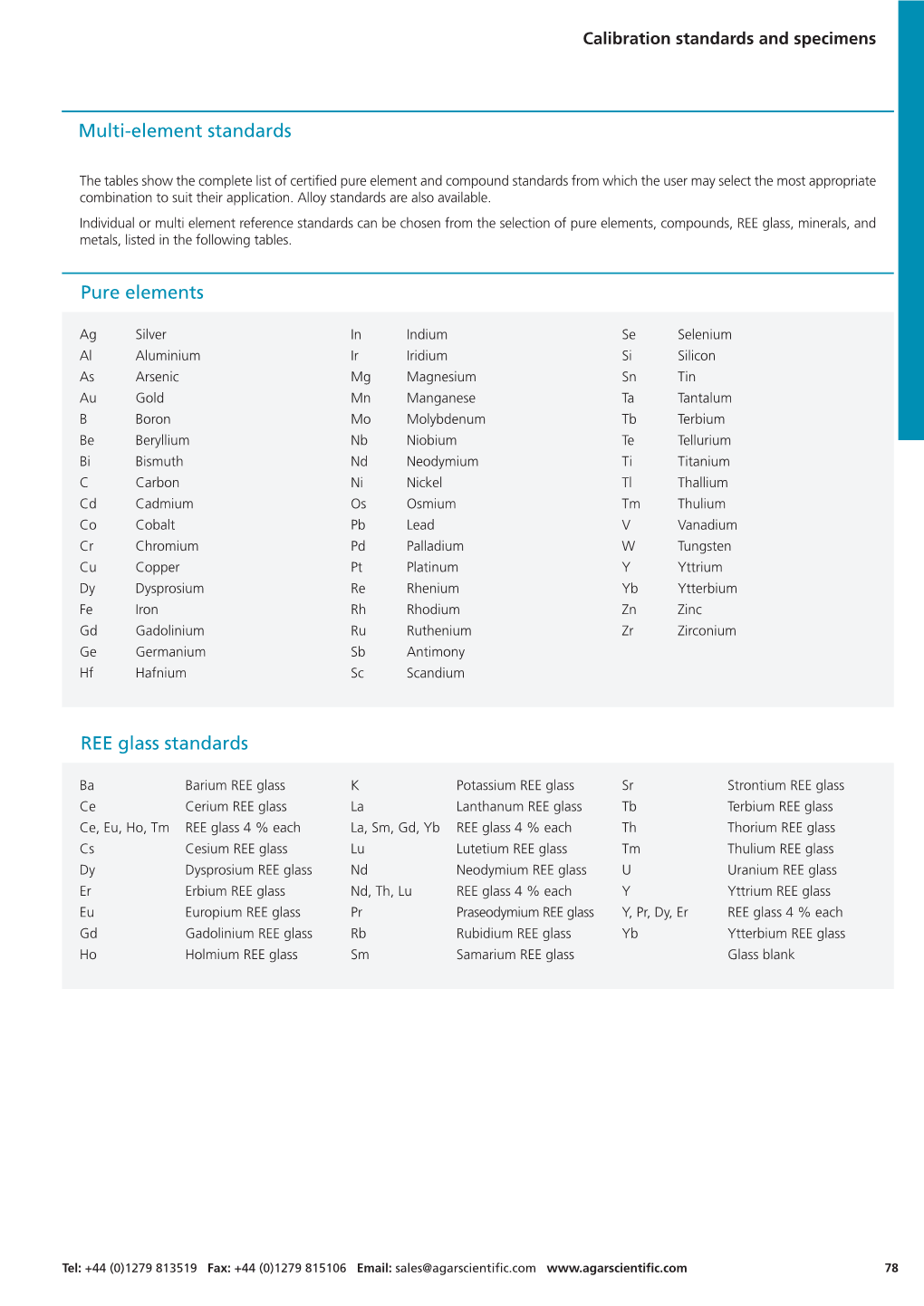

Pure Elements REE Glass Standards Multi-Element Standards

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

CUBIC ZIRCONIA: an UPDATE by Kurt Nassau

CUBIC ZIRCONIA: AN UPDATE By Kurt Nassau Soon after it was first marketed in 1976, ubic zirconia was discovered as a natural mineral in colorless cubic zirconia became the C 1937, when two German mineralogists, von Staclz- dominant diamond imitation, with elberg and Chudoba (1937), were examining a highly current production of approximately 60 metamict zircon given to them by B. W. Anderson. The million carats per year. Although cubic zircon contained some tiny crystals which they identified zirconia was discovered as a natural by X-ray diffraction as the cubic form of zirconium oxide mineral in 1937, crystals usable for (or zirconia), a compound lznown as baddeleyite when in faceting were first produced ill 1969 and it was not until a practical sltull-melting the monoclinic form. So little did von Staclzelberg and technique was developed in the USSR in Chudoba think of this discovery that they did not even 1972 that commercial production became assign a name to the new mineral. As a result, it is lznown feasible. This article reviews the sl<ull- to this day by its scientific name, cubic zirconia, and the melting technique used to produce cubic prefix synthetic, although proper, is not usually included. zirconio and examines the current status This same material had already been used for many of this diamond simulant with regard to years as a ceramic composition for high-temperature in- q~~ality,production, ond market. The dustrial and scientific purposes; because of an exception- patent situation is discussed, as well as ally high melting point, "stabilized zirconia" ceramics prospects lor new diamond imitations can be used at temperatures up to 2540°C (4604°F)and are and the recent surge of interest in colored cubic zirconia. -

United States Patent (19) 11 3,929,495 Broemer Et Al

United States Patent (19) 11 3,929,495 Broemer et al. (45) Dec. 30, 1975 54) OPTICAL BORATE GLASS OF HIGH 3,149,984 9/1964 Faulstich........................... 106/47 R CHEMICAL RESISTANCE AND PROCESS 3,307,929 3/1967 Trap.................................. 106/47 R 3,480,453 it 1/1969 Reid et al.......................... 106/47 R OF MAKING SAME 3,486,915 12/1969 Broemer et al................... 106/47 R (75) Inventors: Heinz Broemer, Hermannstein; 3,510,325 5/1970 Broemer et al................... 106/47 R Norbert Meinert, Wetzlar, both of FOREIGN PATENTS OR APPLICATIONS Germany 863,352 3/1961 United Kingdom............... 106/47 Q 73 Assignee: Ernst Leitz G.m.b.H., Wetzlar, 4,424,420 10/1969 Japan................................ 106/47 Q Germany Filed: May 15, 1973 Primary Examiner-Winston A. Douglas 22) Assistant Examiner-Mark Bell 21 Appl. No.: 360,418 Attorney, Agent, or Firm-Erich M. H. Radde 30 Foreign Application Priority Data 57 ABSTRACT May 15, 1972 Germany............................ 2223564 An optical borate glass of high chemical resistance, with negative anomalous partial dispersion, refraction 52) U.S. Cl. ............................. 106/47 Q; 106/47 R index n between 1,65 and 1,79, and Abbe number ve 51 Int. CI..... C03C 3/14: CO3C 3/00; C03C 3/30 between 40 and 30 is composed of boron trioxide, 58) Field of Search......................... 106/47 O, 47 R lead oxide, and aluminum oxide. It may additionally contain lithium, sodium, and/or potassium oxides, zinc (56) References Cited oxide, zirconium dioxide, tantalum pentoxide, and, if UNITED STATES PATENTS desired, antimony trioxide and/or bismuthum trioxide. -

Physical Properties and Data of Optical Materials

Physical Properties and Data of Optical Materials Moriaki Wakaki Keiei Kudo Takehisa Shibuya Laß) CRC Press ^^ J Taylor &. Francis Group '*-*"' Boca Raton London New York CRC Press is an imprint of the Taylor & Francis Group, an informa business • Table of Contents A AI (Aluminum) 1 AlSb (Aluminium Antimonide) 10 ADP (Ammonium Dihydrogen Phosphate) 16 Sb (Antimony) 21 Arsenic Selenium Glass 26 As (33%) + S (30%) + Br (37%) (Arsenic-Sulfur-Bromine Glass) 28 As2Se3 (Arsenic Tri-Selenide) 30 As2S3 (Arsenic Tri-Sulfide Glass) 33 6 Ba (Barium) 39 BaF2 (Barium Fluoride) 42 BaTi03 (Barium Titanate) 47 Be (Beryllium) 50 BeO (Beryllium Oxide) 54 Bi(Bismuth) 56 B(Boron) 61 C Cd(Cadmium) 65 CdSe (Cadmium Selenide) 70 CdS (Cadmium Sulfide) 75 CdTe (Cadmium Telluride) 82 CaC03 (Calcite) 89 CaF2 (Calcium Fluoride) 96 CaW04 (Calcium Tungstate) 105 CsBr (Cesium Bromide) 108 Csl (Cesium Iodide) 113 Cr(Chromium) 118 Cu(Copper) 122 CuCl (Cuprous Chloride) 128 D Diamond 135 G Ga (Gallium) 139 GaSb (Gallium Antimonide) 142 GaAs (Gallium Arsenide) 149 GaP (Gallium Phosphide) 158 Ge (Germanium) 165 Ge + Se + Te (Germanium-Selenium-Tellurium Glass) 180 Glass 182 Au (Gold) 191 * I In (Indium) 199 InSb (Indium Antimonide) 202 InAs (Indium Arsenide) 212 InP (Indium Phosphide) 218 Ir (Iridium) 224 Fe(Iron) 228 L LaF3 (Lanthanum Fluoride) 233 PbF2 (Lead Fluoride) 236 PbSe (Lead Selenide) 237 PbS (Lead Sulfide) 243 PbTe (Lead Telluride) 251 LiF (Lithium Fluoride) 257 Lucite 266 M Mg (Magnesium) 269 MgF2 (Magnesium Fluoride) 275 Mg2Ge (Magnesium Germanide) 282 MgO (Magnesium -

United States Patent (19) (11) 4,154,806 Szabó Et Al

United States Patent (19) (11) 4,154,806 Szabó et al. 45) May 15, 1979 54 PROCESS FOR THE PRODUCTION OF (56) References Cited NITROUS OXDE U.S. PATENT DOCUMENTS 75) Inventors: Zoltán Szabó; Jenö Trompler; 1,098,305 5/1914 Torley et al. ........................ 423/400 Erzsébet Hollós, née Rakosinyi, all of 2,111,277 3/1938 Castner et al. ....................... 423/400 Budapest, Hungary 2,425,582 8/1947 Vingee ................................. 423/400 3,411,883 11/1968 Smit ................................. 423/400X 73) Assignee: Eötvös Lóránd Tudományegyetem, FOREIGN PATENT DOCUMENTS Budapest, Hungary 276069 5/1913 Fed. Rep. of Germany ........... 423/400 (21) Appl. No.: 865,119 Primary Examiner-G. O. Peters 57 ABSTRACT (22 Filed: Dec. 28, 1977 Ammonium nitrate is mixed, in a weight ratio of higher than 1:5, with a melt containing ammonium hydrogen 30 Foreign Application Priority Data sulfate and ammonium sulfate respectively present in Dec. 30, 1976 HU) Hungary ............................. TO 1047 the melt in a ratio of at least 4:1. The resultant mixture is subjected to thermal decomposition at 200-240 de 51) Int. C.’.............................................. C01B 21/22 grees C to produce nitrous oxide. 52) U.S. C. .................................................... 423/400 58) Field of Search ......................................... 423/400 10 Claims, No Drawings 4,154,806 2 temperature, i.e. over 250 C., the nitrous oxide formed PROCESS FOR THE PRODUCTION OF NITROUS decomposes to higher nitrogen oxides and nitrogen. A OXDE further disadvantage of the increased temperature con sists in that ammonium nitrate sublimates and thus The invention concerns a process for the production causes material loss and operational problems. -

Structural and Dynamical Trends in Alkali-Metal

Article pubs.acs.org/JPCC Structural and Dynamical Trends in Alkali-Metal Silanides Characterized by Neutron-Scattering Methods † ‡ † § ∥ † ∥ Wan Si Tang,*, , Mirjana Dimitrievska,*, , Jean-Noel̈ Chotard, Wei Zhou, Raphael̈ Janot, ⊥ † Alexander V. Skripov, and Terrence J. Udovic † NIST Center for Neutron Research, National Institute of Standards and Technology, Gaithersburg, Maryland 20899-6102, United States ‡ Department of Materials Science and Engineering, University of Maryland, College Park, Maryland 20742-2115, United States § National Renewable Energy Laboratory, Golden, Colorado 80401, United States ∥ Laboratoire de Reactivité ́et Chimie des Solides (LRCS), UMR 7314 CNRS, Universitéde Picardie Jules Verne, 33 rue Saint-Leu, 80039 Amiens Cedex, France ⊥ Institute of Metal Physics, Ural Branch of the Russian Academy of Sciences, Ekaterinburg 620990, Russia *S Supporting Information ABSTRACT: Structural, vibrational, and dynamical properties of the mono- and mixed-alkali silanides (MSiH3, where M = K, Rb, Cs, K0.5Rb0.5,K0.5Cs0.5, and Rb0.5Cs0.5) were investigated by various neutron experiments, including neutron powder diffraction (NPD), neutron vibrational spectroscopy (NVS), neutron- scattering fixed-window scans (FWSs), and quasielastic neutron scattering (QENS) measurements. Structural characterization showed that the mixed compounds exhibit disordered (α) and ordered (β) phases for temperatures above and below about 200− 250 K, respectively, in agreement with their monoalkali correspondents. Vibrational and dynamical properties are strongly influenced by the cation environment; in particular, there is a red shift in the band energies of the librational and bending modes with increasing lattice size as a result of changes in the bond lengths and force constants. Additionally, slightly broader spectral features are observed in the case of the mixed compounds, indicating the presence of structural disorder caused by the random distribution of the alkali-metal cations within the lattice. -

Effects of B2O3 (Boron Trioxide) on Colon Cancer Cells: Our First-Step Experience and in Vitro Results

Turkish Journal of Biology Turk J Biol (2019) 43: 209-223 http://journals.tubitak.gov.tr/biology/ © TÜBİTAK Research Article doi:10.3906/biy-1901-34 Effects of B2O3 (boron trioxide) on colon cancer cells: our first-step experience and in vitro results 1, 2 3 4 5 3 Özgür ALBUZ *, Dilek DÜLGER , Beste Çağdaş TUNALI , Feray AYDIN , Selim YALÇIN , Mustafa TÜRK 1 Department of General Surgery, Keçiören Training and Research Hospital, Ankara, Turkey 2 Department of Medical Microbiology of Basic Medical Sciences, Faculty of Medicine, Karabük University, Karabük, Turkey 3 Department of Bioengineering, Faculty of Engineering, Kırıkkale University, Kırıkkale, Turkey 4 Department of General Surgery, 29 Mayıs State Hospital, Ankara, Turkey 5 Department of Oncology, Faculty of Medicine, Kırıkkale University, Kırıkkale, Turkey Received: 15.01.2019 Accepted/Published Online: 11.06.2019 Final Version: 13.06.2019 Abstract: Boron oxide (B2O3) is derived from dehydration of boric acid and is a colorless, semitransparent, crystalline compound that is moderately soluble in water. On the other hand, boron oxide is chemically hygroscopic. This gives the molecule the ability to soak up water and adhere to tissues. Boron oxide can be used locally after tumor debulking in inoperable tumors and especially when the tumor-free margin distance cannot be provided. For all these reasons we aimed to evaluate the in vitro test results of B2O3 in terms of cytotoxicity, genotoxicity, apoptosis, and necrotic effects on L929 fibroblast cells and DLD-1 colorectal adenocarcinoma cells. Our studies demonstrated that boron oxide compounds appear to be highly cytotoxic for both cell lines according to WST cell viability assay (44.22% and 18.36% on DLD-1 and L929, respectively). -

Doping Effects on Transition-Metal Silicides: Crystal Structures and Physical Properties of Aluminium Doped Rhenium Silicide

BearWorks MSU Graduate Theses Summer 2020 Doping Effects on Transition-Metal Silicides: Crystal Structures and Physical Properties of Aluminium Doped Rhenium Silicide Victoria DeCocq Missouri State University, [email protected] As with any intellectual project, the content and views expressed in this thesis may be considered objectionable by some readers. However, this student-scholar’s work has been judged to have academic value by the student’s thesis committee members trained in the discipline. The content and views expressed in this thesis are those of the student-scholar and are not endorsed by Missouri State University, its Graduate College, or its employees. Follow this and additional works at: https://bearworks.missouristate.edu/theses Part of the Inorganic Chemistry Commons, and the Materials Chemistry Commons Recommended Citation DeCocq, Victoria, "Doping Effects on Transition-Metal Silicides: Crystal Structures and Physical Properties of Aluminium Doped Rhenium Silicide" (2020). MSU Graduate Theses. 3563. https://bearworks.missouristate.edu/theses/3563 This article or document was made available through BearWorks, the institutional repository of Missouri State University. The work contained in it may be protected by copyright and require permission of the copyright holder for reuse or redistribution. For more information, please contact [email protected]. DOPING EFFECTS ON TRANSITION-METAL SILICIDES: CRYSTAL STRUCTURES AND PHYSICAL PROPERTIES OF ALUMINIUM DOPED RHENIUM SILICIDE A Master’s Thesis -

Improving Boron for Combustion Applications

New Jersey Institute of Technology Digital Commons @ NJIT Dissertations Electronic Theses and Dissertations Summer 8-31-2019 Improving boron for combustion applications Kerri-lee Annique Chintersingh New Jersey Institute of Technology Follow this and additional works at: https://digitalcommons.njit.edu/dissertations Part of the Aerospace Engineering Commons, Chemical Engineering Commons, and the Materials Science and Engineering Commons Recommended Citation Chintersingh, Kerri-lee Annique, "Improving boron for combustion applications" (2019). Dissertations. 1420. https://digitalcommons.njit.edu/dissertations/1420 This Dissertation is brought to you for free and open access by the Electronic Theses and Dissertations at Digital Commons @ NJIT. It has been accepted for inclusion in Dissertations by an authorized administrator of Digital Commons @ NJIT. For more information, please contact [email protected]. Copyright Warning & Restrictions The copyright law of the United States (Title 17, United States Code) governs the making of photocopies or other reproductions of copyrighted material. Under certain conditions specified in the law, libraries and archives are authorized to furnish a photocopy or other reproduction. One of these specified conditions is that the photocopy or reproduction is not to be “used for any purpose other than private study, scholarship, or research.” If a, user makes a request for, or later uses, a photocopy or reproduction for purposes in excess of “fair use” that user may be liable for copyright infringement, -

Trace-Metal Content of the Pueblo Viejo Precious-Metal Deposits and Their Relation to Other High-Sulfidation Epithermal Systems

Mineralium Deposita (2003) 38: 668–682 DOI 10.1007/s00126-003-0356-1 ARTICLE Stephen E. Kesler Æ Norman Russell Æ Karr McCurdy Trace-metal content of the Pueblo Viejo precious-metal deposits and their relation to other high-sulfidation epithermal systems Received: 30 November 2002 / Accepted: 12 December 2002 / Published online: 12 April 2003 Ó Springer-Verlag 2003 Abstract We provide here information on the distribu- abruptly in the upper part of the deposits. This change tion of copper, zinc, lead, gold, silver, barium, arsenic, probably reflects boiling of the hydrothermal solutions antimony, mercury, selenium and tellurium in the and partitioning of mercury and tellurium into a rising Moore and Monte Negro high-sulfidation epithermal vapor phase, and it suggests that host rocks overlying deposits in the Pueblo Viejo district, Dominican the deposits will be anomalous in mercury and tellurium. Republic. Moore and Monte Negro are funnel-shaped Comparison to the Broadlands, New Zealand, hydro- zones of advanced argillic alteration and precious-metal thermal system supports these inferred depositional mineralization which extend to depths of about 350 m processes. It shows that the behavior of arsenic and below the present surface. The uppermost part of the antimony at Broadlands was different from that at Moore deposit has been removed by erosion, whereas Pueblo Viejo, possibly because the elements were com- the Monte Negro deposit is covered by rocks containing plexed differently in the two ore fluids. Comparison of low, but still anomalous gold grades. At Moore, con- trace-element abundances at Pueblo Viejo to other high- centrations of all elements except copper increase up- sulfidation epithermal systems shows differences in base- ward through the deposit. -

Download PRIM II Refractive Index Chart

What is Refractive Index (R.I.)? What do the numbers Light travels at different speeds through in the brackets on this chart mean? different types of gemstones due to The numbers in the brackets indicate the Important Note structure of the stone. This affects the tolerance level for readings derived from All testers have been calibrated during the manufacturing process and requires no amount of light refraction and causes the the product. These slight fluctuations further adjustment or user intervention. Self-calibration should not be attempted and is bending of light. The slower the light's indicating a tolerance level are necessary not advised. speed in the material; the greater the due to the optical sensor and electronic REFRACTIVE INDEX CHART FOR bending effect. The refractive index of the components in the product. To minimize any risks associated, users should contact Presidium at gemstone can be defined as the ratio [email protected] or its service center for assistance. PRESIDIUM REFRACTIVE INDEX METER II between the speed of light in vacuum versus the speed of light in gemstone. In the event that users require the manufacturer to re-calibrate the unit, users will have to bear the associated to and fro freight cost for shipping of the unit to the Presidium service center. Presidium Instruments Please note that the gemstone tested on this product must have a flat surface and should Unit 7, 207 Henderson Road Singapore 159550 not be an opaque gemstone. www.presidium.com.sg Family Name of Stones Refractive Index Reading Family -

Colourless Gemstones

GEMS THE gem DeteCTIVE: COLOURLess gemstONes superseded in the 1970s by a man-made gemstone called cubic zirconia that is still the most popular and common diamond imitation in modern jewellery due to its low cost, high dispersion and good hardness (8.5 on Mohs scale). Another man-made gemstone called synthetic Moissanite was introduced as a diamond simulant in the late 1990s. Although TED A synthetic Moissanite tests positive on a FFILI A diamond tester, it is easily distinguished from diamond by a property called double refraction, detected using a 10x loupe. This property is also displayed by zircon, a natural CCREESH, O’NEILS O’NEILS CCREESH, gemstone with a sub-adamantine lustre. M N N A Complicating the process of identification are treatments that may affect the value of gemstones. For example, a laser may be used to drill down to a dark diamond inclusion and remove it using acid in a process called GE COURTESY OF BREND OF COURTESY GE laser drilling. Also common is fracture filling, ma I where a high refractive-index lead glass is used to fill surface-reaching fractures to make Sparkling, colourless gemstones may People love to assume that their great ALTHOUGH them less visible. Fortunately, both of these appear similar to the naked eye but they grandma’s solitaire engagement ring SYNTHETIC treatments are easily identified using a loupe can vary significantly in identity, rarity contained a natural diamond by virtue MOISSANITE or microscope. TESTS POSITIVE and value. Making such distinctions of its age but they should think again. Some off-coloured diamonds may be ON A DIamOND requires the detective skills of a qualified Synthetically-produced sapphire, spinel and TESTER, IT CAN BE whitened using High Pressure High gemmologist. -

Appendix a of Final Environmental Impact Statement for a Geologic Repository for the Disposal of Spent Nuclear Fuel and High-Lev

Appendix A Inventory and Characteristics of Spent Nuclear Fuel, High-Level Radioactive Waste, and Other Materials Inventory and Characteristics of Spent Nuclear Fuel, High-Level Radioactive Waste, and Other Materials TABLE OF CONTENTS Section Page A. Inventory and Characteristics of Spent Nuclear Fuel, High-Level Radioactive Waste, and Other Materials ................................................................................................................................. A-1 A.1 Introduction .............................................................................................................................. A-1 A.1.1 Inventory Data Summary .................................................................................................... A-2 A.1.1.1 Sources ......................................................................................................................... A-2 A.1.1.2 Present Storage and Generation Status ........................................................................ A-4 A.1.1.3 Final Waste Form ......................................................................................................... A-6 A.1.1.4 Waste Characteristics ................................................................................................... A-6 A.1.1.4.1 Mass and Volume ................................................................................................. A-6 A.1.1.4.2 Radionuclide Inventories ...................................................................................... A-8 A.1.1.4.3