Standard Terms: Introduction and Guidance for Use – V.2.1.3 – 16 November 2018 Contents

Standard Terms Introduction and Guidance for Use Version 2.1.3 – 16 November 2018 GENERAL PRINCIPLES AND INSTRUCTIONS FOR USE OF THE LISTS OF STANDARD TERMS The lists of Standard Terms were initially drawn up by the European Pharmacopoeia (Ph. Eur.) Commission further to a request of the EU Commission, for use in marketing authorisation applications (MAAs), labelling (including the summary of product characteristics (SmPC)), and electronic communications. The first list was published as a special edition of Pharmeuropa in October 1996. The European Directorate for the Quality of Medicines & HealthCare (EDQM), a Directorate of the Council of Europe based in Strasbourg, France, is responsible for continuing this work. Standard Terms have the double purpose of bringing information to the patient/user/prescriber and distinguishing medicinal products having the same trade-name. Because of the labelling purposes it is imperative that any Standard Term is constructed with a view to the patient and the prescriber. It conveys essential information on the properties and uses of the particular medicinal products. To avoid a proliferation of over-complicated terms, complete information cannot always be included in a Standard Term, and should instead appear elsewhere in the labelling, in particular the package leaflet and SmPC. Since 2017 the scope of the Standard Terms database has also widened to allow the inclusion of certain additional terms that are not intended for use in MAAs, but are used for related purposes such as adverse event reporting (pharmacovigilance) and clinical trials. At the same time, in an effort to encourage greater global harmonisation of electronic communications, applications for terms to describe concepts that are not used in European Pharmacopoeia Commission member states but are used in other regions are also now accepted for consideration.