Fuel Efficiency and Performance

Total Page:16

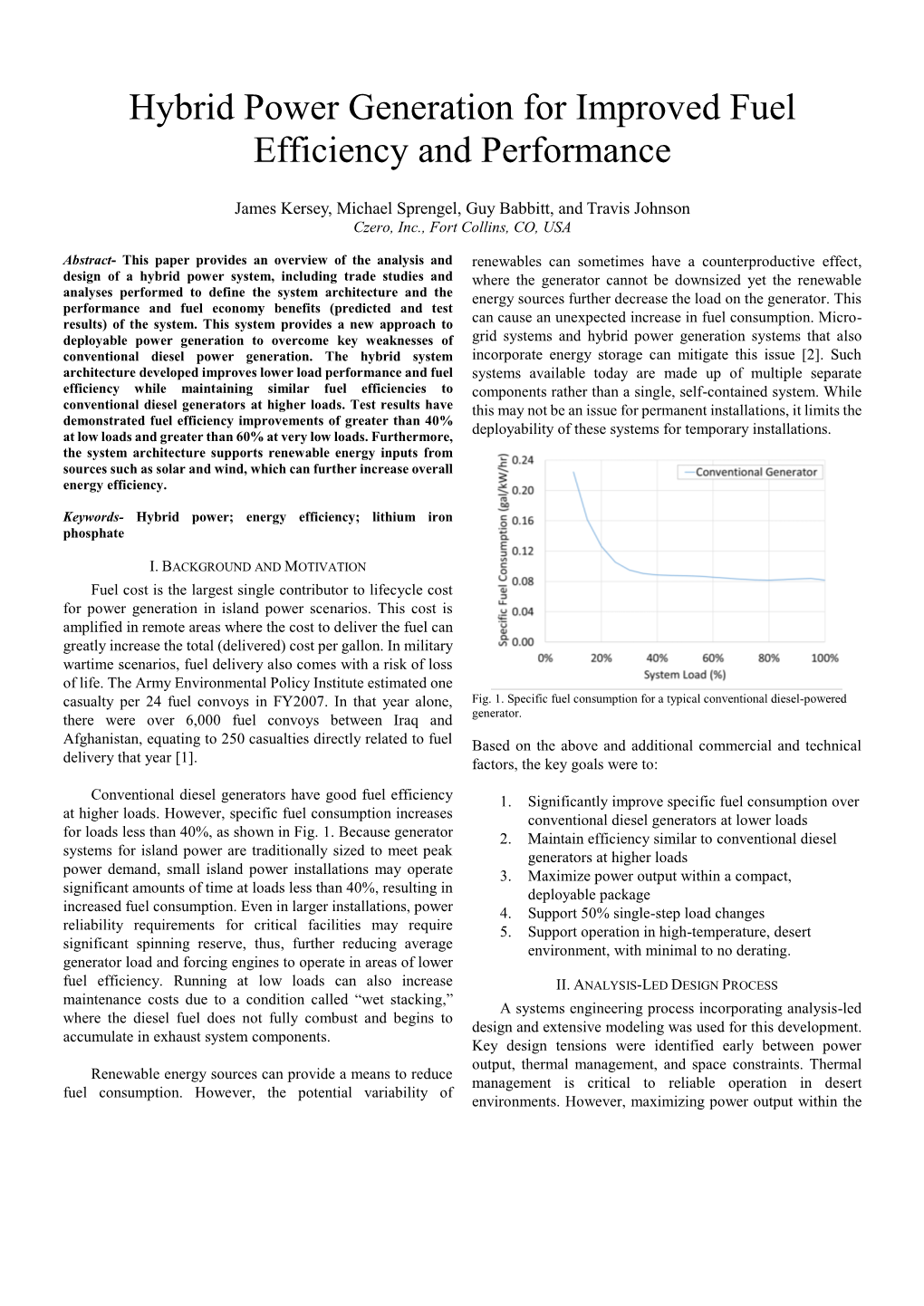

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Alternative Fuels, Vehicles & Technologies Feasibility

ALTERNATIVE FUELS, VEHICLES & TECHNOLOGIES FEASIBILITY REPORT Prepared by Eastern Pennsylvania Alliance for Clean Transportation (EP-ACT)With Technical Support provided by: Clean Fuels Ohio (CFO); & Pittsburgh Region Clean Cities (PRCC) Table of Contents Analysis Background: .................................................................................................................................... 3 1.0: Introduction – Fleet Feasibility Analysis: ............................................................................................... 3 2.0: Fleet Management Goals – Scope of Work & Criteria for Analysis: ...................................................... 4 Priority Review Criteria for Analysis: ........................................................................................................ 4 3.0: Key Performance Indicators – Existing Fleet Analysis ............................................................................ 5 4.0: Alternative Fuel Options – Summary Comparisons & Conclusions: ...................................................... 6 4.1: Detailed Propane Autogas Options Analysis: ......................................................................................... 7 Propane Station Estimate ......................................................................................................................... 8 (Station Capacity: 20,000 GGE/Year) ........................................................................................................ 8 5.0: Key Recommended Actions – Conclusion -

Using Biodiesel Fuel in Your Engine

RENEWABLE AND ALTERNATIVE ENERGY FACT SHEET Using Biodiesel Fuel in Your Engine Introduction Biodiesel is an engine fuel that is created by chemically reacting fatty acids and alcohol. Practically speaking, this usually means combining vegetable oil with methanol in the presence of a cata- lyst (usually sodium hydroxide). Biodiesel is much more suitable for use as an engine fuel than straight vegetable oil for a number of reasons, the most notable one being its lower viscosity. Many large and small producers have begun producing biodiesel, and the fuel can now be found in many parts of Pennsylvania and beyond either as “pure biodiesel” or a blended mixture with tradi- tional petroleum diesel (e.g., B5 is 5 percent biodiesel, 95 percent petroleum diesel). The process of making biodiesel is simple enough that farm- ers can consider producing biodiesel to meet their own needs by growing and harvesting an oil crop and converting it into biodiesel. In this way, farmers are able to “grow” their own fuel (see the Penn State Cooperative Extension publication Biodiesel Safety and Best Management Practices for Small-Scale Noncom- biodiesel fuel has less energy per unit volume than traditional mercial Production). There are many possible reasons to grow or diesel fuel. use biodiesel, including economics, support of local industry, and environmental considerations. • Fuel efficiency: fuel efficiency tends to be slightly lower when However, there is also a great deal of concern about the effect using biodiesel due to the lower energy content of the fuel. of biodiesel on engines. Many stories have been circulating about Typically, the drop-off is in the same range as the reduction in reduced performance, damage to key components, or even engine peak engine power (3–5 percent). -

DOE Transportation Strategy: Improve Internal Combustion Engine Efficiency

DOE Transportation Strategy: Improve Internal Combustion Engine Efficiency Gurpreet Singh, Team Leader Advanced Combustion Engine Technologies Vehicle Technologies Program U.S. Department of Energy Presented at the ARPA-E Distributed Generation Workshop Alexandria, VA June 2, 2011 Program Name or Ancillary Text eere.energy.gov Outline Current state of vehicle engine technology and performance trends (efficiency and emissions) over time Headroom to improve vehicle engine efficiency Future technical pathways and potential impact DOE’s current strategy and pathways eere.energy.gov Passenger Vehicle Fuel Economy Trends Significant fuel economy increases (in spite of increases in vehicle weight, size and performance) can be largely attributed to increase in internal combustion engine efficiency. Source: Light-Duty Automotive Technology, Carbon Dioxide Emissions, and Fuel Economy Trends: 1975 through 2010, EPA. eere.energy.gov Progress In Heavy-Duty Diesel Engine Efficiency and Emissions Historical progress in heavy-duty engine efficiency and the challenge of simultaneous emissions reduction, illustrate positive impact from DOE R&D support. (Adapted from DEER presentation, courtesy of Detroit Diesel Corporation). 20 Steady State 2.0 hr) - Test NOx + HC Particulate Matter 15 1.5 g/bhp NOx Transient Test (Unregulated) 90% NOx NO + HC 10 x 1.0 Oil savings from heavy-duty vehicles alone PM (Unregulated) 2002 (1997 – 2005) represent an over 35:1 return NOx on investment (ROI) of government funds for 5 0.5 heavy-duty combustion engine R&D. PM NOx + NMHC 90% Oxides ofOxides Nitrogen ( Urban Bus PM 0 0.0 Source: Retrospective Benefit-Cost Evaluation of U.S. DOE 1970 1975 1980 1985 1990 1995 2000 2005 2010 Vehicle Advanced Combustion Engine R&D Investments: Model Year 2007 Impacts of a Cluster of Energy Technologies, U.S. -

Vehicle Fuel Efficiency

Vehicle Fuel Efficiency Potential measures to encourage the uptake of more fuel efficient, low carbon emission vehicles Public Discussion Paper Prepared by Australian Transport Council (ATC) and Environment Protection and Heritage Council (EPHC) Vehicle Fuel Efficiency Working Group With support from The Australian Government September 2008 Closing date for comments: 7 November 2008 © Commonwealth of Australia 2008 This work is copyright. You may download, display, print and reproduce this material in unaltered form only (retaining this notice) for your personal, non-commercial use or use within your organisation. Apart from any use as permitted under the Copyright Act 1968, all other rights are reserved. Requests and inquiries concerning reproduction and rights should be addressed to Commonwealth Copyright Administration Attorney General’s Department Robert Garran Offices National Circuit Barton ACT 2600 or posted at http://www.ag.gov.au/cca Disclaimer The discussion paper has been prepared by the Australian Transport Council/Environment Protection & Heritage Council Vehicle Fuel Efficiency Working Group. The opinions, comments and analysis expressed in the discussion paper are for discussion purposes only and cannot be taken in any way as an expression of current or future policy of the Australian Government nor any state or territory government. The views and opinions expressed do not necessarily reflect those of the Australian Government or the Minister for the Environment, Heritage and the Arts, the Minister for Infrastructure, Transport, Regional Services and Local Government, or the Minister for Climate Change and Water. While reasonable efforts have been made to ensure that the contents of this publication are factually correct, the Commonwealth does not accept responsibility for the accuracy or completeness of the contents, and shall not be liable for any loss or damage that may be occasioned directly or indirectly through the use of, or reliance on, the contents of this publication. -

Air Quality Impacts of Biodiesel in the United States

WHITE PAPER MARCH 2021 AIR QUALITY IMPACTS OF BIODIESEL IN THE UNITED STATES Jane O’Malley, Stephanie Searle www.theicct.org [email protected] twitter @theicct BEIJING | BERLIN | SAN FRANCISCO | SÃO PAULO | WASHINGTON ACKNOWLEDGMENTS This study was generously funded by the David and Lucile Packard Foundation and the Norwegian Agency for Development Cooperation. International Council on Clean Transportation 1500 K Street NW, Suite 650, Washington, DC 20005 [email protected] | www.theicct.org | @TheICCT © 2021 International Council on Clean Transportation EXECUTIVE SUMMARY Since the passage of the Clean Air Act in 1970, the U.S. Environmental Protection Agency (EPA) has enacted standards to reduce vehicle exhaust emissions. These standards set emission limits for pollutants that contribute to poor air quality and associated health risks, including nitrous oxide (NOx), hydrocarbons (HC), carbon monoxide (CO), and particulate matter (PM). Although the majority of the on-road vehicle fleet in the United States is fueled by gasoline, diesel combustion makes up an overwhelming share of vehicle air pollution emissions. Air pollution emissions can be affected by blending biodiesel, composed of fatty acid methyl ester (FAME), into diesel fuel. Biodiesel increases the efficiency of fuel combustion due to its high oxygen content and high cetane number. Studies have found that biodiesel combustion results in lower emissions of PM, CO, and HC, likely for this reason. However, studies have consistently found that biodiesel blending increases NOx formation. Industry analysts, academic researchers, and government regulators have conducted extensive study on the emissions impacts of biodiesel blending over the last thirty years. The EPA concluded in a 2002 report that, on the whole, biodiesel combustion does not worsen air quality compared to conventional diesel and reaffirmed that conclusion in a 2020 proposal and subsequent rulemaking. -

Biodiesel Fleet Durability Study

Draft Final Report Biodiesel Fleet Durability Study Prepared for: Mr. Bob Okamoto California Air Resources Board 1001 "I" Street P.O. Box 2815 Sacramento, CA 95812 July 2010 Submitted by: Dr. Thomas D. Durbin Dr. J. Wayne Miller Ms. S. Michelle Jiang University of California CE-CERT Riverside, CA 92521 951-781-5791 951-781-5790 (fax) Disclaimer This report was prepared as an account of work sponsored by the California Air Resource Board. The statements and conclusions in this report are those of the contractor and not necessarily those of California Air Resources Board. The mention of commercial products, their source, or their use in connection with material reported herein is not to be construed as actual or implied endorsement of such products. Acknowledgments We acknowledge funding from the California Air Resources Board (CARB) under the grant No. G06-AF38. i Table of Contents Disclaimer i Acknowledgments i Table of Contents ii List of Tables iv Table of Figures v Abstract vi Acronyms and Abbreviations viii Executive Summary ix 1 Introduction 1 2 Biodiesel Use in Use in Compression Ignition Engines 3 2.1 Biodiesel Basics 3 2.1.1 What is Biodiesel? 3 2.1.2 Properties of Commercial #2 Diesel and Biodiesel Fuels 3 2.1.3 Biodiesel Fuel Standards 5 2.2 Engine and Fuel System with Biodiesel Use 7 2.2.1 Biodiesel Use in Compression Ignition Engines 7 2.2.2 Statement of the Diesel Fuel Injector Manufacturers 9 2.2.3 Warranties 9 2.2.4 Engine Performance 12 2.2.5 Biodiesel Solvency & Filter Plugging 12 2.2.6 Materials Compatibility 12 2.3 -

An Overview of Vehicle Sales and Fuel Consumption Through 2025

Tomorrow’s Vehicles An Overview of Vehicle Sales and Fuel Consumption Through 2025 Tomorrow’s Vehicles An Overview of Vehicle Sales and Fuel Consumption Through 2025 Executive Summary 2 Market Overview 4 Scope Methodology Findings 11 Gasoline and Ethanol Diesel and Biodeisel Electricity Hydrogen Natural Gas Propane Autogas Conclusion and Recommendations 19 About the Author 20 About the Fuels Institute 21 ©2017 Fuels Institute Disclaimer: The opinions and views expressed herein do not necessarily state or reflect those of the individuals on the Fuels Institute Board of Directors and the Fuels Institute Board of Advisors, or any contributing organization to the Fuels Institute. The Fuels Institute makes no warranty, express or implied, nor does it assume any legal liability or responsibility for the use of the report or any product, or process described in these materials. Tomorrow’s Vehicles: An Overview of Vehicle Sales and Fuel Consumption Through 2025 1 Executive Summary Low oil prices resulting from a sustained global oversupply are likely to rise, as production must eventually subside to balance demand. The balancing process will likely play out for some time as new vehicle fuel efficiency improvements and alternative fuel vehicles (AFVs) make advancements to road transportation, oil’s largest market, limiting price gains from production constraints. Though low oil prices place downward pressure on alter- native fuels and fuel-efficient vehicles, growth of particular technologies in various vehicle segments will not likely abate. Both governments and consumers in major light duty and commercial vehicle markets have shown particular interest in electricity and natural gas, and automakers are responding accordingly. -

Analysis of Design of Pure Ethanol Engines

View metadata, citation and similar papers at core.ac.uk brought to you by CORE provided by Federation ResearchOnline 2010-01-1453 ANALYSIS OF DESIGN OF PURE ETHANOL ENGINES Alberto Boretti University of Ballarat, Ballarat, Victoria, Australia Copyright © 2010 SAE International ABSTRACT Ethanol, unlike petroleum, is a renewable resource that can be produced from agricultural feed stocks. Ethanol fuel is widely used by flex-fuel light vehicles in Brazil and as oxygenate to gasoline in the United States. Ethanol can be blended with gasoline in varying quantities up to pure ethanol (E100), and most modern gasoline engines well operate with mixtures of 10% ethanol (E10). E100 consumption in an engine is higher than for gasoline since the energy per unit volume of ethanol is lower than for gasoline. The higher octane number of ethanol may possibly allow increased power output and better fuel economy of pure ethanol engines vs. flexi- fuel engines. High compression ratio ethanol only vehicles possibly will have fuel efficiency equal to or greater than current gasoline engines. The paper explores the impact some advanced technologies, namely downsizing, turbo charging, liquid charge cooling, high pressure direct injection, variable valve actuation may have on performance and emission of a pure ethanol engine. Results of simulations are described in details providing guidelines for development of new dedicated engines. INTRODUCTION Ethanol is an alternative fuel resulting in less greenhouse gas (GHG) emissions than gasoline [1]. The key environmental benefit of ethanol is that, unlike gasoline and diesel, its consumption does not significantly raise atmospheric levels of CO2. This is because the CO2 which is released during the burning of the fuel is counter- balanced by that which is removed from the environment by photosynthesis when growing crops and trees for ethanol production. -

HOW to UNDERSTAND ELECTRIC CAR FUEL EFFICIENCY and FUEL CONSUMPTION (Or, What the Heck Is Mpge)

HOW TO UNDERSTAND ELECTRIC CAR FUEL EFFICIENCY and FUEL CONSUMPTION (or, what the heck is MPGe). Solarponics Energy Solutions 4700 El Camino Real, Atascadero, CA 93422 (805) 466-5595 www.solarponics.com [email protected] Ask anyone what kind of gas mileage their car gets, and they will probably know right off the top of their head. We’re obsessed with the gas mileage of our cars, in large part because of the high cost of gasoline. Gas mileage performance ranks as a top decision when deciding to buy a new car. But how do we determine the fuel costs of an electric vehicle? How do we really know the cost comparison to drive an electric vehicle 100 miles, vs. driving a gasoline vehicle 100 miles? What does MPGe mean? How are the stickers calculating annual fuel cost? How do the manufacturers calculate my five-year fuel savings over a new gasoline vehicle? The first thing I should point out is that the window sticker of an EV makes several assumptions. First, that energy rates are 12¢ per kWh, that gasoline costs $4.00 per gallon, and that a new fuel efficient gasoline vehicle gets 22 miles per gallon. I’ll explain the window sticker using these assumptions, and then compare that to real-life values. The electric vehicle MPGe, or Miles Per Gallon equivalent, represents the number of miles the vehicle can travel using the same energy content as gasoline. My EV window sticker states an MPGe of 99. This is also the maximum distance this vehicle can travel on a full charge. -

Passenger Car Fuel-Efficiency, 2020–2025 Comparing Stringency and Technology Feasibility of the Chinese and US Standards

WORKING papER 2013-3 Passenger car fuel-efficiency, 2020–2025 Comparing stringency and technology feasibility of the Chinese and US standards AUTHOR: Hui He, Anup Bandivadekar DATE: August 2013 KEYWORDS: China, technology penetration, fuel-efficiency standards, technology cost-curves Top Chinese leaders are determined to ensure that A closer look at the standard stringency the domestic auto industry is world-class. Technology US and China upgrades were one of the top priorities in China’s auto industrial strategic plan for the upcoming decade1. The This section compares the standard stringency between plan proposes an average fuel consumption target of China, US in two ways: the absolute-term efficiency 5L/100km for new passenger cars by 2020, aiming targets and the annual improvement required to meet to accelerate technology advances for fuel efficiency. those targets. However, some concerns have been raised about the Corporate average fuel consumption standards for proposed 2020 target of 5 L/100km. These concerns passenger cars in China from were established in two include feasibility, future technology options, and costs of phases. The first phase of standard aims to achieve a meeting the proposed target. fleet-average target of 6.9 L/100km by 2015, while the second phase aims at 5L/100km by 2020. This paper summarizes technology pathways leading to compliance with the US 2020–2025 light-duty vehicle In August 2012, the US Environmental Protection Agency GHG and fuel economy standards and compares the (EPA) and the National Highway Transportation and standard stringency and recent technology trend Safety Administration (NHTSA) issued a joint final between US and China. -

Key Specifications the Mirai Is a Fuel Cell Vehicle (FCV) Which Uses

Outline of the Mirai The Mirai is a fuel cell vehicle (FCV) which uses hydrogen as energy to generate electricity and power the vehicle. Fuel cell system The hydrogen that powers the Mirai, hydrogen, can be produced from various types of primary sources, making it a promising alternative to current energy sources. The Toyota Fuel Cell System (TFCS) combines proprietary fuel cell technology that includes the Toyota FC Stack and high-pressure hydrogen tanks with the hybrid technology. The TFCS has high energy efficiency compared with conventional internal combustion engines, along with superior environmental performance highlighted by zero emissions of CO2 and other pollutants during vehicle operation. The hydrogen tanks can be refuelled in approximately three minutes *1, and with an ample cruising range, the system promises convenience on par with gasoline engine vehicles. The Mirai’s value The Mirai offers the kind of exceptional value drivers would expect from a next-generation car: distinctive exterior design, excellent acceleration performance and unmatched quietness thanks to motor propulsion at all speeds, in addition to enhanced driving pleasure due to a low center of gravity bringing greater handling stability. *1 Toyota measurement under SAEJ2601 standards (ambient temperature: 20 °C; hydrogen tank pressure when fueled: 10 MPa). Fueling time varies with hydrogen fueling pressure and ambient temperature. Key Specifications Height 1,535 mm Wheelbase 2,780 mm Width 1,815 mm Length 4,890 mm Driving performance Dimensions / seating -

Fuel Efficient Commute with Hybrid Cars

Fuel efficient commute with hybrid cars Owning a car is not a cheap affair, especially here in Singapore. Besides the initial payment for the car itself, there are recurring expenses that a car owner has to contend with – fuel, insurance, road tax, toll and parking. Out of these recurring expenses, fuel cost usually forms the largest proportion; and this is expected to grow as the global price of oil increases. It is due to high fuel cost that fuel efficient cars are a big draw to car buyers. Even a small increase in fuel efficiency can lead to large savings over the lifespan of the car. While saving car owners a considerable amount of money, a fuel efficient car also has the additional benefit of lower exhaust emissions, thus reducing the environmental impact of its use. To meet this demand, car makers around the Figure 1: Toyota Prius, a popular hybrid car world have introduced models that are able to go further with less fuel. Some of the most efficient models are the so-called ‘hybrid cars’, which combine conventional internal combustion engines and electric motors to significantly reduce their fuel consumption. Examples of hybrid cars available in the market today include Toyota Prius and Honda Civic Hybrid. What are hybrid cars? Hybrid cars merge the best features of today’s internal combustion engine cars and electric cars, which allows the electric motor and batteries to help the conventional engine operate more efficiently, cutting down on fuel use. Meanwhile, the combustion engine overcomes the limited range of an electric car, giving a hybrid car the ability to travel distances comparable to a conventional car without having to plug-in for recharging, and with much less fuel.