Construction Module

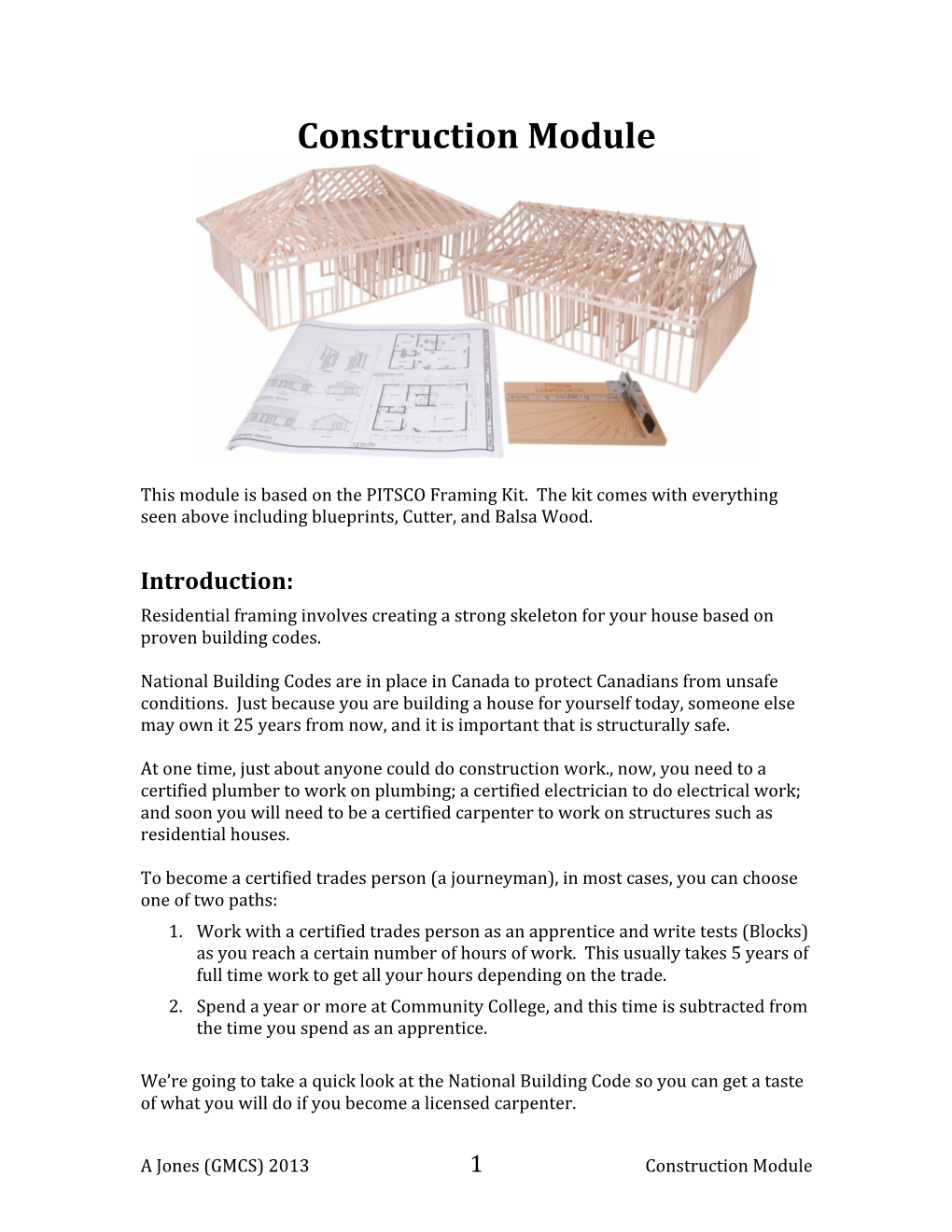

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

15 – Construction Vocabulary

CONSTRUCTION VOCABULARY ABC (Aggregate Base Course): used in mixing with concrete and placed below concrete prior to the pouring of sidewalks, driveways, etc. It serves as a compacted solid base. Air return: A series of ducts in air conditioning system to return used air to air handler to be reconditioned. Ameri-mix: Maker of the pre-blended bag mixes we use in masonry work. Anchor Bolts: (also called J-bolts) Bolts embedded in concrete foundation used to hold sills in place. Anchor Straps: Straps embedded in concrete foundation used to hold sills in place, most commonly MASAs in our houses. Apron: A piece of driveway between sidewalk and curb. Back Fill: The replacement of dirt in holes, trenches and around foundations. Backing (aka blocking): a non-structural (usually 2x) framed support (i.e. for drywall). Balloon Framing: A special situationally required type of construction with studs that are longer than the standard length. Bay: The space between two parallel framing members (i.e. trusses). Beam: A horizontal structural member running between posts, columns or walls. Bearing wall (aka partition): A wall which carries a vertical structural load in addition to its own weight. Bevel: To cut an angle other than a right angle, such as on the edge of a board. Bird block (aka frieze board): An attic vent located between truss tails. Bird’s Mouth: A notch cut in the underside of a rafter to fit the top plate. Blocking (aka backing): A non-structural 2x framing support (i.e. for drywall) Board: Lumber less than 2” thick. Board Foot: The equivalent of a board 1’ square and 1” thick. -

Back Framing

BACK FRAMING Back Framing is required to aide future steps in the construction process, ie cabinet installation, hanging drywall, towel bar installation etc. VERIFY ALL DOOR ROUGH OPENINGS AND KITCHEN WINDOW AND KITCHEN INTERIOR WALL LOCATION: Entry doors 37 ½” X 82” high Garage Utility ( people) Door 38 ½” X 82 ½” Bedroom, Bathroom Swing doors 38” wide X 82 ½” high Basement Door ONLY 34” wide X 82 ½” high Closet/ Bifold doors Width of door + 1 ½” ie 24” door, 25 ½” RO etc X 81” high A Kitchen window must be 78 ½” from garage wall to center of window. A Kitchen interior wall must be 12’ 1” form garage wall, Rough to Rough INSTALLING HURRICANE CLIPS: This fastening devise is used to secure the trusses to the exterior walls' top plates. They will be used on both the HOUSE and GARAGE trusses. Install 1 clip per truss at both ends of truss with 10D Simpson galvanized nails (Tico). Drive nails fully into truss. Because of the size of the nail, a pair of pliers is helpful to hold it to start the nail. There are 2 different styles of clip. Position the clip as shown and nail, Put a nail in EVERY hole. KITCHEN CABINET BLOCKING: MATERIALS 2 X 4 and 2 X 6 of various lengths. Kitchen cabinet blocking is needed for a timely and reduced stress cabinet installation. Full blocking is required on ALL 3 kitchen walls and the bathroom wall behind the vanity. LAYOUT Snap chalk lines at the following heights off the floor 80- ½” – 84” for TOP of the upper cabinets with a 2x4 wall cleat. -

Connectors & Fasteners for Modular Building Catalog

Connectors & Fasteners for Modular Building C-C-MODULAR18 | (800) 999-5099 | strongtie.com Smart Solutions for Modular Building Simpson Strong-Tie® connectors and fasteners offer improved speed, strength and versatility for modular building. These products save time in manufacturing and provide ease of installation on the jobsite. This catalog is designed to help you easily locate the right connector or fastener to meet your modular building construction needs. Our products come with the quality, value, service and on-time delivery that we have built our reputation on for the past 60 years. If you need help finding the right product for your job, give us a call at (800) 999-5099. Simpson Strong-Tie® Connectors & Fasteners for Modular Building Table of Contents Code Reports ...........................................................................6 MMHC Hinged Roof Connector ..............................................21 Corrosion Information .........................................................7–10 BC Post Base .........................................................................22 Important Information and General Notes .........................11–15 LSTA/MSTA Strap Ties ...........................................................23 Connectors CS/CMST Coiled Straps ...................................................24–25 MMLU Face-Mount Hangers ..................................................17 Fasteners H2.5A Roof Tiedown ........................................................18–19 Strong-Drive® SDWC Truss Screw ....................................27–28 -

Residential Seismic Strengthening

Residential Seismic Strengthening Methods to Reduce Potential Earthquake Damage 12 Portland and the surrounding communities are homes, buildings and utilities can reduce damage and the dangers of serious injury or loss of life from located in a seismically active region. an earthquake. Modified from Although most Oregonians have not witnessed a www.oregongeology.org/sub/earthquakes/EQs.htm large earthquake in this region, large earthquakes The City of Portland, Bureau of Development have occurred in the past. The Cascadia Subduction Services has a program to help you make your Zone lies off the Oregon and Washington coasts where two sections of the earth’s crust (tectonic home more secure in our next earthquake. plates) are colliding, with one plate sliding beneath (subducting) the other. Subduction zones have produced some of the most powerful earthquakes ever recorded, often having magnitudes of 8 to 9 or larger. The 2004 Great Sumatra-Andaman (magnitude 9.1) earthquake occurred on a subduction zone. Studies have found evidence that very large earthquakes have occurred repeatedly in the past on the Cascadia Subduction Zone, most recently in January, 1700. Scientists believe the Cascadia Subduction Zone is likely to produce large earthquakes in the future. Extensive damage to buildings as a result of strong and sustained ground Purpose www.portlandoregon.gov/bds shaking is expected in the Portland area in the event The strengthening methods described by this • of a Cascadia Subduction Zone earthquake. program are intended to reduce the likelihood of your home being severely damaged by being displaced from its foundation or cripple walls in an Oregon also has many crustal faults. -

Framing: Walls

8/18/14 Introduction to Framing Terminology and Concepts Terminology: Framing Level Two points on exactly the same horizontal plane. Square Intersecting lines or faces that form an exact 90° angle. Plumb Flush Two points on exactly Two faces on exactly the same vertical plane. the same plane. Terminology: Subfloors Sill Plate Decking (or “subfloor”) Pressure-treated Rimboard (or “rim band”) ¾” thick tongue-and- lumber supported by Engineered lumber (of various heights) groove sheathing, glued foundation and and nailed to joists. shimmed to be level. Joists Engineered joists (of various heights) Flange which span the foundation. Joists sit (or chord) Foundation on the sill plate and support the Poured concrete subfloor decking. Web foundation walls Double Top Plate Terminology: Walls Second top plate (also called “Cap Plate”) overlapping and Top/Bottom Plates tying together multiple walls. Horizontal lumber making up the top and bottom of a wall. Sheathing Components Studs OSB attached to Pre-assembled pieces Vertical lumber outside of exterior installed in walls, like spanning between top walls for strength. windows and doors. and bottom plates. Terminology: Walls Bracing Any material used to Blocking make the wall stronger. Lumber installed in a wall to Some are temporary; provide support and nailing some are permanent for something else (like intersecting walls or cabinets). King studs Terminology: Wall Components Studs framing the left and right of a window/door. Headers Jacks / Trimmers Horizontal supports Support a header. spanning over a 3’ window or door. Structural header 5’ (2) 2x8s on edge with Cripples (2) pcs 1” blueboard insulation between. Vertical supports above and below windows/doors Non-structural header (1) 2x6 on the flat. -

Designing for Durability CONTINUING EDUCATION Strategies for Achieving Maximum Durability with Wood-Frame Construction Sponsored by Rethink Wood

EDUCATIONAL-ADVERTISEMENT Designing for Durability EDUCATION CONTINUING Strategies for achieving maximum durability with wood-frame construction Sponsored by reThink Wood rchitects specify wood for many Examples of wood buildings that have (glulam), cross laminated timber (CLT), and reasons, including cost, ease and stood for centuries exist all over the world, nail-laminated timber, along with a variety A efficiency of construction, design including the Horyu-ji temple in Ikaruga, of structural composite lumber products, are versatility, and sustainability—as well as Japan, built in the eighth century, stave enabling increased dimensional stability and its beauty and the innate appeal of nature churches in Norway, including one in Urnes strength, and greater long-span capabilities. and natural materials. Innovative new built in 1150, and many more. Today, wood These innovations are leading to taller, technologies and building systems are also is being used in a wider range of buildings highly innovative wood buildings. Examples leading to the increased use of wood as a than would have been possible even 20 years include (among others) a 10-story CLT structural material, not only in houses, ago. Next-generation lumber and mass timber apartment building in Australia, a 14-story schools, and other traditional applications, products, such as glue-laminated timber timber-frame apartment in Norway, but in larger, taller, and more visionary wood buildings. But even as the use of wood is expanding, one significant characteristic of wood buildings is often underestimated: their durability. Misperceptions still exist that buildings made of materials such as concrete or steel last longer than buildings made of wood. -

Members' Directory

ROYAL WARRANT HOLDERS ASSOCIATION MEMBERS’ DIRECTORY 2019–2020 SECRETARY’S FOREWORD 3 WELCOME Dear Reader, The Royal Warrant Holders Association represents one of the most diverse groups of companies in the world in terms of size and sector, from traditional craftspeople to global multinationals operating at the cutting edge of technology. The Members’ Directory lists companies by broad categories that further underline the range of skills, products and services that exist within the membership. Also included is a section dedicated to our principal charitable arm, the Queen Elizabeth Scholarship Trust (QEST), of which HRH The Prince of Wales is Patron. The section profiles the most recent alumni of scholars and apprentices to have benefited from funding, who have each developed their skills and promoted excellence in British craftsmanship. As ever, Royal Warrant holders and QEST are united in our dedication to service, quality and excellence as symbolised by the Royal Warrant of Appointment. We hope you find this printed directory of use when thinking of manufacturers and suppliers of products and services. An online version – which is regularly updated with company information and has enhanced search facilities – can be viewed on our website, www.royalwarrant.org “UNITED IN OUR DEDICATION TO Richard Peck SERVICE, QUALITY CEO & Secretary AND EXCELLENCE” The Royal Warrant Holders Association CONTENTS Directory of members Agriculture & Animal Welfare ...............................................................................................5 -

HEADER DESIGN PER 2015 WFCM ENGINEERED and PRESCRIPTIVE PROVISIONS (STD343) John “Buddy” Showalter, P.E

HEADER DESIGN PER 2015 WFCM ENGINEERED AND PRESCRIPTIVE PROVISIONS (STD343) John “Buddy” Showalter, P.E. Vice President, Technology Transfer American Wood Council Description The 2015 Wood Frame Construction Manual (WFCM) is referenced in the 2015 International Building Code and 2015 International Residential Code. For WFCM load calculations, Minimum Design Loads for Buildings and Other Structures (ASCE 7-10) is used. The 2015 WFCM includes design information for wind and seismic loads and gravity loads including snow, roof live, floor live, and dead loads on buildings up to 3 stories. This presentation will provide background and examples for calculation of forces on headers which will enable designers and code officials to quickly determine design loads. It will also provide engineered prescriptive solutions for both solid sawn and glued-laminated timber headers to resist those loads. Related issues including jack studs, king studs, connections for lateral and gravity loads, and the difference between dropped and raised headers will be discussed. Learning Objectives Upon completion of this webinar, participants will: 1. Understand applicable lateral and gravity loads from ASCE 7-10 for headers within the WFCM scope. 2. Be familiar with the difference between dropped and raised headers. 3. Be familiar with the design of jack studs and king studs to resist both gravity and lateral loads. 4. Be familiar with the design of lateral, shear, gravity, and uplift connections related to headers. This presentation is protected by US and International Copyright laws. Reproduction, distribution, display and use of the presentation without written permission of AWC is prohibited. © American Wood Council 2017 • The American Wood Council • This course is registered with is a Registered Provider with AIA CES for continuing The American Institute of professional education. -

2X6 BLOCKING @ PER PLAN MAX @ 2X6 STUDS SHEATHING JOINTS

1 1/2" 1 1/2" H T X F D A I O M W M A % D I 0 U D 2"Ø MAX @ 2x4 6 T SHEATHING STUDS. 3 1/4"Ø S 2x6 BLOCKING @ PER PLAN MAX @ 2x6 STUDS SHEATHING JOINTS. FASTEN EACH END OF BLOCKING USING SIMPSON MSTI 26 STAGGER SPLICES 4'-6" MIN (3) 8d NAILS MINIMUM STRAP TIE w/ (26) DOUBLE 10d NAILS TOTAL @ TOP PLATE DOUBLE STUDS EA SPLICE (TYP) 40% MAX NOTCH 60% MAX STUD WIDTH 1 3/8" MAX @ 2x4 STUDS 2" MAX Ø @ 2x4 STUDS 2 1/8" MAX @ 2x6 STUDS 3 1/4" Ø @ 2x6 STUDS 5/8" MIN EDGE NOTE: AT WALLS DISTANCE TYP PLYWOOD ALL STUDS NOTCHES TO OCCUR AT TOP OR SHEATHING BOTTOM THIRD OF WALL STUD. 2x4 BLOCKING @ (TYP) SHEATHING JOINTS. FASTEN EACH END SHEATHING OF BLOCKING USING PER PLAN NON-BEARING STUDS (3) 8d NAILS MINIMUM 40% MAX STUD WIDTH 1 3/8"Ø MAX @ 2x4 STUDS WALL STUDS PER PLAN CENTER DBL STUD 2 1/4"Ø MAX @ 2x6 STUDS 25% MAX NOTCH @ EA SPLICE 7/8" MAX 2x4 STUDS 1 3/8" MAX @ 2x6 STUDS NOTE: NOTCH AND BORING NOT TO CORNERS INTERSECTIONS OCCUR IN SAME STUD SECTION. NOTE: ROOF TRUSS BEYOND PER PLAN ALL STUDS SHOWN ARE 2x. EXTERIOR AND BEARING STUDS AT ROOF 1 WOOD FRAMING DETAILS 2 STUD NOTCHING DETAILS 3 BLOCKING DETAILS 4 TOP PLATE SPLICE DETAIL S0.5 N.T.S. S0.5 N.T.S. S0.5 N.T.S. S0.5 N.T.S. -

Fastenmaster TER 1308-05 Timberlok Uplift and Top Plate Roll

Use of TimberLOK® Fasteners TER No. 1308-05 to Provide Top Plate Roll Resistance to Trusses & Rafters Attached to the Tops of Walls Issue Date: February 19, 2014 ® OMG , Inc. Updated: March 20, 2019 DBA FastenMaster® Subject to Renewal: April 1, 2020 153 Bowles Rd Agawam, MA 01001-2908 800-518-3569 [email protected] fastenmaster.com DIVISION: 06 00 00 – WOOD, PLASTICS AND COMPOSITES Section: 06 00 90 – Wood and Plastic Fastenings 1. Product(s) Evaluated: 1.1. FastenMaster® TimberLOK® Heavy Duty Wood Screw 1.2. For the most recent version of this Technical Evaluation Report (TER), visit drjengineering.org. For more detailed state professional engineering and code compliance legal requirements and references, visit drjengineering.org/statelaw. DrJ is fully compliant with all state professional engineering and code compliance laws. 1.3. This TER can be used to obtain product approval in any country that is an IAF MLA Signatory (all countries found here) and covered by an IAF MLA Evaluation per the Purpose of the MLA (as an example, see letter to ANSI from the Standards Council of Canada). Manufacturers can go to jurisdictions in the U.S., Canada and other IAF MLA Signatory Countries and have their products readily approved by authorities having jurisdiction using DrJ’s ANSI accreditation. 1.4. Building code regulations require that evaluation reports are provided by an approved agency meeting specific requirements, such as those found in IBC Section 1703. Any agency accredited in accordance with ANSI ISO/IEC 17065 meets this requirement within ANSI’s scope of accreditation. For a list of accredited agencies, visit ANSI’s website. -

Barnwood Design Layout & Installation Guide

Barnwood Design Layout & Installation Guide Design Layout Once You Receive Material For Your Project – It is important to understand that no two boards are exactly the same and once received you will want to layout and select desired boards for primary positions on your wall or ceiling. The Shiplap is all in 16’ 1” lengths but NEW BARNWOOD™ Shiplap is not intended to be installed in all full-length boards. Tip: Optimal look and installation is achieved by understanding the wall-stud or ceiling-joist spacing. Typical construction wall-stud and ceiling-joist spacing is 16” on-center or 24” on-center. Once you have identified the stud or joist on-center spacing NEW BARNWOOD™ boards can be cut into increments of the on- center length so that board joints are on the center of the stud. For Example: 16” on-center – Board lengths can be cut into increments of… 16” – 32” – 48” – 64” – 80” – 96” – 112” – 128” – 144” – 160” – 174” – 192” 24” on-center – Board lengths can be cut into increments of… 24” – 48” – 72” – 96” – 120” – 144” – 168” – 192” Tip: Always add 15% to your total square foot coverage quantity to account for waste, cuts and to achieve your optimal design. 1 Compared to drywall (which includes steps of hanging, taping, mudding, sanding, and painting 2-3 times) installing NEW BARNWOOD™ barnwood is a much easier and cleaner process. Steps for a typical ceiling or horizontal wall application: 1. NEW BARNWOOD™ barnwood is intended for interior use but can be used in an exterior protected area. Upon delivery immediately removed from packaging and move materials indoors where boards can acclimate to the environment where the product will be installed. -

Hybrid Wood and Steel Details– Builder’S Guide

Hybrid Wood and Steel Details– Builder’s Guide U.S. Department of Housing and Urban Development Office of Policy Development and Research PATH (Partnership for Advancing Technology in Housing) is a private/public effort to develop, demonstrate, and gain widespread market acceptance for the “Next Generation” of American housing. Through the use of new or innovative technologies, the goal of PATH is to improve quality, durability, environmental efficiency, and affordability of tomorrow’s homes. PATH is managed and supported by the U.S. Department of Housing and Urban Development (HUD). In addition, all federal agencies that engage in housing research and technology development are PATH Partners, including the Departments of Energy, Commerce, and Agriculture, as well as the Environmental Protection Agency (EPA) and the Federal Emergency Management Agency (FEMA). State and local governments and other participants from the public sector are also partners in PATH. Product manufacturers, home builders, insurance companies, and lenders represent private industry in the PATH Partnership. To learn more about PATH, please contact: 451 7th Street, SW Washington, DC 20410 202-708-4277 (phone) 202-708-5873 (fax) e-mail: [email protected] website: www.pathnet.org Visit PD&R’s website www.huduser.org to find this report and others sponsored by HUD’s Office of Policy Development and Research (PD&R). Other services of HUD USER, PD&R’s Research Information Service, include listservs; special interest, bimonthly publications (best practices, significant studies from other sources); access to public use databases; and a hotline 1-800-245-2691 for help accessing the information you need.