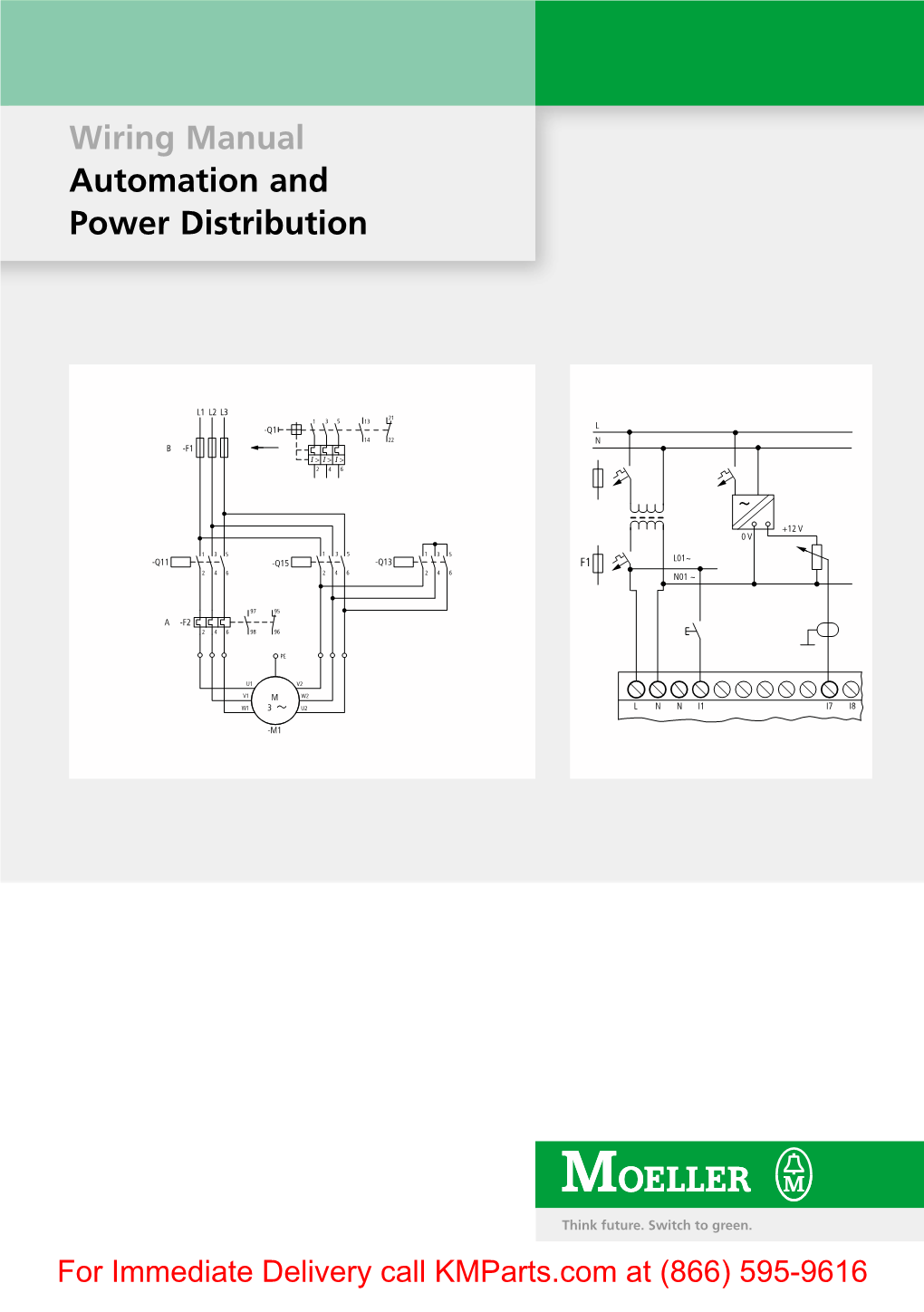

Wiring Manual Automation and Power Distribution

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Schindler Schindler / Westinghouse Quick Locator Guide

www.SEESinc.com SCHINDLER/WESTINGHOUSE SCHINDLER / WESTINGHOUSE QUICK LOCATOR GUIDE Belts . 607 Brushes . 608-611 Brush Holders . 612-613 Capacitators. 630 Car Signal Components . 600-606 Gongs . 606 Emergency Stop Switch . 600, 602-603 Key Switches and Keys . 600, 604, 606 Lantern Lens. 605 Position Indicators . 604 Pushbutton Assemblies . 600-603, 606 Switches, Rocker and Reed. 606 Coils . 614-616 Door Parts And Equipment . 617-629 Cables and Pulleys . 628-629 Door Keys and Escutcheons . 625 Door Roller Assemblies. 628 Gibs, Guides . 625, 656 Hatch Equipment . 619 Interlock Components . 617, 620-622 Door Motors . 619, 629 Operators . 626-627 Safety Edge Parts . 623 Spirator, Reel Closer . 624 Track Liner . 629 Electronics - Tubes, Breakers, Fans . 631 Machine Parts . 632-636 Gaskets, Seals and Bearings. 632-636 Motors . 619, 629, 647 Printed Circuit Boards . 637-641 Rectifiers . 630 Relays . 643-644 Relay Components. 644-648 Resistors. 642 Selector Components . 649-650 Switches . 648-650 Transformers . 651 Wheels And Rollers . 652-655 Hanger Assemblies. 653-654 Hanger Rollers . 653-654 Roller Guide Assemblies . 655 Roller Guide Wheels . 654-655 954.971.1115 / fax 954.917.7337 800.526.0026 599 www.SEESinc.com Car Signal Components SB-2 SB-3 SB-4 SB-1 SCH-KCY-001 SCH-KCY-002 SB-5 SB-6 SB-6-VAN SB-1BR-7 SK-1 SKS-2A SKS-1 SK-3 SK-4 SK-5 SKS-2 SK-2 S.E.E.S. # O.E.M. # Description SB-1 8544C17G04 Button Housing, with lens SB-1BR- 6954C71H01 Braille Plate, braille for SB-1 housing, Stainless Steel, 1” x 1.187” SCHINDLER/WESTINGHOUSE (specify marking) SB-1BR-ARROW_DOWN Braille, Down Arrow For SB-1 SB-1BR-ARROW_UP Braille, Up Arrow For SB-1 SB-2 8540C58H02 Button Retainer Bracket SB-2A 70010CSC3R Screw, 6-32 x 1/2" Hex Washer Head, Slotted SKS-3 SB-3 7283C730G02 Printed Circuit Board Assembly for pushbutton, two micro switch type SB-4 7283C730G01, Printed Circuit Board Assembly for pushbutton, one 998C278H11 micro switch type SCH-KCY-001 D3158-057A/AS100 Key Switch, PHI, 3 position with AS100 key SCH-KCY-002 D3158-057B/AS100 Key Switch, PHII, 3 pos, AS100 key, per yr. -

02-04-00024 Equipment Deep Freezer Compressor 10 Model

02-04-00024 Equipment Deep freezer Compressor 10 model : RSN4-0100-CAV , copeland R502 , V 220 , PH : 1 Compressor 12 model : 1553 89J13 CAJ2446L R502 , V 220 , 50HZ , 4.3 A , tecumseh Compressor 4 model : 8340 S/N 50198 compressor 1/2 HP 4 model : JFP1-0050-JAV B/M 220 N6-535 copland R500 R500 (Frion) 40kg Timer 6 Robertshaw controls co. motor 3 W ,220 V , 50 HZ SW. 1-4 1/3 HP 120/240 VAC SW. 1-2 15A Res. 120VAC Relay 6 184-20302-101 18A , 277 VAC , Coil 208 /240 V 50HZ 02-04-00025 EQUIPMENT: MOTOR CONTROL CENTER FOR OIL & WATER TREATMENT PUMPS COMPANY\MANUFACTURER: SIEMENS - West Germany QUANTITY: 12 SITE: SADDAM MEDICAL CITY\ SERVICE BUILDING CONTACTOR SIZE 4.3 POLE , AC3 3TB4814-OAMO 24 37KW , 380VAC 220V CONTACTOR SIZE 3,3 POLE , AC3 3TB4614-OAMO 24 22KW , 380VAC 220V CONTACTOR SIZE 3,3 POLE , AC3 3TB4617-OAMO 24 22KW , 380VAC 220V CONACTOR SIZE 2,3 POLE , AC3 3TB4417-OAMO 24 15KW , 380VAC 220V CONTACTOR SIZE 1,3 POLE , AC3 3TB4217-OAMO 24 7.5KW , 380VAC 220V CONTACTOR SIZE 0,3 POLE , AC3 3TB4617-OAMO 24 4KW , 380VAC 220V THERMAL DELAYED OVERLOAD 3UA6200-3L 24 RELAY 135 TO 160A THERMAL DELAYED OVERLOAD 3UA6200-2W 24 RELAY 63 TO 90A THERMAL DELAYED RELAY 40 TO 3UA5800-2T 24 57A THERMAL DELAYED OVERLOAD 3UA5800-2F 24 RELAY 32 TO 50A THERMAL DELAYED OVERLOAD 3UA5800-2D 24 RELAY 20 TO 32A THERMAL DELAYED OVERLOAD 3UA5200-2C 24 RELAY 16 TO 25A THERMAL DELAYED OVERLOAD 3UA5000-1K 24 RELAY 8 TO 12.5A UNDER VOLTAGE RELAY AA9943.11 24 220V,380V,50HZ UNDER VOLTAGE RELAY 220 V, A1936.00 24 50HZ STAR-DELTA TIME RELAY 2-20 SEC 7PU6040-7NN20 24 -

Switches and Relays for the Power Industry

Switches and Relays For the Power Industry E L E C T R O NEVER S W I T A DOUBT C H U T I L I T Y ELECTROSWITCH Corporation 180 King Avenue P Weymouth, MA 02188 R TEL: (781) 335-5200 O FAX: (781) 335-4253 www.electroswitch.com D U C T S 5M 113 Printed in USA U.2.D THE ELECTRO SWITCH CORPORATion Family… PROVIDING INTELLIGENT SOLUTIONS FOR SWITCHING AND CONTROL Complete line of electrically and manually activated Rotary Switches and Relays POWER SWITCHES & RELAYS for electric utility, defense, and industrial monitoring and control applications The Best Rotary Switches, Relays, and Electrical Systems Products... Backed by the industry’s most www.electroswitch.com knowledgeable and responsive Rotary Switches; Miniature Toggle, Paddle, Rocker, Power Toggle, and Push- ELECTRONIC PRODUCTS Button Switches; Hall Effect, and Mechanical Encoders; Illuminated Switch engineering and customer Products; and Power Transformers service professionals... Any way you want them... Delivered when you need them. www.electro-nc.com DIGITRAN Digital and Rotary Switch Products designed for aviation, defense, and industrial DIGITAL & ROTARY SWITCHES switch applications ELECTROSWITCH www.digitran-switches.com ARGA CONTROLS Electric utility, industrial and military-grade Power Meters, Battery Monitors, MEASUREMENT & CONTROL INSTRUMENTATION and Transducers for precision measurement applications NEVER www.argacontrols.com Sunrise Technologies Wireless Communication Systems for Smart Grid applications and a complete A DOUBT OUTDOOR LIGHTING CONTROLS & MONITORING line -

Applying Precision Switches

MICRO SWITCH General Technical Bulletin No. 14 APPLYING PRECISION SWITCHES General Technical Bulletin #14 - Applying Precision Switches TABLE OF CONTENTS INTRODUCTION......................................................................................................................................................................1 BRIEF HISTORY OF THE PRECISION SWITCH ..............................................................................................................1 I. THE MECHANICAL CHARACTERISTICS OF A PRECISION SWITCH...................................................................5 A. MECHANICAL ACTION AND TERMINOLOGY..........................................................................................................................5 B. THE RELATION BETWEEN PLUNGER FORCE AND PLUNGER POSITION....................................................................................6 C. THE RELATION BETWEEN CONTACT FORCE AND PLUNGER POSITION....................................................................................8 D. CONTACT BOUNCE AND TRANSIT TIME................................................................................................................................9 E. POLES, THROWS AND BREAKS............................................................................................................................................10 II. THE ELECTRICAL CHARACTERISTICS OF A PRECISION SWITCH................................................................11 A. THE RESISTANCE OF AN OPEN SWITCH...............................................................................................................................11 -

Moeller Wiring Manual 02/05 Specifications, Formulae, Tables

Moeller Wiring Manual 02/05 Specifications, Formulae, Tables Page Marking of electrical equipment 9-2 Circuit symbols, European – North America 9-14 Circuit diagram example to North American specifications 9-27 Approval authorities worldwide 9-28 Test authorities and approval stamps 9-32 Protective measures 9-34 Overcurrent protection of cables and conductors 9-43 Electrical equipment of machines 9-51 Measures for risk reduction 9-56 Measures for risk avoidance 9-57 Degrees of protection for electrical equipment 9-58 North American classifications for control switches 9-68 9 Utilisation categories for contactors 9-70 Utilisation categories for switch-disconnectors 9-74 Rated motor currents 9-77 Conductors 9-81 Formulae 9-90 International unit system 9-94 For Immediate Delivery call KMParts.com at (866) 595-96169-1 Moeller Wiring Manual 02/05 Specifications, Formulae, Tables Marking of electrical equipment General Extracts from the DIN Standards with VDE The marking appears in a suitable position as Classification are quoted with the permission of close as possible to the circuit symbol. The the DIN (Deutsches Institut für Normung e.V.) and marking forms the link between the equipment in the VDE (Verband der Elektrotechnik Elektronik the installations and the various circuit documents Informationstechnik e.V.) It is imperative for the (wiring diagrams, parts lists, circuit diagrams, use of the standards that the issue with the latest instructions). For simpler maintenance, the date is used. These are available from complete marking or part of it, can be affixed on VDE-VERLAG GMBH, Bismarckstr. 33, 10625 or near to the equipment. -

Switching Operator's Manual Distribution Switching

Switching Operator’s Manual Distribution Switching Document Number: 5011675 SECTION ONE Introduction: Distribution Switching Table of Contents 1. Introduction: Distribution Switching ...................................................... 1-1 1.1 Purpose .............................................................................................. 1-1 1.2 Content .............................................................................................. 1-1 1.2.1 Manual One .................................................................................... 1-1 1.2.2 Manual Two .................................................................................... 1-3 1.3 Switching Operator Authorisation Levels ............................................ 1-3 i Switching Operator's Manual One List of Figures No table of figures entries found. List of Tables No table of figures entries found. ii 1. Introduction: Distribution Switching 1.1 Purpose Manual One provides the switching operator with information on the distribution network configuration, apparatus and switching operations. The manual covers the Horizon Power distribution networks associated with the microgrid and Pilbara Grid systems. Manual Two provides the switching operator with information on the transmission network configuration, apparatus and switching operations. This manual covers the transmission network associated with the Pilbara Grid. Both manuals are intended to be used as a resource for all switching operators and also a major resource for the training modules in -

Overload Protection

Overload Protection Before discussing specific control components, it is necessary to review what an overload is and what steps can be taken to limit the damage an overload can cause. Current and Temperature Current flow in a conductor always generates heat due to resistance. The greater the current flow, the hotter the conductor. Excess heat is damaging to electrical components. For that reason, conductors have a rated continuous current carrying capacity or ampacity. Overcurrent protection devices are used to protect conductors from excessive current flow. Thermal overload relays are designed to protect the conductors (windings) in a motor. These protective devices are designed to keep the flow of current in a circuit at a safe level to prevent the circuit conductors from overheating. 22 Excessive current is referred to as overcurrent. The National Electrical Code® defines overcurrent as any current in excess of the rated current of equipment or the ampacity of a conductor. It may result from overload, short circuit, or ground fault (Article 100-definitions). Short Circuits When two bare conductors touch, a short circuit occurs. When a short circuit occurs, resistance drops to almost zero. Short- circuit current can be thousands of times higher than normal operating current. Ohm’s Law demonstrates the relationship of current, voltage, and resistance. For example, a 240 volt motor with 24 ohms of resistance would normally draw 10 amps of current. When a short circuit develops, resistance drops. If resistance drops to 24 milliohms, current will be 10,000 amps. The heat generated by this current will cause extensive damage to connected equipment and conductors. -

How to Use Rotary Stepping Switches Wisely and Fig

$1.45 ROTARY HOW TO USE STEPPING SWITCHES Photographs on the front and back cover are of AE's Type 45 Rotary Stepping Switch Today's rotary stepping switches are wired for hermetic seaJing. the result of decades of service usage and experience. Here, in one book, are the major "DO's" and "DON'T's" of their successful application. AUTOMATIC ELECTRIC Subsidiary 01 GENERAL GENERAL TELEPHONE & ELECTRONICS ~ C·1057-40M -3· Merit Printed in the U.S.A. TCI Library: www.telephonecollectors.info TCI Library: www.telephonecollectors.info II 1- HOW TO USE ,. ROTARY STEPPING SWITCHES V. E. JAMES, Editor Ii· i !I ! I' \ 1 ! r • AUTOMATIC ELECTRIC COMPANY • Northlake,III;no;s I- I ! I I I TCI Library: www.telephonecollectors.info i TCI Library: www.telephonecollectors.info /. ~~ TABLE OF CONTENTS Editor's Preface ......................... v I. THIS IS A ROTARY STEPPING SWITCH 1 II. ROTARY STEPPING SWITCH NOMENCLATURE..... 5 Mechanical Components ......................... 5 Types of "Drive" ............................. .. 10 Direction of Stepping " 12 III. BASIC OPERATING CIRCUITS FOR INDIRECTLY DRIVEN ROTARY STEPPING SWITCHES 15 Pulsed Stepping 16 All rights reserved, including· the right of reproduction Self-Interrupted Stepping 18 in whole or in part, in any form. Considerations of Maximum Circuit-Closure Time " 19 Pulse-Inversion Circuit. ........................ .. 20 Copyright, 1964, AUTOMATIC ELECTRIC COMPANY. IV. "HOMING" OF ROTARY STEPPING SWITCHES 22 Published by AUTOMATIC ELECTRIC COMPANY, Northlake, Illinois. Direct-Drive 22 Indirect-Drive 23 First Edition, March 30, 1964. Self-Interrupted Stepping and Homing of the Type 45NC. 25 V. BASIC THINGS YOU CAN DO WITH Printed in the United States of America. -

Switches C&K 7107

S.P.D.T. ON-OFF-(ON) SWITCHES C&K 7107. SPDT, center-off, momentary (brackets) indicate momentary position one direction, miniature toggle switch. Rated 0.4VA. Plain, 1/4" unthreaded SUB MINIATURE TOGGLE bushing. Flat toggle handle. Horizontal 0.2" dia. threaded bushing unless otherwise noted. switching action. Right-angle pc pins. CAT# MTS-69 $1.00 each S.P.D.T. ON-ON Rated: 1.5 amp @ 250 Vac. D.P.D.T. ON-OFF-ON Solder lug terminals. 0.4” long bat handle. RATED: 3 amp @ 120 Vac. CAT# SMTS-4 $1.35 each Threaded bushing. Solder lug terminals. 10 for $12.50 • 100 for $110.00 0.43" long handle. CAT# MTS-12 $1.85 each D.P.D.T. ON-ON 10 for $17.00 • 100 for $145.00 Rated: 1.5 amp @ 250 Vac. DPDT, CENTER-OFF Solder lug terminals. 0.4” long bat handle. NEW CAT# SMTS-8 $1.75 each MINI-TOGGLE SWITCH ALCO # MTA206P. Miniature 10 for $15.50 • 100 for $135.00 D.P.D.T. ON-OFF-ON toggle switch. 1/4-40 threaded bushing. 0.43" long S.P.D.T. ON-ON handle. Rated: 6A 125 Vac, 3A 250 Vac. NKK # G3T-12. Tiny surface-mount toggle Epoxy sealed gold-plated solder terminals. switch rated 0.4VA 28VAC/DC. Right angle CAT# MTA-206P $6.75 each mounting. Toggle action is parallel to pc board. 8.5 x 9.0 x 5.6mm. Surface mount pads. D.P.D.T. ON-OFF-ON CAT# TSMT-4 $1.75 each • 10 for $15.50 RATED: 6 Amp @ 125 Vac, 2 Amp 250 Vac. -

3. Relays Contents

3. Relays Contents 1 Relay 1 1.1 Basic design and operation ...................................... 1 1.2 Types ................................................. 2 1.2.1 Latching relay ......................................... 2 1.2.2 Reed relay ........................................... 3 1.2.3 Mercury-wetted relay ..................................... 3 1.2.4 Mercury relay ......................................... 3 1.2.5 Polarized relay ........................................ 4 1.2.6 Machine tool relay ...................................... 4 1.2.7 Coaxial relay ......................................... 4 1.2.8 Time delay .......................................... 4 1.2.9 Contactor ........................................... 4 1.2.10 Solid-state relay ........................................ 4 1.2.11 Solid state contactor relay ................................... 5 1.2.12 Buchholz relay ........................................ 5 1.2.13 Forced-guided contacts relay ................................. 5 1.2.14 Overload protection relay ................................... 6 1.2.15 Vacuum relays ........................................ 6 1.3 Pole and throw ............................................. 6 1.4 Applications .............................................. 7 1.5 Relay application considerations .................................... 8 1.5.1 Derating factors ........................................ 9 1.5.2 Undesired arcing ....................................... 9 1.6 Protective relays ........................................... -

Project #6: Building a Shed

Project #6: Building a Shed Lesson #4: Electrical (20 class periods) Objectives Students will be able to… . Understand the progress of using electricity in housing. Develop and apply basic skills in electrical wiring work. Find at least three codes in the NEC that govern electrical construction. Students practice calculating current, resistance, and voltage. Given the power equation, calculate the power consumed in a circuit or load. Name and identify electrical symbols while reading electrical plans . Layout and install a circuit from blueprints. Identify the tools and equipment used by electricians today. Define terms related to electrical safety. Identify electrical wiring tools and materials. Demonstrate safe working procedures in a construction and shop/lab environment. Work cooperatively as a member of a team. Identify electrical hazards and how to avoid or minimize them in the workplace. Common Core Standards LS 11-12.6 RSIT 11-12.2 RLST 11-12.2 Writing 9-10.5 Geometry 4.0 Residential and Commercial Construction pathway D2.8, D3.1, D11.1, D11.2, D11.3, D11.4, D11.9, D11.11 Problem Solving and Critical Thinking 5.2, 5.3, 5.4 Health and Safety 6.2, 6.3, 6.7, 6.10 Responsibility and Leadership 7.3, 7.4, 7.5, 7.6, 7.7, 9.2, 9.3, 9.6, 9.7 Materials © BITA: A program promoted by California Homebuilding Foundation BUILDING INDUSTRY TECHNOLOGY ACADEMY: YEAR TWO CURRICULUM Electrical history terms handout and worksheet History of Wire and Cable Systems Handout History of Wire and Cable Systems Worksheet YouTube Video https://www.youtube.com/watch?v=SdjyNoWQX5k -

An Access-Dictionary of Internationalist High Tech Latinate English

An Access-Dictionary of Internationalist High Tech Latinate English Excerpted from Word Power, Public Speaking Confidence, and Dictionary-Based Learning, Copyright © 2007 by Robert Oliphant, columnist, Education News Author of The Latin-Old English Glossary in British Museum MS 3376 (Mouton, 1966) and A Piano for Mrs. Cimino (Prentice Hall, 1980) INTRODUCTION Strictly speaking, this is simply a list of technical terms: 30,680 of them presented in an alphabetical sequence of 52 professional subject fields ranging from Aeronautics to Zoology. Practically considered, though, every item on the list can be quickly accessed in the Random House Webster’s Unabridged Dictionary (RHU), updated second edition of 2007, or in its CD – ROM WordGenius® version. So what’s here is actually an in-depth learning tool for mastering the basic vocabularies of what today can fairly be called American-Pronunciation Internationalist High Tech Latinate English. Dictionary authority. This list, by virtue of its dictionary link, has far more authority than a conventional professional-subject glossary, even the one offered online by the University of Maryland Medical Center. American dictionaries, after all, have always assigned their technical terms to professional experts in specific fields, identified those experts in print, and in effect held them responsible for the accuracy and comprehensiveness of each entry. Even more important, the entries themselves offer learners a complete sketch of each target word (headword). Memorization. For professionals, memorization is a basic career requirement. Any physician will tell you how much of it is called for in medical school and how hard it is, thanks to thousands of strange, exotic shapes like <myocardium> that have to be taken apart in the mind and reassembled like pieces of an unpronounceable jigsaw puzzle.