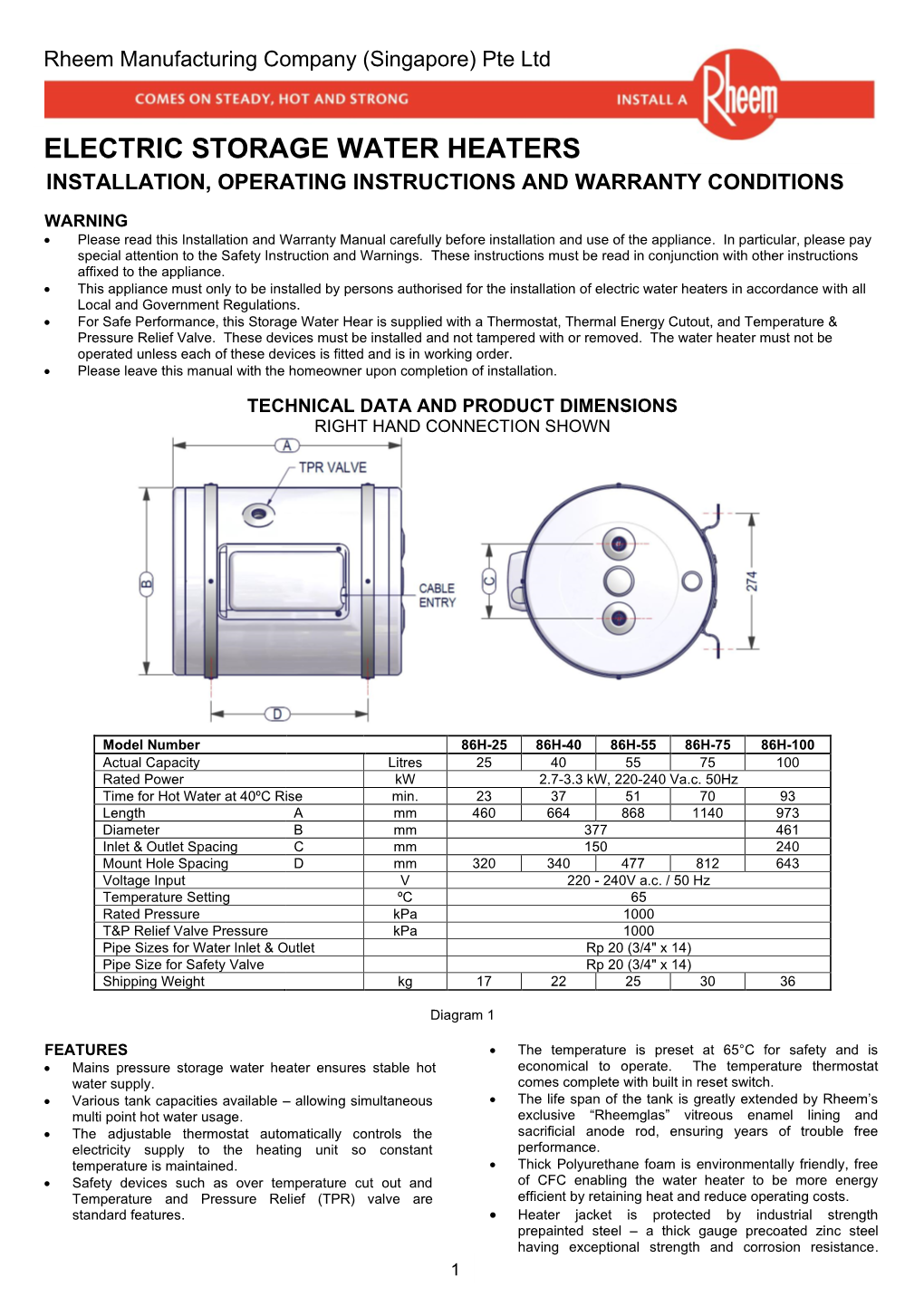

Electric Storage Water Heaters

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

ENERGY STAR Water Heaters Draft 1 Version 3.3 Specification

1 ENERGY STAR® Program Requirements 2 Product Specification for Residential Water Heaters 3 4 Eligibility Criteria 5 Version 3.3 Draft 1 6 7 Following is the Version 3.3 product specification for ENERGY STAR certified water heaters. A product 8 shall meet all of the identified criteria if it is to earn the ENERGY STAR. 9 10 Note: Products may be certified using the Uniform Energy Factor (UEF) metric and current Uniform Test 11 Method for Measuring the Energy Consumption of Water Heaters.1 Criteria that are specific to UEF for 12 electric and gas-fired water heaters are outlined in Appendix A of this document. 13 14 1) Definitions: Below are the definitions of the relevant terms in this document. See Appendix A, 15 Section 1 for definitions relevant to UEF. 16 A. Residential Water Heater (Consumer Water Heater): A product that utilizes gas, electricity, or 17 solar thermal energy to heat potable water for use outside the heater upon demand, including: 18 a. Storage type units designed to heat and store water at a thermostatically-controlled 19 temperature of less than 180 °F, including: gas storage water heaters with a nominal input of 20 75,000 British thermal units (Btu) per hour or less and having a rated storage capacity of not 21 less than 20 gallons nor more than 100 gallons; electric heat pump type units with a 22 maximum current rating of 24 amperes at an input voltage 250 volts or less, and, if the tank is 23 supplied, having a manufacturer’s rated storage capacity of 120 gallons or less.2 24 25 b. -

Owner's Guide and Installation Instructions

Owner’s Guide and Installation Instructions Commercial Stainless Steel Storage Tank This storage tank must be installed and serviced by a qualified person. Please leave this guide with the householder. WARNING: Plumber – Be Aware The primary flow and return pipes between the storage tank(s) and the primary water heating source, including the solar hot and solar cold pipes between the solar storage tank(s) and the solar collectors, MUST BE of copper or metallic pipe. All compression fittings must use brass or copper olives. The full length of the primary flow and return pipes MUST BE insulated. The insulation must: . be of a type suitable for the application and capable of withstanding the temperature of the water generated by the primary water heating source The specification of the chosen insulation material should be checked with the insulation manufacturer prior to installation as different materials may vary in temperature tolerance. Closed cell type or equivalent insulation used between the storage tank(s) and solar collectors, if this storage tank is part of a solar water heater installation, must be able to withstand the temperature of the water generated by the solar collectors under stagnation conditions. Refer to the installation instructions provided with the solar controller for full details on the insulation requirements of the solar hot and solar cold pipes. be at least 13 mm thick, however thicker insulation may be required to comply with the requirements of AS/NZS 3500.4 . be weatherproof and UV resistant if exposed . be fitted up to and cover the connections on both the storage tank(s) and the primary heating source. -

Electric Tankless Water Heating: Competitive Assessment

Electric Tankless Water Heating: Competitive Assessment 1285-5-04 EPRI Retail Technology Application Centers Electric Tankless Water Heating: Competitive Assessment 1285-5-04 Final Report, March 2005 Global Project Manager R. Milward Global Energy Partners, LLC • 3569 Mt. Diablo Blvd., Suite 200, Lafayette, CA 94549 Tel. 925-284-3780 • Fax 925-284-3147 • www.gepllc.com DISCLAIMER OF WARRANTIES AND LIMITATION OF LIABILITIES THIS DOCUMENT WAS PREPARED BY GLOBAL ENERGY PARTNERS, LLC (GLOBAL), A SUBSIDIARY OF EPRISOLUTIONS, INC., AND IS ONE OF THE FAMILY OF COMPANIES OF THE ELECTRIC POWER RESEARCH INSTITUTE, INC. (EPRI). NEITHER GLOBAL NOR ANY PERSON ACTING ON ITS BEHALF: (A) MAKES ANY WARRANTY OR REPRESENTATION WHATSOEVER, EXPRESS OR IMPLIED, (I) WITH RESPECT TO THE USE OF ANY INFORMATION, APPARATUS, METHOD, PROCESS, OR SIMILAR ITEM DISCLOSED IN THIS DOCUMENT, INCLUDING MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, OR (II) THAT SUCH USE DOES NOT INFRINGE ON OR INTERFERE WITH PRIVATELY OWNED RIGHTS, INCLUDING ANY PARTY'S INTELLECTUAL PROPERTY, OR (III) THAT THIS DOCUMENT IS SUITABLE TO ANY PARTICULAR USER'S CIRCUMSTANCE; OR (B) ASSUMES RESPONSIBILITY FOR ANY DAMAGES OR OTHER LIABILITY WHATSOEVER (INCLUDING ANY CONSEQUENTIAL DAMAGES, EVEN IF GLOBAL OR ANY GLOBAL REPRESENTATIVE HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES) RESULTING FROM YOUR SELECTION OR USE OF THIS DOCUMENT OR ANY INFORMATION, APPARATUS, METHOD, PROCESS, OR SIMILAR ITEM DISCLOSED IN THIS DOCUMENT. ORDERING INFORMATION Requests for copies of this report should be directed to Global Energy Partners, LLC 3569 Mt. Diablo Blvd., Suite 200, Lafayette, CA 94549. Telephone number: 925-284-3780; fax: 925-284- 3147 Copyright © 2005 Global Energy Partners, LLC. -

Combined Space and Water Heating Installation and Optimization B

Measure Guideline: Combined Space and Water Heating Installation and Optimization B. Schoenbauer, D. Bohac, and P. Huelman NorthernSTAR March 2017 NOTICE This report was prepared as an account of work sponsored by an agency of the United States government. Neither the United States government nor any agency thereof, nor any of their employees, subcontractors, or affiliated partners makes any warranty, express or implied, or assumes any legal liability or responsibility for the accuracy, completeness, or usefulness of any information, apparatus, product, or process disclosed, or represents that its use would not infringe privately owned rights. Reference herein to any specific commercial product, process, or service by trade name, trademark, manufacturer, or otherwise does not necessarily constitute or imply its endorsement, recommendation, or favoring by the United States government or any agency thereof. The views and opinions of authors expressed herein do not necessarily state or reflect those of the United States government or any agency thereof. This report is available at no cost from the National Renewable Energy Laboratory (NREL) at www.nrel.gov/publications. Available electronically at SciTech Connect http:/www.osti.gov/scitech Available for a processing fee to U.S. Department of Energy and its contractors, in paper, from: U.S. Department of Energy Office of Scientific and Technical Information P.O. Box 62 Oak Ridge, TN 37831-0062 OSTI http://www.osti.gov Phone: 865.576.8401 Fax: 865.576.5728 Email: [email protected] Available for sale to the public, in paper, from: U.S. Department of Commerce National Technical Information Service 5301 Shawnee Road Alexandria, VA 22312 NTIS http://www.ntis.gov Phone: 800.553.6847 or 703.605.6000 Fax: 703.605.6900 Email: [email protected] Measure Guideline: Combined Space and Water Heating Installation and Optimization Prepared for: The National Renewable Energy Laboratory On behalf of the U.S. -

Proper Water Heater Selection

Strategy Guideline: Proper Water Heater Selection M. Hoeschele, D. Springer, A. German, J. Staller, and Y. Zhang Alliance for Residential Building Innovation (ARBI) Revised April 2015 NOTICE This report was prepared as an account of work sponsored by an agency of the United States government. Neither the United States government nor any agency thereof, nor any of their employees, subcontractors, or affiliated partners makes any warranty, express or implied, or assumes any legal liability or responsibility for the accuracy, completeness, or usefulness of any information, apparatus, product, or process disclosed, or represents that its use would not infringe privately owned rights. Reference herein to any specific commercial product, process, or service by trade name, trademark, manufacturer, or otherwise does not necessarily constitute or imply its endorsement, recommendation, or favoring by the United States government or any agency thereof. The views and opinions of authors expressed herein do not necessarily state or reflect those of the United States government or any agency thereof. Available electronically at http://www.osti.gov/bridge Available for a processing fee to U.S. Department of Energy and its contractors, in paper, from: U.S. Department of Energy Office of Scientific and Technical Information P.O. Box 62 Oak Ridge, TN 37831-0062 phone: 865.576.8401 fax: 865.576.5728 email: mailto:[email protected] Available for sale to the public, in paper, from: U.S. Department of Commerce National Technical Information Service 5285 Port Royal Road Springfield, VA 22161 phone: 800.553.6847 fax: 703.605.6900 email: [email protected] online ordering: http://www.ntis.gov/ordering.htm Printed on paper containing at least 50% wastepaper, including 20% postconsumer waste Strategy Guideline: Proper Water Heater Selection Prepared for: Building America Building Technologies Program Office of Energy Efficiency and Renewable Energy U.S. -

PVI Industries Commercial Water Heaters and Hot Water Storage Tanks

PVI Industries Commercial Water Heaters and Hot Water Storage Tanks Full Line Product Catalog PVI.com About PVI Since 1961, PVI Industries has manufactured highly reliable, medium to large ASME water heaters for commercial, institutional and industrial installations including schools, dormitories, hotels, restaurants, hospitals, apartments, correctional facilities and military barracks. With more than 130,000 installations worldwide, PVI has become one of the leading suppliers of engineer-specified plumbing and heating equipment for new construction and building retrofits. PVI heaters can be configured for any common energy source including natural or LP gas, oil, boiler water, solar, steam, electricity and waste heat. Water heaters range from instantaneous (on demand water heating) to storage type heaters with pressure vessels from 150 to 4500 gallons. Many products are “engineered-to-order” to exactly match the requirements of the application. Water heaters and storage tanks are manufactured from AquaPLEX® duplex stainless steel combining innovative duplex alloy material with advanced design and fabrication technology to produce heaters that are impervious to corrosion in potable hot water and require no tank lining or anode rod protection. PVI water heaters are backed by the industry’s strongest warranty and service policy package. Products include no-cost first-year service policies, extended service policies, multi-year heat exchanger warranties, and 15- or 25-year tank and heat exchanger corrosion warranties. 2 AquaPLEX® Advanced Technology AquaPLEX is an engineered blend of austenitic and ferritic steels that combines the advantages and grain structures of both 300 and 400 series stainless steel for unequalled corrosion protection. This synergy makes AquaPLEX very strong and highly resistant to aqueous corrosion in addition to chloride stress corrosion cracking, a known failure mode of 316L and 304L stainless steel in potable water. -

RES 19 Water Heating, Boiler, and Furnace Cost Study

Water Heating, Boiler, and Furnace Cost Study (RES 19) Final Report Prepared for: The Electric and Gas Program Administrators of Massachusetts Part of the Residential Evaluation Program Area Submitted by: Navigant Consulting, Inc. 1375 Walnut Street Suite 100 Boulder, CO 80302 303.728.2500 navigant.com Reference No.: 183406 September 27, 2018 Water Heating, Boiler, and Furnace Cost Study (RES 19) TABLE OF CONTENTS Executive Summary ..................................................................................................... iii Evaluation Objectives & Methodology iii Evaluation Activities iii Findings & Considerations iv 1. Introduction ............................................................................................................... 1 1.1 Program Background 1 1.2 Study Objectives 1 1.3 Structure of this Report 1 2. Methodology .............................................................................................................. 2 2.1 Overview and Sources of Data 2 2.2 Representative Product Sizes 3 2.3 Survey of HVAC Contractors and Plumbers 3 2.4 Program Invoice Review for Water Heaters 4 2.5 Webscraping the Retail Cost-Efficiency Frontier 4 2.6 Cost-Efficiency Curve Construction 5 3. Findings ..................................................................................................................... 8 3.1 Installation Costs of Different Product Types and Technologies 8 3.2 Total Installed Costs of Furnaces, Boilers, and Water Heaters 9 3.2.1 Furnaces – Natural Gas ................................................................................................ -

Residential Water Heaters: Final Criteria Analysis

ENERGY STAR® Residential Water Heaters: Final Criteria Analysis Water heating represents between thirteen and seventeen percent of national residential energy consumption, making it the third largest energy end use in homes, behind heating and cooling and kitchen appliances. As homes become more energy efficient, the percentage of energy used for water heating steadily increases. Water heating is the only major residential energy end use that ENERGY STAR has not addressed. Developing ENERGY STAR criteria is essential to expand the value of the ENERGY STAR brand and its continued relevance in the marketplace. ENERGY STAR is a critical driver of technology in the market. When developing ENERGY STAR criteria, the Department of Energy (DOE) considers and balances a varied set of objectives, ensuring that the established criteria: • Provide meaningful differentiation between ENERGY STAR qualified products and those that just meet the Federal standard. • Will result in significant energy savings, both for consumers and the nation as a whole. • Are cost-effective for consumers as well as manufacturers. • Provide consumer choice, both in terms of number of models and a wide range of manufacturers. • Do not compromise functionality or performance of the qualified product. • Do not rely on proprietary technologies. Almost all water heaters sold in the U.S. are traditional storage units with nearly an even split between gas and electric. Of the 9.8 million water heater shipments in the U.S. in 2006, 4.8 million were conventional electric-resistance and 4.7 million were conventional gas storage. Gas tankless water heaters accounted for 254,600 shipments, representing 2.6% of the market. -

Water Heating

Technology Fact Sheet WATER HEATING When a combustion-type hot water storage For more information, contact: WATER HEATING HOT WATER tank system is used, placing the tank in the RECIRCULATION SYSTEMS Energy Efficiency and following places may improve resistance to Energy-efficient strategies for Renewable Energy These devices Hot and cold water service backdrafting: Clearinghouse (EREC) provide “instant” to sink supplying hot water in the home 1-800-DOE-3732 hot water at • Outside of the home’s conditioned space www.eren.doe.gov point sources (e.g., in garage). ENERGY-EFFICIENT WATER Or visit the BTS Web site at and provide • In a sealed, indoor mechanical room having Demand (tankless or instantaneous) water www.eren.doe.gov/buildings HEATING water cool adequate exterior ventilation. heaters—heat water directly without use of a water Domestic water heating accounts for between Written and prepared for conservation side storage tank. Demand systems produce a warm • Inside the conditioned space when a power 15 and 25 percent of the energy consumed in the U.S. Department of benefits. water limited amount of hot water—a 70°F water side venting system using a fan is incorporated to homes. Water-heating energy costs can be Energy by: Buildings for temperature rise is possible at a flow rate of Sensor expel combustion gases through the flue, managed by selecting the appropriate fuel and NAHB Research Center the 21st Century five gallons per minute through gas water Pump and/or a sealed combustion system water heater type, using efficient system 800-898-2842 heaters and two gallons per minute through separately ducts in outside air for combustion Buildings that are more design, and reducing hot water consumption. -

Energy Efficient Homes: Water Heaters1 Wendell A

FCS3277 Energy Efficient Homes: Water Heaters1 Wendell A. Porter, Kathleen C. Ruppert, and Randall A. Cantrell2 Quick Facts • Install heat traps, one-way valves or loops of pipe, which prevent heated water in a storage tank from mixing with • Water heating is often the third largest energy expense in cooled water in pipes. Most new water heater models your home, after heating and cooling—it can account for have factory-installed heat traps. Heat traps can save you 13–17% of your utility bill. $15–30 per year by preventing convective heat losses • The optimum temperature for both energy efficiency through the inlet and outlet pipes. and function is 120°F. Higher temperatures increase • If you have a tank-style water heater, drain about a quart energy costs and scalding risks. Note: most electric water of water from the water tank every 3–6 months. This heaters have two thermostats (one for each heating helps to remove sediment that slows down heat transfer element), and it is important to make sure they are both and lowers the efficiency of your water heater. Follow the at the same setting. For each 10°F reduction in water manufacturer’s recommendations for your specific unit. temperature, you can save 3–5% in energy costs. Some illnesses and special hygiene conditions might require • If your water heater is more than 10 years old, it is a higher water temperatures for washing certain clothing good idea to start shopping for a new one now. This and linens. will give you a chance to do some research and select the type and model that most appropriately meets your • Install an Energy Star clothes washer. -

Development of a Domestic Active Solar Water Heating System

Development of a Domestic Active Solar Water Heating System by Nesar Ahmad Zaland A thesis submitted in partial fulfillment of the requirements for the degree of Master of Engineering in Mechatronics Examination Committee: Prof. Manukid Parnichkun (Chairperson) Assoc. Prof. Erik L.J. Bohez Dr. Mongkol Ekpanyapong Nationality: Afghan Previous Degree: Bachelor of Engineering in Mechatronics Herat University Afghanistan Scholarship Donor: AFG Western Basins Water Resources Management Project – AIT Fellowship Asian Institute of Technology School of Engineering and Technology Thailand May 2017 ACKNOWLEDGEMENTS First of all I would like to acknowledge my kind advisor Professor Manukid Parnichkun for all of his supports during my master degree, especially for my thesis project. I want to thank all my committee members, Assoc. Pof. Erik L.J. Bohez and Dr. Mongkol Ekpanyapong for their useful ideas and guides for development of my thesis. Thank you to all my family for their biggest supports and motivations within these two years Lastly, I would like to thank Afghanistan’s Ministry of Energy and Water for the provided scholarship. ii ABSTRACT A Domestic Forced Circulation Solar Water Heating System is designed and developed in this paper. This system is an autonomous system which provides free hot water for one person’s needs at temperature of 65˚C in a normal sunny day. As the name of the system is forced circulation system, it needs a water pump to circulate tank’s water through the solar heat collector to get heat energy. It is realized with a control board based on the Arduino Mega board. The control board controls, the functioning of the circulation pump, the level of water into the tank, the solenoid valves which are installed at the tank’s inlet and outlet, and the flow rate of the hot water consumption from the storage tank. -

ENERGY STAR Water Heaters Version 3.0 Program Requirements

ENERGY STAR® Product Specification for Residential Water Heaters Partner Commitments Following are the terms of the ENERGY STAR Partnership Agreement as it pertains to the manufacture and labeling of ENERGY STAR qualified products. The ENERGY STAR Partner must adhere to the following partner commitments: Qualifying Products 1. Comply with current ENERGY STAR Eligibility Criteria, which define performance requirements and test procedures for residential water heaters. A list of eligible products and their corresponding Eligibility Criteria can be found at www.energystar.gov/specifications. 2. Prior to associating the ENERGY STAR name or mark with any product, obtain written certification of ENERGY STAR qualification from a Certification Body recognized by EPA for residential water heaters. As part of this certification process, products must be tested in a laboratory recognized by EPA to perform residential water heater testing. A list of EPA-recognized laboratories and Certification Bodies can be found at www.energystar.gov/testingandverification. Using the ENERGY STAR Name and Marks 3. Comply with current ENERGY STAR Identity Guidelines, which define how the ENERGY STAR name and marks may be used. Partner is responsible for adhering to these guidelines and ensuring that its authorized representatives, such as advertising agencies, dealers, and distributors, are also in compliance. The ENERGY STAR Identity Guidelines are available at www.energystar.gov/logouse. 4. Use the ENERGY STAR name and marks only in association with qualified products. Partner may not refer to itself as an ENERGY STAR Partner unless at least one product is qualified and offered for sale in the U.S. and/or ENERGY STAR partner countries.