History of Development of Cemented Carbides and Cermet Pdf 1.5 MB

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

UNITE-D STATESJPATBNT Omen .V

.' Patented Sept. 11,1934 1,973,428 UNITE-D STATESJPATBNT omen .v ’ 1,973,428 ; CEMEN'I'ED man ommn'm'raamn Gregory J. Comstock, Edgcwoorl, Pa. assignor'to ~: ' ' ' , Firth-Sterling Steel CompanmMcKeeeport, 2a., , a corporation of Pennsylvania Y . ‘ ' ' No Drawing. Application November 8,‘ 1932, Serial No. 641,762 r .' 3 Claims. (ems-1‘) cold-press, method or the hot-ypress' method. In , . This invention relates generally to hard- ce-f the cold-press method thefmixtureis compacted " mented carbide materials made by a cementing into 'a billet under relatively ‘high'pressure, for -' ‘ or sintering process, and more ‘particularly to example 10,000#/sq.~ in.v and is then preferably such materials containing tungsten carbide, tan:- ,. given'a ‘preliminary sinter at about _1600°‘>-F. ‘of 5 talum carbide, titanium carbide and an auxiliary , It is cooled and :reshaped'and then given a ?nal, I , ‘ I metal, or alloy- such as cobalt, iron or nickel. sinter at a temperature of between ‘2600 and‘ Hard cemented carbide materials containing 32009.- E, . 7' . ~ - _ tungsten carbide and iron, cobalt. or nickel are The material may be made according to the ’ now known and have been described in hot-press method in which the heat ‘and pressure 65 10 Schroeter Patent No. 1,549,615. ‘ ' ‘ ' ' - ‘I ' are applied simultaneously. We’ preter in the ' In my application, Serial No. ‘512,917, filed hot-press, method to use. ‘a temperature‘ of about . November 4, 1931, there isdescribed a hard. 3200° F. and a pressure of about 140o#/sq. in'. cemented carbidematerial containing tungsten and.‘ to carry out the sintering‘for, about ?ve _ carbide, tantalum carbide and cobalt, nickel or minutes‘ at thisftemperature. -

Cutting Tools — Trends of Functional Upgrading, Resource Saving Technologies and New Products —

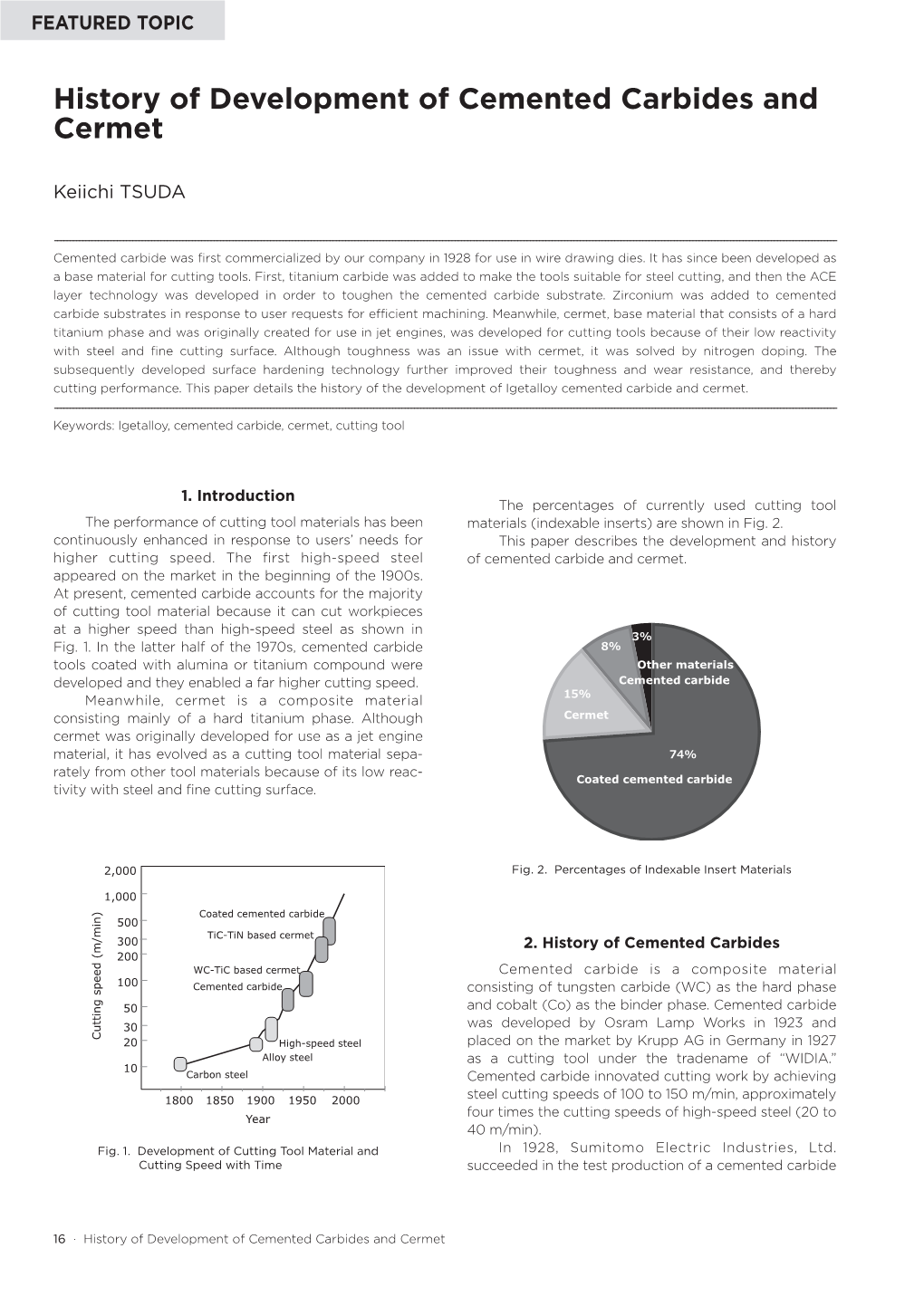

Prefatory Note Special Issue: Cutting Tools — Trends of Functional Upgrading, Resource Saving Technologies and New Products — Yoshihiro Minato Executive Officer and General Manager Advanced Materials R&D Laboratories Of all the tools used for cutting ferrous metals and non- made by sintering CBN, using a specially prepared ceramic ferrous metals, about 90% are cemented carbide or coated binder whose affinity with steel is extremely low. Subse- cemented carbide tools. Cemented carbide (WC-Co) is a quently, another type of CBN sintered body was developed composite material of a tungsten carbide (WC) phase and a by coating specially sintered CBN base material with a highly cobalt (Co) binder phase. It was invented in Germany in wear-resistant ceramic film. Coated CBN sintered body tools 1923 and put on the market in 1927 by the German corpo- are widely used today to cut hardened steels that are ex- ration Krupp AG under the trade name “WIDIA.” Subse- tremely difficult to cut in place of grinding. quently, Sumitomo Electric Industries, Ltd. succeeded in its Metal cutting technology has progressed and developed test manufacture of a cemented carbide wire-drawing die in in conjunction with three elements: tool materials, tool de- 1928, and commercialized a cemented carbide tool in 1931. sign/geometry, and machine tools. Among the above ele- This tool has been marketed under the brand name of ments, Sumitomo Electric has promoted the development of “IGETALLOY” ever since. In 2011, Sumitomo Electric cele- advanced tool materials and tool design/geometry. In the brated 80 years of marketing this product. In the early 1900s, very competitive market environment surrounding cutting high-speed steel tools were used for steel cutting operations. -

Microwave Sintering of Alumina-Titanium Cermets Redacted for Privacy Abstract Approved: (

AN ABSTRACT OF THE THESIS OF Wendell R. Wrzesinski for the degree of Master of Material Science in Mechanical Engineering presented on 10-19-87. Microwave Sintering of Alumina-titanium Cermets Redacted for Privacy Abstract Approved: ( The influence of microwave radiation on the fabrication of cermet materials has been investigated for alumina-titanium cermets with compositions ranging from 20 to 80 wt. % titanium. An industrial microwave oven was characterized and adapted to process cermet materials. Physical and mechanical property determinations were made as a function of microwave processing time and compared to a furnace sintered sample. Electron microscopy was conducted on the composite materials in evaluat- ing the extent of bonding between metal and oxide particles and particle sizing in the cermet. Sintering of composite materials through microwave radiation usagemay be possible as a reduced cost, time-saving, processing technique. Microwave Sintering of Alumina-titanium Cermets by Wendell R. Wrzesinski A THESIS submitted to Oregon State University in partial fulfillment of the requirements for the degree of Master of Material Science Completed: 10-19-87 Commencement June 1988 APPROVED: Redacted for Privacy Profesqr of Material Science and Engineering incharge of major Redacted for Privacy head of department of MechanicalEngineering Redacted for Privacy Dean of Grad School Date thesis presented: 10-19-87 ACKNOWLEDGEMENT The author would like to sincerely thank Dr. JimRawers and Rick Wilson for their assistance and guidance inexperimentation and preparation involved with this thesis, the Bureau ofMines for its support, and those others who offered invaluableassistance including: Dr. Jim Rawers, Kellee Roub, and Rick Wilsonfor technical review of this manuscript, Dan Davis forpreparing furnace sintered materials, Keith Collins formicroscopic eval- uation, and Earl Peterson and Steve Anderson fortheir drafting and photography. -

Method for Producing Thick Ceramic Films by a Sol Gel

Europäisches Patentamt *EP000815285B1* (19) European Patent Office Office européen des brevets (11) EP 0 815 285 B1 (12) EUROPEAN PATENT SPECIFICATION (45) Date of publication and mention (51) Int Cl.7: C23C 18/12 of the grant of the patent: // C04B41/87, C04B41/50 22.08.2001 Bulletin 2001/34 (86) International application number: (21) Application number: 96901675.7 PCT/CA96/00088 (22) Date of filing: 13.02.1996 (87) International publication number: WO 96/29447 (26.09.1996 Gazette 1996/43) (54) METHOD FOR PRODUCING THICK CERAMIC FILMS BY A SOL GEL COATING PROCESS VERFAHREN ZUR HERSTELLUNG DICKER KERAMIKFILMS DURCH SOL-GEL-BESCHICHTUNGSPROZESS PROCEDE DE FABRICATION DE FILMS DE CERAMIQUE EPAIS METTANT EN UVRE UN PROCESSUS DE REVETEMENT SOL-GEL (84) Designated Contracting States: (74) Representative: AT BE CH DE DK ES FR GB GR IE LI NL PT SE Simpson, Alison Elizabeth Fraser et al Urquhart-Dykes & Lord, (30) Priority: 22.03.1995 US 409127 30 Welbeck Street London W1G 8ER (GB) (43) Date of publication of application: 07.01.1998 Bulletin 1998/02 (56) References cited: EP-A- 0 433 915 EP-A- 0 482 659 (73) Proprietor: QUEEN’S UNIVERSITY AT KINGSTON EP-A- 0 564 866 WO-A-96/00198 Kingston Ontario K7L 3N6 (CA) US-A- 4 921 731 (72) Inventors: • TECHNICAL DISCLOSURE BULLETIN, vol. 37, • BARROW, David No 09, September 1994, "Low Leakage, Ajax, Ontario L1S 6Z4 (CA) Temperature Invariant, High Dielectric Constant • PETROFF, Edward, T. Films, using Multilayered Sol-Gel Fabrication", Scarborough, Ontario M1T 1V8 (CA) page 27 - page 28 • SAYER, Michael • PATENT ABSTRACTS OF JAPAN, vol. -

The Titanium Industry: a Case Study in Oligopoly and Public Policy

THE TITANIUM INDUSTRY: A CASE STUDY IN OLIGOPOLY AND PUBLIC POLICY DISSERTATION Presented in Partial Fulfillment of the Requirements for the Degree Doctor of Philosophy In the Graduate School of the Ohio State University by FRANCIS GEORGE MASSON, B.A., M.A. The Ohio State University 1 9 5 k Content* L £MR I. INTRODUCTION............................................................................................... 1 II. THE PRODUCT AND ITS APPLICATIONS...................................... 9 Consumption and Uses ................................. 9 Properties ........................................................ ...... 16 III. INDUSTRY STRUCTURE................................................................................ 28 Definition of the I n d u s t r y ............................................ 28 Financial Structure. ..••••••.••. 32 Alloys and Carbide Branch. ........................... 3 k Pigment Branch .............................................................................. 35 Primary Metal Branch ................................. 1*0 Fabrication Branch ................................. $0 IT. INDUSTRY STRUCTURE - CONTINUED............................................. $2 Introduction ................................ $2 World Production and Resources ................................. $3 Nature of the Demand for Ram Materials . $8 Ores and Concentrates Branch. ••••••• 65 Summary.................................................................. 70 V. TAXATION. ANTITRUST AND TARIFF POLICY............................ -

What Is Cemented Carbide? the History of Cemented Carbide

THE DESIGNER’S GUIDE TO TUNGSTEN CARBIDE THE DESIGNER’S GUIDE TO TUNGSTEN CARBIDE Chapter I - Background What is cemented carbide? Tungsten carbide (WC), also referred to as cemented carbide, is a composite material manufac- tured by a process called powder metallurgy. Tungsten carbide powder, generally ranging in proportion between 70%-97% of the total weight, is mixed with a binder metal, usually cobalt or nickel, compacted in a die and then sintered in a furnace. The term “cemented” refers to the tungsten carbide particles being captured in the metallic binder material and “ cemented” together, forming a metallurgical bond between the tungsten carbide particles and the binder (WC - Co), in the sintering process. The cemented carbide industry commonly refers to this material as simply “carbide”, although the terms tungsten carbide and cemented carbide are used interchangeably. If the permanent deformation of a material at failure is quite small, the material is labeled brittle; if the plastic deformation is very large, the material is called ductile. Carbide is classified techni- cally as a “brittle” material since it exhibits little or no plastic deformation preceding the initiation of a crack and total failure. Without the presence of the metallic binder phase, tungsten carbide could be considered a ceramic material much the same as silicon carbide or aluminum oxide. The definition of a ceramic material is the marriage of a metal to a nonmetal, for example silicon (metal) carbide (carbon, nonmetal), aluminum (metal) oxide (oxygen, non-metal), or silicon ni- tride. A cermet is a composite material composed of ceramic (cer) and metallic (met) materials. -

Pdf 1007.44 K

IJE TRANSACTIONS B: Applications Vol. 29, No. 5, (May 2016) 677-687 International Journal of Engineering Journal Homepage: www.ije.ir A Review on Titanium Nitride and Titanium Carbide Single and Multilayer Coatings Deposited by Plasma Assisted Chemical Vapor Deposition a, A. Sabour Rouhaghdamb, S. Ahangaranic٭M. Azadi a Faculty of metallurgical Engineering and material, Semnan University, Semnan, Iran b Faculty of Engineering, Materials Engineering Department, Surface Engineering Laboratory ,Tarbiat Modares University, Tehran, Iran c Advanced Materials and Renewable Energies Department, Iranian Research Organization for Science and Technology, Tehran, Iran P A P E R I N F O ABSTRACT Paper history: In this paper, we reviewed researches about the titanium nitride (TiN) and titanium carbide (TiC) Received 21 September 2015 single and multilayer coatings. These coatings were deposited by the plasma assisted chemical vapor Received in revised form 06 February 2016 deposition (PACVD) technique. Plasma-based technologies are used for the processing of thin films Accepted 4 March 2016 and coatings for different applications such as automobile and aerospace parts, computer disc drives, food industry and surgical/medical instruments. We describe the state of the performance of different Keywords: coating systems and thin film architectures in PACVD suitable for industrial-scale or laboratory Titanium Nitride applications. Mechanical properties of coatings such as wear resistance, hardness and the scratch Titanium Carbide resistance, structural characteristics, physical and chemical properties like coatings adhesion into Multilayer Coatings different substrates, wetting behavior and corrosion resistance were studied. Thus, this paper represents Hard Coatings a source of information for those who want to familiarize with the status of knowledge in the area of Plasma Assisted Chemical Vapor Deposition materials science of functional coatings, in particular TiN/TiC coatings that was deposited by a new Plasma-based technologies. -

Nasa Tm X-3265 17 Effect of Magnesium Oxide Content

NASA TECHNICAL. NASA TM X-3265 17 MEMORANDUM CO 1 I b- ; X in.l rui LOAN COPY: RE t-1! AFWL TECHNICAL t-1: KIRTLAND AFB EFFECT OF MAGNESIUM OXIDE CONTENT ON OXIDATION BEHAVIOR OF SOME SUPERALLOY-BASE CERMETS Isidor Zaplatynsky Lewis Research Center Cleveland, Ohio 44135 \ NATIONAL AERONAUTICS AND SPACE ADMINISTRATION • WASHINIGTUlUILJD.G - • AUGUST 1975 ERRATA NASA Technical Memorandum X-3265 EFFECT OF MAGNESIUM OXIDE CONTENT ON OXIDATION BEHAVIOR OF SOME SUPERALLOY-BASE CERMETS by Isidor Zaplatynsky August 1975 The composition of the alloy listed as Hastelloy X in table I, page 9, does not fit the specifications for HASTELLOY ® (a registered trademark of the Cabot Corporation) alloy X. Further, an analysis of this alloy indicated deviation from the specifications shown in table I. The following corrected table shows the correct analysis of this alloy, henceforth called Alloy A. Thus, throughout the report, references to Hastelloy X should be read to mean Alloy A. Further, references to Inconel-702 should be read to meanlNCONEL ® alloy 702. ERRATA NASA Technical Memorandum X-3265 EFFECT OF MAGNESIUM OXIDE CONTENT ON OXIDATION BEHAVIOR OF SOME SUPERALLOY-BASE CERMETS by Isidor Zaplatynsky August 1975 The composition of the alloy listed as Hastelloy X in table I, page 9, does not fit the specifications for HASTELLOY © (a registered trademark of the Cabot Corporation) alloy X. Further, an analysis of this alloy indicated deviation from the specifications shown in table I. The following corrected table shows the correct analysis of this alloy, henceforth called Alloy A. Thus, throughout the report, references to Hastelloy X should be read to mean Alloy A. -

Coatings of Cutting Tools and Their Contribution to Improve Mechanical Properties: a Brief Review

International Journal of Applied Engineering Research ISSN 0973-4562 Volume 13, Number 14 (2018) pp. 11653-11664 © Research India Publications. http://www.ripublication.com Coatings of Cutting Tools and Their Contribution to Improve Mechanical Properties: A Brief Review Noor Atiqah Badaluddin1, Wan Fathul Hakim W Zamri1*, Muhammad Faiz Md Din2, Intan Fadhlina Mohamed1 and Jaharah A Ghani1 1Centre for Materials Engineering and Smart Manufacturing (MERCU), Faculty of Engineering and Built Environment, Universiti Kebangsaan Malaysia, 43600 Bangi, Selangor, Malaysia. 2 Faculty of Engineering, Universiti Pertahanan Nasional Malaysia, Kem Sungai Besi, 57000 Kuala Lumpur, Wilayah Persekutuan Kuala Lumpur, Malaysia. (Corresponding Author *) Abstract types of coating structures and materials can be combined to produce high-performance cutting tools. The coating not only Cutting is an important process in the manufacturing industry. functions to extend the lifetime of the cutting tool but it also It is necessary to use good quality cutting tools in order to acts as a protection against wear, especially against abrasions maintain the quality of a product. The coating on a cutting and adhesions, in cutting tool applications. The strength of the tool has a great impact in terms of the mechanical and coating is dependent on the material used for the coating, but tribological properties as well as the end results of the studies have shown that a more layered structure will further product. A cutting tool can made of various types of materials, enhance the hardness of the coating and increase its resistance but the most commonly used material in the industry today is to wear. Currently, a combination of various materials such as cemented tungsten carbide as its characteristics meet the TiALN/TiN, TiCN/TiSiN/TiAlN and many more are being requirements of manufacturers. -

Repository Criticality Control with Depleted-Uranium-Dioxide Cermet Waste Packages

—Summary— REPOSITORY CRITICALITY CONTROL WITH DEPLETED-URANIUM-DIOXIDE CERMET WASTE PACKAGES Charles W. Forsberg Oak Ridge National Laboratory* P.O. Box 2008 Oak Ridge, Tennessee 37831-6180 Tel: (865) 574-6783 Fax: (865) 574-9512 Email: [email protected] File Name: Cermet.DuCermet.Criticality Session: Geological Disposal Prepared for Session: Geological Disposal Embedded Topical Meeting on Practical Implementation of Nuclear Criticality Safety American Nuclear Society Reno, Nevada November 11–15, 2001 Limit: 1000 words Actual: 823 words The submitted manuscript has been authored by a contractor of the U.S. Government under contract DE-AC05-00OR22725. Accordingly, the U.S. Government retains a nonexclusive, royalty-free license to publish or reproduce the published form of this contribution, or allow others to do so, for U.S. Government purposes. _________________________ *Oak Ridge National Laboratory, managed by UT-Battelle, LLC, for the U.S. Department of Energy under contract DE-AC05-00OR22725. REPOSITORY CRITICALITY CONTROL WITH DEPLETED URANIUM DIOXIDE CERMET WASTE PACKAGES It is proposed that the structural components and internal basket structures of spent nuclear fuel (SNF) waste packages (WPs), which will be sequestered with the SNF at the repository, be constructed of depleted uranium dioxide (DUO2 )–steel cermets. The cermet used for the WP basket would also contain neutron absorbers with high-absorption-cross-sections such as boron or rare earth oxides. This strategy would provide both operational and long-term (repository post-closure) criticality control. As the WP degrades, the 238U in the depleted uranium (DU) would mix with the degrading SNF and isotopically dilute 233U and 235U to levels (<1 wt % 235U in 238U; <0.66 wt % 233U in 238 U) that ensure critically will not occur. -

Additive Manufacturing of Ceramics and Cermets: Present Status and Future Perspectives

Sådhanå Ó (2021) 46:162 Indian Academy of Sciences https://doi.org/10.1007/s12046-021-01685-2Sadhana(0123456789().,-volV)FT3](0123456789().,-volV) Additive manufacturing of ceramics and cermets: present status and future perspectives MAINAK SAHA1,2,* and MANAB MALLIK1,* 1 Department of Metallurgical and Materials Engineering, National Institute of Technology, Durgapur 713209, West Bengal, India 2 Department of Metallurgical and Materials Engineering, Indian Institute of Technology, Madras 600036, Tamil Nadu, India e-mail: [email protected]; [email protected] MS received 6 November 2020; revised 19 May 2021; accepted 6 July 2021 Abstract. The present decade has witnessed a huge volume of research revolving around a number of Additive Manufacturing (AM) techniques, especially for the fabrication of different metallic materials. How- ever, fabrication of ceramics and cermets using AM-based techniques mainly suffers from two primary limi- tations which are: (i) low density and (ii) poor mechanical properties of the final components. Although there has been a considerable volume of work on AM based techniques for manufacturing ceramic and cermet parts with enhanced densities and improved mechanical properties, however, there is limited understanding on the cor- relation of microstructure of AM-based ceramic and cermet components with the mechanical properties. The present article is aimed to review some of the most commonly used AM techniques for the fabrication of ceramics and cermets. This has been followed by a brief discussion on the microstructural developments during different AM-based techniques. In addition, an overview of the challenges and future perspectives, mainly associated with the necessity towards developing a systematic structure-property correlation in these materials has been provided based on three factors viz. -

Effects of Vanadium Carbide on Sintered WC-10%Co Produced By

Sains Malaysiana 44(8)(2015): 1175–1181 Effects of Vanadium Carbide on Sintered WC-10%Co Produced by Micro-powder Injection Molding (Kesan Vanadium Karbida ke atas WC-10%Co Bersinter dihasilkan melalui Pengacuan Suntikan Serbuk Mikro) WONG YEE NING, NORHAMIDI MUHAMAD, ABU BAKAR SULONG*, ABDOLALI FAYYAZ & MUHAMMAD RAFI RAZA ABSTRACT Ultrafine, cemented tungsten carbide (WC) possesses exceptional hardness, wear resistance and high strength in various applications. In this study, WC was produced through micro powder injection molding (μPIM), which is also applicable for metals and ceramics in producing complex parts with high-dimensional accuracy. Different inhibitors, such as VC, Cr2C3, NbC, or TaC, were added to improve the mechanical properties of WC and control its grain growth. The effects of a grain growth inhibitor were investigated by adding VC in WC–10%Co–nVC, where n = 0 to 1.2 wt. %. The mechanical properties of the sintered part, such as hardness and flexural strength, were determined. The morphology and elemental distribution of the samples were studied by field emission scanning electron microscopy and energy-dispersive X-ray spectroscopy. X-ray diffraction was employed to study the phases of the obtained samples. The results showed that the sample with 0.4 wt. % VC (optimal amount) sintered at 1410°C exhibited the highest theoretical density, hardness and flexural strength of 95.2%, 1973±31HV and 2586±172 MPa, respectively. The average grain size measured was 519±27 nm. VC acted as a grain growth inhibitor during sintering, thereby improving the mechanical properties. Keywords: Flexure strength; grain growth inhibitor; microstructure; micro powder injection moulding; XRD ABSTRAK Ultra halus, tungsten karbida terikat (WC) memiliki ciri kekerasan yang tinggi, rintangan haus dan kekuatan yang tinggi dalam pelbagai aplikasi.