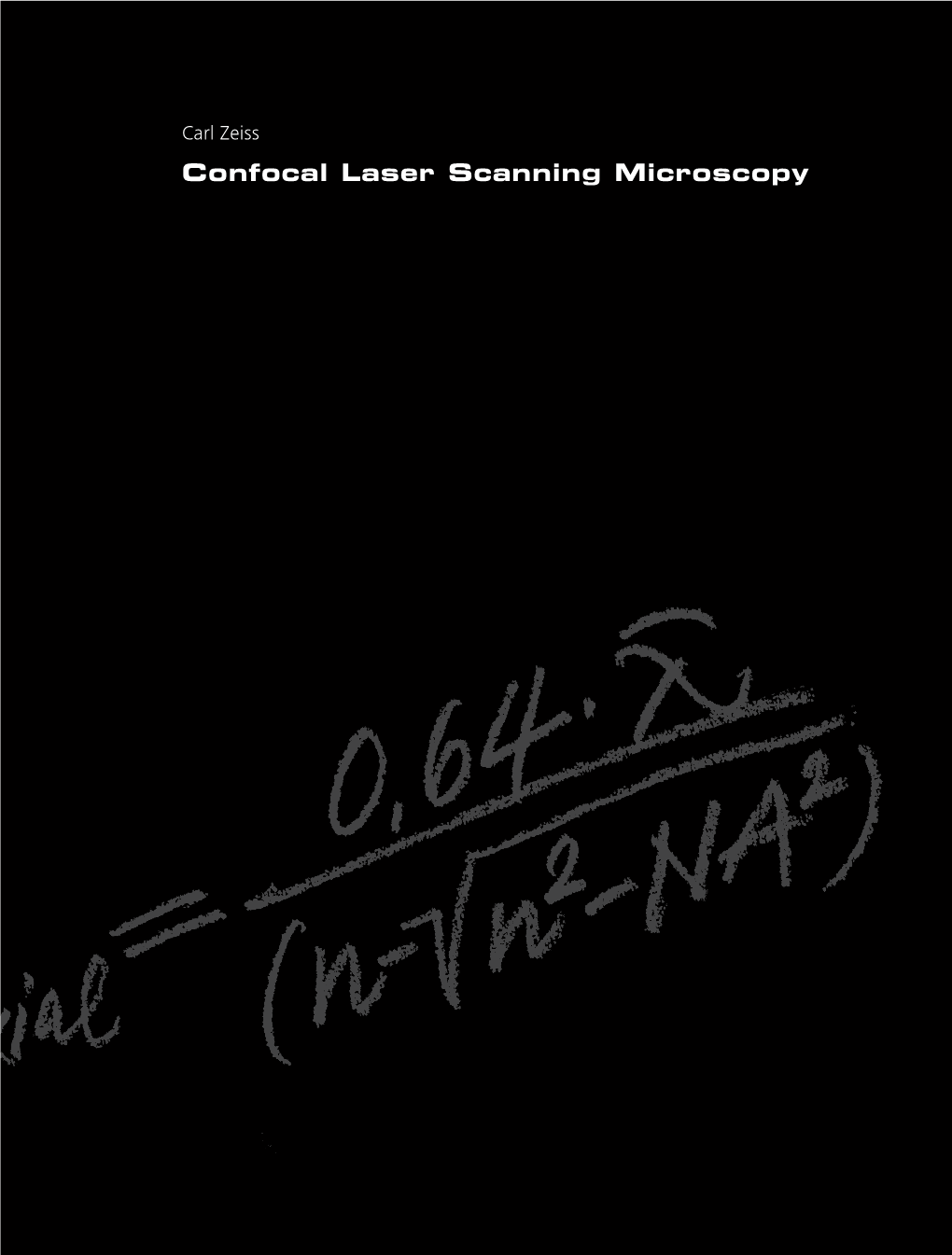

Confocal Laser Scanning Microscopy Deals with the Quality Parameters of Resolution, Depth Discrimination, Noise and Digitization, As Well As Their Mutual Interaction

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

The Gauss-Airy Functions and Their Properties

Annals of the University of Craiova, Mathematics and Computer Science Series Volume 43(2), 2016, Pages 119{127 ISSN: 1223-6934 The Gauss-Airy functions and their properties Alireza Ansari Abstract. In this paper, in connection with the generating function of three-variable Hermite polynomials, we introduce the Gauss-Airy function Z 1 3 1 −yt2 zt GAi(x; y; z) = e cos(xt + )dt; y ≥ 0; x; z 2 R: π 0 3 Some properties of this function such as behaviors of zeros, orthogonal relations, corresponding inequalities and their integral transforms are investigated. Key words and phrases. Gauss-Airy function, Airy function, Inequality, Orthogonality, Integral transforms. 1. Introduction We consider the three-variable Hermite polynomials [ n ] [ n−3j ] X3 X2 zj yk H (x; y; z) = n! xn−3j−2k; (1) 3 n j! k!(n − 2k)! j=0 k=0 2 3 as the coefficient set of the generating function ext+yt +zt 1 n 2 3 X t ext+yt +zt = H (x; y; z) : (2) 3 n n! n=0 For the first time, these polynomials [8] and their generalization [9] was introduced by Dattoli et al. and later Torre [10] used them to describe the behaviors of the Hermite- Gaussian wavefunctions in optics. These are wavefunctions appeared as Gaussian apodized Airy polynomials [3,7] in elegant and standard forms. Also, similar families to the generating function (2) have been stated in literature, see [11, 12]. Now in this paper, it is our motivation to introduce the Gauss-Airy function derived from operational relation 2 3 y d +z d n 3Hn(x; y; z) = e dx2 dx3 x : (3) For this purpose, in view of the operational calculus of the Mellin transform [4{6], we apply the following integral representation 1 2 3 Z eys +zs = esξGAi(ξ; y; z) dξ; (4) −∞ Received February 28, 2015. -

Implementation of Airy Function Using Graphics Processing Unit (GPU)

ITM Web of Conferences 32, 03052 (2020) https://doi.org/10.1051/itmconf/20203203052 ICACC-2020 Implementation of Airy function using Graphics Processing Unit (GPU) Yugesh C. Keluskar1, Megha M. Navada2, Chaitanya S. Jage3 and Navin G. Singhaniya4 Department of Electronics Engineering, Ramrao Adik Institute of Technology, Nerul, Navi Mumbai. Email : [email protected], [email protected], [email protected], [email protected] Abstract—Special mathematical functions are an integral part Airy function is the solution to Airy differential equa- of Fractional Calculus, one of them is the Airy function. But tion,which has the following form [22]: it’s a gruelling task for the processor as well as system that is constructed around the function when it comes to evaluating the d2y special mathematical functions on an ordinary Central Processing = xy (1) Unit (CPU). The Parallel processing capabilities of a Graphics dx2 processing Unit (GPU) hence is used. In this paper GPU is used to get a speedup in time required, with respect to CPU time for It has its applications in classical physics and mainly evaluating the Airy function on its real domain. The objective quantum physics. The Airy function also appears as the so- of this paper is to provide a platform for computing the special lution to many other differential equations related to elasticity, functions which will accelerate the time required for obtaining the heat equation, the Orr-Sommerfield equation, etc in case of result and thus comparing the performance of numerical solution classical physics. While in the case of Quantum physics,the of Airy function using CPU and GPU. -

Simple and Robust Method for Determination of Laser Fluence

Open Research Europe Open Research Europe 2021, 1:7 Last updated: 30 JUN 2021 METHOD ARTICLE Simple and robust method for determination of laser fluence thresholds for material modifications: an extension of Liu’s approach to imperfect beams [version 1; peer review: 1 approved, 2 approved with reservations] Mario Garcia-Lechuga 1,2, David Grojo 1 1Aix Marseille Université, CNRS, LP3, UMR7341, Marseille, 13288, France 2Departamento de Física Aplicada, Universidad Autónoma de Madrid, Madrid, 28049, Spain v1 First published: 24 Mar 2021, 1:7 Open Peer Review https://doi.org/10.12688/openreseurope.13073.1 Latest published: 25 Jun 2021, 1:7 https://doi.org/10.12688/openreseurope.13073.2 Reviewer Status Invited Reviewers Abstract The so-called D-squared or Liu’s method is an extensively applied 1 2 3 approach to determine the irradiation fluence thresholds for laser- induced damage or modification of materials. However, one of the version 2 assumptions behind the method is the use of an ideal Gaussian profile (revision) report that can lead in practice to significant errors depending on beam 25 Jun 2021 imperfections. In this work, we rigorously calculate the bias corrections required when applying the same method to Airy-disk like version 1 profiles. Those profiles are readily produced from any beam by 24 Mar 2021 report report report insertion of an aperture in the optical path. Thus, the correction method gives a robust solution for exact threshold determination without any added technical complications as for instance advanced 1. Laurent Lamaignere , CEA-CESTA, Le control or metrology of the beam. Illustrated by two case-studies, the Barp, France approach holds potential to solve the strong discrepancies existing between the laser-induced damage thresholds reported in the 2. -

On Airy Solutions of the Second Painlevé Equation

On Airy Solutions of the Second Painleve´ Equation Peter A. Clarkson School of Mathematics, Statistics and Actuarial Science, University of Kent, Canterbury, CT2 7NF, UK [email protected] October 18, 2018 Abstract In this paper we discuss Airy solutions of the second Painleve´ equation (PII) and two related equations, the Painleve´ XXXIV equation (P34) and the Jimbo-Miwa-Okamoto σ form of PII (SII), are discussed. It is shown that solutions which depend only on the Airy function Ai(z) have a completely difference structure to those which involve a linear combination of the Airy functions Ai(z) and Bi(z). For all three equations, the special solutions which depend only on Ai(t) are tronquee´ solutions, i.e. they have no poles in a sector of the complex plane. Further for both P34 and SII, it is shown that amongst these tronquee´ solutions there is a family of solutions which have no poles on the real axis. Dedicated to Mark Ablowitz on his 70th birthday 1 Introduction The six Painleve´ equations (PI–PVI) were first discovered by Painleve,´ Gambier and their colleagues in an investigation of which second order ordinary differential equations of the form d2q dq = F ; q; z ; (1.1) dz2 dz where F is rational in dq=dz and q and analytic in z, have the property that their solutions have no movable branch points. They showed that there were fifty canonical equations of the form (1.1) with this property, now known as the Painleve´ property. Further Painleve,´ Gambier and their colleagues showed that of these fifty equations, forty-four can be reduced to linear equations, solved in terms of elliptic functions, or are reducible to one of six new nonlinear ordinary differential equations that define new transcendental functions, see Ince [1]. -

Part III - Microscopy

Part III - Microscopy Chapter 6: Fundamentals Resolution Limits, Modulation Transfer Function, Lens Aberrations, Comparison Optical and Electron Microscopy, 3D Imaging Chapter 7: X-Ray and Electron Microscopy Chapter 8: Contrast and Modulation Transfer Function Chapter 9: Advanced Techniques Confocal Scanning Microscopy, 3D Optical Imaging, Super-resolution using PALM, STORM, STED, NSOM Chapter VI: Fundamentals of Optical Microscopy G. Springholz - Nanocharacterization I VI / 1 Chapter VI: Fundamentals of Optical Microscopy G. Springholz - Nanocharacterization I VI / 2 Chapter 6 Fundamentals of Optical Microscopy Instrumentation, Resolution Limits, Aberrations, Practical Resolution: Optical Microscopy versus TEM Chapter VI: Fundamentals of Optical Microscopy G. Springholz - Nanocharacterization I VI / 3 Contents - Chapter 6: Fundamentals of Optical Microscopy 6.1 Introduction ......................................................................................................................... 1 6.2 How to Perform Spatial Imaging with High Resolution ? ................................................. 3 6.3 Scanning Microscopy ......................................................................................................... 5 6.4 Imaging Microscopy ............................................................................................................ 7 6.5 Resolution Limits of Imaging Microscopy ....................................................................... 11 6.6 Resolution Limit due to Diffraction (see, e.g., -

Part I Geometrical Optics Part II Diffraction Optics Aperture and Field Stops

Astronomische Waarneemtechnieken (Astronomical Observing Techniques) 6th Lecture: 8 October 2012 1. Geometrical Optics Definitions Aberrations 2. Diffraction Optics Fraunhofer Diff. PSF, MTF SR & EE high contrast im. Based on “Astronomical Optics” by Daniel J. Schroeder, “Principles of 2SWLFVµE\0D[%RUQ (PLO:ROIWKH´2SWLFDO(QJLQHHU·V'HVN Reference” by William L. Wolfe, Lena book, and Wikipedia Part I Geometrical Optics Part II Diffraction Optics Aperture and Field Stops telescope camera Aperture stop: determines the diameter of the light cone from an axial point on the object. Field stop: determines the field of view of the system. Entrance pupil: image of the aperture stop in the object space Exit pupil: image of the aperture stop in the image space Marginal ray: ray from an object point on the optical axis that passes at the edge of the entrance pupil Chief ray: ray from an object point at the edge of the field, passing through the center of the aperture stop. The Speed of the System f IJ D The speed of an optical system is described by the numerical aperture NA and the F number, where: f 1 NA nsinT and F { D 2(NA) Generally, fast optics (large NA) has a high light power, is compact, but has tight tolerances and is difficult to manufacture. Slow optics (small NA) is just the opposite. Étendue and Ax The geometrical étendue (frz. `extent· is the product of area A of the source times the solid angle (of the system's entrance pupil as seen from the source). The étendue is the maximum beam size the instrument can accept. -

Advanced Microscopy Lecture 3 Physical Optics Of

Microscopy Lecture 3: Physical optics of widefield microscopes 2012-10-29 Herbert Gross Winter term 2012 www.iap.uni-jena.de 3 Physical optics of widefield microscopes 2 Preliminary time schedule No Date Main subject Detailed topics Lecturer overview, general setup, binoculars, objective lenses, performance and types of lenses, 1 15.10. Optical system of a microscope I tube optics Gross Etendue, pupil, telecentricity, confocal systems, illumination setups, Köhler principle, 2 22.10. Optical system of a microscope II fluorescence systems and TIRF, adjustment of objective lenses Gross Physical optics of widefield Point spread function, high-NA-effects, apodization, defocussing, index mismatch, 3 29.10. Gross microscopes coherence, partial coherent imaging Wave aberrations and Zernikes, Strehl ratio, point resolution, sine condition, optical 4 05.11. Performance assessment transfer function, conoscopic observation, isoplantism, straylight and ghost images, Gross thermal degradation, measuring of system quality basic concepts, 2-point-resolution (Rayleigh, Sparrow), Frequency-based resolution (Abbe), 5 12.11. Fourier optical description CTF and Born Approximation Heintzmann 6 19.11. Methods, DIC Rytov approximation, a comment on holography, Ptychography, DIC Heintzmann Multibeam illumination, Cofocal coherent, Incoherent processes (Fluorescence, Raman), 7 26.11. Imaging of scatter OTF for incoherent light, Missing cone problem, imaging of a fluorescent plane, incoherent Heintzmann confocal OTF/PSF Fluorescence, Structured illumination, Image based identification of experimental 8 03.12. Incoherent emission to improve resolution parameters, image reconstruction Heintzmann 9 10.12. The quantum world in microscopy Photons, Poisson distribution, squeezed light, antibunching, Ghost imaging Wicker 10 17.12. Deconvolution Building a forward model and inverting it based on statistics Wicker 11 07.01. -

Chapter on Diffraction

Chapter 3 Diffraction While the particle description of Chapter 1 works amazingly well to understand how ra- diation is generated and transported in (and out of) astrophysical objects, it falls short when we investigate how we detect this radiation with our telescopes. In particular the diffraction limit of a telescope is the limit in spatial resolution a telescope of a given size can achieve because of the wave nature of light. Diffraction gives rise to a “Point Spread Function”, meaning that a point source on the sky will appear as a blob of a certain size on your image plane. The size of this blob limits your spatial resolution. The only way to improve this is to go to a larger telescope. Since the theory of diffraction is such a fundamental part of the theory of telescopes, and since it gives a good demonstration of the wave-like nature of light, this chapter is devoted to a relatively detailed ab-initio study of diffraction and the derivation of the point spread function. Literature: Born & Wolf, “Principles of Optics”, 1959, 2002, Press Syndicate of the Univeristy of Cambridge, ISBN 0521642221. A classic. Steward, “Fourier Optics: An Introduction”, 2nd Edition, 2004, Dover Publications, ISBN 0486435040 Goodman, “Introduction to Fourier Optics”, 3rd Edition, 2005, Roberts & Company Publishers, ISBN 0974707724 3.1 Fresnel diffraction Let us construct a simple “Camera Obscura” type of telescope, as shown in Fig. 3.1. We have a point-source at location “a”, and we point our telescope exactly at that source. Our telescope consists simply of a screen with a circular hole called the aperture or alternatively the pupil. -

Preview of “Olympus Microscopy Resou... in Confocal Microscopy”

12/17/12 Olympus Microscopy Resource Center | Confocal Microscopy - Resolution and Contrast in Confocal … Olympus America | Research | Imaging Software | Confocal | Clinical | FAQ’s Resolution and Contrast in Confocal Microscopy Home Page Interactive Tutorials All optical microscopes, including conventional widefield, confocal, and two-photon instruments are limited in the resolution that they can achieve by a series of fundamental physical factors. In a perfect optical Microscopy Primer system, resolution is restricted by the numerical aperture of optical components and by the wavelength of light, both incident (excitation) and detected (emission). The concept of resolution is inseparable from Physics of Light & Color contrast, and is defined as the minimum separation between two points that results in a certain level of contrast between them. In a typical fluorescence microscope, contrast is determined by the number of Microscopy Basic Concepts photons collected from the specimen, the dynamic range of the signal, optical aberrations of the imaging system, and the number of picture elements (pixels) per unit area in the final image. Special Techniques Fluorescence Microscopy Confocal Microscopy Confocal Applications Digital Imaging Digital Image Galleries Digital Video Galleries Virtual Microscopy The influence of noise on the image of two closely spaced small objects is further interconnected with the related factors mentioned above, and can readily affect the quality of resulting images. While the effects of many instrumental and experimental variables on image contrast, and consequently on resolution, are familiar and rather obvious, the limitation on effective resolution resulting from the division of the image into a finite number of picture elements (pixels) may be unfamiliar to those new to digital microscopy. -

Abramowitz Function Computed by Clenshaw's Method, 74 Absolute

Copyright ©2007 by the Society for Industrial and Applied Mathematics. This electronic version is for personal use and may not be duplicated or distributed. Index Abramowitz function for parabolic cylinder functions, computed by Clenshaw’s method, 378 74 for prolate spheroidal harmonics, absolute error, 356 364 Airy function for Scorer functions, 361 contour integral for, 166 for toroidal harmonics, 366 Airy functions of Remes, 290 algorithm, 359 analytic continuation of generalized asymptotic estimate of, 18 hypergeometric function, 27 asymptotic expansions, 81, 360 anomalous behavior of recursions, 118 Chebyshev expansions, 80, 85 a warning, 122 computing confluent hypergeometric complex arguments, 359 functions, 120 Gauss quadrature, 145 exponential integrals, 121 scaled functions, 359 first order inhomogeneous zeros, 224 equation, 121 connection formulas, 360, 361 modified Bessel functions, 118 contour integral for, 264 anti-Miller algorithm, 110, 112 differential equation, 249, 359 associated Legendre functions relation with hypergeometric computation for z>0, 363 function, 28 asymptotic expansion used in uniform asymptotic uniform, 237 expansion, 250 asymptotic expansions Airy-type asymptotic expansion alternative asymptotic for modified Bessel functions of representation for (z),49 purely imaginary order, 375 alternative expansion for parabolic cylinder functions, for (z),49 383 for (a, z),47 obtained from integrals, 249, 264 convergent asymptotic algorithm representation, 46 for Airy functions, 359 converging factor, 40 for computing zeros of Bessel exponentially improved, 39 functions, 385 for (a, z),39 for modified Bessel functions, 370 exponentially small remainders, 38 for oblate spheroidal harmonics, hyperasymptotics, 40 365 of exponential integral, 37, 38 405 From "Numerical Methods for Special Functions" by Amparo Gil, Javier Segura, and Nico Temme Copyright ©2007 by the Society for Industrial and Applied Mathematics. -

Modified Airy Function and WKB Solutions to the Wave Equation

NAT L INST. OF STAND & TECH R.I.C. NIST REFERENCE PUBLICATIONS A11103 VlOVDl NIST Monograph 176 Modified Airy Function and WKB Solutions to the Wave Equation I A. K. Ghataky R. L. GallawUy and 1. C. Goyal - QC- 100 U556 M United States Department of Commerce #176 National Institute of standards and Technology 1991 NIST Monograph 176 QClO mi Modified Airy Function and WKB Solutions to the Wave Equation A. K. Ghatak R. L. Gallawa I. C. Goyal Electromagnetic Technology Division Electronics and Electrical Engineering Laboratory National Institute of Standards and Technology Boulder, CO 80303 This monograph was prepared, in part, under the auspices of the Indo-US Collaborative Program in Materials Sciences. Permanent Affiliation of Professors Ghatak and Goyal is Physics Department, Indian Institute of Technology New Delhi, India. November 1991 U.S. Department of Commerce Robert A. Mosbacher, Secretary National Institute of Standards and Technology John W. Lyons, Director National Institute of Standards and Technology Monograph 176 Natl. Inst. Stand. Technol. Mono. 176, 172 pages (Nov. 1991) CODEN: NIMOEZ U.S. GOVERNMENT PRINTING OFFICE WASHINGTON: 1991 For sale by the Superintendent of Documents, U.S. Government Printing Office, Washington, DC 20402-9325 TABLE OF CONTENTS PREFACE vii 1. INTRODUCTION 1 2. WKB SOLUTIONS TO INITIAL VALUE PROBLEMS 6 2.1 Introduction 6 2.2 The WKB Solutions 6 2.3 An Alternative Derivation 11 2.4 The General WKB Solution 14 Case I: Barrier to the Right 15 Case II: Barrier to the Left 19 2.5 Examples 21 Example 2.1 21 Example 2.2 27 3. -

Second Order Linear Equations and the Airy Functions:

Table of Contents Second Order Linear Equations and the Airy Functions: ............................................................ 1 Airy's Equation .................................................................................................................. 2 Graphing Airy functions ...................................................................................................... 3 Some Qualitative Analysis ................................................................................................... 7 Numerical solutions to yield a graphical presentation ................................................................ 7 Stability ............................................................................................................................ 8 The Nature of Special Functions ......................................................................................... 10 Second Order Linear Equations and the Airy Functions: Why Special Functions are Really No More Complicated than Most Elementary Functions % We shall consider here the most important second order % ordinary differential equations, namely linear equations. % The standard format for such an equation is % y''(t) + p(t) y'(t) + q(t) y(t) = g(t), % where y(t) is the unknown function satisfying the % equation and p, q and g are given functions, all % continuous on some specified interval. We say that the % equation is homogeneous if g = 0. Thus: % y''(t) + p(t) y'(t) + q(t) y(t) = 0. % We have studied methods for solving an inhomogeneous % equation for