Roundness: Determining the Reference Circle for MCCI and MICI System

Total Page:16

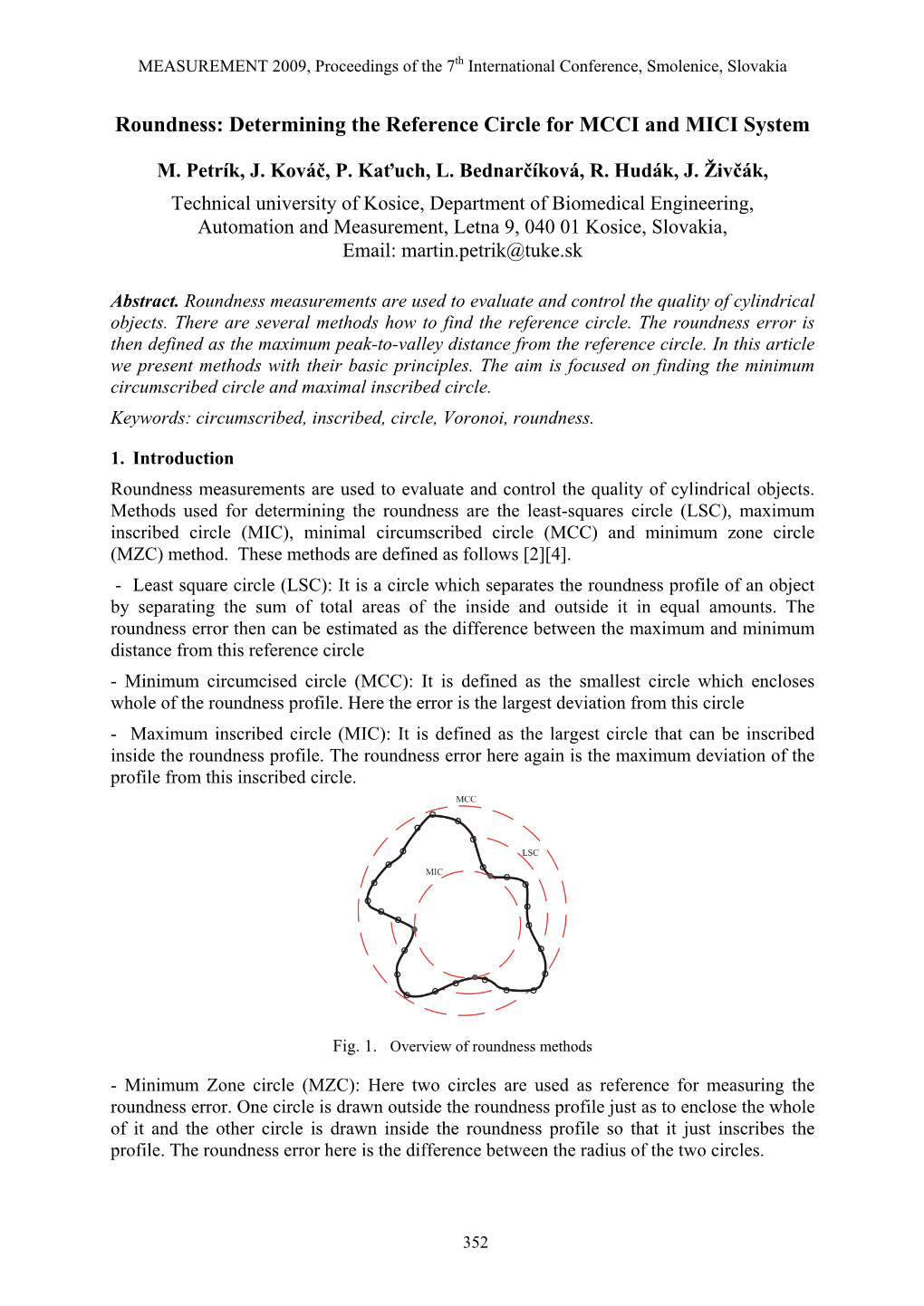

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Tetrahedra and Relative Directions in Space Using 2 and 3-Space Simplexes for 3-Space Localization

Tetrahedra and Relative Directions in Space Using 2 and 3-Space Simplexes for 3-Space Localization Kevin T. Acres and Jan C. Barca Monash Swarm Robotics Laboratory Faculty of Information Technology Monash University, Victoria, Australia Abstract This research presents a novel method of determining relative bearing and elevation measurements, to a remote signal, that is suitable for implementation on small embedded systems – potentially in a GPS denied environment. This is an important, currently open, problem in a number of areas, particularly in the field of swarm robotics, where rapid updates of positional information are of great importance. We achieve our solution by means of a tetrahedral phased array of receivers at which we measure the phase difference, or time difference of arrival, of the signal. We then perform an elegant and novel, albeit simple, series of direct calculations, on this information, in order to derive the relative bearing and elevation to the signal. This solution opens up a number of applications where rapidly updated and accurate directional awareness in 3-space is of importance and where the available processing power is limited by energy or CPU constraints. 1. Introduction Motivated, in part, by the currently open, and important, problem of GPS free 3D localisation, or pose recognition, in swarm robotics as mentioned in (Cognetti, M. et al., 2012; Spears, W. M. et al. 2007; Navarro-serment, L. E. et al.1999; Pugh, J. et al. 2009), we derive a method that provides relative elevation and bearing information to a remote signal. An efficient solution to this problem opens up a number of significant applications, including such implementations as space based X/Gamma ray source identification, airfield based aircraft location, submerged black box location, formation control in aerial swarm robotics, aircraft based anti-collision aids and spherical sonar systems. -

Theta Circles and Polygons Test #112

Theta Circles and Polygons Test #112 Directions: 1. Fill out the top section of the Round 1 Google Form answer sheet and select Theta- Circles and Polygons as the test. Do not abbreviate your school name. Enter an email address that will accept outside emails (some school email addresses do not). 2. Scoring for this test is 5 times the number correct plus the number omitted. 3. TURN OFF ALL CELL PHONES. 4. No calculators may be used on this test. 5. Any inappropriate behavior or any form of cheating will lead to a ban of the student and/or school from future National Conventions, disqualification of the student and/or school from this Convention, at the discretion of the Mu Alpha Theta Governing Council. 6. If a student believes a test item is defective, select “E) NOTA” and file a dispute explaining why. 7. If an answer choice is incomplete, it is considered incorrect. For example, if an equation has three solutions, an answer choice containing only two of those solutions is incorrect. 8. If a problem has wording like “which of the following could be” or “what is one solution of”, an answer choice providing one of the possibilities is considered to be correct. Do not select “E) NOTA” in that instance. 9. If a problem has multiple equivalent answers, any of those answers will be counted as correct, even if one answer choice is in a simpler format than another. Do not select “E) NOTA” in that instance. 10. Unless a question asks for an approximation or a rounded answer, give the exact answer. -

Circles JV Practice 1/26/20 Matthew Shi

Western PA ARML January 26, 2020 Circles JV Practice 1/26/20 Matthew Shi 1 Warm-up Questions 1. A square of area 40 is inscribed in a semicircle as shown: Find the radius of the semicircle. 2. The number of inches in the perimeter of an equilateral triangle equals the number of square inches in the area of its circumscribed circle. What is the radius, in inches, of the circle? 3. Two distinct lines pass through the center of three concentric circles of radii 3, 2, and 1. The 8 area of the shaded region in the diagram is 13 of the area of the unshaded region. What is the radian measure of the acute angle formed by the two lines? (Note: π radians is 180 degrees.) 4. Let C1 and C2 be circles of radius 1 that are in the same plane and tangent to each other. How many circles of radius 3 are in this plane and tangent to both C1 and C2? 1 Western PA ARML January 26, 2020 2 Problems 1. Each of the small circles in the figure has radius one. The innermost circle is tangent to the six circles that surround it, and each of those circles is tangent to the large circle and to its small-circle neighbors. Find the area of the shaded region. 2. A square has sides of length 10, and a circle centered at one of its vertices has radius 10. What is the area of the union of the regions enclosed by the square and the circle? 3. -

Talking Geometry: a Classroom Episode

Learning and Teaching Mathematics, No. 6 Page 3 Talking Geometry: a Classroom Episode Erna Lampen Wits School of Education The Geometry course forms part of the first year early in the course and they used the programme mathematics offering for education students at to investigate their conjectures in an informal way Wits School of Education. The course is outside class time. The course has a distinctly compulsory for all first years who want to major problem-centred approach. Students did not get in mathematics education at FET level. Most of demonstrations of the constructions or guidelines these students obtained about 60% on standard that show “How to construct a line perpendicular grade for mathematics at Grade 12 level and to another line.” Instead, we discussed what it many confessed not to have done geometry means to ask “spatial” questions, and decided beyond Grade 9 level. A few students who together that spatial questions involve questions specialize in Foundation Phase as well as about shape, structure, size and position. The Intermediate and Senior Phase also attended. This course is dedicated to asking and seeking answers class consisted of 85 students of whom close to to spatial questions. We started by investigating 70 attended regularly. All eleven official languages relative positions of points and lines in a plane. were represented in the class. There was also a We did constructions to answer questions like: deaf student and a Chinese student who “Where are all points that are equidistant from a immigrated in 2005 – imagine the need to have given point A? Where are all points that are shared objects to refer to when we discussed the equidistant from two given points A and B?” and mathematics! There was always a tutor, a fellow so on. -

MYSTERIES of the EQUILATERAL TRIANGLE, First Published 2010

MYSTERIES OF THE EQUILATERAL TRIANGLE Brian J. McCartin Applied Mathematics Kettering University HIKARI LT D HIKARI LTD Hikari Ltd is a publisher of international scientific journals and books. www.m-hikari.com Brian J. McCartin, MYSTERIES OF THE EQUILATERAL TRIANGLE, First published 2010. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form or by any means, without the prior permission of the publisher Hikari Ltd. ISBN 978-954-91999-5-6 Copyright c 2010 by Brian J. McCartin Typeset using LATEX. Mathematics Subject Classification: 00A08, 00A09, 00A69, 01A05, 01A70, 51M04, 97U40 Keywords: equilateral triangle, history of mathematics, mathematical bi- ography, recreational mathematics, mathematics competitions, applied math- ematics Published by Hikari Ltd Dedicated to our beloved Beta Katzenteufel for completing our equilateral triangle. Euclid and the Equilateral Triangle (Elements: Book I, Proposition 1) Preface v PREFACE Welcome to Mysteries of the Equilateral Triangle (MOTET), my collection of equilateral triangular arcana. While at first sight this might seem an id- iosyncratic choice of subject matter for such a detailed and elaborate study, a moment’s reflection reveals the worthiness of its selection. Human beings, “being as they be”, tend to take for granted some of their greatest discoveries (witness the wheel, fire, language, music,...). In Mathe- matics, the once flourishing topic of Triangle Geometry has turned fallow and fallen out of vogue (although Phil Davis offers us hope that it may be resusci- tated by The Computer [70]). A regrettable casualty of this general decline in prominence has been the Equilateral Triangle. Yet, the facts remain that Mathematics resides at the very core of human civilization, Geometry lies at the structural heart of Mathematics and the Equilateral Triangle provides one of the marble pillars of Geometry. -

Mod 5 10H Aim 3.Pdf

CC Geometry H Aim #3: What is the relationship between tangents to a circle from an outside point? Do Now: Find the value of each variable. q0 0 0 1. 2. 0 0 95 3. 4. p a c 250 0 x0 72 b0 b0 580 0 c0 y a0 THEOREM: ____________________________________________________________ ____________________________________________________________________ B A Given: Circle O, center O O Prove: Theorem, AB ≅ AC C 1. Circle O, center O 1. Given 2. Draw OB, OC, OA. 2. Two points determine a segment. 1. PS and PT are tangent segments. a) Solve for x, if SP = x2 - 5x, TP = 3x2 + 4x - 5. b) Find SP. S P T Definition: A circle circumscribed about a polygon is a circle that passes through each vertex of the polygon. Definition: A circle inscribed in a polygon is a circle that has a point of tangency with each side of the polygon. CIRCUMSCRIBED CIRCLE INSCRIBED CIRCLE (inscribed polygon) (circumscribed polygon) Each side of the inscribed polygon is a Each side of the circumscribed polygon _________________ of the circle. is a _________________ to the circle. 2. Circle O is inscribed in ΔABC. Find the perimeter of ΔABC. B E 8 F A O 10 D 15 C 3. ΔCDE is circumscribed about circle O. Find DE. F G O C #4-6 Each polygon circumscribes the circle. Find the perimeter of the polygon. 4. 9 cm 5. 13 in. O 10 in. O 14 in. 13 cm 16 cm 8 in. 5 m 6. 11 m 7.5 m O 5 m 7 m 7. -

Complements to Classic Topics of Circles Geometry

University of New Mexico UNM Digital Repository Mathematics and Statistics Faculty and Staff Publications Academic Department Resources 2016 Complements to Classic Topics of Circles Geometry Florentin Smarandache University of New Mexico, [email protected] Ion Patrascu Follow this and additional works at: https://digitalrepository.unm.edu/math_fsp Part of the Algebra Commons, Algebraic Geometry Commons, Applied Mathematics Commons, Geometry and Topology Commons, and the Other Mathematics Commons Recommended Citation Smarandache, Florentin and Ion Patrascu. "Complements to Classic Topics of Circles Geometry." (2016). https://digitalrepository.unm.edu/math_fsp/264 This Book is brought to you for free and open access by the Academic Department Resources at UNM Digital Repository. It has been accepted for inclusion in Mathematics and Statistics Faculty and Staff Publications by an authorized administrator of UNM Digital Repository. For more information, please contact [email protected], [email protected], [email protected]. Ion Patrascu | Florentin Smarandache Complements to Classic Topics of Circles Geometry Pons Editions Brussels | 2016 Complements to Classic Topics of Circles Geometry Ion Patrascu | Florentin Smarandache Complements to Classic Topics of Circles Geometry 1 Ion Patrascu, Florentin Smarandache In the memory of the first author's father Mihail Patrascu and the second author's mother Maria (Marioara) Smarandache, recently passed to eternity... 2 Complements to Classic Topics of Circles Geometry Ion Patrascu | Florentin Smarandache Complements to Classic Topics of Circles Geometry Pons Editions Brussels | 2016 3 Ion Patrascu, Florentin Smarandache © 2016 Ion Patrascu & Florentin Smarandache All rights reserved. This book is protected by copyright. No part of this book may be reproduced in any form or by any means, including photocopying or using any information storage and retrieval system without written permission from the copyright owners. -

Construction 12: Construct a Circle Circumscribed About a Triangle. 1

Geometry Week 21 sec. 9.7 to 10.2 section 9.7 Construction 12: Construct a circle circumscribed about a triangle. 1. Draw any triangle, ABC. 2. Construct the perpendicular bisector of two sides of the triangle and call their point of intersection D. 3. Measure the distance from D to one of the vertices and construct a circle with this radius and center D. Construction 13: Construct a Circle inscribed in a given triangle. 1. Draw any triangle, ABC. 2. Construct the angle bisector of two of the angles of the triangle. Call their point of intersection D. 3. Construct a perpendicular segment from point D to one of the sides of the triangle. 4. Measure the distance from point D to the side where the perpendicular segment intersects the side. 5. Construct a circle with this radius and center. 1 Construction 14: Construct a regular pentagon. 1. Draw a circle M. Draw a diameter of circle M. and construct is perpendicular bisector. 2. Bisect one of the radii. Point X is the midpoint. 3. Measure XA (midpoint of radius to the endpoint of another radius). Mark off the same length on the original diameter from the midpoint of the radius. Call this point Y. 4. Measure the length of AY. Using this length, mark off consecutive arcs on the circle. 5. Connect consecutive marks with segments to form a regular pentagon. Construction 15: Construct a regular 2n-gon from a regular n-gon. 1. Construct the perpendicular bisector of two sides. 2. The bisectors intersect at the center of the regular polygon. -

Metrical Relations in Barycentric Coordinates

Mathematical Communications 8(2003), 55-68 55 Metrical relations in barycentric coordinates Vladimir Volenec∗ Abstract.Let∆ be the area of the fundamental triangle ABC of barycentric coordinates and let α =cotA, β =cotB, γ =cotC.The vectors vi =[xi,yi,zi](i =1, 2) have the scalar product 2∆(αx1x2 + βy1y2 + γz1z2). This fact implies all important formulas about metrical relations of points and lines. The main and probably new results are Theorems 1 and 8. Key words: barycentric coordinates AMS subject classifications: 51N20 Received December 20, 2002 Accepted April 2, 2003 Let ABC be a given triangle with the sidelengths a = |BC|,b= |CA|,c= |AB|, A, B, C P P the measures of the opposite angles and the area ∆. For any point−→ let be PQ Q−P the radiusvector of this point with respect to any origin. Then−→ we have−→ =−→ . There are uniquely determined numbers y,z ∈ R so that AP = y · AB + z · AC, i.e. P − A = y(B − A)+z(C − A). If we put x =1− y − z, i.e. x + y + z =1, (1) then we have P = xA + yB + zC. (2) Numbers x, y, z, such that (1) and (2) are valid, are uniquely determined by point P and triangle ABC, i.e. these numbers do not depend on the choice of the origin. We say that x, y, z,aretheabsolute barycentric coordinates of point P with respect to triangle ABC and write P =(x, y, z). Obviously A =(1, 0, 0), B =(0, 1, 0), C =(0, 0, 1). Actually, point P is the barycenter of the mass point system of points A, B, C with masses x, y, z, respectively. -

Circle and Squares This Problem Gives You the Chance To: • Calculate Ratios of Nested Circles and Squares

Circle and Squares This problem gives you the chance to: • calculate ratios of nested circles and squares This diagram shows a circle with one square inside and one square outside. The circle has radius r inches. 1. Write down the side of the large square in terms of r. _________ inches 2. Find the side of the small square in terms of r. _________ inches Show your work. 3. What is the ratio of the areas of the two squares? ____________________ Show your work. 4. Draw a second circle inscribed inside the small square. Find the ratio of the areas of the two circles. ____________________ Show your work. 8 Geometry – 2008 77 Copyright © 2008 by Mathematics Assessment Resource Service All rights reserved. Circles and Squares Rubric The core elements of performance required by this task are: • calculate ratios of nested circles and squares section Based on these, credit for specific aspects of performance should be assigned as follows points points 1. Gives correct answer: 2r 1 1 2. Gives correct answer: √2r or 1.4r 1 Uses the Pythagorean rule or trig ratios 1 2 3. Gives correct answer: 2 or 1/2 1 Shows work such as: (2r)2 ÷ (√2r)2 1 2 4. Gives correct answer: 2 or 1/2 1 Shows some correct work such as: the radius of the small circle is r/√2 2 the areas of the large and small circles are πr2 and πr2/2 3 Total Points 8 Geometry – 2008 78 Copyright © 2008 by Mathematics Assessment Resource Service All rights reserved. Circles and Squares Work the task and look at the rubric? What are the mathematical demands needed to interpret the diagrams? To solve the ratios? __________________________________ Look at student work on interpreting the diagrams part 1 and 2. -

On a Relation Between Four Line-Segments

On a relation between four line-segments. Memoria di O. BOTTEMA (a :Delft) In memory of Guido Casteln~tovo, i~ thc recurrence of the first centenary of his birth. Sammary. - A symmetrical relation between four line-segments is defined which is a genera- lization of an elementary one for three segments. A tetrahedron A=(A~ A~AsA4) being given the locus E of the points _P for which PAi satisfy the relation is shown to be a cyclide. F is the envelops of the set of spheres orthogonal to the circumsphere of A and whith their centres on the Steiner ellipsoid of A. 1)roperties of ~ are discussed for special types of tetrahedra. If A is a square the surface F is a torus. 1. - Three line-segments p,, p, and P8 are the sides of a (real, non-de- generated) triangle if and only if each of them is less than the sum of the other two, that is if 4 4 (1) If T~0 we have T=16 02 where 0 stands for the area of the triangle; if T = 0 the triangle is degenered. We consider an extension dealing with four line-segments p~, p~, P3, P4 in three-dimensional Euclidean space. The edges A~Aj of a tetrahedron A = (AiA2A~A4) shall be denoted by a~j. A is in general determined by its six edges, but we need two inequalities between them for the tetrahedron to be real, for instance one expressing the existence of one face and another the real value of the corresponding height. -

Geometrical Constructions 1

Geometrical Constructions 1 by Pál Ledneczki Ph.D. Geometrical Constructions 1 „Let no one destitute of geometry enter my doors” (Plato, 427-347 BC) RAFFAELLO: School of Athens, Plato & Aristotle Budapest University of Technology and Economics ? Faculty of Architecture ? Department of Architectural Representation 2005 Fall Semester 2 © Pál Ledneczki Geometrical Constructions 1 Drawing Instruments For note taking and constructions For drawings (assignments) - loose-leaf white papers of the size A4 - three A2 sheets of drawing paper (594 mm × 420 mm) - pencils of 0.3 (H) and 0.5 (2B) - set of drawing pens (0.2, 0.4, 0.7) - eraser, white, soft - set square (two triangles, 30 cm) - set square (two triangles, 20 cm) - A1 sheet of drawing paper for folder - pair of compasses with joint for pen frame 10 folder - French-curves (title box on drawings) - set of color pencils 15 I -1 NAME (A1 size of 15 Date Signature GR # - drawing board paper folded into two) 30 30 60 30 lettering Name Architectural Representation Budapest University of Technology and Economics ? Faculty of Architecture ? Department of Architectural Representation 2005 Fall Semester 3 © Pál Ledneczki Geometrical Constructions 1 Contents 1) Basic constructions 2) Loci problems 3) Geometrical transformations, symmetries 4) Pencils of circles, Apollonian problems 5) Regular polygons, golden ratio 6) Affine mapping, axial affinity 7) Conic sections Budapest University of Technology and Economics ? Faculty of Architecture ? Department of Architectural Representation 2005 Fall Semester