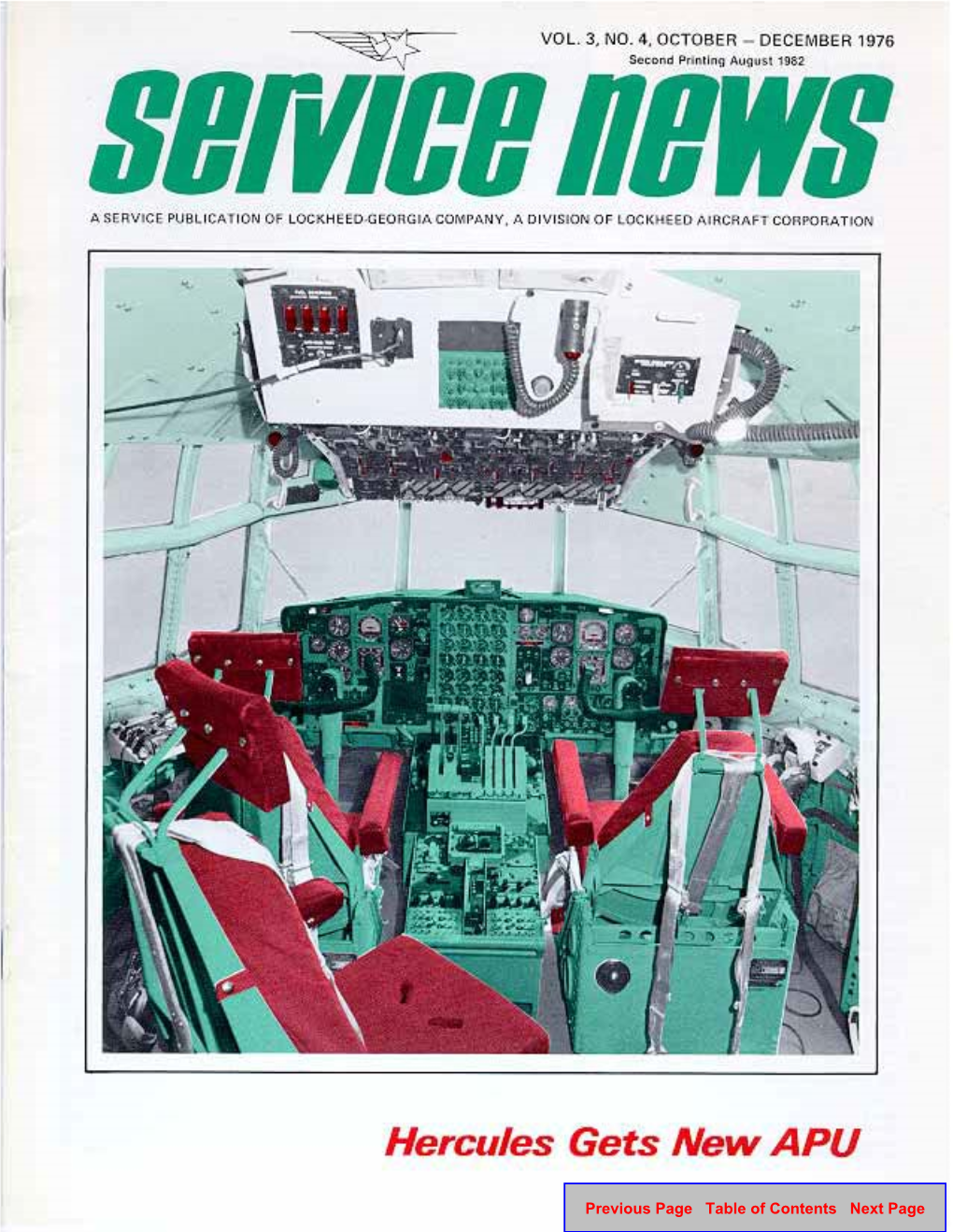

Hercules Gets New APU Vol

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Cranfield University Xue Longxian Actuation

CRANFIELD UNIVERSITY XUE LONGXIAN ACTUATION TECHNOLOGY FOR FLIGHT CONTROL SYSTEM ON CIVIL AIRCRAFT SCHOOL OF ENGINEERING MSc by Research THESIS CRANFIELD UNIVERSITY SCHOOL OF ENGINEERING MSc by Research THESIS Academic Year 2008-2009 XUE LONGXIAN Actuation Technology for Flight Control System on Civil Aircraft Supervisor: Dr. C. P. Lawson Prof. J. P. Fielding January 2009 This thesis is submitted in fulfilment of the requirements for the degree of Master of Science © Cranfield University 2009. All rights reserved. No part of this publication may be reproduced without the written permission of the copyright owner. ABSTRACT This report addresses the author’s Group Design Project (GDP) and Individual Research Project (IRP). The IRP is discussed primarily herein, presenting the actuation technology for the Flight Control System (FCS) on civil aircraft. Actuation technology is one of the key technologies for next generation More Electric Aircraft (MEA) and All Electric Aircraft (AEA); it is also an important input for the preliminary design of the Flying Crane, the aircraft designed in the author’s GDP. Information regarding actuation technologies is investigated firstly. After initial comparison and engineering consideration, Electrohydrostatic Actuation (EHA) and variable area actuation are selected for further research. The tail unit of the Flying Crane is selected as the case study flight control surfaces and is analysed for the requirements. Based on these requirements, an EHA system and a variable area actuation system powered by localised hydraulic systems are designed and sized in terms of power, mass and Thermal Management System (TMS), and thereafter the reliability of each system is estimated and the safety is analysed. -

PROPULSION SYSTEM/FLIGHT CONTROL INTEGRATION for SUPERSONIC AIRCRAFT Paul J

PROPULSION SYSTEM/FLIGHT CONTROL INTEGRATION FOR SUPERSONIC AIRCRAFT Paul J. Reukauf and Frank W. Burcham , Jr. NASA Dryden Flight Research Center SUMMARY The NASA Dryden Flight Research Center is engaged in several programs to study digital integrated control systems. Such systems allow minimization of undesirable interactions while maximizing performance at all flight conditions. One such program is the YF-12 cooperative control program. In this program, the existing analog air-data computer, autothrottle, autopilot, and inlet control systems are to be converted to digital systems by using a general purpose airborne computer and interface unit. First, the existing control laws are to be programed and tested in flight. Then, integrated control laws, derived using accurate mathematical models of the airplane and propulsion system in conjunction with modern control techniques, are to be tested in flight. Analysis indicates that an integrated autothrottle-autopilot gives good flight path control and that observers can be used to replace failed sensors. INTRODUCTION Supersonic airplanes, such as the XB-70, YF-12, F-111, and F-15 airplanes, exhibit strong interactions between the engine and the inlet or between the propul- sion system and the airframe (refs. 1 and 2) . Taking advantage of possible favor- able interactions and eliminating or minimizing unfavorable interactions is a chal- lenging control problem with the potential for significant improvements in fuel consumption, range, and performance. In the past, engine, inlet, and flight control systems were usually developed separately, with a minimum of integration. It has often been possible to optimize the controls for a single design point, but off-design control performance usually suffered. -

GENERAL ENGINE BLEED Fokker 50

Fokker 50 - Bleed Air System GENERAL Bleed-air is used for airconditioning, pressurization, airframe and engine air intake de-icing, and for pressurizing the hydraulic tank. Bleed-air is supplied by the engines. For aircraft equipped with APU On the ground bleed-air can be supplied by the APU for air conditioning. ENGINE BLEED Tappings Bleed-air is obtained via tappings on each engine, referred to as Low-Pressure (LP) bleed and High-Pressure (HP) bleed. LP-bleed is normally in use during flight. HP-bleed will be used at idling and low engine speeds, when LP-bleed is insufficient. The HP-bleed valve will open automatically provided the BLEED push button, located at the AIR CONDITIONING panel, is blank. Bleed-air from the HP-Bleed is prevented from flowing into the LP-bleed by a check valve. Duct leak detection A duct leak between the engine tappings and the firewall, resulting in a significant leakage of bleed-air, is monitored by the engine fire detection and warning system. Distribution Bleed-air from both engines is used to supply the following services: • Airframe, and engine air intake de-icing, see ICE AND RAIN PROTECTION • Hydraulic tank pressurization, see HYDRAULIC SYSTEM. • Airconditioning and pressurization, see below. • If mentioned in aircraft system deviation table: Watertank pressurization, see AIRCRAFT GENERAL. Page 1 Fokker 50 - Bleed Air System BLEED AIR FOR AIRCONDITIONING Supply Controls and indicators are located at the AIRCONDITIONING panel. Bleed-air is available when the engines are running and the BLEED push buttons are blank. When a BLEED push button is depressed to OFF, the Pressure Regulating/Shut-Off valve (PR/SO) and the HP- bleed valve close. -

EWIS Practices Job Aid 2.0

Aircraft EWIS Practices Job Aid 2.0 Federal Aviation Administration Aircraft Electrical Wiring Interconnect System (EWIS) Best Practices Job Aid Revision: 2.0 This job aid covers applicable 14 CFR part 25 aircraft (although it is also widely acceptable for use with other types of aircraft such as military, small airplanes, and rotorcraft). This job aid addresses policy; industry EWIS practices; primary factors associated with EWIS degradation; information on TC/STC data package requirements; EWIS selection and protection; routing, splicing and termination practices; and EWIS maintenance concepts (including how to perform a EWIS general visual inspection). The job aid also includes numerous actual aircraft EWIS photos and examples. UNCONTROLLED COPY WHEN DOWNLOADED 1 Aircraft EWIS Practices Job Aid 2.0 Additional Notes • This presentation contains additional speaker notes for most slides • It’s advisable to read these notes while viewing the slide presentation Aircraft EWIS Best Practices Job Aid 2.0 Federal Aviation 2 Administration UNCONTROLLED COPY WHEN DOWNLOADED 2 Aircraft EWIS Practices Job Aid 2.0 Printing the Additional Notes To print the slides and accompanying speaker notes: – Navigate back to the FAA Aircraft Certification job aids web page – Open and print Printable Slides and Notes Aircraft EWIS Best Practices Job Aid 2.0 Federal Aviation 3 Administration UNCONTROLLED COPY WHEN DOWNLOADED 3 Aircraft EWIS Practices Job Aid 2.0 Background • Why the need for EWIS best practices Job Aid? – Accident/Incident Service History – Aging Transport Systems Rulemaking Advisory Committee (ATSRAC) – Enhanced Airworthiness Program for Airplane System (EAPAS) – EAPAS Rule Making Aircraft EWIS Best Practices Job Aid 2.0 Federal Aviation 4 Administration Historically, wiring and associated components were installed without much thought given to the aging aspects: • Fit and forget. -

Auxiliary Power Unit / Environmental Control Unit (APU/ECU) for the Multiple Launch Rocket System

Auxiliary Power Unit / Environmental Control Unit (APU/ECU) for the Multiple Launch Rocket System Multiple Launch Rocket System (MLRS) APU KEY FEATURES: − 8.5 kW 28 VDC Power Output − 18,500 BTU Net Cooling Capacity ECU Condenser GENERAL PRODUCT DESCRIPTION: The MLS Auxiliary Power Unit brushless, permanent magnet conditions. /Environmental Control Unit generator. The generator system (APU/ECU) has been designed to output and Engine power is The APU gross weight is under provide electrical power and controlled by a variable speed 330 pounds with the ECU cooling to the MLRS tracked governor which, depending on weighing 150 lbs. The System vehicle. Both systems can operate system load, optimizes the engine provides 18,500 Btu/hr cooling independently of one another. The operating speed. The vapor cycle capacity and 8.5 kW at 28-vDC ECU is completely electrically air conditioning system is power output (with voltage ripple driven and can be operated from designed to be in compliance with independent of the engine speed the main engine alternators or the the current environmental or load at less than 100 mV APU. regulations using R-134a RMS). refrigerant and is capable of The power plant is a Hatz 2G-40 operating in severe desert air-cooled diesel engine with a conditions. Its power draw is 150 shaft mounted three-phase amps at 28-vDC at full load APU/ECU FOR MILITARY APPLICATIONS Auxiliary Power Unit / Environmental Control Unit (APU/ECU) for the Multiple Launch Rocket System Condenser Assembly APU Evaporator Assembly Overall APU/ECU Specifications: Exterior Dimensions (L x W x H)........................................…........... -

Lockheed Martin F-35 Lightning II Incorporates Many Significant Technological Enhancements Derived from Predecessor Development Programs

AIAA AVIATION Forum 10.2514/6.2018-3368 June 25-29, 2018, Atlanta, Georgia 2018 Aviation Technology, Integration, and Operations Conference F-35 Air Vehicle Technology Overview Chris Wiegand,1 Bruce A. Bullick,2 Jeffrey A. Catt,3 Jeffrey W. Hamstra,4 Greg P. Walker,5 and Steve Wurth6 Lockheed Martin Aeronautics Company, Fort Worth, TX, 76109, United States of America The Lockheed Martin F-35 Lightning II incorporates many significant technological enhancements derived from predecessor development programs. The X-35 concept demonstrator program incorporated some that were deemed critical to establish the technical credibility and readiness to enter the System Development and Demonstration (SDD) program. Key among them were the elements of the F-35B short takeoff and vertical landing propulsion system using the revolutionary shaft-driven LiftFan® system. However, due to X- 35 schedule constraints and technical risks, the incorporation of some technologies was deferred to the SDD program. This paper provides insight into several of the key air vehicle and propulsion systems technologies selected for incorporation into the F-35. It describes the transition from several highly successful technology development projects to their incorporation into the production aircraft. I. Introduction HE F-35 Lightning II is a true 5th Generation trivariant, multiservice air system. It provides outstanding fighter T class aerodynamic performance, supersonic speed, all-aspect stealth with weapons, and highly integrated and networked avionics. The F-35 aircraft -

The Market for Aviation APU Engines

The Market for Aviation APU Engines Product Code #F644 A Special Focused Market Segment Analysis by: Aviation Gas Turbine Forecast Analysis 2 The Market for Aviation APU Engines 2011 - 2020 Table of Contents Executive Summary .................................................................................................................................................2 Introduction................................................................................................................................................................2 Methodology ..............................................................................................................................................................2 Trends..........................................................................................................................................................................3 The Competitive Environment...............................................................................................................................3 Market Statistics .......................................................................................................................................................3 Table 1 - The Market for Aviation APU Engines Unit Production by Headquarters/Company/Program 2011 - 2020 ..................................................5 Table 2 - The Market for Aviation APU Engines Value Statistics by Headquarters/Company/Program 2011 - 2020.................................................10 Figure 1 - The Market -

Wings Over the Bay NEW ZEALAND DIVISION Journal of the Bay of Plenty Branch of the NZ Division, Raes: 02-17 ______

Wings Over the Bay NEW ZEALAND DIVISION Journal of the Bay of Plenty Branch of the NZ Division, RAeS: 02-17 __________________________________________________________________________________________ Welcome to the newsletter for the Bay of was reflected in a graphic which noted composites Plenty Branch, NZ Division, RAeS for February at 50% and metal content down to 20% on leading 2017 edges, engine pylon mounts and elsewhere. Engine cowls too are made from composites. Meeting Recap The February meeting of the Bay of Plenty Branch was held at the clubrooms of the Tauranga Gliding Club on the north west of Tauranga airfield. This was the same venue we had used for the Branch meeting and BBQ last year which was a great place for the AGM and accompanying lecture this year, titled: B787 Operations. The lecture was delivered by Owen Bieleski who holds an ATPL with military transport experience with the RNZAF before embarking on a commercial The extensive use of electric-based systems has career with major airlines overseas. Recently, he almost entirely replaced bleed-air and a good returned home with his family to Tauranga from number of hydraulic-based services. Flight Dubai, where he had flown all six variants B777 controls, too, use fly-by-wire (FBW) with no with Emirates. manual back-up. Owen suggested with the extent of the changes to electrically-based systems, the B787 is sometimes called the ‘electric jet’. Owen explained the B787 is a very different design to its predecessors, with a heavy emphasis on electrical powered systems and multiple layers of automatically managed redundancy. Pilots are alerted to most failures via the EICAS (Engine Indicating and Crew Alerting System) as a Warning, Owen Bieleski showing an RNZAF F27 – Friendship at the start of his Caution or Advisory. -

Analytical Design and Estimation of Conventional and Electrical Aircraft Environmental Control Systems

Analytical Design and Estimation of Conventional and Electrical Aircraft Environmental Control Systems Hemanth Devadurgam , Soorya Rajagopal , Raghu Chaitanya Munjulury Division of Fluid and Mechatronic Systems, Department of Management and Engineering, Linköping University, Linköping, Sweden - 58183 Symbol Description Units ABSTRACT A Area m2 Environmental control system holds vital importance P Perimeter m as it is responsible for passenger’s ventilation and T Temperature degree C kg comfort. This paper presents an analytical design of k Thermal Conductiv- mK environmental control systems and represents the esti- ity mated design in three-dimensional. Knowledge-based K Kelvin K engineering application serves as the base for design- D Hydraulic Diameter m ing and methodology for the environmental control kg m Mass flow rate s systems. Flexibility in the model enables the user p Pressure Pa to control the size and positioning of the system and kg m Dynamics viscosity ms also sub-systems associated with it. The number of passengers serves as the driving input and three- dimensional model gives the exact representation with 1 Introduction respect to the volume occupied and dependencies on The Environmental Control System (ECS) is responsi- the number of passengers. It also provides a faster ble for passengers comfort and one of the most impor- method to alter the system to user needs with respect tant systems of an aircraft. Temperature and pressure to the number of air supply pipes, number of ducts and of the air vary on the altitude and ECS works on reg- pipe length. Knowledge-based engineering gives the ulating the air, takes-in the bleed air mixes it with the freedom to visualize various options in the conceptual recirculating air so that the pressure and temperature design process. -

Depressurisation Event 246 Km South-West of Coolangatta, Queensland 17 November 2007 VH-VBC Boeing Company 737-7Q8

ATSB TRANSPORT SAFETY REPORT Aviation Occurrence Investigation AO-2007-062 Final Depressurisation event 246 km south-west of Coolangatta, Queensland 17 November 2007 VH-VBC Boeing Company 737-7Q8 ATSB TRANSPORT SAFETY REPORT Aviation Occurrence Report AO-2007-062 Final Depressurisation event 246 km south-west of Coolangatta, Queensland 17 November 2007 VH-VBC Boeing Company 737-7Q8 Released in accordance with section 25 of the Transport Safety Investigation Act 2003 - i - Published by: Australian Transport Safety Bureau Postal address: PO Box 967. Civic Square ACT 2608 Office location: 62 Northbourne Ave, Canberra City, Australian Capital Territory, 2601 Telephone: 1800 020 616, from overseas +61 2 6257 4150 Accident and incident notification: 1800 011 034 (24 hours) Facsimile: 02 6247 3117, from overseas +61 2 6247 3117 Email: [email protected] Internet: www.atsb.gov.au © Commonwealth of Australia 2010. This work is copyright. In the interests of enhancing the value of the information contained in this publication you may copy, download, display, print, reproduce and distribute this material in unaltered form (retaining this notice). However, copyright in the material obtained from other agencies, private individuals or organisations, belongs to those agencies, individuals or organisations. Where you want to use their material you will need to contact them directly. Subject to the provisions of the Copyright Act 1968, you must not make any other use of the material in this publication unless you have the permission of the Australian Transport Safety Bureau. Please direct requests for further information or authorisation to: Commonwealth Copyright Administration, Copyright Law Branch Attorney-General’s Department, Robert Garran Offices, National Circuit, Barton, ACT 2600 www.ag.gov.au/cca ISBN and formal report title: see ‘Document retrieval information’ on page v - ii - CONTENTS THE AUSTRALIAN TRANSPORT SAFETY BUREAU ............................... -

FAA-H-8083-3A, Airplane Flying Handbook -- 3 of 7 Files

Ch 04.qxd 5/7/04 6:46 AM Page 4-1 NTRODUCTION Maneuvering during slow flight should be performed I using both instrument indications and outside visual The maintenance of lift and control of an airplane in reference. Slow flight should be practiced from straight flight requires a certain minimum airspeed. This glides, straight-and-level flight, and from medium critical airspeed depends on certain factors, such as banked gliding and level flight turns. Slow flight at gross weight, load factors, and existing density altitude. approach speeds should include slowing the airplane The minimum speed below which further controlled smoothly and promptly from cruising to approach flight is impossible is called the stalling speed. An speeds without changes in altitude or heading, and important feature of pilot training is the development determining and using appropriate power and trim of the ability to estimate the margin of safety above the settings. Slow flight at approach speed should also stalling speed. Also, the ability to determine the include configuration changes, such as landing gear characteristic responses of any airplane at different and flaps, while maintaining heading and altitude. airspeeds is of great importance to the pilot. The student pilot, therefore, must develop this awareness in FLIGHT AT MINIMUM CONTROLLABLE order to safely avoid stalls and to operate an airplane AIRSPEED This maneuver demonstrates the flight characteristics correctly and safely at slow airspeeds. and degree of controllability of the airplane at its minimum flying speed. By definition, the term “flight SLOW FLIGHT at minimum controllable airspeed” means a speed at Slow flight could be thought of, by some, as a speed which any further increase in angle of attack or load that is less than cruise. -

Comparison of Control Strategies for Aircraft Bleed-Air Systems

View metadata, citation and similar papers at core.ac.uk brought to you by CORE provided by Archivio istituzionale della ricerca - Politecnico di Milano Comparison of Control Strategies for Aircraft Bleed-Air Systems Alexander Pollok ∗;∗∗ Francesco Casella ∗∗ ∗ DLR German Aerospace Center, Institute of System Dynamics and Control, Oberpfaffenhofen, Germany (e-mail: [email protected]) ∗∗ Politecnico di Milano, Dipartimento di Elettronica, Informazione e Bioingegneria, Milan, Italy (e-mail: [email protected]) Abstract: Bleed-air systems in passenger aircraft are often prone to limit cycle oscillations. Tuning of such systems makes additional flight-tests necessary, generating large expenses. In this paper, several control approaches to improve the performance of bleed-air systems are compared. These approaches combine a base-controller with stiction-compensation techniques. The different approaches are implemented, optimized and evaluated using a high-fidelity bleed- air system model, described in the equation-based modelling language Modelica. Results indicate that interaction between different valves should be reduced as much as possible. If a suitable base control approach is chosen, the influence of a superimposed stiction compensation technique seems to be small. Keywords: Friction, Stiction, Compensation, Limit Cycles, Modelica, Pistons, Modelling, Oscillation, Pneumatic, Valves 1. INTRODUCTION used to control the surge bleed valve of an auxiliary power unit. The technique is not expanded to the complete bleed- In modern passenger aircraft, the cabin is pressurized air system or to the main engines. and temperature-controlled by the Environmental Control System (ECS). Hot and dense air is bled from the engine In preliminary work, the authors developed a high-fidelity compressor stages.