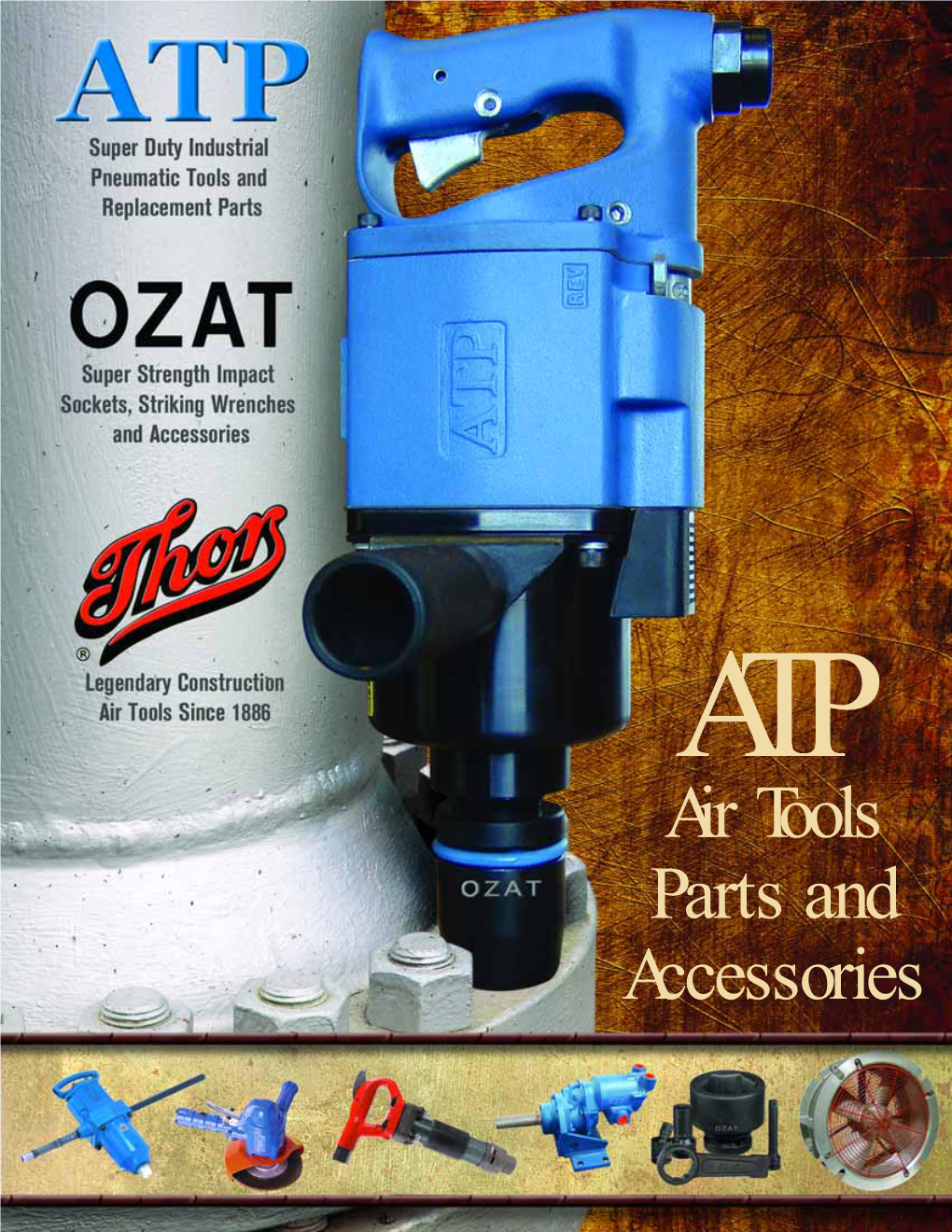

Air Tools Parts and Accessories

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

LXP® 200 - 500 Logix Processor

LXP® 200 - 500 Logix Processor SAFETY & OPERATOR’S MANUAL CONTACT INFORMATION World Headquarters Europe/Africa/Middle East Genesis Attachments Genesis GmbH 1000 Genesis Drive Teramostrasse 23 Superior, WI 54880 USA 87700 Memmingen, Germany Toll Free: 888-SHEAR-IT (888-743-2748) Phone: +49 83 31 9 25 98 0 Phone: 715.395.5252 Fax: +49 83 31 9 25 98 80 Fax: 715.395.5255 genesis-europe.com E-mail: E-mail: [email protected] [email protected] Asia Pacific Representative Office 24 Upper Serangoon View #12-28 Singapore 534205 Phone: +65 9673 9730 E-mail: [email protected] Central & South America, The Caribbean Cra 13A #89-38 / Ofi 613 Bogota, Colombia Phone: +57 1 610 8160 / 795 8747 E-mail: [email protected] Brazil Rua José Alves dos Santos, 281 - Sala 413 São José dos Campos / SP - Brazil Phone: +55 12 3905 3405 E-mail: [email protected] View and download all manuals at genesisattachments.com/manuals.asp Patents: genesisattachments.com/patents 2 Genesis LXP® 200 - 500 © 2016 Genesis Attachments, LLC PREFACE To ensure years of safe, dependable service, only trained and authorized persons should operate and service your Genesis attachment. It is the responsibility of the product’s owner to ensure the operator is trained in the safe operation of the product and has available this manual for review. It is the responsibility of the operator and maintenance personnel to read, fully understand and follow all operational and safety-related instructions in this manual. The attachment should not be operated until you have read and fully understand these instructions. -

Torque Multiplier CATALOG Table of Contents

Torque Multiplier CATALOG Table of Contents (1.1) Torque Multiplier Intro (1.2) Torque Multiplier Intro (1.3) Torque Chart (1.4) EFCip (1.5) EF & EFW (1.6) EF & EFW (1.7) CLD (1.8) CLS (1.9) MTM (1.10) HG (1.11) HSD (1.12) RG (1.13) Accessories (1.14) 6Pt Sockets TABLE OF CONTENTS i MC 14 (version1.0) Mountz Eliminator Torque Multipliers are available in hand, pneumatic and electric models. These tools are the ideal solution for true torque control, speed, power, physical ease, silence and safety. Torque Multipliers In nearly every heavy industrial application, Technicians are finding that the best Torque Multipliers increase speed and turning threaded fasteners, nuts and bolts solution for applying high torque today productivity, as it is faster than a hydraulic is generally viewed by two criteria: is with a complete range of torque control wrench and is less expensive. Designed (1) The need to fasten tightly enough to products, including manual and powered to deliver smooth torque control, with prevent movement of parts and achieve torque wrenches and torque multipliers. continuous rotation, these torque a good seal without exceeding the Mountz torque multipliers provide multipliers eliminate the cumbersome set fastener s elasticity level. precision torque control, making it up time and slow ratcheting process of (2) Successful removal of fasteners after easier and often safer to assemble and hydraulic wrenches. long periods of environmental exposure service-threaded fasteners while to harsh conditions. reducing application problems and Mountz Torque Multipliers vs. tool costs. Impact Wrenches - Selecting the right heavy torque tool for Impact wrenches are destructive by nature the job is crucial. -

Cordless Alliance System (CAS): a Cross-Manufacturer Battery Pack System of Leading Power Tool Brands

THE MOST ADVANCED 18V BATTERY SYSTEM The Cordless Alliance System (CAS): A cross-manufacturer battery pack system of leading power tool brands. Electronic Single Cell Protection (ESCP): Each cell evenly charges and discharges, extending the life of the battery, helping protect the motor and extending the life of the tool. 3-Year The Cordless Alliance System (CAS): A cross-manufacturer battery pack system of Battery Warranty leading power tool brands. 10 01 Cordless Solutions Over 90 tools on our cordless lineup, and many more coming! Most complete range of cordless metalworking and industrial tools on the market n Powered by the breakthrough LiHD (Lithium High-Density) battery technology, Metabo cordless tools deliver true industrial productivity, replacing the need for cords and hoses n Metabo offers more specialty metalworking tools than any other tool manufacturer n Using the most advanced charging system, Metabo batteries charge faster and last longer, making sure you are always ready to work 11 3 CLASSES OF POWER 1 CHARGINGClasses ofPLATFORM Power 12V 18V 36V BS 12 BL Q WPB 18 LTX BL 150 WPB 36-18 LTX BL 230 12V Power Tool Line 16 Assembly Solutions 18 Angle Grinders 20-21 Saws 21 (Metal), 30-31 (Wood) Welding Prep: Die Grinders and Beveling 22 Stainless Steel and Metal Finishing 23 Rivet Gun, Tapping Tool 24 Impact Drivers, Drill/Drivers 25-27 Drywall Screw Gun, Mixer, Heat Gun 28 Rotary Hammers 29 Shop Fan, Blower, Cordless Vac, Radio 32 Lighting Solutions and Measuring Laser 33 Batteries, Chargers and Accessories 34-39 12 Ultra-M: The Most Advanced Battery System The best metalworking cordless tools deserve the best battery system: Metabo offers a unique set of technologies designed to provide users with the power to tackle the most demanding applications. -

Gedore Torque Solutions

GEDORE TORQUE SOLUTIONS formerly 1617 TOTAL ASSORTMENT 2016 / 17 „WE CANNOT CHANGE THE WIND BUT WE CAN ADJUST OUR SAILS.“ Aristoteles (384 - 322 B.C.), Greek philosopher Dear custumors, business partners, dear tool users, with a new logo and fresh impetus, the LÖSOMATS from GEDORE remain the proven product of your choice for 2016. Made in Germany in proven quality and with top service for you. Nothing changes for you - as usual we ofer you active and competent support with our equipment and solutions. Also your usual sales channels and contacts will remain unchanged just as the high-quality fast service we ofer. Our products remain innovative, demanding and beneft from 40 years of concentrated expertise in toolmaking and high level torque bolting technology. We have succeeded in turning an eagerly awaited customer wish into reality: With the launch of the new hybrid drive for our cordless wrenches, customers can now operate the wrench in battery mode or connected to the mains. As a further highlight, we present the world‘s most powerful Cordless Torque Wrench with a massive 6.000 Nm torque, brand new with our more powerful high-power battery (140 Wh / 5 Ah / 28 V) - a strong team! Our cordless Railway Torque Wrench LDB-10 is another new development, awarded with the Competence Prize for Innovation and Quality Baden-Württemberg 2015. The LDB-10 is a battery-driven lightweight (only 17.2 kg) suitable for one-man operation, also replacing the classic bolting machine, impact wrench and sleeper drill. The latest generation of high-speed bolting also comes from GEDORE Torque Solutions GmbH. -

Main Catalogue.Pdf (17.7 Mib)

GEDORE TORQUE SOLUTIONS CORDLESS TORQUE WRENCH WITH COLOUR DISPLAY LDA/LAW SOLUTION up to 6000 Nm Dear customers, business partners, and tool users, GEDORE Torque Solutions GmbH is a high-tech centre for innovative product development and individual solu- tions in the field of bolting technology. The company has been part of the GEDORE Group since 2008 and has been trading under the name GEDORE Torque Solutions since 2016. Our own engeneering department, a vertical range of manufacture of well over 90% on state-of-the-art machines and excellent service are a guarantee for Made in Germany. Our proven high torque cordless torque wrench is now also available with a sunlight-readable colour display. The LDA Solution is your reliable partner for safety bolting requiring documentation. GEDORE Torque Solutions has developed the series of gate valve machines especially for gate valve assembly. The gate valve machines are available with various accessories and are electrically and battery operated. Information on our gate valve machines is available from page 64 onwards. We hope you enjoy browsing through the new catalogue. YOUR GEDORE TORQUE SOLUTIONS GMBH TEAM OF EXPERTS INDEX 1 FOREWORD 3 CORDLESS TORQUE WRENCH GDA Solution series 70-250 Nm 8 GDA series 60-200 Nm 10 LDA/LAW Solution series 90–6000 Nm 12 2 LDA/LAW series 90–6000 Nm 16 ELECTRIC TORQUE WRENCH 3 LDE/LEW series 90–13 000 Nm 22 CRANE TORQUE WRENCH LEW-L series, LAW-L Solution, LAW-L 1100–9500 Nm 27 PNEUMATIC TORQUE WRENCH 4 LPK series 80–12 800 Nm 30 LPK-X series 80–4200 Nm 32 HYDRAULIC -

Gedore Torque Solutions Company, Products, Services, Overview

GEDORE TORQUE SOLUTIONS COMPANY, PRODUCTS, SERVICES, OVERVIEW formerly THE LÖSOMATS BY GEDORE YOUR SPECIALIST FOR HIGH-TORQUE BOLTING TECHNOLOGY FROM PIONEER TO HIGH-TECH CENTRE The brand LÖSOMAT, now GEDORE Torque Solutions, has represented quality and innovation in all branches of bolting technology for over 40 years. A production depth of nearly 100 % on state of the art machining centres ensures excellent quality and precision in our high-torque wrenches. The dierence is quite simply in the detail. We are Made in Germany. WE DEVELOP THE TORQUE WRENCHES FOR YOUR FUTURE Our specialists develop your high-torque wrenches with state of the art construction and analysis methods (CAD/CAM/FEM). If a suitable solution is not available in our product range, we can design a specically customised solution for you. Your applications are our challenge. PRECISION TESTING BEFORE RELEASE In our in-house test laboratory, all dynamic devices are precisely measured and congured before they are sent to you. The torque deviation is usually signicantly under 3% for identical bolting operations. The individual factory calibration certicate is the proof that is required by every QM system as per DIN EN ISO 9001:2008. 2 3 ALWAYS THE RIGHT SOLUTION FOR YOU Our experts can advise you on site and analyse your application case together with you in order to oer you the appropriate bolting system. Our extensive range of bolting devices is available here for you. With the LÖSOMATS by GEDORE you are ideally equipped for just about everything. INHOUSE TRAINING We can organise the compulsory annual safety instruction and training courses for you in our in-house training centre. -

End User Repair Pricing

END USER REPAIR PRICING REVISED: 12/12/2018 MATERIAL DESCRIPTION PRICE CATEGORY CAP1512-OF BOS TRIM AIR II $91.99 1-MAN DIY COMPRESSORS D55140 135 PSI 1 Gallon Trim Boss Compressor $91.99 1-MAN DIY COMPRESSORS DCC2560T1 60V MAX 2.5GAL CORDLESS COMPRESSOR $149.99 1-MAN DIY COMPRESSORS C1010 1G 150PSI COMPRESSOR $99.00 1-MAN/DIY COMPRESSORS CAP1516 AIR COMPRESSOR $99.99 1-MAN/DIY COMPRESSORS BTFP01012 2.5 Gal. 150 PSI Easy Carry Compressor $99.99 2-MAN PRO COMPRESSORS BTFP02012 COMP 6.0G 150PSI UMC_OF120V BT $99.99 2-MAN PRO COMPRESSORS C2002 150 PSI 6 GAL OIL-FREE PANCAKE COMPRESSOR $99.99 2-MAN PRO COMPRESSORS C2002-WK 150 PSI 6 GAL OIL-FREE PANCAKE COMPRESSOR VALUE KIT $99.99 2-MAN PRO COMPRESSORS DWFP55126 DeWalt 6 Gallon 165psi Low Noise Pancake Compressor $111.99 2-MAN PRO COMPRESSORS DWFP55130 DEWALT UTC (Ultimate Trim Compressor ) $149.99 2-MAN PRO COMPRESSORS BTFP02011 6G 150PSI COMPRESSOR $99.99 2-MAN/PRO COMPRESSORS C2000-WK A 2.5HP 6G PC UM 1STG 120 $99.99 2-MAN/PRO COMPRESSORS C2001-WK A 1.5HP 6G PC UM 1STG 120 $99.99 2-MAN/PRO COMPRESSORS C2005 COMPRESSOR $99.99 2-MAN/PRO COMPRESSORS CAP1545PT-OL AIR COMPRESSOR $129.99 2-MAN/PRO COMPRESSORS CAP2000P-OF AIR COMPRESSOR $99.99 2-MAN/PRO COMPRESSORS CAP2040P-OF AIR COMPRESSOR $99.99 2-MAN/PRO COMPRESSORS CAP2045ST-OL AIR COMPRESSOR $129.99 2-MAN/PRO COMPRESSORS CAP2060P AIR COMPRESSOR $99.99 2-MAN/PRO COMPRESSORS CAP60PB-OF AIR COMPRESSOR $99.99 2-MAN/PRO COMPRESSORS CAP60P-OF AIR COMPRESSOR $99.99 2-MAN/PRO COMPRESSORS CF1400 A 1.0HP 4G PC UM 1STG 120 $99.99 2-MAN/PRO COMPRESSORS -

391A Torque Multiplier Operating Manual

Operating Instruction 391A-OI Page 1 of 2, REV: A Model 391A Torque Multiplier WARNINGS 3. DESCRIPTION AND DESIGN FEATURES 3.1 The 391 torque multiplier uses a planetary geared action to Maintain firm hand control of torque wrench or input handle tighten and loosen nuts, bolts and cap screws with a when releasing multiplier, since recoil (wind-up) will be continuous 360° rotation in either clockwise or experienced. counterclockwise direction. Input and output rotation directions Inspect output square drive (Fig. 1, Item 3) for visible sign are the same (EXAMPLE: Clockwise input rotation creates of fatigue or fracture prior to EACH use. Replace if clockwise output rotation). necessary (See Section 8). 3.2 The reaction anchor tube is held in place by a spring loaded Failure of the output square drive, due to torque overload or detent pin, which is easily removed by depressing the end of fatigue, could result in an immediate torque release, the plunger. Note: The torque multiplier’s anchor stub can be potentially causing the torque multiplier to fall from the used as a suitable anchor in confined areas. fastener, and result in personal injury. 3.3 A controlled-shear output square drive (Fig. 1 Item 3) protects internal components in the event maximum output capacity is Do not hold torque multiplier or reaction anchor tube (Fig. exceeded. This overload-protection feature causes the drive to 1, Item 2) while applying torque since normal multiplier fracture when output exceeds from 3% to 10% of rated output deflection might cause fingers to be pinched; especially in capacity. -

JT8D Tooling 8 31 10.Xlsx

Tool No. S/N Description Remarks Dept. ATA SWE10678 12995 Wrench Turbine exh.fan duct outer duct ball hsg retaining nut 101 72-54-00 # PWA75134 STI-112 Hook, safety 6000 lbs capacity for engine hoist 102 72-00-00 #*PWA45327 11563 Eye, vetical lift Rear hub LPC 102 72-33-00 *ATT0173 11263A Puller #1 spur gear puller 102 *ATT0173 11263B puller #1 spur gear puller 102 *ATT0174 11265A Crimp tool #2 key washer crimper 102 *ATT0174 11265B Crimp tool #2 key washer crimper 102 *ATT0175 11267A Remover Coupling remover - LPT 102 *ATT0175 11267B Remover Coupling remover, LPT 102 *ATT0175 11267C Remover Coupling remover, LPT 102 *ATT0222 11339 Lifting ring C-1 hub 102 *ATT0245 11377A Removal fixture Intermed.Case removal cross 102 *ATT0245 11377D Removal fixture Intermediate case 102 *ATT0254 11388 Socket set 1/2"Drive Sockets,ImpactWrench 102 *ATT0265 11417 Tube protector Intermed.Case PS3 tube 102 *ATT0293 11452 Wrench, spanner Adustable, Remv.Air Duct l.nut 102 *ATT0304 11476 Removal tool #3 brg.Integral upper nut rmvr 102 *ATT0307 11486 Puller #4 front forward seal, manual 102 *ATT0322 11517 Plug remover Borescope plug remover 102 *ATT0324 11521 Removal tool Air seal remover 102 *ATT0327 11532B Puller Air seal puller, high compressor 102 *ATT0330 11539 Knocker C-knocker, high compressor 102 *ATT0332 11545 Puller Forward air seal #5, puller 102 *ATT0339 11522 Knocker T4 Knocker 102 *ATT0342 11586 Wrench Strut nut driver 102 *ATT0344 11589 Wrench Exhaust case, strut wrench 102 *ATT0348 11593 Bar, lifting Exhaust removal bar 102 *ATT0402 11727A -

WORKSHOP TOOLS CB-04 Groz Has Always Exceeded the Expectations of Tool Manufacturers and Users the World Over

WORKSHOP TOOLS WORKSHOP WORKSHOP TOOLS For the professional! CB-04 CB-04 Groz has always exceeded the expectations of tool manufacturers and users the world over. Groz carefully makes each tool under stringent quality control processes that are achieved in a hi-tech environment spread over 500,000 square feet Total quality & control via advanced Robotically armed & conveyorized Pressure die casting - PLC controlled horizontal & vertical machining centres double booth powder coating plant semi automatic equipment with a capacity of 15 million sq inches / month Multi-station Cold Forging Shop Multi-Spindle Turning Machines – Design Center, with high end software with equipment from NEDSCHROEF, Davenports for high volume production & equipment to develop custom Belgium, for manufacture of high volume & concentricity solutions automotive parts, sockets etc. QUICK FACTS YRS IN BUSINESS GLOBAL REACH SELLING POINTS SKU’S EMPLOYEES ENGINEERS 40+ 82 COUNTRIES 750 12,000 2,592 125 Quality Assurance Statement The satisfaction of all customers is the fundamental principle of the GROZ corporate philosophy. GROZ stands committed to the quality of its products and service with the assurance of complete back-up support. With a wide range of products, prompt service and vast experience, GROZ remains dedicated to the customer. INSIDE SOCKETS & TOOLS STORAGE & I SOCKET ACCESSORIES VI ASSORTMENTS Hand Sockets & Sets 7 Portable Workstation 68 Socket Accessories 14 Tool Cart 70 Ratchet Handles 17 Tool Chest 71 Impact Sockets & Sets 26 Universal Tool Kit 72 -

AB 0100 EN Servicing SAMSON Products Tightening Torques · Lubricants · Tools

AB 0100 EN Servicing SAMSON Products Tightening Torques · Lubricants · Tools Electric and Pneumatic Control Valves SAMSON AKTIENGESELLSCHAFT · Weismüllerstraße 3 · 60314 Frankfurt am Main, Germany Edition February 2021 Phone: +49 69 4009-0 · Fax: +49 69 4009-1507 · [email protected] · www.samsongroup.com Contents Information for All Valve Series and Types 1 Contact data of SAMSON's After-sales Service ....................................................................................................1 2 Safety instructions and measures ........................................................................................................................1 3 Special tools for tightening torques .....................................................................................................................1 3.1 Torque wrench ....................................................................................................................................................1 3.2 Torque multiplier .................................................................................................................................................2 3.3 Adapter .............................................................................................................................................................2 3.4 Pneumatic adapter ..............................................................................................................................................3 3.5 Hydraulic power tool ...........................................................................................................................................3 -

Proto Catalog

PRECISION TORQUE There are times when being obsessive is a real virtue – like when Proto ® micrometer torque wrenches are offered in three different you're designing and building torque wrenches. Just consider what product series: “C” series wrenches are designed for normal these tools are asked to do. When a wrench tightens a bolt the torque applications in industrial and manufacturing settings while rotational force, or torque, actually causes the bolt to stretch a bit “CX” series wrenches are calibrated for use where extreme as the threads seat tightly against one another. The trick is to put precision and accuracy is required, such as in aerospace, aviation, enough force on the threads that the bolt won't work loose, yet not and military applications. The CXCERT series wrenches include enough that you risk cracking the metal. This "tolerance" range can documents certifying N.I.S.T. (National Institute of Standards and be quite narrow, and staying within it may be the difference between Technology) traceability. a smooth running machine and one stopped dead in its tracks. In the case of military equipment or an aircraft it can literally be a matter Other features include: of life and death. A torque wrench has to make sure that fasteners • Scales with metric and English numbers on select models. are tightened within their tolerance range, and it has to continue • A positive locking mechanism that tells users doing so even after many uses. when they have locked in the desired torque. • A thin head design that fits into tight areas. Because they're so important, we spare no effort to make our • Long handles, which let the user reach the set wrenches accurate.