Rail Infrastructure HIGHLIGHTS

Total Page:16

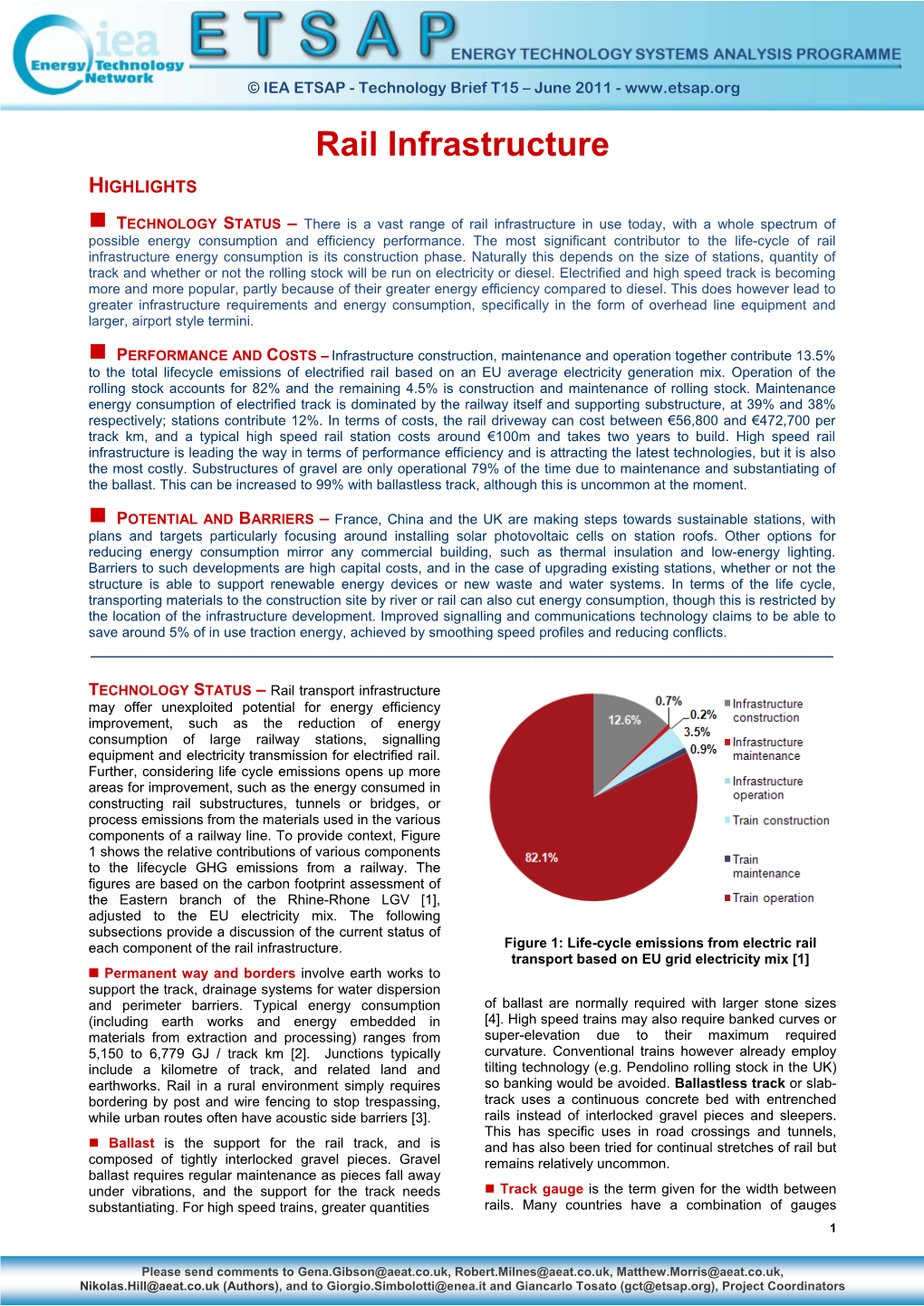

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

NORTH WEST Freight Transport Strategy

NORTH WEST Freight Transport Strategy Department of Infrastructure NORTH WEST FREIGHT TRANSPORT STRATEGY Final Report May 2002 This report has been prepared by the Department of Infrastructure, VicRoads, Mildura Rural City Council, Swan Hill Rural City Council and the North West Municipalities Association to guide planning and development of the freight transport network in the north-west of Victoria. The State Government acknowledges the participation and support of the Councils of the north-west in preparing the strategy and the many stakeholders and individuals who contributed comments and ideas. Department of Infrastructure Strategic Planning Division Level 23, 80 Collins St Melbourne VIC 3000 www.doi.vic.gov.au Final Report North West Freight Transport Strategy Table of Contents Executive Summary ......................................................................................................................... i 1. Strategy Outline. ...........................................................................................................................1 1.1 Background .............................................................................................................................1 1.2 Strategy Outcomes.................................................................................................................1 1.3 Planning Horizon.....................................................................................................................1 1.4 Other Investigations ................................................................................................................1 -

Notes on Curves for Railways

NOTES ON CURVES FOR RAILWAYS BY V B SOOD PROFESSOR BRIDGES INDIAN RAILWAYS INSTITUTE OF CIVIL ENGINEERING PUNE- 411001 Notes on —Curves“ Dated 040809 1 COMMONLY USED TERMS IN THE BOOK BG Broad Gauge track, 1676 mm gauge MG Meter Gauge track, 1000 mm gauge NG Narrow Gauge track, 762 mm or 610 mm gauge G Dynamic Gauge or center to center of the running rails, 1750 mm for BG and 1080 mm for MG g Acceleration due to gravity, 9.81 m/sec2 KMPH Speed in Kilometers Per Hour m/sec Speed in metres per second m/sec2 Acceleration in metre per second square m Length or distance in metres cm Length or distance in centimetres mm Length or distance in millimetres D Degree of curve R Radius of curve Ca Actual Cant or superelevation provided Cd Cant Deficiency Cex Cant Excess Camax Maximum actual Cant or superelevation permissible Cdmax Maximum Cant Deficiency permissible Cexmax Maximum Cant Excess permissible Veq Equilibrium Speed Vg Booked speed of goods trains Vmax Maximum speed permissible on the curve BG SOD Indian Railways Schedule of Dimensions 1676 mm Gauge, Revised 2004 IR Indian Railways IRPWM Indian Railways Permanent Way Manual second reprint 2004 IRTMM Indian railways Track Machines Manual , March 2000 LWR Manual Manual of Instructions on Long Welded Rails, 1996 Notes on —Curves“ Dated 040809 2 PWI Permanent Way Inspector, Refers to Senior Section Engineer, Section Engineer or Junior Engineer looking after the Permanent Way or Track on Indian railways. The term may also include the Permanent Way Supervisor/ Gang Mate etc who might look after the maintenance work in the track. -

Derailment of Freight Train 9204V, Sims Street Junction, West Melbourne

DerailmentInsert document of freight title train 9204V LocationSims Street | Date Junction, West Melbourne, Victoria | 4 December 2013 ATSB Transport Safety Report Investigation [InsertRail Occurrence Mode] Occurrence Investigation Investigation XX-YYYY-####RO-2013-027 Final – 13 January 2015 Cover photo source: Chief Investigator, Transport Safety (Vic) This investigation was conducted under the Transport Safety Investigation Act 2003 (Cth) by the Chief Investigator Transport Safety (Victoria) on behalf of the Australian Transport Safety Bureau in accordance with the Collaboration Agreement entered into on 18 January 2013. Released in accordance with section 25 of the Transport Safety Investigation Act 2003 Publishing information Published by: Australian Transport Safety Bureau Postal address: PO Box 967, Civic Square ACT 2608 Office: 62 Northbourne Avenue Canberra, Australian Capital Territory 2601 Telephone: 1800 020 616, from overseas +61 2 6257 4150 (24 hours) Accident and incident notification: 1800 011 034 (24 hours) Facsimile: 02 6247 3117, from overseas +61 2 6247 3117 Email: [email protected] Internet: www.atsb.gov.au © Commonwealth of Australia 2015 Ownership of intellectual property rights in this publication Unless otherwise noted, copyright (and any other intellectual property rights, if any) in this publication is owned by the Commonwealth of Australia. Creative Commons licence With the exception of the Coat of Arms, ATSB logo, and photos and graphics in which a third party holds copyright, this publication is licensed under a Creative Commons Attribution 3.0 Australia licence. Creative Commons Attribution 3.0 Australia Licence is a standard form license agreement that allows you to copy, distribute, transmit and adapt this publication provided that you attribute the work. -

Technical Investigation Report on Train Derailment Incident at Hung Hom Station on MTR East Rail Line on 17 September 2019

港鐵東鐵綫 紅磡站列車出軌事故 技術調查報告 Technical Investigation Report on Train Derailment Incident at Hung Hom Station on MTR East Rail Line 事故日期︰2019 年 9 月 17 日 Date of Incident : 17 September 2019 英文版 English Version 出版日期︰2020 年 3 月 3 日 Date of Issue: 3 March 2020 CONTENTS Page Executive Summary 2 1 Objective 3 2 Background of Incident 3 3 Technical Details Relating to Incident 4 4 Incident Investigation 8 5 EMSD’s Findings 19 6 Conclusions 22 7 Measures Taken after Incident 22 Appendix I – Photos of Wheel Flange Marks, Broken Rails, Rail Cracks and Damaged Point Machines On-Site 23 1 Executive Summary On 17 September 2019, a passenger train derailed while it was entering Platform No. 1 of Hung Hom Station of the East Rail Line (EAL). This report presents the results of the Electrical and Mechanical Services Department’s (EMSD) technical investigation into the causes of the incident. The investigation of EMSD revealed that the cause of the derailment was track gauge widening1. The sleepers2 at the incident location were found to have various issues including rotting and screw hole elongation, which reduced the strength of the sleepers and their ability to retain the rails in the correct position. The track gauge under dynamic loading of trains would be even wider, and this excessive gauge widening caused the train to derail at the time of incident. After the incident, MTR Corporation Limited (MTRCL) have reviewed the timber sleeper condition across the entire EAL route and replaced the sleepers of dissatisfactory condition. MTRCL were requested to enhance the maintenance regime to closely monitor the track conditions with reference to relevant trade practices to ensure railway safety. -

Track Report 2009 V1:G 08063 PANDROLTEXT

The Journal of Pandrol Rail Fastenings 2009 DIRECT FIXATION ASSEMBLIES Pandrol and the Railways in China................................................................................................page 03 by Zhenping ZHAO, Dean WHITMORE, Zhenhua WU, RailTech-Pandrol China;, Junxun WANG, Chief Engineer, China Railway Construction Co. No. 22, P. R. of China Korean Metro Shinbundang Project ..............................................................................................page 08 Port River Expressway Rail Bridge, Adelaide, Australia...............................................................page 11 PANDROL FASTCLIP Pandrol, Vortok and Rosenqvist Increasing Productivity During Tracklaying...................................................................................page 14 PANDROL FASTCLIP on the Gaziantep Light Rail System, Turkey ...............................................page 18 The Arad Tram Modernisation, Romania .....................................................................................page 20 PROJECTS Managing the Rail Thermal Stress Levels on MRS Tracks - Brazil ...............................................page 23 by Célia Rodrigues, Railroad Specialist, MRS Logistics, Juiz de Fora, MG-Brazil Cristiano Mendonça, Railroad Specialist, MRS Logistics, Juiz de Fora, MG-Brazil Cristiano Jorge, Railroad Specialist, MRS Logistics, Juiz de Fora, MG-Brazil Alexandre Bicalho, Track Maintenance Manager, MRS Logistics, Juiz de Fora, MG-Brazil Walter Vidon Jr., Railroad Consultant, Ch Vidon, Juiz de Fora, MG-Brazil -

Rail Equipment Catalogue

Version 1.2 Rail Equipment Catalogue Partners in excellence RAIL EQUIPMENT CATALOGUE Contents Contents Rail Pullers and Tampers 1 Welding Equipment 3 Power Units 02800A 60 Ton Bridge Jack / Spreader 15 02800-6 100 Ton Bridge Jack / Spreader 02850 Bridge Jack / Spreader Stool 16 -KIT Rail Saws 02900A Diesel Power Unit 33 01100RM Lightweight Two-Stage Spike Puller 16 00800A Rail Saw 7 00100K Dual Circuit Power Unit 34 03100C Rail Puller 18 03900A Reversing Rail Saw 7 03700A Electric Power Unit 35 08300 Spike Driver 18 Battery-Operated 00100 36 Shearing Machines 01200 Spring Clip Applicator 19 Hydraulic Power Unit EME1 06500 Hydraulic Intensifier 37 Electric Shearing Machines 8 08200 Tamper 19 EME2 EMB1 Ignition 03000 Hydraulic Manifold Circuit 37 Battery Shearing Machines 8 EMB2 Startwel® Ignition System 20 06700 Mobile Diesel Power Unit 38 EGH1 EGH2 Dead Head Rail Welding Traceability App 02050RM Modular Power Unit 39 Cutter TM Hydraulic Shearing Machines 9 05100A Pandrol Connect 22 05100B 06300 Power Unit Mobility Cart 40 EPM2 Hydraulic Hand Pump 9 06600 Power Unit Transport 41 05000 Shearing Machine Twin Power Unit Alignment 05500 42 2 Grinding Equipment W/ Generator BA240 Alignment Beam 10 Magnetic Straight Edge 10 CR57 Profile / Frog Grinders 4 Clipping Equipment A Frame Rail Aligner 11 CR61 Alpha Grinder 25 ap-1 Alignment Plates 11 09200A Precision Frog Grinder 26 Preheaters Clip Driver CD100 45 MR150 Profile Grinder 26 03800B Hydraulic Preheater 12 Clip Driver CD200 IQ 45 Our products stand the test RPLE Profile Grinder 26 Precision Torch Stand 12 Clip Driver CD300 IQ 46 06000 of time. -

Finished Vehicle Logistics by Rail in Europe

Finished Vehicle Logistics by Rail in Europe Version 3 December 2017 This publication was prepared by Oleh Shchuryk, Research & Projects Manager, ECG – the Association of European Vehicle Logistics. Foreword The project to produce this book on ‘Finished Vehicle Logistics by Rail in Europe’ was initiated during the ECG Land Transport Working Group meeting in January 2014, Frankfurt am Main. Initially, it was suggested by the members of the group that Oleh Shchuryk prepares a short briefing paper about the current status quo of rail transport and FVLs by rail in Europe. It was to be a concise document explaining the complex nature of rail, its difficulties and challenges, main players, and their roles and responsibilities to be used by ECG’s members. However, it rapidly grew way beyond these simple objectives as you will see. The first draft of the project was presented at the following Land Transport WG meeting which took place in May 2014, Frankfurt am Main. It received further support from the group and in order to gain more knowledge on specific rail technical issues it was decided that ECG should organise site visits with rail technical experts of ECG member companies at their railway operations sites. These were held with DB Schenker Rail Automotive in Frankfurt am Main, BLG Automotive in Bremerhaven, ARS Altmann in Wolnzach, and STVA in Valenton and Paris. As a result of these collaborations, and continuous research on various rail issues, the document was extensively enlarged. The document consists of several parts, namely a historical section that covers railway development in Europe and specific EU countries; a technical section that discusses the different technical issues of the railway (gauges, electrification, controlling and signalling systems, etc.); a section on the liberalisation process in Europe; a section on the key rail players, and a section on logistics services provided by rail. -

SOUTHEASTERN PENNSYLVANIA TRANSPORTATION AUTHORITY Norrisown High Speed Line – Bryn Mawr Interlocking Apr 1, 2016

SOUTHEASTERN PENNSYLVANIA TRANSPORTATION AUTHORITY SPECIFICATIONS FOR THE PROCUREMENT OF TRACKWORK MATERIALS: Norrisown High Speed Line – Bryn Mawr Interlocking Apr 1, 2016 TRACKWORK MATERIAL SPECIFICATIONS FOR BRYN MAWR INTERLOCKING PART 1 GENERAL 1.01 SUMMARY A. This specification is intended to cover the requirements of the Southeastern Pennsylvania Transportation Authority, (SEPTA), for the manufacture of track work to be installed on the Norristown High Speed Line (NHSL) at Bryn Mawr. B. This work includes all labor, material, equipment and tools necessary in order to design, manufacture, furnish, shop assemble, mark, inspect, disassemble, package, and deliver all track work materials including wood cross ties, for a complete layout of the following: 1. One (1) 115#RE interlocked standard left hand number 8 crossover at 13’0” track centers, including required long ties to support electrified contact rail insulators (third rail) for normal and crossover routes. C. Prior to manufacturing, the Vendor must provide detailed shop drawings including a bill of materials for SEPTA approval. D. After shop assembly, an outside inspection agency shall be hired by the Vendor, at no additional cost to SEPTA to inspect all parts and the layout assembled in its entirety for fit, quality, and conformance to these specifications. The inspection agency must submit detailed inspection reports including color photographs, to SEPTA for approval prior to shipping. The inspection agency will also be responsible for production update reports to SEPTA. Any parts or dimensions not meeting the parameters of this specification or in the judgment of the inspector determined as defective shall be replaced and/or corrected by the Manufacturer at no additional cost to SEPTA. -

Trackway Infrastructure Guidelines Light Rail Circulator Systems

Trackway Infrastructure Guidelines for Light Rail Circulator Systems A Report Prepared by J. H. Graebner R. E. Jackson L. G. Lovejoy April 2007 FOREWORD In the array of land, water and air transport methods, a major position is occupied by railway technology that is based upon the proven and time-tested concept of flanged metal wheels rolling on a pair of metal rails. The provenance and first major application of this excellent (some might say, ingenious) technology occurred during the latter half of the 19 th century when the majority of intercity and transcontinental railroads were constructed. As the 20 th century dawned its most popular use shifted to the development of urban streetcar lines. In the larger cities, it was also used by the designers of rapid transit elevated and underground rail lines. Toward the end of the last century the same technology was utilized in the design of light rail transit (LRT) systems that are still growing in number worldwide. Through all of the evolution of these somewhat diverse railway modes, the fundamental technology has endured and it promises to do so for the foreseeable future. However, as railways in their various versions matured the technology evolved and was adapted. New design skills, products and applications emerged while some of the older ones faded. The application that declined the most steeply was the street railway. By the beginning of the last quarter of the 20 th century, outside of Europe, streetcar lines had largely vanished. Now, as we move into the 21 st century and many urban cores are experiencing revitalization, new streetcar lines are being developed to provide circulator service in these dense and often constricted districts. -

Railway Track Geometry Inspection Optimization

Railway track geometry inspection optimization Michael Simba Muinde Maintenance Engineering, master's level (120 credits) 2018 Luleå University of Technology Department of Civil, Environmental and Natural Resources Engineering ACKNOWLEDGEMENTS The research presented in this master thesis has been carried out at the division of Operation and Maintenance Engineering at Luleå University of Technology (LTU), Sweden. First, I would like to express my utmost gratitude to my supervisor Prof. Alireza Ahmadi and my co-supervisor Iman Soleimanmeigouni for the continuous support during my Masters Degree thesis research, for their motivation, patience, immense knowledge and enthusiasm. Their guidance helped me in the process of my study and writing my thesis. I would like also to thank Dr. Johan Odelius, Dr. Adithya Thaduri and Dr. Stephen Mayowa Famurewa for their insightful guidance, encouragement, and help with simulations. I would like to thank the JVTC and Trafikverket for all of the support they provided to perform this research. I am particularly grateful to Dr. Arne Nissen for his support. I would like to appreciate my fellow classmates: Keegan Mbiyana, Andreas Papadimitriou, Isaac Nkurunziza and Aly Hassabelnaby for the stimulating discussions and the fun we had the last 2 years of our Masters degree studies. I am also grateful to the Swedish Institute scholarship for giving me the opportunity to see my dream come true in achieving my academic plans. Last but not least, my sincere appreciation to my parents for their continued support. Michael Simba Muinde June 2018 Luleå, Sweden ABSTRACT Railway transportation plays a vital role in modern societies. Due to increasing demands for transportation of passengers and goods, higher speed trains with heavier axle loads are introduced to the railway system, and it is expected to continue in the future. -

HSL Report Template. Issue 1. Date 04/04/2002

Harpur Hill, Buxton, SK17 9JN Telephone: 01298 218000 Facsimile: 01298 218590 E Mail: [email protected] A survey of UK tram and light railway systems relating to the wheel/rail interface FE/04/14 Project Leader: E J Hollis Author(s): E J Hollis PhD CEng MIMechE Science Group: Engineering Control DISTRIBUTION HSE/HMRI: Dr D Hoddinott Customer Project Officer/HM Railway Inspectorate Mr E Gilmurray HIDS12F Research Management LIS (9) HSL: Dr N West HSL Operations Director Dr M Stewart Head of Field Engineering Section Author PRIVACY MARKING: D Available to the public HSL report approval: Dr M Stewart Date of issue: 14 March 2006 Job number: JR 32107 Registry file: FE/05/2003/21511 (Box 433) Electronic filename: Report FE-04-14.doc © Crown Copyright (2006) ACKNOWLEDGEMENTS To the people listed below, and their colleagues, I would like to express my thanks for all for the help given: Blackpool Borough Council Brian Vaughan Blackpool Transport Ltd Bill Gibson Croydon Tramlink Jim Snowdon Dockland Light Railway Keith Norgrove Manchester Metrolink Steve Dale Tony Dale Mark Howard Mark Terry (now with Rail Division of Mott Macdonald) Midland Metro Des Coulson Paul Morgan Fred Roberts Andy Steel (retired) National Tram Museum David Baker Geoffrey Claydon Mike Crabtree Allan Smith Nottingham Express Transit Clive Pennington South Yorkshire Supertram Ian Milne Paul Seddon Steve Willis Tyne & Wear Metro (Nexus) Jim Davidson Peter Johnson David Walker Parsons Brinkerhoff/Permanent Way Institution Joe Brown iii Manchester Metropolitan University Simon Iwnicki Julian Snow Paul Allen Transdev Edinburgh Tram Andy Wood HM Railway Inspectorate Dudley Hoddinott Dave Keay Ian Raxton iv CONTENTS 1 Introduction............................................................................................................. -

Full-Scale Train Derailment Testing and Analysis of Post-Derailment Behavior of Casting Bogie

applied sciences Article Full-Scale Train Derailment Testing and Analysis of Post-Derailment Behavior of Casting Bogie Hyun-Ung Bae 1 , Jiho Moon 2 , Seung-Jae Lim 3, Jong-Chan Park 4 and Nam-Hyoung Lim 4,* 1 R&D Lab., Road Kinematics co., Ltd., Cheonan 31094, Korea; [email protected] 2 Department of Civil Engineering, Kangwon National University, Chuncheon 24341, Korea; [email protected] 3 Chungnam Railway Research Institute, Chungnam National University, Daejeon 34134, Korea; [email protected] 4 Department of Civil Engineering, Chungnam National University, Daejeon 34134, Korea; [email protected] * Correspondence: [email protected]; Tel.: +82-42-821-8867 Received: 10 November 2019; Accepted: 18 December 2019; Published: 19 December 2019 Abstract: In this study, a full-scale train bogie derailment test was conducted. For this, test methodologies to describe the wheel-climbing derailment of the train bogie and to obtain accurate test data were proposed. The derailment test was performed with the casting bogie for a freight train and a Rheda 2000 concrete track. Two different derailment velocities (28.08 km/h and 55.05 km/h) were considered. From the test, it was found that humps in the concrete track affected the post-derailment behavior of the bogie when the derailment velocity was 28.08 km/h. For a higher derailment velocity (55.05 km/h), significant lateral movement of the derailed bogie was observed. This lateral movement was first controlled by wheel–rail contact, followed by contact with the containment wall. Finally, the train was returned to the track center.