Radium Hill: Bindi to Boom Town

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Davidite and Other Early Events in Australia's Uranium Story

Journal & Proceedings of the Royal Society of New South Wales, Vol. 140, p. 1–9, 2007 ISSN 0035-9173/07/01001–9 $4.00/1 Davidite and Other Early Events in Australia’s Uranium Story david branagan Abstract: The uranium-bearing mineral davidite was named for T.W. Edgeworth David. The controversy about its validity as a true mineral lasted some years. Significant studies of radioactivity and age determinations were carried out at Sydney University during the years 1904 to 1930. Keywords: Edgeworth David, davidite, age determinations, Sydney University INTRODUCTION ent substances, and he suspected there might be a new mineral present. Alderman (1967) With the present interest in the use of uranium makes the point that Mawson had not only as a source of energy, it is an appropriate time a deep interest in minerals, but also an ency- to present a few snippets of early Australian clopaedic knowledge. ‘He displayed the hall- research on that subject. The first scientific mark of the great mineralogist–that uncanny studies in Australia on radioactivity were car- ability to recognise almost instantly whether a ried out more than one hundred years ago. Al- mineral is unusual or “new” ’. though not himself an experimenter in this field, Mawson described the ‘new’ substance as T.W. Edgeworth David (1858–1934), Professor cuboid crystals of a black mineral with specific of Geology at the University of Sydney between gravity about 4, having a brilliant lustre and 1891 and 1924, through his encouragement and glassy fracture, containing over 50% of TiO2, a support of various students, played a signifi- large quantity of iron and a notable amount of cant part in the development of this research. -

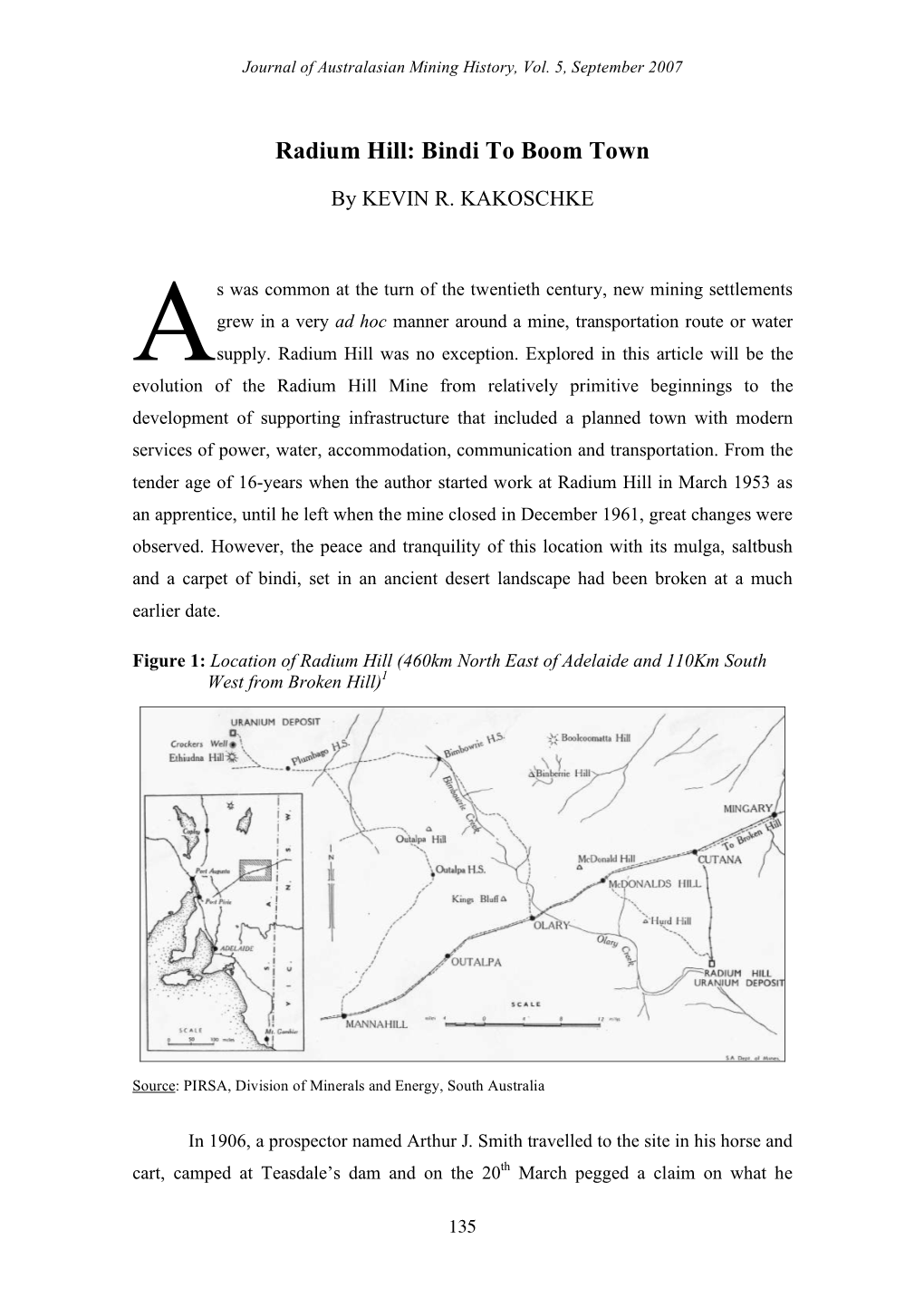

Radium Hill, South Australia in 1906 by Arthur Smith

Dear Sir, The attached submission is relevant to the evidence being presented to the Royal Commission hearings into the uranium industry. I trust this information will help the Commission in its deliberations. Kindest regards Kevin R Kakoschke OAM 'NUKE' OR POLLUTE? Recent editions of the 'Advertiser', Saturday Dec. 13, and the 'Australian', Saturday Dec. 13, 2014, highlighted two contentious environment issues, namely the reduction of carbon emissions and nuclear energy. The production of electricity using nuclear energy as the power source was an option for reducing carbon emissions. But what of the radioactive waste? Where did the nuclear dilemma in Australia begin? Radioactive uranium/radium was discovered at Radium Hill, South Australia in 1906 by Arthur Smith. The use of radium for producing electricity was highlighted way back in 1906. A newspaper article stated; 'that one ounce of it is equal to one hundred thousand nominal horsepower'. ...and that small quantity would be sufficient to drive or propel three of the largest battleships afloat for a period of two thousand years. By 1912, there were thirty-five miners working in the mine at Radium Hill extracting the uranium/radium bearing ore which was concentrated before being dispatched to Hunters Hill in Sydney for further processing into radium bromide (350mgms) and uranium (150kgms). Many of these men had links with Broken Hill. In 1913 an article in the 'Adelaide Register' newspaper claimed, 'It will mean that foreign nations will be obliged to seek from us the power wherewith to heat and light their cities, and find means of defence and offence,...The small space for storing radium would be infinitesimally small in comparison to that required for the storing of oil, coal or coke,.. -

….News Bulletin…

…THE… ….NEWS BULLETIN…. For information of ex-Radium Hill Community and families Official Organ of the Radium Hill Historical Association Inc. February 2021 CONTENTS Hello There, BIRTHS Hello there, Birthdays 1 Well, 2021 saw the sixtieth year They say that 40 is the old age of Our Achievements 2 since the closure of the Radium youth and that 60 is the youth of Hill uranium mine. A sad time for old age. Where do you fit in? the hundreds of people who lived Radium Hill Visits and 2 and worked there. What a year 1961 was at the Access Update A.I.M. Hospital, the last year that Miss Radium Hill 3 Many folk have been in touch this babies were born in Radium Hill past year from around the world, including; Closing down 4 with news, advice, and best wishes. Thanks to all of you. Kym Pudler, Atillio Scopel, Paul Glandore Reunion 2021 5 Bertocchi, Steven Westover, Pier R. H. School Fete photo 6 It has been a mixed year, Scalet, Brian Ford, Cynthia Wade, comprising the good and the not so Michael Clayton, Kathryn Lawrie, good. and Graham Paull. Townsite Layout map 6 Entry to our old town of Radium Hill and cemetery, via the “old Gee, how time flies. th track” through both Tikalina and Happy 60 birthday to you all. CONTACT NAMES Maldorky stations is still restricted. Kevin Kakoschke (President) Hopefully this state of affairs will Graham Paull, who at number 32A Mortimer Street, change in the not too distant 117, was the last babe born at the KURRALTA PARK future. -

Consultancy Report Radioactive Waste Store Feasibility Study

ENVIRONMENT PROTECTION AUTHORITY Consultancy report Radioactive Waste Store Feasibility Study - Stage Three This report has been prepared by consultants for the Environment Protection Authority (EPA) and the views expressed do not necessarily reflect those of the EPA. The EPA cannot guarantee the accuracy of the report, and does not accept liability for any loss or damage incurred as a result of relying on its accuracy. R E P O R T Radioactive Waste Store Feasibility Study - Stage Three Prepared for Environmental Protection Authority GPO Box 2607 Adelaide SA 5001 3 November 2005 42656131 URS Australia Pty Ltd Project Manager: ………………………………….. 25 North Terrace Malcolm Wedd Hackney SA 5069 Associate, Environmental Management Project Director: ………………………………….. Vic Farrington Senior Principal Environmental Engineer Date: 3 November 2005 Reference: 42656131 Status: Final Rev 1 21-NOV-05 Contents Executive Summary-----------------------------------------------------------------------------------ES-1 1 Introduction------------------------------------------------------------------------------------------------ 1-1 1.1 Background 1-1 1.2 Feasibility Study Topics 1-1 1.3 Feasibility Study Scope 1-2 2 Interim Store Location --------------------------------------------------------------------------------- 2-1 2.1 Introduction 2-1 2.2 Olympic Dam 2-2 2.2.1 Background 2-2 2.2.2 Potential Interim Store Site Description 2-2 2.2.3 Interim Store Selection Criteria 2-5 2.2.4 The Quantity of Radioactive Waste 2-10 2.2.5 Potential Risks to People and the Environment -

Governing Uranium in Australia

A Service of Leibniz-Informationszentrum econstor Wirtschaft Leibniz Information Centre Make Your Publications Visible. zbw for Economics Vestergaard, Cindy Research Report Governing uranium in Australia DIIS Report, No. 2015:11 Provided in Cooperation with: Danish Institute for International Studies (DIIS), Copenhagen Suggested Citation: Vestergaard, Cindy (2015) : Governing uranium in Australia, DIIS Report, No. 2015:11, ISBN 978-87-7605-762-6, Danish Institute for International Studies (DIIS), Copenhagen This Version is available at: http://hdl.handle.net/10419/144725 Standard-Nutzungsbedingungen: Terms of use: Die Dokumente auf EconStor dürfen zu eigenen wissenschaftlichen Documents in EconStor may be saved and copied for your Zwecken und zum Privatgebrauch gespeichert und kopiert werden. personal and scholarly purposes. Sie dürfen die Dokumente nicht für öffentliche oder kommerzielle You are not to copy documents for public or commercial Zwecke vervielfältigen, öffentlich ausstellen, öffentlich zugänglich purposes, to exhibit the documents publicly, to make them machen, vertreiben oder anderweitig nutzen. publicly available on the internet, or to distribute or otherwise use the documents in public. Sofern die Verfasser die Dokumente unter Open-Content-Lizenzen (insbesondere CC-Lizenzen) zur Verfügung gestellt haben sollten, If the documents have been made available under an Open gelten abweichend von diesen Nutzungsbedingungen die in der dort Content Licence (especially Creative Commons Licences), you genannten Lizenz gewährten Nutzungsrechte. -

Radiation Workers' Handbook

Radiation Workers’ Handbook Radiation Control in the Mining & Mineral Processing Industry Uranium Mineral Sands Rare Earths NORM 1 Radiation Workers’ Handbook Contents: Quick-Start Summary 1 Introduction: Radioactive Ores, their Uses & Control 2 History of Radiation & Discovery of the Health Risks 3 History of Australian Uranium Mining 4 Radiation Basics: Atoms; Alpha, Beta & Gamma rays; Activity and Dose Units 5 Health Effects of Radiation 6 Natural Background Radiation & comparisons with Medical Doses 7 Sources of Radiation in the Resources Industries, U-238 & Th-232 decay chains 8 Dose Limit Philosophy & History 9 Regulatory Regime in Australia 10 Dose Control Methods for Different Situations: Mining: Open Pit, Underground, In Situ Leach Processing: Uranium, Mineral Sands, Rare Earths NORM: Oil / Gas, Fertilizer Plants, Coal Washeries, Sinter Plants, Smelters 11 Environmental Controls 12 Transport 13 Surface Contamination Controls & Clearances 14 Radiation Monitoring Plans & Personal Dose Calculations 15 Your Role, Responsibilities, & Required Competencies 16 Comparison with Other Hazards 17 Conclusion Glossary Further Resources & Contributors Image Credits PLEASE NOTE: This booklet has been written about the hazard of radiation and its controls. Other hazards have not been discussed in detail. Safety manuals are available at mines and mills which deal specifi cally with other hazards. Radiation has been given a booklet of its own, not because it is the greater hazard, but because it is invisible and not widely understood. 2 3 Quick-Start Summary: Radiation Dose Delivery Pathways, their monitoring and control As a worker in the mining and resources industries who mines or processes radioactive materials, or treats radioactive wastes, you can be exposed to radiation. -

URANIUM Resources, Geology and Development of Deposits

Australia’s URANIUM resources, geology and development of deposits A.D. McKay and Y. Miezitis AGSO – Geoscience Australia Mineral Resource Report 1 AGSO – GEOSCIENCE AUSTRALIA Mineral Resource Report 1 AUSTRALIA’S URANIUM RESOURCES, GEOLOGY AND DEVELOPMENT OF DEPOSITS Aden D. McKay & Yanis Miezitis i AGSO – Geoscience Australia Chief Executive Officer: Dr Neil Williams Department of Industry, Science & Resources Minister for Industry, Science & Resources: Senator the Hon. Nick Minchin Parliamentary Secretary: The Hon. Warren Entsch, MP © Commonwealth of Australia 2001 Reprinted 2007 This work is copyright. Apart from any fair dealings for the purposes of study, research, criticism, or review, as permitted under the Copyright Act 1968, no part may be reproduced by any process without written permission. Inquiries should be directed to the Communications Unit, AGSO – Geoscience Australia, GPO Box 378, Canberra, ACT 2601. ISBN 0 642 46716 1 GeoCat No. 37672 Bibliographic reference: McKay, A.D. & Miezitis, Y., 2001. Australia’s uranium resources, geology and development of deposits. AGSO – Geoscience Australia, Mineral Resource Report 1. AGSO – Geoscience Australia has tried to make the information in this product as accurate as possible. However, it does not guarantee that the information is totally accurate or complete. THEREFORE, YOU SHOULD NOT RELY SOLELY ON THIS INFORMATION WHEN MAKING A COMMERCIAL DECISION. Front cover: Aerial view of the Olympic Dam mine, South Australia. Photo courtesy of WMC (Olympic Dam Corporation) Pty Ltd. Back cover: Uranium recovery plant, Beverley mine, South Australia. Large diameter trunk lines carry leach solutions from the plant to the wellfield, and leachate containing dissolved uranium from the wellfield to the plant. -

M4074240 Radium Hill Informat

Contaminated Site Risk Assessment and Remediation Scoping Project: Radium Hill Uranium Mine and Low-Level Radioactive Waste Repository Introduction The Department of Primary Industries & Resources South Australia (PIRSA) has engaged consultants ENSR Australia (ENSR) to perform a Contaminated Site Risk Assessment and Remediation Control Scoping study as part of the Radium Hill Uranium Mine Remediation project. This will include a human health and ecological risk assessment covering radiological and non-radiological contaminants for the marine and terrestrial environments. PIRSA manages the former Radium Hill Uranium Mine & Low Level Radioactive Waste Repository site on behalf of the South Australian Government. Recognising that there was a need for long-term management of radioactive material at the site, a decision was made in 2003 to formally investigate the site and develop a comprehensive management strategy to effectively deal with issues relevant to the site now and into the future. The approach adopted by PIRSA is compatible with new safety guidance being developed by the Australian Radiation Protection and Nuclear Safety Agency (ARPANSA) for management of naturally occurring radioactive materials (NORM). Risk assessment considers the potential human health and ecological ('receptor') exposures which might occur in a given environmental situation in combination with relevant radiological and chemical toxicities. Estimates of exposure and risk are made using realistic but worst case assumptions of contact with the contaminants. Consistent with international practice, the assessment aims to provide risk estimates that are no lower, and almost certainly higher, than actual risks. The assessment then forms a basis for decision-making. Person-specific risks resulting from exposures would be estimated by taking into account actual individual exposure lifestyle factors such as visitation times to the site. -

Sa Nuclear Fuel Cycle Royal Commission Mr Kevin Scarce

SA NUCLEAR FUEL CYCLE ROYAL COMMISSION MR KEVIN SCARCE, Presiding Commissioner MR CHAD JACOBI, Counsel Assisting SPEAKERS: MR KEVIN KAKOSCHKE OAM, Radium Hill Historical Association MR GREG MARSHALLl and MR TONY WARD, Department of State Development MR KEITH BALDRY, MR GRAEME PALMER and DR ARTEM BORYSENKO, Environmental Protection Authority DR PAUL ASHLEY, University of New England TRANSCRIPT OF PROCEEDINGS ADELAIDE 10.30 AM, THURSDAY, 8 OCTOBER 2015 DAY TEN PROCEEDINGS RECORDED BY SPARK AND CANNON COMMISIONER: Good morning. It being 10.30 we will convene. Topic six is the environmental impacts, lessons learnt from past mining and milling practices in South Australia, case studies for Port Pirie Rare Earths Treatment Facility and Radium Hill. Might just start with a context statement about what 5 we are attempting to achieve in this particular section. The commission’s terms of reference expressly require it to give considerations to the environmental impact of the potential expansion of exploration and extraction activities. That much of the exercise is to be conducted by considering what has occurred elsewhere, largely overseas, and what might occur were those 10 activities to be carried out in Australia. Our terms of reference expressly require us to give consideration to the lessons that can be learnt from past exploration and extraction activities in South Australia. The commission, before it considers any possible expansion of operations will examine South Australian history to see whether that might inform what we should do 15 in the future. In short, the commission will pay heed to the past, lest mistakes be repeated. The most significant of these past extraction activities was the radium and later uranium mine operated at Radium Hill in South Australia’s north-east and the 20 associated processing works operated here where we are today in Port Pirie. -

Summary of State Heritage Place

South Australian HERITAGE COUNCIL SUMMARY OF STATE HERITAGE PLACE REGISTER ENTRY Entry in the South Australian Heritage Register in accordance with the Heritage Places Act 1993 NAME: Radium Hill Townsite and Cemetery PLACE NO.: 21246 ADDRESS: Maldorky Station, off the Barrier Highway, East of Olary CL1338/32 H835400 BL1192 Hundred of Olary STATEMENT OF HERITAGE SIGNIFICANCE Radium Hill Townsite and Cemetery are significant for their close associations with the early development of uranium mining in South Australia. Radium Hill has a number of important historic associations, including as the site of one of Australia’s earliest uranium finds, its naming by Douglas Mawson, and desultory mining activities from 1906 to the early 1940s. However, it was not until after the Second World War that the location really came into prominence. The destruction of Hiroshima in 1945 not only heralded the end of the Second World War, but also played a crucial role in the inception of the Atomic Age. The subsequent development and use of nuclear technology required fuel, and Radium Hill was recognised as a potential source of uranium, with exploration recommencing there in 1947. Within two years, a decision was made to establish a uranium mine at Radium Hill, with construction of a crushing and sampling plant, the passing of the Uranium Mining Act, and the first structures of the Radium Hill township appearing by the end of 1949. In 1951, Premier Thomas Playford escalated the importance of Radium Hill by negotiating with the US Atomic Energy Commission and the Combined Development Agency to create an agreement for supplying uranium to the United States, and by 1954, full-scale mining and processing was underway at the site. -

Peculiar Knob – Iron

ExplorationExploration andand DevelopmentDevelopment OpportunitiesOpportunities inin SouthSouth AustraliaAustralia MarkMark McGeoughMcGeough ManagerManager ofof GeologicalGeological SurveySurvey andand TedTed TyneTyne DirectorDirector ofof MineralMineral ResourcesResources PrimaryPrimary IndustriesIndustries andand ResourcesResources SouthSouth AustraliaAustralia SouthSouth Australia’sAustralia’s MineralMineral SectorSector HighlightsHighlights forfor 20072007 RecordRecord levelslevels ofof mineralmineral andand geothermalgeothermal explorationexploration expenditureexpenditure andand drillingdrilling inin 20072007 drivendriven by:by: •• Copper-Gold;Copper-Gold; Uranium;Uranium; Gold;Gold; BaseBase Metals;Metals; MineralMineral SandsSands andand hothot RocksRocks (geothermal)(geothermal) •• NewNew discoveriesdiscoveries andand encouragingencouraging intersectionsintersections inin allall mineralmineral provincesprovinces andand acrossacross allall commoditiescommodities •• NewNew geosciencegeoscience andand PACEPACE collaborativecollaborative drillingdrilling successessuccesses •• MajorMajor miningmining developmentsdevelopments forfor Copper-Gold;Copper-Gold; Uranium;Uranium; Gold;Gold; BaseBase Metals;Metals; IronIron OreOre andand MineralMineral SandsSands South Australian Export Figures Minerals contribution has almost doubled in 3 years Other Other Petroleum 11% Agriculture and 14% Agriculture and 2% Petroleum Food Road Food 3% 23% vehicles 34% Road vehicles 17% 11% Wine 20% Minerals Wine Machinery Machinery 13% 18% Minerals 5% 24% -

The Mineralogical Magazine

THE MINERALOGICAL MAGAZINE AND JOURNAL OF THE MINERALOGICAL SOCIETY No. 209 June, 1950 Vol. XXIX A radioactive mineral from Mozambique related to davidite. By F. A. BANNISTER, M.A., Sc.D., F.IUSt.P. Department of Mineralogy, British Museum and J. E. T. HOR~, M.A., F.G.S. Geological Survey and Museum London.x [Read April 1, 1948.] ARLY in 1947 a black, opaque, radioactive mineral resembling E samarskite in appearance was discovered at Mavnzi in the Tete dis- trier of Mozambique, Portuguese East Africa. Two small specimens, one a rough twinned crystal with trigonal symmetry (fig. 3), were sent by h. M. Macgregor; then Director of the Geological Survey of Southern Rhodesia, to the British Museum (Natural History) for investigation, and a chemical analysis by E. Golding (table I, no. 2) followed later in the same year. X-ray photographs of fragments and powder from both specimens were taken, but revealed on development no diffraction spots, lines, or haloes. Only after prolonged heat-treatment could powder lines characteristic of crystalline material be obtained. The metamict nature of the mineral before heat-treatment is not unexpected in view of its chemical composition, optical isotropy, and glassy fracture. Subsequently, a quantity of larger crystals and also massive material was received by the Geological Survey of Great Britain, making possible a more detailed study of the morphology, the chemical composition, and of the X-ray patterns of the mineral after heat-treatment. It was recognized by Dr. C. F. Davidson that chemically the radioactive mineral from Tete is very similar to davidite from Radium Hill, 20 miles ESE.