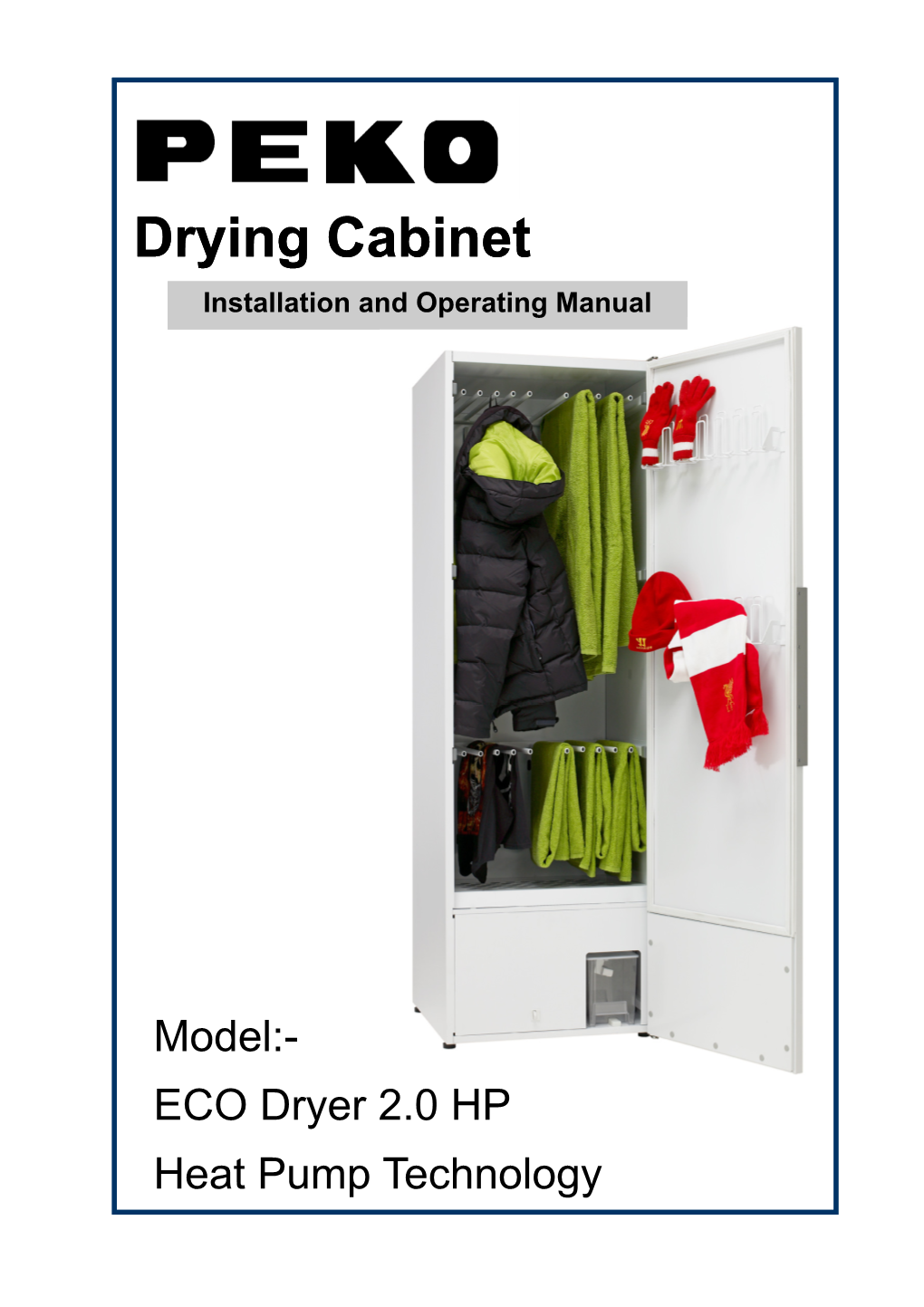

ECO Dryer 2.0 HP Heat Pump Technology

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Eb0320 1947.Pdf (968.5Kb)

PLANNING EXTENSION BULLETIN 320 MAY 1947 l EXTENSION SERVICE INSTITUTE OF AGRICULTURAL SCIENCES THE STATE COLLEGE OF WASHINGTON PULLMAN, WASHIN.GTON / PLANNING EXTENSION BULLETIN 320 MAY 1947 ~~ HELEN NOYES Extension Economist in Home Management ORIGINAL MANUSCRIPT PRE PA RED ~~ ESTHER POND SMITH Formerly Extension Economist in Home Management EXTENSION SERVICE INSTITUTE OF AGRICULTURAL SCIENCES THE STATE COLLEGE OF WASHINGTON PULLMAN, WASHINGTON it help you with those countless big and little jobs which have to be done. A utility room is a service room located preferably on the first floor of the house near The size of the utility room and the amount the kitchen and the rear entrance. This loca of storage space needed is determined by the amount and kind of work to be done there. If tion makes it easily accessible from inside or a back porch, a bedroom, or part of a large outside the house. It provides a place for kitchen is being remodeled into a utility room, laundry work. All washing equipment, includ the uses of the room will be limited by the ing an indoor clothesline, can be incorporated amount of space available. into this room. It provides a place for men to wash, and for such jobs as sorting eggs, clean The utility room is a workroom and not a ing vegetables, cutting meat, and arranging back entrance to the house. A small rear hall flowers. If so desired, space can be set aside that leads to the kitchen, the utility room, and for a well-planned sewing room. The hot the basement makes a good entrance. -

Ship's Serviceman Laundry Handbook: Rate Training Naval

DOCUMENT RESUME ED 123 475 CE 007 265 TITLE Ship's Serviceman Laundry Handbook: Rate Training Manual and Nan-Resident Career Courise. INSTITUTION Naval Education and Training Command, Pensacola, Fla. PEPORT NO NAVEDTRA-10293 PUB DATE 76 NOTE 232p. AVAILABLE FROM Superintendent of Documents, 'U.S. Government Printing Office, Washington, D.C. 20402 (Stock Number 0502-LP-051-4650) EDFS PRICE MF-$0.83 HC-$12.-11 Plus Postage. DESCRIPTORS *Clothing Maintenance Specialists; Course Content; Individual Instruction; *Instructional Materials; *Job Training; *Manuals; *Military Training; Technical Education; Textiles Instruction IDENTIFIERS Laundrymen; Navy ABSTRACT The manual and course form a self study package that enables laundrymen to fulfill the requirements of the Ship's Serviceman (Laundry) rating. Chapter 1provides information regarding the administration of ship's service activities (equipment maintenance, supervisory responsibilities, and procurement of suppiies).,Chapters 2 through 12 cover the following topics: laundry organization and management, fibers and fabrics, washing, extracting and drying, flatwork ironing, pressing and finishirig, assembly and issue, drycleaning and finishing, removal of spots and stains, decontaminating and disinfecting, and portable laundry equipment. Photographs and diagrams supplement the narration. The set of assignments in the Nonresident Career Course include learning objectives and supporting questions designed to guide students through the manual.A list .of commonly used Federal supply laundry products, a glossary, an explanation of the metric system, a subject index, and a 37 -page .nonresident career course assignment booklet conclude the document. (AUChor/BP) *********************************************************************** Documents \acquired by ERIC include many informal unpublished * materials not available from other sources. ERIC makes every effort * * to obtakn the best copy available. -

The Design of Energy Efficient Everyday Practices

REVISED VERSION 2015-06-18 The design of energy efficient everyday practices Wiktoria Glad Linköping University Department of Thematic Studies SE-581 83 Linköping Sweden [email protected] Keywords everyday life, practices, design, socio-technical, user perspec- energy-efficiency objectives. This confuses users and makes tive, communication it difficult for household members to take the “right” actions in everyday life. Recommendations to housing companies are Abstract to focus on both product and organizational designs to better target energy efficiency goals. Activity-centred design has been proposed as a way to en- courage energy-efficient practices. This approach suggests that “good” designs can improve communication between the Introduction sender and receiver of a message, for example, “save energy”. Design has been promoted as an effective tool for reaching The approach also concerns recent advances in research into energy-efficiency goals (EU Directive, 2005, 2009). Legislation how objects can be inscribed to steer users in certain direc- such as the Eco Design Directive has focused on appliances and tions. The approach has been expanded to include not only products. The current research has users’ perspectives on de- the use of individual things but the practices of everyday life. sign and the starting point is rather the activities of people than This paper examines design issues related to everyday prac- appliances and products. Norman (2013) introduced activity- tices and reports on findings in three household domains cru- centred designs as a perspective to focus on high-level struc- cial to efforts to influence household behaviour to promote tures such as “care of clothes” rather than “using the washing energy-efficient everyday lives: a bright and comfortable home machine”. -

DAMASK: a Firm, Glossy, Jacquard-Patterned Fabric That May Be Made from Linen, Cotton, Rayon, Silk, Or a Combination of These with Various Manufactured Fibers

D DAMASK: A firm, glossy, Jacquard-patterned fabric that may be made from linen, cotton, rayon, silk, or a combination of these with various manufactured fibers. Similar to brocade, but flatter and reversible, damask is used for napkins, tablecloths, draperies, and upholstery. DAMPENING (IN TIRE CORD): The relative ability to absorb energy and deaden oscillation after excitation. DECATING MARK: A crease mark or impression extending fillingwise across the fabric near the beginning or end of the piece. DECATIZING: A finishing process in which fabric, wound tightly on a perforated roller, either has hot water circulated through it (wet decatizing), or has steam blown through it (dry decatizing). The process is aimed chiefly at improving the hand and removing wrinkles. DECITEX: One tenth of a tex. DECORTICATING: A mechanical process for separating the woody matter from the bast fiber of such plants as ramie and hemp. DEEP-DYEING VARIANTS: Polymers that have been chemically modified to increase their dyeability. Fibers and fabrics made therefrom can be dyed to very heavy depth. DEFECTS: A general term that refers to some flaw in a textile product that detracts from either performance or appearance properties. DEFORMATION: A change in the shape of a specimen, e.g., an increase in length produced as the result of the application of a tensile load or force. Deformation may be immediate or delayed, and the latter may be recoverable or nonrecoverable. DEGRADATION: The loss of desirable physical properties by a textile material as a result of some process or physical/chemical phenomenon. DEGREE OF ESTERIFICATION: The extent to which the acid groups of terephthalic and/or other acids have reacted with diols to form ester groups in polyester polymer production. -

Architect Laundry Planning File

ARCHITECT LAUNDRY PLANNING FILE B22SL05006/14504 Laundry Systems for hotels and motels WHY INSTALL AN ON-PREMISES LAUNDRY? 1. Launder everything on premises. A MILNOR on-premises laundry can handle all of a hotel/motel's clean fabric needs in a simple manner. MILNOR washer-extractors can process bath and bed linens, blankets, pillows, restaurant and banquet napery, and kitchen linen, plus such items as employee uniforms, slip covers and cleaning rags and mops. Many types of rugs and drapes can be processed in a MILNOR on-premises laundry. 2. Distinctive linens build prestige. Many hotel and motel operators have enhanced their image of quality through tasteful fabric selection. Everything from linen to drapes can be selected in the colors and patterns of your choice. 3. Get more use from less inventory. An on-premises laundry provides more use from less inventory. Table napery, bath linen, and other goods can be laundered immediately after use and be ready again in about an hour if necessary. Smaller inventories mean less storage space and more money for investment elsewhere. 4. You won't be caught short. On-premises laundering eliminates "caught short" situations. It gives you a ready supply of towels, sheets, napkins, tablecloths, and uniforms. This is especially important during weekends and holidays, when outside services are not available. 5. Control quality, sanitation. On-premises laundering assures quality processing because you are in control. You can prolong fabric life by using a distinct formula for the specific degree of soil. MILNOR's E-P Plus® washer-extractors make this easy, with several specific formulas developed and field-tested by chemists for hotels and motels. -

ASKO Laundry ASKO Laundry

ASKO Laundry ASKO Laundry Introduction Scandinavian design 4 ASKO Laundry 6 Washers Features 10 Range 17 Tumble dryers Features 22 Range 29 Drying cabinets Features 34 Range 38 Hidden Helpers™ Features 40 Range 42 2 3 Scandinavian design The combination of everyday functionalism, environmental concern and clean, pleasant lines is the principal hallmark of Scandinavian design – and that of ASKO. The fundamental idea is that carefully designed products should improve people’s quality of life. To distinguish ourselves in a market of cluttered, complex and voluptuous designs, we aim for a soft, humanistic minimalism based on the principle of quiet being the new loud. The key elements of Scandinavian design – understated elegance, high-quality craftsmanship and natural materials – are reflected in ASKO’s design language. Much emphasis is also placed on functionality. We strive to make life easier by offering truly user-friendly interfaces, integration of practical functions and trouble-free, durable products that please people for a long time. “The key elements of Scandinavian design – understated elegance, high-quality craftsmanship and natural materials – are reflected in ASKO’s design language. ” Jon Carlehed, Head of Design at Asko Appliances. 4 Is it possible to keep up with the volumes of dirty laundry? Despite our 60 years in the industry we cannot help but load up to 11 kg you can wash items that you normally marvel at people’s laundry habits. Almost everyone we can´t do like kitchen rugs, pillows, large blankets or meet complains about how much laundry they have and duvets. After the washing is done you put the whole wash that they never have time to wash it all before the laundry load in the dryer which can take as much as 11 kg in its basket is filled with even more dirty laundry. -

Product Catalogue Professional Drying Equipment

Product Catalogue Professional Drying Equipment PODAB - Professional Drying Equipment 1 Specialised in professional drying equipment With over seventy years of experience and the ability to constantly innovate, the Swedish company PODAB has become one of the leading providers of technologically advanced drying equipment. We develop and produce drying equipment and represent Alliance and Schulthess in the Swedish market. Internationally, we mainly market drying cabinets, renowned for their quality, reliability and performance. PODAB offers a wide range of drying cabinets, to be used in residen- tial and domestic settings, professional laundries, at fire stations, airports, nurseries and theatres. Our drying cabinets, designed specifically to dry protective garments, have the ability to dry from both the inside and the outside, at the same time. A unique technology that we were the first to develop. As you would expect from Swedish engineering, we produce the best drying cabinets in the world. Jimmy Nilsson, CEO 2 PODAB - Professional Drying Equipment Content About PODAB 4 Products 6 Drying cabinets 7 Tumble dryer 12 Optional extras 14 Accessories 15 Spare parts 17 References 18 Product data 20 PODAB - Professional Drying Equipment 3 Professional laundry care Since 1945, PODAB has equipped thousands of Swedish laundries with washing and drying equipment. For the inter- national market we offer a high performance tumble dryer and drying cabinets, complemented by various accessory products. Our range is not limited to a large number of drying products, we also offer customised solutions. Technological innovations User-friendly products PODAB has established itself as innovators and a driving We develop products that withstand extreme conditions in force of technological progress. -

Download the Nimo Product Brochure

Drying cabinets, ironing board cabinets, utility sinks and dehumidifiers. All manufactured in Sweden. 03 Introduction Contents 04 Drying cabinets 14 Ironing board cabinets 16 Utility sinks 26 Nimo Pro Introduction New clothes – every wash. Nimo's products are all manufactured in Sweden. For more than 50 years we have manufactured the products that help you look after your clothes so they last longer. Cabinet control All of our Eco drying In this brochure we present these cabinets use heat pump technology. products so that you can easily This means that you don’t choose from the market's widest need to think about either power levels or time. range of ironing board cabinets, When the laundry is dry, the drying cabinet turns off – utility sinks and energy-efficient completely automatically. To find these drying cabinets, drying cabinets for both home and look for the Eco Dryer label! professional environments. Welcome! www.nimoverken.com 3 Drying cabinets Hurrah for the drying cabinet! There are many ways of drying The prize-winning and heat wet clothes. But only one is energy pump powered Eco Dryer 2.0 drying cabinet is the market's efficient and gentle. A drying most energy-efficient way of drying clothes. The NB 1000 cabinet from Nimo dries your TMS utility sink (page 21) is a handy utility sink with both clothes in the best possible way. baskets and enclosed sections. A drying cabinet dries everything from wet shoes and dirty children's snowsuits to your most delicate garments. Nimo’s drying cabinets with sensor technology switch off when the clothes are dry. -

That's Better

Perfection in design and performance. THAT’S BETTER. Built Strong to Last Long. It has taken 100 years to reach the point of perfection. Now you can enjoy all the benefits. Back in the 1890’s, Fredrick Louis Maytag was a 16 year old field hand dreaming of creating safe, labour saving tools to do the work traditionally carried out manually. Today, well over 100 years later, his surname has come to embody all that’s best in high quality, hi-tech American design. In the USA, Maytag is the number one brand for laundry. A byword for panache and performance, form and function, elegance and efficiency... the name behind the most desirable range of home appliances, chosen by discerning customers across the whole continent. After a century of inspired advancement and ground breaking innovation, Maytag has reached the highest standard ever - combining time-honoured craftsmanship with outstanding new technology and the ultimate in sophisticated styling. Laundry, dishwashing and refrigeration as you have never known it before. It’s time for you to enjoy all the benefits... with a range of appliances that enhance your home, and perfectly compliment your lifestyle. That’s Maytag... that’s better. 2008 ‘Stylish, smart - with inspired ideas for the way we live’ That’s better THAT’S BETTER Design classics to suit your style…and your home. THE TOTAL STYLISH DESIGN, STUNNING LAUNDRY ROOM SPACIOUS REFRIGERATION CONCEPT DISHWASHING INNOVATION Maytag sets new standards in contemporary home appliances, ushering in a new age of design classics with stunning style and inspirational innovation throughout the range. -

Eb0320 1945.Pdf (372.3Kb)

Extension Bulletin No. 320 February, 194 5 Agrieultttral Extension Set•viee State College of Washington PULLMAN, WASHINGTON Planning A ·Utility Room By Esther Pond Horne Management Specialist A utility room is a service room near the back entrance of the house and near the kitchen. It might be a place where the men or children wash, where the laundry and other work is done or where the hot water tank and .furnace are placed. For some farm families the utility room might be used for such things as, sorting eggs, cleaning vegetables, cutting meat and separting milk. Many such jobs clutter the kitchen or make extra steps to the basement.· I n planning a utility room, first make a list of the things you want to do in the room. Then opposite each job list the equipment and materials needed to do the job efficiently. Include things you do not yet have, so that there will be a place for them when you add them to your household. Your list might look something like this: Jobs Equipment To Be Used Materials Needed Men wash. Wash bowl or laundry tub. / Soap, towels, combs, mirror. Shine shoes. Shoe shining board, polishing cloth I Shoe polish. or brushes. Arrange flowers. Table or counter, flower bowls, I Water. frogs, scissors and knife. Clean vegetables. Counter, scissors, knife, peeler, I Water, newspapers. brushes, garbage can. Wrap packages. ~&issors, pencil. I Paper, cord and labels. Cut out garments. ~-C-o-u-nt_e_r_,-sc-i-ss_o_r-s,_p_i_n_s,-ta_p_e_m-ea_ s_u_r_e -+~-P-a-t-te_r_n_s_a_n_d_m~ . ~a-t_e~r-i_a~l.~~=====- Sew Counter, sewing machine, lap table, Thread, trimmings, materials, sewing closet, scissors, pins, thimble, snaps. -

Love Your Laundry Program Your Laundry Space to Save Time, Eliminate Stress and Make Wash-Day Chores a Breeze WORDS Anna Koorey

{laundries} transform love your laundry Program your laundry space to save time, eliminate stress and make wash-day chores a breeze WORDS AnnA Koorey WhEn yOu consider how much time you spend washing, drying lwell a and ironing, it makes sense to create a laundry that’s as user-friendly as sw possible. With a little careful planning, you can streamline your space k E r E to maximise its efficiency – whatever its size. Start by creating task- oriented zones: washing, drying, ironing and folding. “For a laundry to function and flow it’s important to reassess everything in the space – if graphy d it doesn’t belong there, move it!” says Tanya Lewis of Eco Organiser. > oto ph homebeautiful.com.au {OCTOBER 2012} 181 shopping shopping ‘WH70F60WV1’ 4.5-star WELS- rated, 3-star ERL-rated washing machine, $909, Fisher & Paykel. ‘WD14030FD6’ 4.5-star ‘T 8000 WP Supertronic Heat WELS-rated, 4-star (washer) Pump’ 6-star ERL-rated 7kg dryer, & 1.5-star (dryer) ERL-rated $4699, Miele, miele.com.au. steam washer/dryer, $1999, LG. ‘Mulig’ laundry bag with stand, $24.99, Ikea. ‘Portis’ drying rack, $49.95, Ikea. ‘WF1104XAC’ wash wisely 4.5-star WELS- rated, 4-star ERL-rated 10kg ‘HDY-C70’ front load washer, Front loading washing machines are generally 1.5-star $1999, Samsung. more energy-efficient than top loaders, and Doing the dirty ERL-rated 7kg can be neatly tucked under a benchtop or a a mounting pile of grubby clothes is the condenser dryer can be hung above. “a 600mm washer is bane of laundries everywhere, but a few dryer, $749, usually 6.5kg-7kg capacity, which is perfect for simple tricks will have the space spick and Haier. -

Organization of Laundry Facility Types and Energy Use in Owner-Occupied Multi-Family Buildings in Sweden

Sustainability 2014, 6, 3843-3860; doi:10.3390/su6063843 OPEN ACCESS sustainability ISSN 2071-1050 www.mdpi.com/journal/sustainability Article Organization of Laundry Facility Types and Energy Use in Owner-Occupied Multi-Family Buildings in Sweden Lena Borg * and Lovisa Högberg Department of Real Estate and Construction Management, KTH Royal Institute of Technology, Stockholm SE-100 44, Sweden; E-Mail: [email protected] * Author to whom correspondence should be addressed; E-Mail: [email protected]; Tel.: +46-8-790-84-17. Received: 25 April 2014; in revised form: 3 June 2014 / Accepted: 9 June 2014 / Published: 16 June 2014 Abstract: The way in which we plan and produce buildings today will influence our energy consumption in the future. This paper explores how the types of laundry facilities provided in owner-occupied multi-family buildings in Sweden have changed since the 1990s and seeks to draw attention to how this may impact energy consumption for laundry. Three factors are analyzed that influence energy consumption: the number of laundry appliances, energy performance in laundry appliances and user demand for laundry. The results indicate that there has been a change in building practices, from the domination of communal laundry rooms towards in-unit laundry facilities. The findings imply that the changes in provision of laundry facilities increase the number of appliances but do not necessarily increase energy consumption during the usage phase depending on energy performance and user behavior. Thus, developers should consider laundry facility organization when designing multi-family buildings in order to optimize the use of space and resources, given user demand and building regulations.